Abstract

Cationic polyallylamine (PAH), was adsorbed onto lignocellulosic fibres, and a fluorescent label on the polyelectrolyte enabled its location to be shown by confocal fluorescence microscopy. The adsorption time and ionic strength were varied to study their effect on the localisation of the adsorbed PAH. The microscopy showed that a long adsorption time, 24 h, and a high ionic strength, 10−1 M NaCl + 5 × 10−3 M NaHCO3 or higher, resulted in the adsorption of polyallylamine throughout the fibre walls. Shorter adsorption times and/or lower ionic strength resulted in adsorption only to the fibre exterior. By preparing sheets from fibres with polyelectrolyte adsorbed either to the exterior parts or into the fibre cell wall and testing their mechanical behaviour, a link was established between the localisation of adsorbed polyelectrolyte and the mechanical properties. Adsorption to the fibre exterior led to an increase in tensile strength and strain at break. The creep deformation at 90%RH was also slightly reduced by the adsorption of low molecular weight PAH (15 kDa). When polyallylamine was adsorbed throughout the wall of the lignocellulosic fibres, the mechanical properties were not however improved and the creep deformation at 90%RH actually increased somewhat.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Background

Paper shows a viscoelastic material behaviour, i.e. its mechanical response depends on the rate of straining or stressing. For example, the longer the time to reach the final stress value at a constant rate of stressing, the greater is the strain. Since time is a very important factor in the behaviour of viscoelastic materials, they are also referred to as time-dependent materials. A viscoelastic material also shows creep and stress-relaxation. Creep is the slow continuous deformation of a material subjected to a constant stress, whereas stress-relaxation is the slow decay of stress in a material subjected to a constant strain.

The viscoelastic material behaviour influences the way in which paper materials perform during converting and end-use. For example, the inherent creep of paper materials can eventually lead to the collapse of paper-based boxes when loaded in compression for long times. The creep of paper materials is affected by humidity and is faster at higher moisture conditions (i.e. with larger amounts of adsorbed water). Moreover, variations in humidity lead to an acceleration in the creep rate, so that the creep during cycling between low and high humidity exceeds the creep at a constant high humidity (Byrd 1972a, b). This phenomenon is usually referred to as mechano-sorptive creep or accelerated creep. The production of a paper having a lower creep rate would reduce the safety allowance required when designing paper-based boxes, yielding both economic and environmental benefits.

The general understanding is that the viscoelasticity of a paper material is determined primarily by the viscoelasticity of the component fibres and that the sheet structure and the fibre/fibre joints play a subordinate role. Seth and Page (1981) found that the mechanical behaviour of paper, including plasticity and viscoelasticity, is related to that of the component fibres with an orientation factor (describing average fibre orientation) and an efficiency factor (describing the efficiency of stress transfer between fibres). They therefore claimed that “the non-linearity of the stress-strain curve and the visco-elastic properties of paper originate from within the fibre wall”. DeMaio and Patterson (2005) studied the effect of wet-pressing and addition of a bonder or de-bonder on creep. They found that the de-bonder and bonder had no effect on the creep curves for sheets wet-pressed at a high pressure, but that they did have an effect on sheets wet-pressed at a low pressure. Thus they concluded that, for sheets with a fully efficient stress transfer, changes in specific bond strength and relative bonded area do not influence creep deformation, which due only to the creep of the fibres.

In an earlier study (Gimåker et al. 2007), it was shown that the adsorption of high charge density cationic polyelectrolyte, polyallylamine, to the exterior parts of lignocellulosic fibres reduced the creep of the resulting paper sheets. The primary amine bases present on the polyallylamine molecules are capable of reacting with aldehydes present in lignocellulosic fibres to form imine and aminal linkages (Laleg and Pikulik 1991; DiFlavio et al. 2005), and these covalent linkages might be important for the observed creep reduction. The sheets produced had high strength and high density, i.e. the sheets were efficiently loaded structures. Since the viscoelastic behaviour of such strong papers depends primarily on the viscoelasticity of the composing fibres and not on sheet structure or fibre-fibre joints, it can be speculated that if polyallylamine were adsorbed throughout the fibres, the effect would be much greater. It has for example been suggested by Lindström et al. (2005) that it is necessary to treat/modify the entire fibre wall in order to achieve a large reduction in the creep rate.

Cationic polyelectrolytes are widely used in the paper industry to improve the retention of fines and fillers, and also to increase the strength of the paper. Polyelectrolyte adsorption to cellulosic fibres has therefore attracted considerable attention over recent decades. High charge density polyelectrolytes generally adsorb to cellulosic fibres through pure electrosorption (Wågberg 2000), and the adsorption generally increases with increasing electrolyte concentration up to a maximum at some intermediate salt concentration and then again decreases at high salt concentrations. The initial increase in electrolyte concentration will tend to coil the polyelectrolyte molecules. Which, in combination with the porous nature of the cellulose fibres, means that a greater surface area will be available for the polyelectrolyte, and hence an increased adsorption. At very high electrolyte concentrations, however, the interaction between polyelectrolyte and charged fibre will diminish, resulting in a decrease in the adsorbed amount. The adsorption generally increases with decreasing molecular mass. Lower molecular mass gives a smaller radius of gyration and increases the number of charges available to the polyelectrolyte. A low polyelectrolyte molecular mass and high electrolyte concentration would thus probably give such a small effective hydrodynamic radius that the polyelectrolyte would be able to penetrate throughout the entire fibre wall, although too high an electrolyte concentration could make the driving force for adsorption to small.

Until recently there has been a lack of direct experimental evidence for where the adsorbed polyelectrolyte is located. However, a novel technique (Horvath and Wågberg 2006) involving labelling the polyelectrolyte with a fluorescent dye and examination of fibres in a confocal laser scanning microscope makes it possible to obtain a visual record of where the adsorbed polyelectrolyte is located. This technique has here been used to establish the adsorption conditions necessary to ensure that polyallylamine (PAH) is adsorbed throughout the fibre wall of lignocellulosic fibres, and to study the influence of the localisation of the adsorbed polyallylamine on the mechanical properties of the papers.

