Abstract

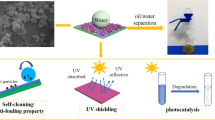

In this work, a durable and sunlight-driven self-cleaning superhydrophobic cotton fabric was developed as a multifunctional oil/water separation material. First of all, Ag/AgCl was successfully deposited on the polydopamine modified cotton fabric surface by electrostatic adsorption, then the Ag/AgCl loaded fabric was coated by the polydimethylsiloxane (PDMS) via simple dip-coating method. The as-prepared cotton fabric (PDMS-Ag/AgCl@CF) presented the superhydrophobic property with water contact angle about 155°. Meanwhile, the prepared PDMS-Ag/AgCl@CF exhibited great tolerance and resistance to broad pH and various organic solvents, and it can also withstand 50 cycles of abrasion or 60 min of ultrasound treatment without an apparent decrease of superhydrophobicity, indicating its outstanding mechanical durability. As expected, this durable superhydrophobic fabric can availably separate various oil/water mixtures by gravity-driven force with high separation efficiency (over 97.8%), and it possessed good reusability. Additionally, the PDMS-Ag/AgCl@CF exhibited an outstanding self-cleaning performance under sunlight irradiation, due to visible light photocatalytic performance of Ag/AgCl. Finally, the resultant cotton fabric displayed good antibacterial activity. Therefore, in consideration of its prominent comprehensive performances, it is expected that the PDMS-Ag/AgCl@CF can be used as a promising material for oily water remediation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

How to effectively address oily wastewater pollution has become an issue of worldwide common concern, due to the ever-growing daily life and industrial oily effluent discharge, and the frequent leakage of crude petroleum accidents (Gao et al. 2014; Gupta et al. 2017; Li et al. 2016; Xue et al. 2014). Oily pollution has now been viewed as a serious environmental issue, threatening the human living environment and global ecosystem. Therefore, a variety of routes have been explored for the oily remediation (Ge et al. 2018; Ismail et al. 2020). Among all of them, membrane separation technology based on the special wettability surfaces (superhydrophilic surface, superhydrophobic surface, smart controlled surface) has been viewed as one of the most effective methods to achieve oil/water separation, due to its features including low cost, high efficiency, recyclability and without secondary pollution (Chen et al. 2020a, b; Kung et al. 2018; Tao et al. 2014; Xue et al. 2011; Zhang and Seeger 2011; Zhang et al. 2013a). As one of special wettability surface, superhydrophobic surface (water contact angles higher than 150°) has been rapidly developed in the past few decades for selectively filtering or absorbing oil from water (Ma et al. 2020; Yuan et al. 2018). It is well-known that the superhydrophobic surfaces are mainly regulated by both the chemical compositions and the micro/nano geometrical structures (Chu et al. 2015). Based on this principle, lots of superhydrophobic membranes based on porous materials such as fabric, nanofibrous membrane, filter paper and metal mesh have been successfully prepared for oil/water separation (Li et al. 2019; Ma et al. 2016; Ma et al. 2020; Zeng et al. 2017; Zhou et al. 2017).

Among them, cotton fabric has been widely employed as the substrate to prepare superhydrophobic membrane for oil/water separation, owing to its various characteristics such as flexibility, porosity, good mechanical properties, low cost and biodegradability (Chen et al. 2017; Wang et al. 2019). Recently, fluorine-free materials have been widely used to prepare superhydrophobic cotton fabrics, because of their nontoxic feature (Cheng et al. 2019; Ma et al. 2019; Mai et al. 2019; Yang et al. 2019b). For example, Zeng’s group prepared superhydrophobic oil/water separation membrane via coating polydivinylbenzene on the surface of cotton fabric (Cheng et al. 2019). Chen and co-workers designed a robust superhydrophobic cotton fabric for oil/water separation based on the polydimethylsiloxane (PDMS)/calcite particles (Mai et al. 2019). However, similar with common superhydrophobic materials, these superhydrophobic cotton fabrics easily suffer from oily and bacterial contaminations in practical applications, which cause their sharp decreases in oil/water separation efficiency, flux and lifespan (Zhang et al. 2013b). To tackle these issues, numerous efforts have been made to develop self-cleaning superhydrophobic cotton fabrics to remove the oil foulant via introduction of photocatalysts with UV-driven self-cleaning ability such as TiO2, SnO2 and ZnO (Gao et al. 2017; Huang et al. 2015; Shi et al. 2014; Wang et al. 2019; Yang et al. 2019a; Zhu et al. 2017). For instance, Lai’s group prepared a superhydrophobic and photocatalytic self-cleaning cotton fabric by in situ growth of TiO2 on the surface of cotton fabric (Gao et al. 2017). Liu et al. fabricated a durable, robust and UV-driven self-cleaning superhydrophobic cotton fabric via ZnO/PDMS coatings (Yang et al. 2019a). Undeniably, the lifetime of these cotton fabrics can be largely extended due to their self-cleaning feature. Nevertheless, the self-cleaning behavior of these superhydrophobic cotton fabrics cannot be realized under visible or solar light irradiation (Chen et al. 2010; Qi et al. 2019). Moreover, UV induced self-cleaning process is time-consuming. As we know, the organic material would accelerate aging if it exposes to long-term UV irradiation. Therefore, fabrication of superhydrophobic cotton fabrics with more effective behavior and relatively mild self-cleaning condition is desirable. Recently, visible light or sunlight induced photocatalytic self-cleaning behavior has been developed and shown promising applications in self-cleaning field (Ren et al. 2020). However, visible light or sunlight-driven self-cleaning cotton fabric for oil/water separation is rarely reported. Hence, it will be meaningful to develop superhydrophobic oil/water separation cotton fabrics with sunlight-driven self-cleaning ability. Fortunately, in our previous works, it has demonstrated that Ag/AgCl nanoparticles exhibited highly efficient photocatalytic activity under visible light and sunlight irradiation (Guan et al. 2019; Guan et al. 2020; Zhan et al. 2020). To be emphasized, introduction of Ag/AgCl nanoparticles on the surface of superhydrophobic cotton fabric not only endows it with sunlight-driven self-cleaning behavior, but also inhibits formation of biofilm on the surface of cotton fabric due to antibacterial property of silver ion. To the best of our knowledge, there are few reports on the design of superhydrophobic oil/water separation membrane with both antibacterial performance and sunlight-driven self-cleaning behavior.

