Abstract

The pulping byproducts (black liquor) cause serious environmental problem due to its high pollution load. In order to search the degradability of black liquor, the potential bacterial strains Citrobacter freundii (FJ581026) and Citrobacter sp. (FJ581023) were applied in axenic and mixed condition. Results revealed that the mixed bacterial culture are more effective than axenic condition and can reduce 82% COD, 79% AOX, 79% color and 60% lignin after 144 h of incubation period. Additionally, the optimum activity of lignin degrading enzyme was noted at 96 h and characterized as manganese peroxidase (MnP) by SDS–PAGE analysis. Further, the HPLC analysis of control and bacterial degraded sample has shown the reduction as well as shifting of peaks compared to control indicating the degradation as well as transformation of compounds of black liquor. The comparative GC–MS analysis of control and degraded black liquor revealed that along with lignin fragment some chlorophenolic compounds 2,4,6-trichlorophenol, 2,3,4,5-tetrachlorophenol and pentachlorophenol were detected in black liquor degraded by axenic culture whereas these chlorophenolic compounds were completely absent in black liquor degraded by mixed bacterial culture. These chlorophenol inhibit the oxidative degradation which seems a major reason behind the low degradability of axenic degradation compared to mixed culture. The innovation of this aerobic treatment of alkaline black liquor opens additional possibilities for the better treatment of black liquor along with its metabolic product.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pulp manufacturing in pulp paper industries involve two main processes i.e. wood digestion and bleaching. In the process of wood digestion, wood chips are cooked in the solution of sodium hydroxide and sodium sulphate at elevated temperature and pressure to break chips into fiber mass. The chemical reaction with wood fibers, dissolve all the depository materials which are hard to degrade and these derivatives are washed away from the fiber during washing and dewatering process. Among the various extracts during washing are mainly lignins, cellulose, phenolics, resins, fatty acids and tannins mixed together and make dark black viscous alkaline waste known as black liquor. The alkaline effluent consisting only 10–15% of total wastewater, but contributes almost above 90–95% of the total pollution load in terms of high pH, BOD, COD and color which make it significantly toxic to the environment (Grover et al. 1999). Hence, the adequate treatment of black liquor prior to it discharge into environment is warranted. Recent developments in treatment of pulp and paper mill wastewaters such as electrocoagulation, ozonation, ultrafiltration has shown the various application of physical and chemical methods or combination of different methods in series (Pokhrel and Viraraghavan 2004; Zaied and Bellakhal 2009). However, the problem remains unsolved, since lignin undergoes a spatial rather than chemical change and thus, persists albeit in a different form even after treatment (Ugurlu et al. 2008). To date most effective method for management of black liquor is the combustion with sodium recovery process in which the black liquor is first concentrated and then incinerated. In this way organic substance in wastewater is burn and sodium simultaneous recovered (Grover et al. 1999). However, medium and small scale paper plants worldwide are gradually closing due to their incapability of sodium and energy recovery from black liquor. Therefore, more practical method is needed for the treatment process for small pulping mill effluent.

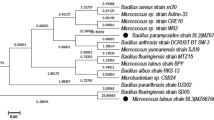

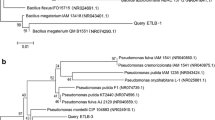

The biological methods involving the use of fungi, bacteria, algae and enzymes as single step treatment or in combination with other physical and chemical methods are seem to be more economical and eco-friendly. Among biological methods tried so far, most of the literature confined to a few genera of white rot fungi because of their non specific extracellular enzymatic system (LiP, MnP and Laccase) involve in lignin biodegradation (Hammel and Cullen 2008). On other hand, the stability of fungi is not good in practical treatment under extreme environmental and substrate conditions, such as higher pH, oxygen limitation, and high extraction and lignin concentrations. In recent years some bacterial strains have been reported for degradation of lignin and lignin related model compounds due to their immense environmental adaptability and biochemical versatility (Gupta et al. 2001; Jokela et al. 1985; Raj et al. 2007; Daniel and Nilsson 1998). Previously we have reported three potential bacterial strains of Panibacillus sp. (AY952466) Aneurinibacillus aneurinilyticus (AY856831) and Bacillus sp. (AY952465) isolated from pulp paper sludge for degradation and decolorization of synthetic lignin at 500 mgl-1 and characterization of metabolic product by GC–MS analysis (Chandra et al. 2007; Raj et al. 2007). However, the above study provide indirect evidence for the degradation of lignin and/or its model compounds can not be directly explained to the degradation of lignin which are present in pulp waste water.