Experimental

Fibres

The fibres used in the study were unbleached never-dried softwood kraft fibres (kappa number 76), supplied by Kappa Kraftliner, Piteå, Sweden. When received, the pulp was carefully washed with deionised water until the conductivity of the filtrate was below 10 μS/cm, and the pulp was then beaten in an Escher-Wyss beater to 30 M SR (corresponding to about 16 SR). In order to prepare a pulp that is suitable for evaluating the influence of fibre properties on sheet properties it is necessary to remove most of the fines material from the pulp. The fines were removed from the pulp by successive spraying through a spray disk filter fitted with a plastic wire with 75 μm openings.

The long fibre fraction of the pulp was washed at both high and low pH in order to remove most of the remaining adsorbed metal ions and dissolved and colloidal material, as described earlier (Gimåker et al. 2007). As a final step the pulp was dewatered to a dry content of approximately 20%, and thereafter sealed in plastic bags and stored in a refrigerator until further use.

Chemicals

Polyallylamine hydrochloride (PAH) with an average molecular mass of 15 kDa was purchased from Sigma-Aldrich, Sweden. Polyallylamine with a molecular mass of 150 kDa was kindly provided by Nittobo Boseki, Japan, and delivered as an aqueous solution. All polyelectrolytes were used without further purification. Fluorescein isothiocyanate (FITC), used for labelling PAH, was purchased from Sigma-Aldrich, Sweden. The labelling was performed as previously described (Gimåker et al. 2007). Hydrochloric acid, sodium hydroxide, sodium chloride and sodium bicarbonate were all of analytical grade.

Polyelectrolyte titration

Polyelectrolyte charge density can be determined by titration with an oppositely charged polyelectrolyte in the presence of an indicator (Terayama 1952). By performing the titration at pH 2, the charge density of fully charged PAH was obtained, i.e. the charge when all the primary amines on the polymer were fully protonated. Potassium poly vinyl sulphate was used as the titrant with orthotoluidine blue as the indicator in an equipment setup similar to that described by Horn (1978). Polyelectrolyte titration was used accordingly to determine the charge density of both un-labelled and fluorescent labelled polyallylamine.

Adsorption of fluorescently labelled polyallylamine

In the earlier study (Gimåker et al. 2007), it was established that a salt concentration of 5 × 10−3 M NaHCO3 and an adsorption time of 30 min results only in the adsorption of polyallylamine to the exterior parts of lignocellulosic fibres. This electrolyte concentration was used as a reference level in the present study. To achieve fibre wall penetration, the adsorption time was increased to 24 h and the salt concentration by additional 10−1 M NaCl.

As a second experimental step, the salt concentration and the adsorptions time were varied in several smaller steps, in order to establish the minimum requirements for full fibre wall penetration and the kinetics of this process. The purpose was also to obtain a better understanding of whether time or ionic strength is the most important parameter. A summary of the conditions and dosages used is given in table 1.

All adsorption experiments were conducted at a fibre concentration of 5 g/L, and the pH was carefully controlled to be 8 throughout the adsorption time. After the set time, the adsorption process was discontinued by dewatering the fibre suspension in a Büchner funnel fitted with a filter paper. The fibres were washed with a salt solution of the same concentration as that used during the adsorption in order to remove weakly bound polyelectrolyte, and they were then immediately frozen using liquid nitrogen. The frozen fibre samples were then freeze dried in order to dry the fibres without collapsing the lumen.

Nitrogen content analysis

To determine how much of the added PAH that was adsorbed to the fibres, the nitrogen content of the fibres was determined using an elemental analyser (ANTEK 7000, Model 737). By testing small amounts of fibres or sheets, it was possible to determine the amount of nitrogen and hence the adsorbed amount PAH from prepared calibration curves.

Confocal fluorescence imaging

A Bio-Rad Radiance 2000 confocal system mounted on a Nikon Eclipse 800 microscope was used to obtain images of thin optical sections of fibres saturated with the fluorescently labelled polyallylamine. A Krypton Argon laser was used for excitation at 488 and 568 nm. Images of the fibres were taken using a 100× N.A. 1.4 oil-immersion lens.

Dynamic laser light scattering

A Malvern Zetasizer NanoZS was used to determine the hydrodynamic radius of 15 kDa PAH. The polyelectrolyte concentration was 2.5 g/L in 1 M NaCl and the pH was adjusted to 8.3. Before measurement, the sample solution was centrifuged at 8,000 rpm for 10 min in order to settle any contaminations that might disturb the measurement. The hydrodynamic radius was evaluated by the method of cumulants. The first cumulant yields the z-average diffusion coefficient, which is converted to an average apparent hydrodynamic radius by the software supplied together with the apparatus.

Reliable measurements could only be obtained at high ionic strength. At lower ionic strengths, the polyelectrolytes have a more rod-like conformation and the rotational diffusion coefficient has to be considered, resulting in a complicated dependence between the apparent diffusion coefficient and the scattering vector. This makes an unambiguous analysis of the dynamic light scattering data virtually impossible.

Sheet preparation

A low ionic strength and a short adsorption time, 5 × 10−3 M NaHCO3 and 30 min, were used to adsorb PAH (Mw 15 kDa and 150 kDa) to the surfaces of the fibres. The dosage was varied in order to obtain sheets with different amount of adsorbed polyelectrolyte. A high salt concentration and a long adsorption time, 5 × 10−3 M NaHCO3 + 10−1 M NaCl and 24 h, were used to adsorb PAH (Mw 15 kDa) into the wall of the fibres. The dosage was 300 mg PAH per gram fibre. In all adsorptions, the fibre concentration was 5 g/L and the pH was carefully controlled to 8.