Herein, the aim of this work is to develop a facile and efficient approach to fabricate a robust superhydrophobic cotton fabric with highly efficient sunlight-driven self-cleaning and antibacterial behaviors for oil/water separation (Scheme 1). Then, the surface micromorphology and chemical composition of the resulting cotton fabric are characterized by Fourier transform infrared (FTIR) spectroscopy, scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS), respectively. What’s more, the oil/water separation behavior and its durability of the resultant superhydrophobic cotton fabric are investigated in detail. Additionally, the self-cleaning performance is evaluated by the removal of contaminants under sunlight irradiation. Finally, the antibacterial activity of the resultant cotton fabric is also investigated by the zone inhibition test. The results show that the as-prepared multifunctional superhydrophobic cotton fabric exhibits promising oil/water separation application especially in harsh environment.

Experimental section

Materials

Cotton fabric (CF) with twill weave was bought from a local store (Chengdu, China). Polydimethylsiloxane (PDMS) (Sylgard 184A) and the curing agent (Sylgard 184B) were manufactured by Dow Corning Corporation. Dopamine hydrochloride (98%) and oleic acid (≥ 99.8%) were provided by Aladdin Reagent Co., Ltd. (Shanghai, China). Silver nitrate (AgNO3, ≥ 99.8%), zinc chloride (ZnCl2, ≥ 98%), tris(hydroxymethyl)methyl aminomethane (THAM, ≥ 99.5%) tetrahydrofuran (THF, ≥ 99.0%), N,N-dimethylformamide (DMF, ≥ 99.5%), dichloromethane (DCM, ≥ 99.5%), petroleum ether 60–90, toluene (≥ 99.5%) and n-hexane (≥ 97.0%) were all supplied by Chengdu Chron Chemicals and used without further purification.

Poly(dopamine) (PDA) coated cotton fabric

First, the cotton fabrics (6 cm × 6 cm) were cleaned by deionized (DI) water and ethanol for three times to remove impurities and dried at oven at 80 °C for 3 h for further processing. Then, the cleaned cotton fabric samples were immersed into a 10 mM Tris–HCl buffer (the pH was adjusted to 8.5) solution with 2 mg/mL dopamine for 24 h to achieve dopamine self-polymerization on the surface of cotton fabric. Finally, the PDA coated cotton fabric was washed with DI water and dried in a vacuum oven at 60 °C before use.

Preparation of Ag/AgCl nanoparticles

In this work, Ag/AgCl nanoparticles were prepared following our previous paper (Guan et al. 2019; Guan et al. 2020; Zhan et al. 2020). Briefly, 7.48 g of AgNO3 was dissolved in 440 mL of DI water, and then 2.6 g of ZnCl2 was stepwise added into the solution to obtain AgCl. After stirring for 1 h, the mixture was irradiated with a xenon lamp for 30 min to reduce silver chloride to metallic silver. The original white suspension turned to purple-black after irradiation. After suction filtration and washing with DI water three times, the resultant Ag/AgCl was dried in a vacuum oven at 60 °C. Finally, the dried purple-black powder was ball milled for 1 h to yield targeted Ag/AgCl with small particle size.

Preparation of Ag/AgCl decorated cotton fabric

0.4 g of Ag/AgCl nanoparticles were dispersed into 200 ml of DI water by ultrasonic. After that, the PDA modified cotton fabric was immersed into the as-prepared suspension with magnetic stirring for 4 h. After this step, the Ag/AgCl nanoparticles were anchored on the PDA coated cotton fabric surface via electrostatic adsorption (Chen et al. 2019; Xu et al. 2018; Yang et al. 2017). Finally, the resultant cotton fabric was dried in a vacuum oven at 60 °C for the next step, named as Ag/AgCl@CF.

Preparation of superhydrophobic cotton fabric

The targeted superhydrophobic cotton fabric was prepared by a simple dip-coating method. First of all, PDMS and curing agent with weight ratio of 10:1 were mixed into THF and then underwent magnetic stirring at room temperature to form a homogeneous PDMS solution. Subsequently, the as-prepared Ag/AgCl@CF was immersed in the 20 mg/mL PDMS solution for 20 min and then cured at 100 °C for 2 h in an oven to complete the PDMS curing. The resultant cotton fabrics were named as PDMS-Ag/AgCl@CF for following experiments.