The Citrobacter sp. showing good potential for the degradation of various azo, anthraquinone and other toxic pollutants (Wang et al. 2009; Khalid et al. 2009). Despite the good degrading potential, this organism has not been used for the treatment of black liquor and only few reports are available regarding the bacterial ligninolytic enzymatic system i.e. MnP catalyzing lignin degradation (Dick et al. 2008; Oliveira et al. 2009). Hence, there is need to explore the detail mechanism of bacterial MnP system facilitating the lignin depolymerization for its biotechnological application at industrial scale. Therefore, the objectives of this study are the decolorization of black liquor by isolated aerobic bacteria in axenic and mixed condition as well as to characterize the ligninolytic enzyme and metabolites produced during the bacterial degradation of lignin present in black liquor.

Materials and methods

Sample collection and analysis

The samples were collected from M/s Yash paper mill Ltd., Darsannagar, Faizabad (U.P.), India. The effluent was collected from pulping stage before bleaching stage in sterile plastic containers, brought to laboratory and stored at 4°C for further study. This industry came into operation in 1982 and uses eucalyptus, wheat straw and sugarcane bagasse as a raw material and adopts kraft process for pulping followed by multistage chlorine bleaching for making white paper. This is a medium scale paper industry with average production of paper 158 ton/day and discharges about 11,200 m3/day of wastewater. The physicochemical analysis of effluent before and after bacterial degradation was done as per standard methods (APHA 2005). Adsorbable organic halogen was analyzed by IDC Multi X-2000 AOX Analyzer according to the manufacturers recommended procedure.

Bacterial culture and culture conditions

Two bacterial strains IITRL1 and IITRSU7 identified as Citrobacter freundii (FJ581022) and Citrobacter sp. (FJ581023), respectively were isolated in our laboratory for their ability to reduce color and lignin from pulp paper mill effluent. The cultures maintained at –20°C were used to inoculate L-MSM agar plates (Chandra et al. 2007) and after 6th day of growth on solid medium at 30°C. The seed culture was prepared for degradation by inoculating the pure bacterial colonies in broth medium and incubated for 24 h in continuous shaking condition (120 rpm).

Biodegradation of black liquor by axenic and mixed culture

For degradation studies, 10% (v/v) black liquor having COD 12,245 mg/l supplemented with 1% carbon source (glucose) and 0.3% nitrogen source (peptone) was used throughout the experiment. For the decolorization study in axenic condition, 5% (v/v) overnight grown optimized suspension of IITRL1 and IITRSU7 having inoculum size 32 × 104 and 29 × 104 respectively, was transferred aseptically to 250 ml flask containing 95 ml MSM supplemented with black liquor (pH 8.5). Similarly, in mixed condition, 2.5% (v/v) of inoculum from each culture was added to obtained final inoculum size 5% (v/v) in same condition. The inoculated flasks were incubated at 34 ± 2°C under shaking flask condition (140 rpm) for 144 h. Samples from flasks were analyzed for bacterial growth, pH, color and lignin at zero time and daily at 24 h interval up to 144 h. Determination of growth in terms of colony forming unit (cfu/ml) was performed by spreading sample dilutions on the surface of nutrient agar plates (APHA 2005). The pH of the medium was measured with the selective pH electrode (9172 BN) of Thermo Orion (Model 960). For the measurement of color and residual lignin, samples were centrifuged at 8,000 g for 30 min. Supernatant (1 ml) was diluted by adding 3 ml phosphate buffer (pH 7.6) and absorbance measured at 465 nm for color reduction and at 280 nm for lignin degradation on a UV–visible spectrophotometer (GBC Cintra-40, Australia). Dissolve oxygen (DO) was measured as partial oxygen pressure using a Clark-type polarographic DO probe model-835A of Thermo Orion. The degradation experiments were carried out in triplicates.