Sheets with a grammage of 100 g/m2 were prepared using a Rapid-Köthen sheet preparation apparatus (Paper Testing Instruments, Pettenbach, Austria) following the ISO 5269-2:1998 standard. The ionic strength in the sheet former unit was adjusted to be approximately equal for all the sheets, irrespectively of the ionic strength during PAH adsorption. Sheets were dried under restrained conditions at 93 °C and at a pressure of 95 kPa below atmospheric pressure for 15 min.

Paper testing

Tensile testing was conducted according to the SCAN P:67 standard for tensile testing of laboratory-made sheets. The thickness of the prepared sheets was measured as structural thickness (Schultz-Eklund et al. 1992) and was used to calculate sheet density.

Creep was measured under tension at constant climates of 50%RH and 90%RH, with the temperature set to 23 °C. All samples were conditioned at 50%RH or 90%RH for at least 24 h prior to testing in order to allow the samples to reach equilibrium moisture content.

The apparatus used to perform the creep measurements was developed at STFI-Packforsk, Stockholm, Sweden. A detailed description of the apparatus can be found elsewhere (Panek et al. 2004). The paper strips tested in the apparatus were subjected to different loads and the resulting strain was recorded as function of time. The strips used were 25 mm wide and 130 mm long. Ten strips were tested for each sheet type. A creep time of 300 s was used.

Results

Confocal fluorescence imaging for localisation of adsorbed polyelectrolyte

Adsorption of fluorescent labelled polyallylamine and CLS-microscopy of separate fibres resulted in images of thin optical cross-sections which provided a visual image of the localisation of the adsorbed polyelectrolyte. Labelled PAH had a very low degree of substitution of fluorophores (D.S. < 0.01). The charge density of labelled PAH was determined by polyelectrolyte titration. Within the experimental uncertainty of the method, no difference in charge density between the original and the labelled polyelectrolytes could be detected. Thus the presence of the fluorophores should have no significant effect on the polyelectrolyte conformation or on the adsorption behaviour (Tanaka et al. 1990), and the images obtained reflect how the unlabelled polyallylamine adsorbs to the fibres.

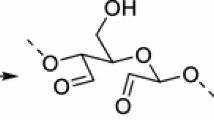

Figure 1 shows the result when using the reference condition of 5 × 10−3 M NaHCO3 and 30 min adsorption time. From the figure it is clear that this condition resulted in adsorption only to the fibre exterior. Yet it is to be noticed that for the thinnest earlywood fibres the thickness of the adsorbed layer was almost as thick as the fibre cell wall. For these fibres, a considerable part of the total fibre cell wall volume was influenced by the adsorbed polyelectrolyte. Thus it is possible that the mechanical properties of these fibres could be markedly influenced by the adsorbed polyelectrolyte. Another feature to notice in the figure is that the adsorbed layer thickness is approximately the same for all the fibres. Thus the polyelectrolyte molecules did not seem to penetrate more easily or faster into certain types of fibres.

CLSM micrographs of radial cross-sections of fibres saturated with 15 kDa F-PAH. The polyelectrolyte was adsorbed at 5 × 10−3 M NaHCO3 and pH 8 for 30 min. The red and green pictures were obtained by excitation at 488 and 568 nm, respectively. At 568 nm there was a considerable auto-fluorescence from the lignin in the fibre wall, and hence the thickness of the fibre cell wall was visualised. It is seen that the labelled polyallylamine molecules did not penetrate the fibre cell wall fully in any of the examined fibres, although the thickness of the adsorbed layer was almost as thick as the fibre cell wall in the case of the thinnest earlywood fibres. For these fibres a considerable volume of the total cell wall volume was affected by the adsorbed polyelectrolyte

Figure 2 shows the result of increasing the ionic strength and adsorption time to 5 × 10−3 M NaHCO3 + 10−1 M NaCl and 24 h, respectively. This change in the adsorption conditions did indeed enable the polyallylamine molecules to penetrate through the fibre wall of all the examined fibres. In this case, the adsorbed PAH is thus able to influence the mechanical properties of the fibre wall of all the fibres.

CLSM micrographs of radial cross-sections of fibres saturated with 15 kDa F-PAH. The polyelectrolyte was adsorbed at 5 × 10−3 M NaHCO3 + 10−1 M NaCl and pH 8 for 24 h. The red and green pictures were obtained by excitation at 488 and 568 nm, respectively. In contrast to Fig. 1, the labelled polyallylamine molecules did in this case penetrate the fibre cell wall fully, for all the examined fibres

The results presented in Fig. 2 showed that the more extreme condition were sufficient for fibre wall penetration, but they did not indicate whether the higher salt concentration alone was sufficient or whether it has to be combined with a long adsorption time. In a second study the ionic strength and adsorption times were therefore varied in smaller steps. Since the diffusion into the fibre wall was easier to study in the case of thick-walled latewood fibres, only such fibres were examined in this case. Figure 3 shows that a high ionic strength alone was not enough to enable the PAH to penetrate throughout thick latewood fibres, but that it had to be combined with extended adsorption times. At the two highest ionic strengths (5 × 10−1 M NaCl and 1 M NaCl) the molecules had started to migrate into the fibre wall within 3 h, but there was still a noticeable gradient in fluorescence intensity. Full migration all the way to the lumen, with a fairly even fluorescent intensity across the fibre wall, was first seen after 24 h.

Micrographs of axial cross-sections of latewood fibres saturated with fluorescent labelled polyallylamine (15 kDa) at different ionic strengths and different adsorption times. The images were recorded at an excitation wavelength of 568 nm. The auto-fluoresce of lignin in the fibre wall at this wavelength reveals the fibre wall thickness and lumen. It is seen that a combination of high ionic strength and long adsorption time was needed to achieve adsorption of polyelectrolyte throughout the fibre wall of latewood fibres. The figure includes the adsorbed amounts measured by nitrogen content analysis. The 95% confidence intervals for these are approximately ±8 mg/g

It was thus clear that full fibre wall penetration in thick latewood fibres required an ionic strength slightly higher than 10−1 M NaCl and an adsorption time between 3 and 24 h. It is possible that full penetration can be obtained at a low ionic strength (10−2 and 10−1 M NaCl), if adsorption times considerably longer than 24 h are allowed. More experiments are, however, needed to test this hypothesis.