Characterization

Fourier transform infrared (FTIR) spectra were recorded in the reflective mode with the resolution of 4 cm−1 using Nicolet Avatar 370 spectrometer. The surface microstructures of the fabricated samples were investigated on a field-emission scanning electron microscopy (SEM, JEOL JSM-7500F) at an accelerating voltage of 15 kV. Chemical composition and mapping ware measured by SEM with energy-dispersive X-ray spectroscopy (EDS) analysis. X-ray photoelectron spectroscopy (XPS, Kratos XSAM800) measurements were employed to determine surface elements. Water contact angle (WCA) was characterized by an optical contact angle measuring instrument (Biolin Theta Lite) with 15 µL of DI water droplet at room temperature. Each sample was measured at five different positions, and the average values were presented.

Oil/water separation property of PDMS-Ag/AgCl@CF

100 mL oil/water mixture with a volume ratio of 1:1 was utilized to evaluate separation performance of the superhydrophobic PDMS-Ag/AgCl@CF. For better observation, the water phase and oil phase were colored by methylene blue (MB) and Sudan III, respectively. Herein, five different oils including petroleum ether, n-hexane, DCM, toluene and chloroform were selected to prepare oil–water mixtures. The separated liquids were collected by the bottle to determine the separation efficiency. Each measurement was performed in triplicate and the average values were presented. The separation efficiency (E) of the PDMS-Ag/AgCl@CF to the various mixtures was calculated through equation below (1):

where W0 and W1 represent the weight of oil before and after the separation.

The separation flux (F) through the superhydrophobic PDMS-Ag/AgCl@CF was calculated according to the following Eq. (2):

where S represents the valid test area of the superhydrophobic cotton fabric, V is the volume of the collected oil and t is the time cost for the oil to permeate through the resultant cotton fabric.

Mechanical durability of PDMS-Ag/AgCl@CF

The mechanical durability of the superhydrophobic PDMS-Ag/AgCl@CF was investigated via sandpaper abrasion and ultrasound resistance tests, respectively. For sandpaper abrasion test, the PDMS-Ag/AgCl@CF was dragged in one direction on the 20 cm length of sandpaper with the speed of approximately 5 cm/s under 200 g weight. The WCA of sample was evaluated after every ten times. For ultrasound resistance measurement, the PDMS-Ag/AgCl@CF was submerged in ethanol with ultrasound treatments for 1 h. The WCA of sample was determined at interval of every 15 min.

Chemical stability of PDMS-Ag/AgCl@CF

The PDMS-Ag/AgCl@CFs were immersed into various aqueous solutions with different pH values (pH 1, 3, 5, 7, 9, 11 and 13), and various organic solvents including DMF, THF, DCM and ethanol for 30 h. After that, the treated PDMS-Ag/AgCl@CFs were washed with excess DI water and dried in an oven at 80 °C. Subsequently, the WCA of each sample was measured to determine chemical stability of the PDMS-Ag/AgCl@CF.

Sunlight-driven self-cleaning behavior of PDMS-Ag/AgCl@CF

For the sunlight-driven self-cleaning behavior test, the as-prepared PDMS-Ag/AgCl@CF was immersed into an acetone solution of 5 wt% oleic acid (OA) for 1 min and left at room temperature for 30 min. Then, the OA contaminated PDMS-Ag/AgCl@CF was exposed under natural sunlight for 3 h. The experiments were performed during sunny days under the maximum intensity of the sunlight between 11 a.m. and 2 p.m. in July and August in Chengdu, China. The average sunlight illumination was about 110,000 lx during this time. After irradiation, the OA contaminated PDMS-Ag/AgCl@CF was heated at 140 °C for 1 h. Finally, the WCA of sample was measured to evaluate sunlight-driven self-cleaning behavior of PDMS-Ag/AgCl@CF.

Antibacterial activity

Gram positive S. aureus and Gram-negative E. coli were used as model bacteria to test the antibacterial property of the PDMS-Ag/AgCl@CFs. First of all, the as-prepared PDMS-Ag/AgCl@CF was cut into size of 1.0 × 1.0 cm2. Then, the bacterial suspension (105–106 CFU mL−1,100 µL) was transferred to the culture medium. Afterwards, the sterilized samples were placed on the surface of agar plates with bacterial solution. The plates were then cultured at 37 °C for 24 h. Finally, colony growths were observed and the corresponding inhibition zones were evaluated.

