Abstract

A method for the decolourization of coloured cotton fabric dyed with vat dyes, based on exposure to infrared laser light, has been tested. Pulsed CO2 laser has been used for all experiments. To detect changes in colour shade, reflection data of original and dyed cotton irradiated at various fluency of infrared laser light were measured on a UV–VIS spectrophotometer, and then colour intensity was calculated for each vat dye. To observe changes in chemical composition and morphology of fiber surfaces, an analysis was performed by X-ray photoelectron spectroscopy and scanning electron microscopy due to thermal effects. Thermal stability of vat dyes and cotton fabric was determined with differential scanning calorimetry method to simulate the heating process during exposure of samples to the infrared laser irradiation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

UV lasers are used for the modification of fiber surfaces due to their high absorption of UV laser light. UV laser treatment can change adhesion, wetting and optical properties of synthetic fibers such as polyamide and polyester (Knittel et al. 1997; Laude et al. 2001; Yip et al. 2004). This process can be exactly localized due to low wavelength of radiation. There are no thermal effects from the localization, and various structures can be obtained with closely defined sizes on polymer surfaces (Laude et al. 2001; Bahners and Schollmeyer 1987; Bahners and Schollmeyer 1989; Arenholz et al. 1991; Arenholz et al. 1993).

IR laser light irradiates only a few layers of fiber in textile structure during one irradiation. Deep penetration of IR laser light is caused by lower absorption of this light into the polymer. IR lasers provide a wider field of application due to cheaper light sources working with higher energy output and no use of toxic gases. CO2 lasers, which produce light with a wavelength of 10.6 μm, are used for creation of the worn look of denim fabrics in the textile industry as an alternative method to conventional techniques for the fading process (Brannon and Lankard 1986). Decolourization with CO2 lasers is applied to denim fabric to create a worn look (Öndogan et al. 2005; Dascalu et al. 2000; Özguney et al. 2009).

Experimental

Materials

Hundred percentage cotton fabric twill-weave (3/1) with fabric areal weight of 259 g m−2, warp density of 31 threads/cm, weft density of 14 threads/cm and fabric thickness of 0.58 mm was used for all experiments. Aqueous solutions containing various amount of vat dye (0.2, 0.5, 1, 1.5 and 3% w.o.f.) were employed for dyeing cotton fabric (Fig. 1). Cotton samples were dyed with the M I method according to the common dying process described in the pattern card. The addition of caustic soda and sodium hydrosulphite is necessary. Liquor ratio was 1:50, and dyeing time was 60 min. Samples were dyed in a laboratory dyeing machine with infrared heating (Ahiba Nuance ECO, Datacolor). Fabrics were rinsed with cold water after dyeing and then dried at 100 °C in a laboratory drier (Chirana HS 62A).

Laser irradiation

Infrared laser irradiation was performed with a commercial pulsed infrared laser (Marcatex 150 Flexi, Easy-Laser). The gas laser operates by carbon dioxide and produces a wavelength of 10.6 μm. The laser device contains the following parts (Fig. 2): laser resonator (1), optical tube (2), optics box (3), the marking head (4), personal computer unit (5), central personal computer module (6), direct current source (7) and radio frequency source (8). The applied energy density per pulse was 3.1–15.6 mJ/mm2 (Table 1).

X-ray photoelectron spectroscopy

Chemical composition of surfaces of non-dyed cotton fabric before and after laser irradiation has been investigated using XPS. It can provide chemical state information of the detected elements. Measurement is performed on equipment ESCA (Electron Spectroscopy for Chemical Analysis) PROBE P (Omicron Nanotechnology Ltd.) at ultra-high vacuum (under pressure of 10−10 mbar). An area of approximately 1 mm was analyzed according to setting of equipment. Source of X-ray radiation was Al anode with energy of 1486,7 eV. Information was obtained from surface layer of a thickness of approximately 5–10 nm. Measured spectra were analyzed by way of CasaXPS programme.