The adsorbed amount of PAH, measured by nitrogen content analysis is included in the figure. Due to the limited amount of fibre material available, it was only possible to make two measurements for each sample and the 95% confidence intervals for the average values are therefore large, approximately ± 8 mg/g. Hence, the numbers are only very approximate and show a general trend rather than absolute values. The general trend was that the adsorbed amount increased with increasing time and increasing ionic strength and that the PAH molecules migrated into the fibre wall and accessed pores throughout the entire fibre, which agrees with the generally accepted theory that a polyelectrolytes access to the fibre wall increases with increasing ionic strength (Wågberg 2000). The probable explanation to this is that increased ionic strength tends to coil the polyelectrolyte, and that this, in combination with porous nature of the cellulose fibres, means that a greater surface area will be available to the polyelectrolyte.

Several of the images showed, however, that the polyelectrolyte adsorbed only to the fibre exterior although there was a large average adsorbed amount as determined by the nitrogen content analysis. The explanation of this apparent contradiction is found in Fig. 4, where images of earlywood fibres with PAH adsorbed at 10−1 M NaCl for 24 h are shown. In this figure, the PAH had access to more or less the entire fibre wall for these thin walled fibres. Hence the PAH molecules had almost full access to the fibre wall in early- and transitionwood fibres but not in latewood fibres, so that explains that the average adsorbed amount can be large, even if the polyelectrolyte molecules do not have access to the thick-walled latewood fibres. The difference in access to early- and latewood fibre may be due to the fact that early and latewood fibres have different porosities. This has not been shown before and further experiments are needed to verify or reject this hypothesis.

The results also show that there is no single threshold for full fibre wall penetration since this differs from fibre to fibre. While shorter adsorption times were sufficient to enable the polyelectrolyte molecules to migrate throughout thin-walled earlywood fibres, significantly longer times were needed for thicker latewood fibres.

Dynamic light scattering showed that the 15 kDa PAH had a hydrodynamic radius of approximately 6 nm at 1 M NaCl. Andreasson et al (2005) investigated the pore size distribution of unbleached kraft pulp fibres (kappa number 60) using NMR relaxation and ISEC measurements. NMR measurements showed that the pore radius ranged from 13 to 17 nm. ISEC measurements on the other hand showed that most pores were in the range 0.6–4 nm and only a few had a radius larger than 10 nm. Their conclusion was that the dextrans used as probe molecules in the ISEC measurements primarily measure the size of the pore openings in the more external parts of the fibre, and that these are smaller than the pores deeper in the cell wall. This result shows that at least some of the pores in the external part of the fibre wall were larger than the average polyelectrolyte hydrodynamic size at 1 M NaCl. Regarding the molecular dimensions, the polyallylamine molecules should thus been able to enter the porous fibre wall. The relation between polymer size and ability to penetrate the fibre wall will be further discussed.

Mechanical properties of paper sheets

It is important that papers made from fibres subjected to different treatments can be compared at a constant density. Consequently, the densities of the different sheets were determined. The apparent sheet density was fairly constant at approximately 680 kg/m3, when PAH was adsorbed to the fibre surfaces (Fig. 5), but when PAH was adsorbed throughout the fibre cell walls, the density decreased slightly to 644 kg/m3.

Apparent sheet density as a function of the adsorbed amount of PAH. With adsorption only to the fibre surfaces, the density remained constant. However, with adsorption throughout the fibre walls, the density was slightly reduced. Low salt concentration corresponds to 5 × 10−3 M NaHCO3 and high salt to 5 × 10−3 M NaHCO3 + 10−1 M NaCl

The results of the mechanical testing of the paper sheets are presented in Figs. 6–8. In agreement with previous results, mechanical properties such as tensile strength, strain-at-break and tensile stiffness increased with increasing amount of adsorbed polyallylamine. A distinct exception was however noted when polyallylamine was adsorbed throughout the fibre wall. In this case, despite the high adsorbed amount, the mechanical properties were only at the level of the reference paper.

Tensile strength as a function of the adsorbed amount of PAH. With adsorption only to the fibre surfaces, the tensile strength increased with increasing amount of PAH. However, with adsorption throughout the fibre walls, there was no increase compared to the reference, despite the large adsorbed amount

Strain-at-break as a function of the adsorbed amount of PAH. When PAH was adsorbed only to the fibre surfaces, the strain-at-break increased with increasing amount of PAH. However, when adsorbed throughout the fibre walls, there was no increase compared to the reference, despite the large adsorbed amount

Tensile stiffness index as a function of the adsorbed amount of PAH. When PAH was adsorbed only to the fibre surfaces, the tensile stiffness increased slightly but significantly with increasing amount of PAH. However, when adsorbed throughout the fibre walls, there was no increase compared to the reference, despite the large adsorbed amount of PAH

The results of the short-time creep testing of the sheets are presented in Figs. 9–12. Creep deformation can be divided into instantaneous and delayed deformation, and the delayed part can then be further subdivided into delayed elastic and permanent creep. The instantaneous response is an idealisation, as it does take some time for the deformation to develop. In this study the instantaneous response is evaluated as the deformation detected after 1 s. Figures 9 and 11 show so called isochronous stress–strain curves (Panek et al. 2004) and these relate the applied stress with the total deformation a given time, in this case 300 s. For paper materials it is preferable to express the applied stress as specific stress (force per unit grammage per unit width). The figures also include the model function proposed by Panek et al. (2004) fitted to some of the data sets. There is some scatter in the measured data and the fitted curves show the average behaviour for each sheet type. In order to estimate the scatter of the data, non-simultaneous 95% confidence limits for the predicted fit are also included. There is 95% probability that the fit (the average stress-strain behaviour) would lie between these limits if the measurements were repeated an infinite number of times.