Ligninolytic enzyme and its characterization

Unless otherwise stated, all the steps were carried out at 4°C. The peroxidase (MnP) enzyme was determined by the oxidation of phenol red (BDH Ltd) in presence of MnSO4 and H2O2 as described by Boer et al. (2006). The enzyme activities were expressed as international unit (IU), defined as the amount of enzyme required to produce 1 μmol product min–1. For purification, the crude extract was loaded into a column (80 × 2.0 cm) containing Sephadex G-100, which was previously equilibrated with sodium malonate buffer, pH 4.5. Protein fraction (0.5 ml) eluted with same buffer with increasing concentration gradient from 0 to 0.1 M NaCl at the flow rate of 0.5 min–1 was collected and stored at –20°C. The fraction having peroxidase activity was subjected to 10% denaturing SDS–PAGE analysis.

Metabolites characterization by HPLC and GC–MS

For the metabolite characterization, the bacteria degraded and undegraded (control) samples of black liquor were centrifuged at 5,000 rpm and acidified (pH 1–2) by 0.1 N HCl. The precipitate was extracted thrice with ethyl acetate and dewatered over anhydrous sodium sulphate. The residues were dried under a stream of nitrogen gas and dissolved in acetonitrile (HPLC grade), filtered through Whatman no. 54 filter paper for HPLC analysis, The samples were analysed using a Waters, 515 HPLC, equipped with 2487 UV/VIS detector, via millennium software. Samples (20 μl) were injected followed by implementation of HPLC grade acetonitrile/water (70:30) at the rate of 1 ml min–1. Reverse phase C-18 column (250 mm × 4.6, particle size 5 μm) at 27°C were used to analyze the lignin at 280 nm.

For GC–MS analysis, the dry residues of ethyl acetate extracts were derivatized with trimethyl silyl [BSTFA (N, O-bis (trimethylsilyl) trifluoroacetamide) TMCS] (Raj et al. 2007). An aliquot of 1 μl of silylated compounds was injected into the GC–MS equipped with a PE Auto system XL gas chromatograph interfaced with a Turbomass Mass spectrometric mass selective detector. The analytical column connected to the system was a PE-5MS capillary column (20 m × 0.18 mm i.d., 0.18 μm film thickness). Helium gas with flow rate of 1 ml min–1 was used as carrier gas. The column temperature was programmed as 50°C (5 min); 50–300°C (10°C min–1, hold time: 5 min).

Results and discussion

Physico-chemical characteristics of black liquor before and after bacterial degradation

Lignin and its derivatives are soluble in alkaline pH that is why the effluent was dark brown in color and had high COD, BOD and sulphate values. The mixed bacterial culture was found effective as it decolorize the black liquor upto 79% with considerable reduction in COD, AOX, lignin and total phenol value up to 82, 79, 60 and 71%, respectively (Table 1). Additionally, a significant reduction in metal contents is also observed which might be either due to bioaccumulation of metals inside the cell or binding with lipopolysaccharide of extracellular membrane (Roan et al. 2001). The reduction of COD, TS, AOX and total phenols after bacterial treatment may be attributed to the degradation of complex colorant compounds (i.e. lignin) and other organic and inorganic substances in black liquor to meet the nutritional requirements.

Biodegradation of black liquor

During the time course of bacterial degradation of black liquor, mixed culture of IITRL1 and IITRSU7 showed much faster growth in terms of cfu/ml, which reached to maximum at 96 h of incubation period (Fig. 1a). Moreover, the mixed bacterial culture was found more effective for the black liquor decolorization, as it decolorized 79.94% whereas axenic culture IITRL1 and IITRSU7 could decolorize up to 51 and 46%, respectively (data not shown). The less reduction in color and lignin content was observed at initial 48 h incubation period in spite of fast bacterial growth. Thereafter, a sharp reduction in color intensity was observed up to 96 h of incubation period and this reduction might be attributed to the lignin depolymerization by oxidizing enzyme (bacterial peroxidase). This significant reduction in color was observed at the end of experiment i.e. after 144 h indicated a co-metabolism process for black liquor degradation. This could be possible due to the initial utilization of glucose and peptone as a carbon and nitrogen sources by the bacterium for initializing their growth and subsequently utilization of lignin as a co-metabolite (Jeffries et al. 1981). Similar to this study, a co-metabolism mechanism in bacteria and fungi during lignin degradation of kraft pine lignin and synthetic lignin (DHP) has been reported (Perestelo et al. 1989; Kirk et al. 1978). In addition, the enhanced reduction of color and lignin content was also observed during black liquor degradation by mixed culture of IITRL1 and IITRSU7. The actual reason is not known but it might be due species difference of Citrobacter which exhibits some physiological variations.