Colour measurement and mechanical properties

Photographs of original (non-dyed) and dyed cotton fabric were taken with a camera (Canon PC 1023, Japan) before and after laser irradiation. To present achieved depth of dyeing were made out photos of dyed (non-irradiated) samples. To observe the color change of dyed cotton fabrics were provided photos after laser irradiation. For objective evaluation, intensities of colour shade of the samples were measured by using a UV-VIS Reflective Spectrophotometer (Datacolor 3890). Reflection factor R was obtained in the range of 400–700 nm. For testing the load at break values, yarn of length 5 cm was mounted on a dynamometer (Tiratest 2150, Germany) at speed of 50 mm.min−1. The tensile strength of samples was measured in weft and warp direction.

Scanning electron microscopy

The surface morphology of the fabrics before and after laser irradiation was examined by SEM. Micrographs were taken using scanning electron microscope (VEGA TS 5130, Tescan Brno) at magnification 1,000×, operating typically at 30 kV. All of the samples were gold-coated (Sputter anlage for SEM, Proben SCD 030, Balzers Union Ltd.) prior to SEM examination.

Differential scanning calorimetry

DSC curves were recorded using DSC 6 (Perkin Elmer). The amount of analyzed dyestuff was from 8 to 10 mg and it was hermetically sealed in an aluminium pan. Each sample was heated from 25 °C (holding for 1 min) to 450 °C, heating rate 15 °C min−1 followed by cooling to 25 °C in nitrogen medium, and flow rate was set to 10 L min−1.

Results and discussion

XPS analysis

XPS analysis can be used to determine quantitative atomic composition and chemistry. Interaction of infrared laser light and textile fabric assigned thermal effect, and this analysis was performed to detect chemical composition changes of irradiated surfaces of non-dyed cotton fabrics. Atomic composition ratios of original and irradiated cotton fabrics were calculated from the data obtained by XPS, as shown in Table 2. Atomic composition ratio O/C is higher at lower and medium laser fluency, and textile sample is oxidized due to atmospheric oxygen. The highest laser fluency already caused sample carbonization at operating time of laser beam in the range of milliseconds. The changes in a content of oxygen and carbon are displayed in deconvoluted XPS spectra for C1 s peaks in Fig. 3. It was observed significant increase of content of carbon with higher laser fluency.

Relative ratios of functional groups with various laser treatments are summarized in Fig. 4. Relative ratio of C=O/C–C is increased at lower laser fluency (3.1 mJ cm−2) in comparison with original non-irradiated sample of cotton fabric in Fig. 4 (left). It happened to decreasing of relative ratio C=O/C–C groups with medium laser fluency (7.8 mJ cm−2). No ketone groups were present at the highest irradiation intensity (15.6 mJ cm−2). Ratios of C–O–/C–C are decreased with increase of laser fluency with comparison with original non-irradiated cotton fabric in Fig. 4 (right).

Colour measurement and mechanical properties

The change of appearance of cotton fabric after irradiation by infrared laser light was not visible with human eye. Browning of original (non-dyed) cotton fabric was observed with increasing of laser fluency (Fig. 5).

In this study the decolourization of dyed cotton fabric has been examined by infrared pulsed laser at various laser fluency of laser beam. Reflection factor R of original and laser-irradiated samples of cotton fabric was measured on UV–VIS spectrophotometer, in the range of 400–700 nm. K/S values were calculated from obtained reflection factor R according to the well-known Kubelka-Munk equation:

where K is absorption and S is scattering coefficients, respectively. K/S values increased with higher laser fluency applied on original (non-dyed) cotton samples and are summarized in Table 3.

There are showed images of dyed samples of cotton fabric with various dye percentage (0.2, 0.5, 1, 1.5 and 3) in Fig. 6. It can be seen from obtained photos that we achieved level dyeings of each sample of cotton. K/S values for each vat dye at wavelength with maximal absorption are summarized in Table 4.

Samples of dyed cotton fabric were irradiated by infrared laser light with increasing laser fluency. Color changes of dyed cotton samples (1%) before and after irradiation with the highest laser fluency can be seen in Fig. 7.

Wavelength with maximal absorption were different with increasing laser fluency at all samples in case of C. I. Vat Green 1 (630–650 nm) and C. I. Vat Red 13 (470–490 nm) as is shown in Fig. 8. That is why the color change of irradiated samples could not be evaluated in wavelength with maximal absorption for each vat dye. The decolourization effect of dyed cotton samples after laser irradiation can be demonstrated by colour intensity, and it can be calculated according to the equation:

where K is absorption and S is scattering coefficients, respectively.