Isochronous stress–strain data recorded at 300 s in 50%RH. The model by Panek et al (2004) and also non-simultaneous 95% confidence limits for the predicted fit are included for PAH adsorbed at high ionic strength, high addition of PAH at low ionic strength, and the reference. Low salt (L.S) concentration corresponds to 5 × 10−3 M NaHCO3 and high salt (H.S) to 5 × 10−3 M NaHCO3 + 10−1 M NaCl

Specific stress versus delayed creep deformation (difference in strain between 300 and 1 s) for selected samples at 50%RH. If the scatter of the data, indicated by non-simultaneous 95% confidence limits for the predicted fits, is considered it is found that there was no significant difference in delayed creep deformation for the different samples. Low salt (L.S) concentration corresponds to 5 × 10−3 M NaHCO3 and high salt (H.S) to 5 × 10−3 M NaHCO3 + 10−1 M NaCl

Isochronous stress-strain data recorded at 300 s in 90%RH. The model by Panek et al (2004) and also non-simultaneous 95% confidence bounds for the predicted fit are included for PAH adsorbed at high ionic strength, high addition of PAH at low ionic strength and the reference. Low salt (L.S) concentration corresponds to 5 × 10−3 M NaHCO3 and high salt (H.S) to 5 × 10−3 M NaHCO3 + 10−1 M NaCl

Specific stress versus delayed creep deformation (difference in strain between 300 and 1 s) for selected samples at 90%RH. If the scatter of the data, indicated by non-simultaneous 95% confidence bounds for the predicted fit, is considered it is found that for strains >0.1% there are significant differences between the samples. Low salt (L.S) concentration corresponds to 5 × 10−3 M NaHCO3 and high salt (H.S) to 5 × 10−3 M NaHCO3 + 10−1 M NaCl

Figure 9 shows the isochronous curves for 300 s and 50%RH where the highest addition of 15 kDa PAH at low ionic strength and the addition of PAH at high ionic strength resulted in a small, but significant difference in the total creep deformation during 300 s (for strains larger than 0.3%). At lower dosages of 15 kDa PAH and for 150 kDa PAH, there was no significant difference in total creep deformation. If only the samples with a significant difference in total creep deformation are considered, it is seen in Fig. 10 that there was no significant difference in the delayed creep deformation (difference in strain between 300 and 1 s). There is a small tendency that the sheets with PAH adsorbed to the fibre surfaces creep slightly less than the reference and that the sheets with PAH adsorbed throughout the fibre wall creep slightly more than the reference. But as seen in Fig. 10, the confidence limits for the different samples overlap and the differences are thus not significant. If the isochronous curves for 300 s (Fig. 9) are normalised with respect to the tensile stiffness index of the respective samples they fall together on a single curve. The difference in total creep deformation was thus a result only of the difference in elastic modulus between the different samples, and the time-dependent mechanical behaviour of the sheets in 50%RH was not altered by the presence of adsorbed polyelectrolyte. It is thus suggested that the inherent creep of the constituent fibres at 50%RH was not altered by the adsorbed polyelectrolyte.

Figure 11 shows the isochronous stress–strain curves for 300 s at 90%RH. There was a considerable difference in total creep deformation for the 15 kDa PAH sheets, but not for the 150 kDa sheets. With a high dosage of 150 kDa, the total creep deformation actually appeared to be larger. The delayed creep deformation for selected samples is plotted in Fig. 12, where significant differences are evident. Due to the difference in creep rate, the isochronous curves for 300 s could not be normalised with the tensile stiffness indexes to form a single curve. So it is clear that the 15 kDa PAH altered the creep behaviour of the sheets at 90%RH, whereas the 150 kDa did not.

When the ionic strength during adsorption was low the creep rate was reduced, but with a high ionic strength the creep rate actually increased. From the results regarding the adsorption of fluorescently labelled PAH it was clear that at low ionic strength only a part of the fibre wall was affected by the adsorbed polymer, however, for thin walled fibres the affected volume was considerable. With a high ionic strength the polylelectrolyte molecules were able to reach throughout the fibre cell walls. The creep of fully efficiently loaded sheets is believed to be determined by the creep of the component fibres. Thus it is somewhat counter intuitive that the creep rate increased when the entire fibre wall was treated with polyelectrolyte, since the initial hypothesis was that a treatment of the fibre wall would result in less creep of the individual fibres.

Discussion

Polyallylamine adsorption

Due to the porous nature of the fibre cell wall, the effective size and chain flexibility of the polyelectolyte will determine whether or not the molecules are able to diffuse into the fibre wall. A measure of polyelectrolyte chain flexibility is the persistence length (Lp), i.e. the distance over which an uninterrupted polymer chain persists in a particular direction. For a polyelectrolyte, the persistence length is the sum of an intrinsic persistence length (Lpi) and an electrostatic persistence length (Lpe) (Eq. 1). A theory for calculating the electrostatic persistence length (Eq. 2), based on the Debye-Hückel approach and the worm-like chain model of Kratky and Porod was developed by Odjik (Odijk 1977; Odijk and Houwaart 1978; Odijk 1979) and by Skolnick and Fixman (1977). The worm-like chain model can describe polymer chains of different flexibilities from random walk chains to stiff rods and is thus appropriate for polyelectrolytes.

where b is the average distance between two charged groups, λB is the Bjerrum length, λD is the Debye length and the factor ξM = 1 for b ≥ λB and ξM = λB/b for b ≤ λB. In the case of PAH in water at room temperature, b ≈ 2.4 Å and λB ≈ 7 Å, thus ξM = λB/b.