Results and discussion

Preparation, surface morphology and wettability of PDMS-Ag/AgCl@CF

After successful preparation of Ag/AgCl nanoparticles (Fig. S1), the targeted superhydrophobic cotton fabric for oil/water separation was prepared. The First of all, the cotton fabric was modified by polydopamine (PDA). Then, Ag/AgCl nanoparticles are anchored on the surface of PDA modified cotton fabric via electrostatic adsorption (Fig. S2). Finally, Ag/AgCl decorated cotton fabric was immersed into the as-prepared PDMS solution to obtain superhydrophobicity. Figure 1a, b showed a process that the pristine cotton fabric was modified by polydopamine (PDA). As displayed in Fig. 1c, the Ag/AgCl can successfully deposit on the PDA modified cotton fabric surface via electrostatic interaction. Then, Ag/AgCl coated cotton fabric was immersed into as-prepared PDMS solution in THF to generate the PDMS-Ag/AgCl@CF (Fig. 1d). In this work, the successful preparation of superhydrophobic PDMS-Ag/AgCl@CF was confirmed by SEM, FTIR, XPS, and WCA measurements, respectively. Firstly, the SEM measurement was also conducted to characterize the morphological structures of the samples. Figure 1f presented the surface morphology of PDA coated cotton fabric. It did not undergo significantly morphological transition compared to that of initial cotton fabric (Fig. 1e). However, the surface morphology of cotton fabric obviously changed in Fig. 1g, numerous Ag/AgCl nanoparticles deposited on the cotton fabric surface via the interaction between PDA and Ag/AgCl, which demonstrated the Ag/AgCl coated cotton fabric has been successfully prepared. Herein, the successful immobilization of Ag/AgCl on the cotton fabric surface not only improved the roughness degree of cotton fabric surface, but also endowed resultant cotton fabric with photocatalytic self-cleaning performance. The SEM image of PDMS coated cotton fabric was presented in Fig. 1h. The PDMS film can be obviously observed compared to Fig. 1g. Meanwhile, the energy-dispersive X-ray spectrometer (EDS) was used to further confirm the elements on the resultant sample. As expected, in Fig. 1i, there appeared N, Ag, Cl and Si on the modified cotton fabric. Therefore, it can be inferred that the Ag/AgCl and PDMS were successfully coated on the PDA modified cotton fabric (Chen et al. 2020b). Moreover, the surface element distribution was examined by EDS elemental mapping images (Fig. 1j–o). Then the surface chemical composition of the prepared cotton fabric was investigated by FTIR. As shown in Fig. 2, the characteristic adsorption bands ascribed to PDA from NH group at 1508 cm−1 and 1608 cm−1 can be observed in the PDA modified cotton fabric (Chen et al. 2019). Meanwhile, the characteristic adsorption band of Si–C stretching and CH3 rocking bands at 794 cm−1 and 1255 cm−1 can be found after coating the Ag/AgCl@CF with PDMS (Cho et al. 2014; Gao et al. 2018; Lin et al. 2020). Subsequently, the chemical composition of resultant PDMS-Ag/AgCl@CF was also examined by XPS measurement. As shown in Fig. 3a, besides peaks from C (284.78 eV) and O (102.31 eV), the additional characteristic peaks from Ag and Si can be observed on the PDMS-Ag/AgCl@CF compared to that of the pristine cotton fabric, which was consistent with the result from EDS characterization. All of the peaks can give an index to the successful preparation of PDMS-Ag/AgCl@CF (Dahiya et al. 2015; Wang et al. 2020). The characteristic peaks at 102.3 eV and 152.0 eV were attributable to Si 2p and Si 2s from PDMS (Cao et al. 2016; Strohmeier 1991). In Fig. 3c, the Ag 3d spectrum can be grouped into Ag 3d5/2 and Ag 3d3/2, these two peaks then can be further divided into 367.45 eV, 368.25 eV and 373.45 eV, 374.15 eV. According to the previous report, there were the characteristic peaks at 367.45 eV and 373.45 eV for the silver ions in AgCl; and the peaks at 368.25 eV and 374.15 eV for Ag0 of metallic silver (Zheng et al. 2015). Therefore, these results indicated successful deposition of Ag/AgCl and PDMS on the cotton fabric surface.

Next, the superhydorphobicity of prepared cotton fabric was demonstrated. As illustrated in Fig. 4a, the water droplets kept the ball-shape on the PDMS-Ag/AgCl@CF surface. The resultant cotton fabric was proved to be superhydrophobic with a WCA of 155o ± 2o. Meanwhile, a jet of water from a straw could bounce off the PDMS-Ag/AgCl@CF surface without leaving a trace, indicating the weak interaction between water and the PDMS-Ag/AgCl@CF surface (Fig. 4b). Additionally, upon immersion into water, a mirror-like phenomenon appeared on the surface of PDMS-Ag/AgCl@CF due to the existence of air layer between the PDMS-Ag/AgCl@CF and the water (Fig. 4c), which resulted that the PDMS-Ag/AgCl@CF was still dry after taking out from the water. Based on above mentioned results, it can be confirmed that PDMS-Ag/AgCl@CF with superhydrophobicity has been successfully prepared.

Oil/water separation of PDMS-Ag/AgCl@CF

The obtained PDMS-Ag/AgCl@CF exhibited superhydrophobicity while superoleophilicity and hence it was expected to excellent oil/water separation. Figure 5 presented the selective adsorption of oil from oil/water mixture. The Sudan III stained DCM and n-hexane were dropped into water, respectively. Subsequently, the PDMS-Ag/AgCl@CFs were immersed into contaminated aqueous solutions. As expected, n-hexane and DCM could be utterly adsorbed by the prepared cotton fabrics within few seconds due to their superhydrophobic nature, leaving clean and transparent water. Further, the gravity-driven oil/water separation behavior was investigated. The corresponding photographs in Fig. 6 presented the separation process of different kinds of oil/water mixture (v:v = 1:1) via a simple oil/water separation setup. When the density of oil is denser than that of water, the mixtures can be separated with a vertical placement device (Fig. 6a). If the density of oil is lower than that of water, the mixtures can be purified with an inclined device (Fig. 6b). As shown in Fig. 6a, the MB stained water was completely retained in the upper container, while the Sudan III stained DCM as the oil phase could permeate and pass through the superhydrophobic cotton fabric quickly by gravity and was collected by the container below, exhibiting efficient oil/water separation behavior. Additionally, the same separation processes were performed for the various mixtures of n-hexane/water, toluene/water and petroleum ether/water, etc. and the results were as good as the DCM/water mixture. The corresponding oil/water separation efficiencies and separation fluxes were calculated by corresponding equations and presented in Fig. 7a. The separation efficiency of the PDMS-Ag/AgCl@CFs towards various mixtures was all above 97.8%. The separation efficiency could not reach to 100%, which mainly attributed to adsorption capacity of the superhydrophobic PDMS-Ag/AgCl@CFs towards oils.