The basic idea is as follows. Total colour intensity I T can be estimated the same as sum of colour intensity of dyestuff I D (Fig. 9; left) and colour intensity of fiber I F (Fig. 9; right).

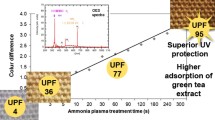

Colour intensity of original (non-dyed) cotton samples presents colour intensity of fiber I F after laser irradiation (Fig. 10a). If laser fluency applied on original (non-dyed) cotton fabric grows then colour intensity of fiber I F will increase because colour shade of fabric changes to yellow or brown shade. Colour intensity I of laser irradiated dyed cotton fabric decreases with increased level of laser fluency (Fig. 10b–d). This fact indicates that dyed fabric is decolourized by infrared laser light. If we irradiate textile by high laser fluency (more than 8 mJ cm−2) than in some cases color intensity of dyed textile is lower than color intensity of non-dyed textile (Fig. 10c).

The changes of tensile strength of yarns were measured at selected dyeings in weft and warp direction. The fixing length of yarn was 5 cm and there were tested 10 yarns for each sample of experiment. It is seen in Fig. 11a that strength in weft direction of all dyed irradiated yarns is similar in weft direction with increasing laser fluency. Medium and high laser fluency, 7.8 and 15.6 mJ cm−2, caused the decrease of tensile strength in weft direction of dyed irradiated cotton yarns approximately 15, 45%, respectively. Very low laser fluency (3.1 mJ cm−2) showed only small decline of strength of original (non-dyed) cotton yarn in weft direction (Fig. 11a, b). There is significant decrease of strength in weft direction of original (non-dyed) irradiated thread in comparison with dyed irradiated threads in case of laser fluency 7.8 mJ cm−2 and higher laser fluency (Fig. 11a, b). Strength in weft direction of original (non-dyed) irradiated cotton yarn dropped down by approximately 35% at medium laser fluency (7.8 mJ cm−2) and approximately 70% at high laser fluency (15.6 mJ cm−2). Almost the same behaviour of non-dyed and dyed irradiated samples is possible to see in the case of various depths of dyeings at C. I. Vat Red 13 (Fig. 11b). The decrease of strength in warp direction of dyed irradiated cotton yarns at C. I. Vat Green 1 is about 31 and 69% for laser fluency 7.8 and 15.6 mJ cm−2, respectively (Fig. 11c). Strength in warp direction of original (non-dyed) cotton yarn dropped approximately about 56 and 100% at laser fluency 7.8 and 15.6 mJ cm−2 (Fig. 11c, d). At irradiated cotton yarns with C. I. Vat Yellow 2, strength in warp direction decreased approximately about 31 and 71% at laser fluency 7.8 and 15.6 mJ cm−2 (Fig. 11d). It was also observed the significant drop in strength in warp direction at original (non-dyed) cotton yarn in comparison with dyed cotton yarns. It results that dyestuff protects dyed cotton yarns from infrared laser light.

SEM analysis

Thermal effects of infrared laser were observed on SEM images in Figs. 12, 13, 14 and 15. A view of original (non-dyed) cotton fabric is shown in Fig. 12a, and the results of laser irradiated samples are shown in Fig. 12b–d at various laser fluency. It can be seen that damage of cotton fibers is increased with increase of laser fluency. Exposure of cotton fabric to infrared laser radiation causes carbonization of samples.

SEM micrographs of dyed cotton fabric before and after laser irradiation are shown in Figs. 13, 14 and 15. Exposure of cotton fabric to increasing laser fluency causes fiber damage, and it leads to the carbonization of fiber samples due to thermal effects.

DSC analysis

All dyestuffs were separately observed by DSC analysis to simulate the heating of cotton fabric during laser irradiation. Results are summarized in Table 5. It can be seen that water contained in fibre is evaporated. It was verified that cotton is decomposed at around 330 °C by DSC method (Fig. 16a). Decomposition of C. I. Vat Green 1 is observed at a temperature of 390 °C (Fig. 16b), which is the lowest decomposition point. C. I. Vat Yellow 2 has the highest decomposition point (Fig. 16c), and due to this fact is the most stable in comparison with others. The results of DSC method are in the correspondence between DSC and colour intensity.