Mattison et al. (1998) has published data for the intrinsic persistence length of three different vinyl type polyelectrolytes (–CH2–CHX–) and all three polyelectrolytes have an intrinsic persistence length of 24 Å. It is thus reasonable to assume that PAH (which is also a vinyl type polyelectrolyte) has an intrinsic persistence length that is close to 24 Å. Under theta-conditions, a quantative relation between persistence length, contour length and radius of gyration has been established for a worm-like chain (Dautzenberg 1994) (Eq. 3). Assuming that theta-conditions prevail an approximate radius of gyration for 15 kDa PAH at different ionic strengths could be calculated according to Eq. 3 (Fig. 13).

NMR relaxation measurements have shown that the pore radii in unbleached cellulose fibres range from 13 to 17 nm in radius (Andreasson et al. 2005). Inverse size exclusion chromatography, however, indicated for the same fibres that most pores had a radius in the range of 0.6–4 nm and only a small part had a radius larger than 10 nm (Andreasson et al. 2005). It is evident in Fig. 13 that a radius of gyration of 10 nm for 15 kDa PAH corresponds to an electrolyte concentration of 10−3 M NaCl. The ionic strengths examined in this study were all higher than 10−3 M NaCl. The hydrodynamic radius for 15 kDa PAH at 1 M NaCl was determined by dynamic light scattering to be 6 nm. Thus both the calculated radius of gyration and the hydrodynamic radius measured by dynamic light scattering, suggest that the PAH molecules should be able to access pores in the fibre cell wall.

The above reasoning suggests that the 15 kDa PAH molecules should be small enough in 10−2 and 10−1 M NaCl to enter the pores in the fibre wall, but at these concentrations of electrolyte, the molecules had not migrated throughout thick walled fibres within 24 h. The migration of the polyelectrolyte is also a rather slow process at 1 M NaCl. The kinetics of diffusion/reptation into the fibre wall probably depends on the polyelectrolyte chain flexibility as well as on the interaction between the polyelectrolyte and fibre material. The persistence length, which is a measure of the chain flexibility, has been calculated, using OSF-theory (Eqs. 1 and 2) and the result is shown in Fig. 14 as function of electrolyte concentration. The persistence length decreases considerable with increasing electrolyte concentration in the range of 10−2 to 10−1 M NaCl. If Fig. 14 is compared with the results in Fig. 3 it appears that the electrostatic contribution to the persistence length must be almost fully screened for the migration process to become so fast that full fibre wall penetration is reached within 24 h. For electrolyte concentrations between 5 × 10−1 and 1 M NaCl, the persistence length does not change much. Figure 3 shows that the kinetics for PAH migration in thick-walled fibres is more or less the same at 5 × 10−1 and 1 M NaCl, indicating that the chain flexibility, estimated by the persistence length, is indeed important for the kinetics of PAH migration into the fibre cell wall. The importance of the persistence length for the diffusion kinetics of poly(AM-co-DADMAC) and cationic dextran into the cell wall of cellulosic fibres have also been studied by Horvath et al (unpublished results).

As mentioned earlier, it is, however, improbable that chain flexibility is the only factor that influences the kinetics of the migration process. The electrostatic interaction between the charged fibre and the polyelectrolyte will tend to lock the polyelectrolyte when it is adsorbed to the fibre surface, and thus hinder/slow its propagation into the fibre wall. Increasing electrolyte concentration will screen the electrostatic interaction and thus reduce the energetic barrier for migration of already adsorbed polyelectrolyte molecules, and so facilitate the migration process. However, the decrease in interaction energy also means that the driving force for adsorption is reduced, so that there is probably an optimal electrolyte concentration. If this is exceeded by far, the result is probably a complete depletion of the adsorption. Still the polyelectrolyte molecules would probably diffuse into the fibre wall by Fickian diffusion, i.e. diffusion driven by a concentration gradient. The results from Fig. 3 show that for PAH, high electrolyte concentration (1 M NaCl) was favourable for fibre wall penetration. 1 M NaCl is a high ionic strength and it could indeed be inferred that the electrostatics are almost completely screened at 1 M NaCl, and that the fibre wall penetration seen for this ionic strength is just a result of Fickian diffusion into the fibre wall. But the high adsorbed amount in combination with the slow kinetics of the migration process shows that this is not the case, since if there were no electrostatic interaction between the polyelectrolyte molecules and the fibre, the Fickian diffusion into the fibre wall would probably have been considerably faster and the adsorbed amount less.

Mechanical properties of resulting paper sheets

At low ionic strength, the adsorption of PAH took place on the exterior of the fibre. The adsorption of polyallylamine to the fibre exterior increased mechanical properties, such as tensile strength, strain-at-break and tensile stiffness. The adsorption of PAH did not have any significant effect on the creep rate at 50%RH. In contrast, at 90%RH, the adsorption of 15 kDa PAH at low ionic strength led to a slower creep. The differences in creep rate at 90%RH mean that a normalisation of the isochronous stress-strain curves at 300 s with respect to the elastic modulus did not transpose them to a single curve. Hence, at 90%RH, the effect of the adsorbed polyelectrolyte on the viscoelasticity could not be explained by the concept of efficiency factors.

It is suggested that the creep of the cellulosic fibres themselves is caused by mechanisms such as molecular relaxations and slip between cellulose chains which give rise to minute movements of fibrils in the fibre wall and deformation thereof (Hill 1967; Olsson and Salmen 2001). Primary amines are capable of reacting with aldehydes present in lingocellulosic fibres to form imine and aminal linkages (Laleg and Pikulik 1991; DiFlavio et al. 2005). Hence, polyallylamine can form covalent linkages within the fibres. These linkages could hinder molecular relaxations and chain slips, thereby stiffening the fibres and slow their viscous deformation. The micrographs of fibres with PAH adsorbed at low ionic strength (Fig. 1) showed that polyelectrolyte molecules were present in a considerable part of the fibre wall in the case of thin early- and transitionwood fibres, even though they could not reach all the way to the lumen. Hence it is probable that the mechanical properties of early- and transitionwood fibres were considerably effected by the presence of PAH, probably by the introduction of cross-links, and this is a plausible reason for why the creep rate at 90%RH was reduced by the adsorption of 15 kDa PAH. No creep reduction was found for the 150 kDa PAH, this is probably due to the fact that the 150 kDa molecules with their larger hydrodynamic size had to limited access to the fibre wall in order to have a significant effect on the mechanical properties of the fibres. It is possible that similar molecular movements as in the fibre wall could take place in the fibre/fibre joints. The opinion of the authors is that the fibre/fibre joint should not be considered to be totally inextensible, and that it could have a small effect on the viscoelasticity of paper, even if the properties of the component fibres are more important. The fact that creep reduction only was found for 90%RH might be associated with the fact the wood polymers are softened by moisture (Cousins 1976, 1978) since the effect of cross-links should be more pronounced when the polymers are in a more softened state.