To be noted, the reusability of PDMS-Ag/AgCl@CFs for oil/water separation is an important parameter to evaluate its practical application. Herein, recyclability of PDMS-Ag/AgCl@CFs was investigated via using n-hexane/water mixture as the model. Figure 7b showed that the separation efficiency of PDMS-Ag/AgCl@CF towards n-hexane/water mixture always maintained above 97.6% even after 20 cycles, which implied outstanding recyclability of the as-prepared PDMS-Ag/AgCl@CF for oil/water separation. Until now, it can be concluded from above results that the as-prepared superhydrophboic cotton fabric could be employed as a membrane to realize highly effective oil/water separation.

Durability of PDMS-Ag/AgCl@CF

As important criteria for practical applications, the long-term superhydrophobic durability of the prepared PDMS-Ag/AgCl@CF was also investigated. Herein, evaluation of durability of the prepared PDMS-Ag/AgCl@CF was tested under various rigorous conditions. To investigate the robustness of the sample against mechanical forces, the typical method of the abrasion test was performed (Fig. 8a). As a result, the WCA of PDMS-Ag/AgCl@CF decreased with increment of the number of abrasion cycles (Fig. 8b). However, it still maintained around 131° ± 1° even after the 50 abrasion cycles, exhibiting desirable hydrophobicity. Moreover, the WCA of PDMS-Ag/AgCl@CF was still above 150° after 1 h ultrasound treatment (Fig. 8c), indicating good mechanical stability of PDMS-Ag/AgCl@CF.

Apart from the physical damage assessment, the chemical resistance property of the as-prepared PDMS-Ag/AgCl@CF was also evaluated by immersing them into extreme chemical environment. As illustrated in Fig. 8d, e, WCAs were in the range from 151° to 160° after the PDMS-Ag/AgCl@CFs were immersed into the strong acidic or alkaline solutions and various organic solvents for 30 h, respectively, exhibiting desirable superhydrophobicity. Herein, it is worth pointing out that the WCAs of sample treated by the strong alkaline solutions and DMF were slightly decreased. This result can be attributed to the slight hydrolyzation and dissolution of PDMS under these conditions. However, even after attack by strong alkali and DMF, the PDMS-Ag/AgCl@CFs were still capable of achievement of oil/water separation. Until now, it can be concluded from the results of mechanical and chemical durability tests that the superhydrophobic PDMS-Ag/AgCl@CF displayed satisfactory stability in extreme harsh environment.

Self-cleaning performance of PDMS-Ag/AgCl@CF

Herein, the self-cleaning performance of the superhydrophobic PDMS-Ag/AgCl@CF was verified via utilization of MB powder as contaminants model firstly. A sparse amount of MB powder was distributed randomly on the surfaces of the pristine and coated cotton, which was pasted tightly on the glass slide. As for the PDMS-Ag/AgCl@CF (Fig. 9a), water droplets were fallen on the MB contaminated fabric, and the powder was immediately carried away by the water droplets and finally PDMS-Ag/AgCl@CF returned back to a clean surface. In contrast, the MB powder dissolved in water immediately and then contaminated the surface of the pristine CF leaving a blue trace (Fig. 9b). Meanwhile, the related schematic diagram was presented in Fig. 9c. This observation confirmed that the PDMS-Ag/AgCl@CF has high water surface tension and low surface energy, which plays an essential role in anti-fouling behavior.

It is well known that the superhydrophobic surfaces are very easy to suffer from oily pollution, resulting in sharply decrease of oil/water separation efficiency and flux. To avoid this problem, Ag/AgCl was anchored on the surface of cotton fabric due to its outstanding visible light photocatalytic performance. Herein, the sunlight-driven self-cleaning behavior of the PDMS-Ag/AgCl@CF was conducted via oleic acid as an organic contamination model. As shown in Fig. 10a, the oleic acid contaminated PDMS-Ag/AgCl@CF surface lost its superhydrophobicity and changed to be hydrophobic with a WCA of 94°. As expected, the superphydrophobic property of PDMS-Ag/AgCl@CF can be completely recovered after successive sunlight irradiation and heating treatment. Based on previous studies (Kamegawa et al. 2012; Zhang et al. 2015), we speculate that the reason for this phenomenon may be the photocatalysis of Ag/AgCl. Under sunlight irradiation, the active species such as hydroxyl radical (·OH), photo-generated h+ and ·O2− would be produced on the PDMS-Ag/AgCl@CF due to existence of Ag/AgCl, which decomposed oleic acid into some more hydrophilic compounds such as nonanal and 9-oxononanoic. Moreover, those hydrophilic compounds are usually small volatile molecules and they can easily evaporate after heating. This is the reason that the WCA of the PDMS-Ag/AgCl@CF decreased to 57° after sunlight irradiation, and then recovery after heating at 140 °C for 1 h (Fig. 10b). This phenomenon confirmed that the PDMS-Ag/AgCl@CF has outstanding self-cleaning performance under sunlight irradiation. It is very important to degrade organic pollutants residing on the material surfaces and maintain the oil/water separation performance.