Conclusions

Chemical composition changes of fiber surfaces can be observed by XPS analysis. Relative ratio of groups of ketone/carbon is increased at lower laser fluency of dyed cotton fabric in comparison with original non-irradiated sample of cotton fabric due to oxidation of fiber surfaces with atmospheric oxygen at lower and medium laser fluency. Ketone groups were not recorded at the highest laser fluency, but the increase of carbon bonds, which is caused by carbonization of fiber surfaces at higher laser fluency, was found. It was found that used vat dyes have ability to protect dyed cotton fabric from infrared laser light. It appears from experiments that the decrease of tensile strength of dyed cotton yarns in weft or warp direction is lower in comparison with original cotton fabric after irradiation with increasing laser fluency (more than 7.8 mJ cm−2). In all cases was observed that the drop in strength in warp and weft direction of all depths of shade is similar for all used vat dyes. SEM images show craters arisen from thermal damage of fiber surfaces. Medium laser fluency of infrared laser light causes the decolourization of dyed cotton fabrics at a relatively low level of damage of fibers. It was observed that the dyestuff protects dyed cotton fabric from infrared laser light. Colour intensity of dye has the highest negative value in case of C. I. Vat Yellow 2, which means that the most stable vat dye is C. I. Vat Yellow 2 according to colour measurement. This was also confirmed with DSC analysis. The lowest negative value of colour intensity of dye has C. I. Vat Green 1, and it is the lowest stable dye. It also corresponds with DSC analysis. The highest decomposition point has C. I. Vat Yellow 2 according DSC analysis. Results of DSC are not in direct connection with the behavior of dyed fabrics during laser irradiation; it happens during very fast heating of textile fabric at temperatures around 1,000 °C that are localized to the thin layer on the fabric surface. The heating and cooling takes place at an extreme rate-around 10,000 °C/min. Processes with high activation energy can occur at these conditions. Anaerobic processes are preferred due to deficiency of oxygen in surroundings of the fiber. DSC device can heat the samples at a rate of 15 °C/min, and the results are therefore different because this process is very slow.

References

Arenholz E, Svorcik V, Kefer T, Heitz J, Bäuerle D (1991) Structure formation in UV-laser ablated poly-ethylene-terephthalate (PET). Appl. Phys. A 53:330–331

Arenholz E, Heitz J, Wagner M, Bäuerle D, Hibst H, Hagemeyer A (1993) Laser-induced surface modification and structure formation of polymers. Appl Surf Sci 69:16–19

Bahners T, Schollmeyer E (1987) Surface modification of polymer fibres by irradiation with excimer laser. III. Synergetic model for the development of surface structures. Angew Makromol Chem 151:39–47

Bahners T, Schollmeyer E (1989) Morphological changes of the surface structure of polymers due to excimer laser radiation: a synergetic effect? J Appl Phys 66:1884–1886

Brannon JH, Lankard JR (1986) Pulsed CO2 laser etching of polyimide. Appl Phys 48:1226–1228

Dascalu T, Acosta-Ortiz SE, Ortiz-Morales M, Compean I (2000) Removal of the indigo color by laser beam-denim interaction. Opt Lasers Eng 34:179–189

Knittel D, Kesting W, Scholmeyer E (1997) Surface structuring of synthetic fibres by UV laser irradiation, Part I: phenomenological report. Polym Int 43:231–239

Laude LD et al (2001) The ablation of polymers under excimer laser irradiation: the physics of the process and the polymer structure. Nucl Instr Meth Phys Res Sect B 185:147–155

Öndogan Z, Pamuk O, Öndogan EN, Özguney A (2005) Improving the appearance of all textile products from clothing to home textile using laser technology. Opt Laser Tech 37:631–637

Özguney AT, Özcelik G, Özkaya K (2009) A study on specifying the effect of laser fading process on the colour and mechanical properties of the denim fabrics. Tekstil ve Konfeksiyon 19(2):133–138

Yip J, Chan K, Sin KM, Lau KS (2004) Comprehensive study of polymer fiber surface modifications Part 1: high-fluence UV-excimer-laser-induced structures. Polym Int 153:627–633

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Štěpánková, M., Wiener, J. & Rusinová, K. Decolourization of vat dyes on cotton fabric with infrared laser light. Cellulose 18, 469–478 (2011). https://doi.org/10.1007/s10570-011-9494-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-011-9494-2