There are many differences between the effects of adsorbed PAH on creep properties found in this study and those found in the previous study (Gimåker et al. 2007). In the previous study, a significant effect on creep rate was found at both 50%RH and 90%RH, whereas in this study there was a difference only at 90%RH. Furthermore, in the present study it was only the 15 kDa PAH that reduced the creep rate, whereas all molecular masses gave similar improvements in the previous study. The only reasonable explanation of these differences is the nature of the fibres used. The fibres in this study had a higher yield than those in the previous study and thus a higher content of lignin. It is possible that the interaction between additive and fibre is affected by the lignin content. The difference in yield also implies that there was a difference in average pore radius between the two pulps (Andreasson et al. 2005). This could in turn affect the way in which the polyelectrolytes influence the properties of the fibres and the resulting sheets. As an example the larger pores in a pulp with lower yield would give the high molecular mass PAH greater access to the fibre wall. This explains why creep reduction was seen for all molecular masses in the previous study but not in the present.

Figure 2 shows clearly that when the ionic strength and adsorption time were increased the PAH molecules had full access to the fibre cell wall. The influence on the fibre cell wall properties was therefore expected to be greater than at low ionic strength, but the mechanical properties of the sheets actually deteriorated slightly when the polyelectrolyte molecules accessed the entire fibre cell wall. For sheets with PAH adsorbed at high ionic strength, the creep rate at 90%RH was higher than that of the reference, which conflicts with the initial hypothesis.

The exact mechanism behind the observed increase in creep rate is not fully understood. However, it can be noted that the density of these sheets was lower, indicating a less effective consolidation. The fact that the sheet strength dropped to the same level as that of the reference when PAH was adsorbed throughout the fibre wall also suggests a less effective consolidation. The poor consolidation was most probably due to less flexible and swollen fibres after adsorption of PAH, that in turn led to poorer packing and less efficient contact between fibres. It has in fact been shown that cationic polyelectrolytes do lead to a deswelling of cellulosic fibres (Swerin et al. 1990). In the same study, it was also found that a low molecular mass polyelectrolyte that has access to all fibre charges give greater deswelling than a high molecular mass polyelectrolyte that has access only to surface charges. This implies that the fibre deswelling was less when PAH was adsorbed to the fibre exterior than when it was adsorbed throughout the fibre wall. When PAH was adsorbed to the fibre exterior, the loss in fibre surface flexibility was compensated for by the increase in fibre/fibre joint strength to which the PAH gave rise, and the sheet strength consequently increased. When PAH was adsorbed into the fibre wall, however, the loss in fibre swelling was so severe that it could not be fully compensated for by the strengthening effect PAH had on the fibre/fibre joints.

The less effective consolidation leads to fewer fibre/fibre contact points and hence a less efficient distribution of stresses in the fibre-network. The less efficient stress distribution means that some fibres will be more stressed than the fibres in the reference sheets, and this in turn can explain the observed increase in creep rate.

It should also be emphasised that no direct measurements of the mechanical properties of the individual fibres have been made in the present study. It is thus difficult to draw any decisive conclusions about the effect of the adsorbed polyelectrolyte on the mechanical properties of the individual fibres. It is therefore possible that the mechanical properties of the individual fibres were unaffected, improved or even deteriorated by the adsorbed polyelectrolyte.

The decrease in creep rate at 90%RH for sheets with PAH adsorbed to the fibre exterior could in fact be a result solely of changed fibre/fibre joint properties. This does not, however, seem probable in the light of all the literature that shows the importance of the fibre cell wall for the viscoelasticity of paper. To further clarify the influence which polymeric additives and other fibre modifications have on the mechanical properties of the fibres and the resulting sheets, it is suggested that future studies should also seek to characterise the mechanical behaviour of individual fibres.

Conclusion

Addition of 15 kDa PAH at low ionic strength (5 × 10−3 M NaHCO3) results in the adsorption of PAH to the exterior of unbleached lignocellulosic fibres. In the case of thin earlywood fibres, however, PAH molecules reached a considerable part of the fibre cell wall. The combination of high ionic strength and long adsorption time (5 × 10−3 M NaHCO3 +10−1 M NaCl and 24 h) made it possible for the 15 kDa PAH to penetrate throughout the fibre cell wall, even in thick-walled latewood fibres.

The mechanical testing of sheets produced from the fibres clearly showed that the time-dependent deformation in a 50%RH environment was not influenced by the adsorbed PAH. In a 90%RH environment, adsorption of 15 kDa PAH to the fibre exterior reduced the delayed creep deformation slightly, but significantly. There is no conclusive indication as to whether this is caused by alterations in fibre/fibre joint properties or in the inherent viscoelasticity of the component fibres. The fact that the polyelectrolyte molecules reached a significant part of the fibre wall in the case of thin-walled fibres, taking into consideration the earlier literature which has emphasised the importance of the fibre, perhaps indicates that alterations in fibre properties are the most likely cause.

When the electrolyte strength during adsorption was higher, so that the PAH molecules gained full access to the fibre wall, the creep was actually increased. It is suggested that this is due to a deswelling of the fibres, which results in less consolidation and fewer fibre/fibre contact points and a poorer stress transfer within the sheet and thus a higher creep rate.