Antibacterial property of PDMS-Ag/AgCl@CF

Owing to the successful immobilization of Ag/AgCl particles on the surface of cotton fabric, the PDMS-Ag/AgCl@CF is expected to exhibit outstanding antibacterial performances. Herein, the antibacterial properties of PDMS-Ag/AgCl@CF were investigated by the zone inhibition test. As shown in Fig. 11, the inhibitory effect of the as-prepared PDMS-Ag/AgCl@CF towards bacteria can be clearly observed. As results, the pristine cotton fabric did not present any activity against both S. aureus and E. coli. In contrast, apparent inhibition zones of the PDMS-Ag/AgCl@CF were observed visually on the culture medium, implying that it has good antibacterial activity against S. aureus and E. coli.

Conclusions

In this work, the PDMS-Ag/AgCl@CF composite has been successfully developed as a highly efficient multifunctional oil–water separation material for the first time. We deposited Ag/AgCl on the polydopamine (PDA) modified cotton fabric surface via electrostatic adsorption, then the fabric was coated by PDMS with simple dip-coating. The results showed the successful preparation of PDMS-Ag/AgCl@CF with superhydrophobic property (WCA of 155 ± 2o). Meanwhile, the separation efficiencies of the PDMS-Ag/AgCl@CF towards various oil/water mixtures were all above 97.8% with flux up to 3500 L m−2h−1, following the outstanding recyclability. Moreover, the resultant PDMS-Ag/AgCl@CF exhibited robust feature. It can maintain superhydrophobicity well even after various extreme treatments such as sandpaper abrasion, ultrasonic treatment, immersing to strong acidic or alkaline solutions and various organic solvents. Most importantly, the PDMS-Ag/AgCl@CF can remove oil contaminant and completely recover superphydrophobic property after successive sunlight irradiation and heating treatment, exhibiting outstanding sunlight-driven self-cleaning performance. Additionally, the PDMS-Ag/AgCl@CF displayed effective antibacterial activity in zone inhibition test. Hence, the resultant PDMS-Ag/AgCl@CF with superhydrophobic, sunlight-driven self-cleaning and antibacterial features can be viewed as a potential material for oily water treatment.

References

Cao C, Ge M, Huang J et al (2016) Robust fluorine-free superhydrophobic PDMS-ormosil@fabrics for highly effective self-cleaning and efficient oil–water separation. J Mater Chem A 4:12179–12187. https://doi.org/10.1039/c6ta04420d

Chen C, Ma W, Zhao J (2010) Semiconductor-mediated photodegradation of pollutants under visible-light irradiation. Chem Soc Rev 39:4206–4219. https://doi.org/10.1039/b921692h

Chen J, Shen C, Yang S, Rana M, Ma P-C (2017) Acid and temperature dual-responsive cotton fabrics with polymer coating. Compos Commun 4:10–15. https://doi.org/10.1016/j.coco.2017.03.003

Chen Z, Yu W, Du Z (2019) Study of electrothermal properties of silver nanowire/polydopamine/cotton-based nanocomposites. Cellulose 26:5995–6007. https://doi.org/10.1007/s10570-019-02506-w

Chen S, Xie Y, Chinnappan A et al (2020a) A self-cleaning zwitterionic nano fibrous membrane for highly ef ficient oil-in-water separation. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2020.138876

Chen Y, Zhang L, Mei CT et al (2020b) Wood-inspired anisotropic cellulose nanofibril composite sponges for multifunctional applications. ACS Appl Mater Interfaces 12:35513–35522. https://doi.org/10.1021/acsami.0c10645

Cheng Q-Y, Guan C-S, Li Y-D, Zhu J, Zeng J-B (2019) Robust and durable superhydrophobic cotton fabrics via a one-step solvothermal method for efficient oil/water separation. Cellulose 26:2861–2872. https://doi.org/10.1007/s10570-019-02267-6

Cho YK, Park EJ, Kim D (2014) Removal of oil by gelation using hydrophobic silica nanoparticles. J Ind Eng Chem 20:1231–1235. https://doi.org/10.1016/j.jiec.2013.08.005

Chu Z, Feng Y, Seeger S (2015) Oil/water separation with selective superantiwetting/superwetting surface materials. Angew Chem Int Ed 54:2328–2338. https://doi.org/10.1002/anie.201405785

Dahiya R, Gottardi G, Laidani N (2015) PDMS residues-free micro/macrostructures on flexible substrates. Microelectron Eng 136:57–62. https://doi.org/10.1016/j.mee.2015.04.037

Gao X, Xu L-P, Xue Z et al (2014) Dual-scaled porous nitrocellulose membranes with underwater superoleophobicity for highly efficient oil/water separation. Adv Mater 26:1771–1775. https://doi.org/10.1002/adma.201304487

Gao S, Huang J, Li S et al (2017) Facile construction of robust fluorine-free superhydrophobic TiO2@fabrics with excellent anti-fouling, water-oil separation and UV-protective properties. Mater Des 128:1–8. https://doi.org/10.1016/j.matdes.2017.04.091

Gao S, Dong X, Huang J, Li S, Li Y, Chen Z, Lai Y (2018) Rational construction of highly transparent superhydrophobic coatings based on a non-particle, fluorine-free and water-rich system for versatile oil–water separation. Chem Eng J 333:621–629. https://doi.org/10.1016/j.cej.2017.10.006

Ge J, Zong D, Jin Q, Yu J, Ding B (2018) Biomimetic and superwettable nanofibrous skins for highly efficient separation of oil-in-water emulsions. Adv Funct Mater. https://doi.org/10.1002/adfm.201705051

Guan XM, Lin SJ, Lan JW et al (2019) Fabrication of Ag/AgCl/ZIF-8/TiO2 decorated cotton fabric as a highly efficient photocatalyst for degradation of organic dyes under visible light. Cellulose 26:7437–7450. https://doi.org/10.1007/s10570-019-02621-8

Guan XM, Zhan YF, Yang L et al (2020) Durable and recyclable Ag/AgCl/CeO2 coated cotton fabrics with enhanced visible light photocatalytic performance for degradation of dyes. Cellulose 27:6383–6398. https://doi.org/10.1007/s10570-020-03241-3

Gupta RK, Dunderdale GJ, England MW, Hozumi A (2017) Oil/water separation techniques: a review of recent progresses and future directions. J Mater Chem A 5:16025–16058. https://doi.org/10.1039/c7ta02070h

Huang JY, Li SH, Ge MZ et al (2015) Robust superhydrophobic TiO2@fabrics for UV shielding, self-cleaning and oil–water separation. J Mater Chem A 3:2825–2832. https://doi.org/10.1039/c4ta05332j

Ismail NH, Salleh WNW, Ismail AF, Hasbullah H, Yusof N, Aziz F, Jaafar J (2020) Hydrophilic polymer-based membrane for oily wastewater treatment: a review. Sep Purif Technol. https://doi.org/10.1016/j.seppur.2019.116007

Kamegawa T, Shimizu Y, Yamashita H (2012) Superhydrophobic surfaces with photocatalytic self-cleaning properties by nanocomposite coating of TiO2 and polytetrafluoroethylene. Adv Mater 24:3697–3700. https://doi.org/10.1002/adma.201201037

Kung CH, Zahiri B, Sow PK, Merida W (2018) On-demand oil–water separation via low-voltage wettability switching of core–shell structures on copper substrates. Appl Surf Sci 444:15–27. https://doi.org/10.1016/j.apsusc.2018.02.238

Li J, Kang R, Tang X, She H, Yang Y, Zha F (2016) Superhydrophobic meshes that can repel hot water and strong corrosive liquids used for efficient gravity-driven oil/water separation. Nanoscale 8:7638–7645. https://doi.org/10.1039/c6nr01298a

Li X, Cao M, Shan H, Tezer FH, Li B (2019) Facile and scalable fabrication of superhydrophobic and superoleophilic PDMS-co-PMHS coating on porous substrates for highly effective oil/water separation. Chem Eng J 358:1101–1113. https://doi.org/10.1016/j.cej.2018.10.097

Lin Y-T, Ting Y-S, Chen B-Y, Cheng Y-W, Liu T-Y (2020) Bionic shark skin replica and zwitterionic polymer brushes functionalized PDMS membrane for anti-fouling and wound dressing applications. Surf Coat Technol. https://doi.org/10.1016/j.surfcoat.2020.125663

Ma Q, Cheng H, Fane AG, Wang R, Zhang H (2016) Recent development of advanced materials with special wettability for selective oil/water separation. Small 12:2186–2202. https://doi.org/10.1002/smll.201503685

Ma W, Zhang M, Liu Z, Kang M, Huang C, Fu G (2019) Fabrication of highly durable and robust superhydrophobic–superoleophilic nanofibrous membranes based on a fluorine-free system for efficient oil/water separation. J Membr Sci 570:303–313. https://doi.org/10.1016/j.memsci.2018.10.035

Ma W, Ding Y, Zhang M, Gao S, Li Y, Huang C, Fu G (2020) Nature-inspired chemistry toward hierarchical superhydrophobic, antibacterial and biocompatible nanofibrous membranes for effective UV-shielding, self-cleaning and oil–water separation. J Hazard Mater. https://doi.org/10.1016/j.jhazmat.2019.121476

Mai Z, Shu X, Li G, Chen D, Liu M, Xu W, Zhang H (2019) One-step fabrication of flexible, durable and fluorine-free superhydrophobic cotton fabrics for efficient oil/water separation. Cellulose 26:6349–6363. https://doi.org/10.1007/s10570-019-02515-9

Qi Z, Wang K, Jiang Y et al (2019) Preparation and characterization of SnO2-x/GO composite photocatalyst and its visible light photocatalytic activity for self-cleaning cotton fabrics. Cellulose 26:8919–8937. https://doi.org/10.1007/s10570-019-02662-z

Ren Y, Li W, Cao Z et al (2020) Robust TiO2 nanorods-SiO2 core–shell coating with high-performance self-cleaning properties under visible light. Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2020.145377

Shi H, Zhou M, Song D et al (2014) Highly porous SnO2/TiO2 electrospun nanofibers with high photocatalytic activities. Ceram Int 40:10383–10393. https://doi.org/10.1016/j.ceramint.2014.02.124

Strohmeier BR (1991) Evaluation of polymeric standard reference materials for monitoring the performance of X-ray photoelectron spectrometers. Appl Surf Sci 47:225–234. https://doi.org/10.1016/0169-4332(91)90036-j

Tao M, Xue L, Liu F, Jiang L (2014) An intelligent superwetting PVDF membrane showing switchable transport performance for oil/water separation. Adv Mater 26:2943–2948. https://doi.org/10.1002/adma.201305112

Wang M, Peng M, Weng Y-X, Li Y-D, Zeng J-B (2019) Toward durable and robust superhydrophobic cotton fabric through hydrothermal growth of ZnO for oil/water separation. Cellulose 26:8121–8133. https://doi.org/10.1007/s10570-019-02635-2