There are significant differences between the impact of PAH adsorption on the creep behaviour found here and the effect reported in the previous study (Gimåker et al. 2007). Since the fibres used have different yields, it is thus concluded that the effect of PAH on the viscoelasticity of paper is strongly dependent upon the character of the fibres used.

References

Andreasson B, Forsström J, Wågberg L (2005) Determination of fibre pore structure: influence of salt, pH and conventional wet strength resins. Cellulose 12(3):253–265. doi:10.1007/s10570-004-5837-6

Byrd VL (1972a) Effect of relative humidity changes during creep on handsheet paper properties. Tappi 55(2):247–252

Byrd VL (1972b) Effect of relative humidity changes on compressive creep response of paper. Tappi 55(11):1612–1613

Cousins WJ (1976) Elastic modulus of lignin as related to moisture content. Wood Sci Technol 10(1):9–17. doi:10.1007/BF00376380

Cousins WJ (1978) Young’s modulus of hemicellulose as related to moisture content. Wood Sci Technol 12(3):161–167. doi:10.1007/BF00372862

Dautzenberg H (1994) Polyelectrolytes: formation, characterization and application, Hanser/Gardner, Munich/Cincinnati

DeMaio A, Patterson T (2005) Influence of fiber–fiber bonding on the tensile creep compliance of paper. In: Advances in paper science and technology, 13th fundamental research symposium, Cambridge, UK, September, 2005, pp 749–775

DiFlavio J-L, Bertoia R, Pelton R, Leduc M (2005) The mechanism of polyvinylamine wet-strengthening. In Advances in paper science and technology, 13th fundamental research symposium, Cambridge, UK, September, 2005, pp 1293–1316.

Gimåker M, Horvath A, Wågberg L (2007) Influence of polymeric additives on short-time creep of paper. Nord Pulp Pap Res J 22(2):217–227. doi:10.3183/NPPRJ-2007-22-02-p217-227

Hill RL (1967) The creep behavior of individual pulp fibers under tensile stress. Tappi 50(8):432–440

Horn D (1978) Optical two-beam method for the determination of polyelectrolytes in water and for the measurement of polymer adsorption at interfaces. Prog Colloid Polym Sci 65:251–264. doi:10.1007/BFb0117226

Horvath AT, Wågberg L (2006) Chemical approaches for modifying the fiber wall properties to improve paper strength properties. In: Abstracts of papers, 231st ACS National Meeting, Atlanta, GA, United States, March 26–30, 2006, CELL-128

Laleg M, Pikulik II (1991) Wet-web strength increase by chitosan. Nord Pulp Pap Res J 6(3):99–103, 109

Lindström T, Wågberg L, Larsson T (2005) On the nature of joint strength in paper—a review of dry and wet strength resins used in paper manufacturing. In: Advances in paper science and technology, 13th fundamental research symposium. Cambridge, UK, September, 2005, pp 457–562

Mattison KW, Dubin PL, Brittain IJ (1998) Complex formation between bovine serum albumin and strong polyelectrolytes: effect of polymer charge density. J Phys Chem B 102(19):3830–3836. doi:10.1021/jp980486u

Odijk T (1977) Polyelectrolytes near the rod limit. J Polym Sci, Polym Phys Ed 15(3):477–483

Odijk T (1979) Possible scaling relations for semidilute polyelectrolyte solutions. Macromolecules 12(4):688–693. doi:10.1021/ma60070a028

Odijk T, Houwaart AC (1978) Theory of the excluded-volume effect of a polyelectrolyte in a 1–1 electrolyte solution. J Polym Sci, Polym Phys Ed 16(4):627–39

Olsson A-M, Salmen L (2001) Molecular mechanisms involved in creep phenomena of paper. J Appl Polym Sci 79(9):1590–1595. doi:10.1002/1097-4628(20010228)79:9<1590::AID-APP70>3.0.CO;2-5

Panek J, Fellers C, Haraldsson T (2004) Principles of evaluation for the creep of paperboard in constant and cyclic humidity. Nord Pulp Pap Res J 19(2):155–163. doi:10.3183/NPPRJ-2004-19-02-p155-163

Schultz-Eklund O, Fellers C, Johansson PÅ (1992) Method for the local determination of the thickness and density of paper. Nord Pulp Pap Res J 7(3):133–139, 154

Seth RS, Page DH (1981) The stress strain curve of paper, the role of fundamental research in paper making. In: 7th fundamental research symposium, Cambridge, UK, September, 1981, pp 421–452

Skolnick J, Fixman M (1977) Electrostatic persistence length of a wormlike polyelectrolyte. Macromolecules 10(5):944–948. doi:10.1021/ma60059a011

Swerin A, Ödberg L, Lindström T (1990) Deswelling of hardwood kraft pulp fibers by cationic polymers: the effect on wet pressing and sheet properties. Nord Pulp Pap Res J 5(4):188–196. doi:10.3183/NPPRJ-1990-05-04-p188-196

Tanaka H, Ödberg L, Wågberg L, Lindström T (1990) Adsorption of cationic polyacrylamides onto monodisperse polystyrene latices and cellulose fiber: effect of molecular weight and charge density of cationic polyacrylamides. J Colloid Interface Sci 134(1):219–228

Terayama H (1952) Method of colloid titration (a new titration between polymer ions). J Polym Sci 8:243–253. doi:10.1002/pol.1952.120080209

Wågberg L (2000) Polyelectrolyte adsorption onto cellulose fibers—a review. Nord Pulp Pap Res J 15(5):586–597. doi:10.3183/NPPRJ-2000-15-05-p586-597

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gimåker, M., Wågberg, L. Adsorption of polyallylamine to lignocellulosic fibres: effect of adsorption conditions on localisation of adsorbed polyelectrolyte and mechanical properties of resulting paper sheets. Cellulose 16, 87–101 (2009). https://doi.org/10.1007/s10570-008-9240-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-008-9240-6