Wang F, Chen L, Li H et al (2020) N-doped honeycomb-like porous carbon towards high-performance supercapacitor. Chin Chem Lett 31:1986–1990. https://doi.org/10.1016/j.cclet.2020.02.020

Xu C, Feng R, Song F, Wang X-L, Wang Y-Z (2018) Desert beetle-inspired superhydrophilic/superhydrophobic patterned cellulose film with efficient water collection and antibacterial performance. ACS Sustain Chem Eng 6:14679–14684. https://doi.org/10.1021/acssuschemeng.8b03247

Xue Z, Wang S, Lin L, Chen L, Liu M, Feng L, Jiang L (2011) A novel superhydrophilic and underwater superoleophobic hydrogel-coated mesh for oil/water separation. Adv Mater 23:4270–4273. https://doi.org/10.1002/adma.201102616

Xue Z, Cao Y, Liu N, Feng L, Jiang L (2014) Special wettable materials for oil/water separation. J Mater Chem A 2:2445–2460. https://doi.org/10.1039/c3ta13397d

Yang J, Xu H, Zhang L, Zhong Y, Sui X, Mao Z (2017) Lasting superhydrophobicity and antibacterial activity of Cu nanoparticles immobilized on the surface of dopamine modified cotton fabrics. Surf Coat Technol 309:149–154. https://doi.org/10.1016/j.surfcoat.2016.11.058

Yang M, Liu W, Jiang C, Xie Y, Shi H, Zhang F (2019a) Facile fabrication of robust fluorine-free superhydrophobic cellulosic fabric for self-cleaning, photocatalysis and UV shielding. Cellulose 26:8153–8164. https://doi.org/10.1007/s10570-019-02640-5

Yang Y, Huang W, Guo Z et al (2019b) Robust fluorine-free colorful superhydrophobic PDMS/NH2-MIL-125(Ti)@cotton fabrics for improved ultraviolet resistance and efficient oil–water separation. Cellulose 26:9335–9348. https://doi.org/10.1007/s10570-019-02707-3

Yuan D, Zhang T, Guo Q, Qiu F, Yang D, Ou Z (2018) Superhydrophobic hierarchical biomass carbon aerogel assembled with TiO2 nanorods for selective immiscible oil/water mixture and emulsion separation. Ind Eng Chem Res 57:14758–14766. https://doi.org/10.1021/acs.iecr.8b03661

Zeng X, Qian L, Yuan X et al (2017) Inspired by stenocara beetles: from water collection to high-efficiency water-in-oil emulsion separation. ACS Nano 11:760–769. https://doi.org/10.1021/acsnano.6b07182

Zhan YF, Lan JW, Shang JJ et al (2020) Durable ZIF-8/Ag/AgCl/TiO2 decorated PAN nanofibers with high visible light photocatalytic and antibacterial activities for degradation of dyes. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2019.153579

Zhang J, Seeger S (2011) Polyester materials with superwetting silicone nanofilaments for oil/water separation and selective oil absorption. Adv Funct Mater 21:4699–4704. https://doi.org/10.1002/adfm.201101090

Zhang W, Shi Z, Zhang F, Liu X, Jin J, Jiang L (2013a) Superhydrophobic and superoleophilic PVDF membranes for effective separation of water-in-oil emulsions with high flux. Adv Mater 25:2071–2076. https://doi.org/10.1002/adma.201204520

Zhang X, Li Z, Liu K, Jiang L (2013b) Bioinspired multifunctional foam with self-cleaning and oil/water separation. Adv Funct Mater 23:2881–2886. https://doi.org/10.1002/adfm.201202662

Zhang W, Lu X, Xin Z, Zhou C (2015) A self-cleaning polybenzoxazine/TiO2 surface with superhydrophobicity and superoleophilicity for oil/water separation. Nanoscale 7:19476–19483. https://doi.org/10.1039/c5nr06425b

Zheng Y, Shu J, Wang Z (2015) AgCl@Ag composites with rough surfaces as bifunctional catalyst for the photooxidation and catalytic reduction of 4-nitrophenol. Mater Lett 158:339–342. https://doi.org/10.1016/j.matlet.2015.06.033

Zhou C, Chen Z, Yang H, Hou K, Zeng X, Zheng Y, Cheng J (2017) Nature-inspired strategy toward superhydrophobic fabrics for versatile oil/water separation. ACS Appl Mater Interfaces 9:9184–9194. https://doi.org/10.1021/acsami.7b00412

Zhu T, Li S, Huang J, Mihailiasa M, Lai Y (2017) Rational design of multi-layered superhydrophobic coating on cotton fabrics for UV shielding, self-cleaning and oil–water separation. Mater Des 134:342–351. https://doi.org/10.1016/j.matdes.2017.08.071

Acknowledgments

This research is financially supported by the National Natural Science Foundation of China (No: 52003171), the Fundamental Research Funds for the Central Universities (No: YJ201823), the Science and Technology Cooperation Project between Sichuan Unversity and Zigong City (No: 2019CDZG-23) and Sichuan Science and Technology Program (No: 2020YJ0316). We would like to thank the Analytical & Testing Center of Sichuan University for SEM and XPS measurements. We also thank Sha Deng and Hongyan Xiao for the experimental assistance.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, H., Yang, L., Zhan, Y. et al. A robust and antibacterial superhydrophobic cotton fabric with sunlight-driven self-cleaning performance for oil/water separation. Cellulose 28, 1715–1729 (2021). https://doi.org/10.1007/s10570-020-03585-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03585-w