a Bacterial growth and decolorization in color intensity during the degradation of black liquor. b The comparative DO (mg l–1) and pH of culture media in control and bacterial degraded black liquor. c Time course of peroxidase activity in black liquor. d SDS–PAGE of bacterial peroxidase (MnP). Lane M peroxidase (standard 43 KDa), Lane L protein ladder (16–97.4 KDa), Lane 1 strain IITRL1, Lane 2 IITRSU7, Lane 3 mixed culture. IITRL1 (filled square), IITRSU7 (opendiamond), mixed culture (X) and control (*)

The continuous monitoring of culture medium pH revealed that as initial reduction after 48 h; which subsequently increases to a level of neutral pH at the end of experiment which are shown in Fig. 1b. However the alteration of pH did not affect the bacterial growth hence it may be related with bacterial metabolic activity in medium supplemented with glucose and peptone. Similar observation during the microbial degradation of alkali lignin and pulp paper mill effluent has been reported (Hernandez et al. 2001; Diez et al. 2002). In the standard decolorization experiment described above, the incubation mixtures were in cotton-plugged shake flasks. Under these conditions, atmospheric oxygen is admitted to the system. However, in present investigation the DO content after 144 h were 0.21 mg/l for strain IITRL1 and 0.1 mg/l for strains IITRSU7 as compared to control (3.26 mg/l; Fig. 1b). As decolorization was not apparently affected by low O2 concentration, inhibition is more likely to be a metabolism dependent event. The decrease of DO may be attributed to glucose fermentation, contribute to decrease its concentration in the medium. However, the decolorization at low oxygen concentrations (<0.2 mg/l) can be considered to indicate the facultative microaerophilic nature of the bacteria (Isik and Sponza 2003).

Bioassay of ligninolytic enzyme and its characterization

Although very few reports are available regarding the presence of MnP enzyme in bacterial system (Dick et al. 2008). During the time course of enzyme assay, the optimum level of enzymatic activity was recorded at 96 h of incubation period. The mixed bacterial culture showed more peroxidase activity (MnP; 5.4 IU) compared to axenic culture. This showed higher MnP activity in bacterial cell compared to previous report (Oliveira et al. 2009). The production of extracellular H2O2 and peroxidase involved in lignin degradation because peroxidase activity requires H2O2, which is produced during the glucose oxidation and thus, establishing the necessity to add glucose as extra carbon source (Lundquist and Kirk 1971). The molecular weight of purified enzyme determined by SDS–PAGE was found 43 KDa which is usually between MnP families 37–46 KDa (Boer et al. 2006) (Fig. 1c and d).

Metabolite characterization

The HPLC analysis of degraded samples of black liquor after 144 h of incubation period has shown the reduction in peak area compared to controls (Fig. 2). A decrease in color intensity by bacterial culture clearly indicated the degradation of lignin by bacterial peroxidase action (Lara et al. 2003). The bacterial degraded black liquor sample exhibited shifting of peaks compared to control indicating the formation of new compounds. The treatment with mixed bacterial culture has revealed that presence of each bacterial strain in culture medium has cumulative enhancing effect on growth, lignin degradation and decolorization rather than inhibition.

In GC–MS analysis, the TIC of control sample of black liquor showed less peaks than degraded sample which might be due to lignin complexity become more complex when it associated with various organic and inorganic compounds during the processing and it can not be fractionated easily into low molecular weight compound at the time of derivatization. This led to the difficulty during the analysis by GC–MS, that is why fewer peaks were observed in control black liquor compared to bacterial degraded black liquor (Fig. 3). Further, the GC–MS analysis has identified the lignin fragments such as benzoic acid, phthalic anhydride, dibutyl phthalate, bis (2-ethylhexyl) phthalate, etc. was found in degraded sample of black liquor. The fragmentation obtained was somewhat identical to that of reported for these compounds in literature (Ko et al. 2009; Shin and Lee 1999; Ksibi et al. 2003; Raj et al. 2007) (Table 2). In addition, the black liquor degraded with axenic culture showed the presence of some chlorophenols identified as 2,4,6-trichlorophenol (RT-16.1), 2,3,4,5-tetrachlorophenol (RT-19.3) and pentachlorophenol (RT-22.1), whereas these compounds were completely absent in black liquor degraded with mixed bacterial culture. This might be due to co-metabolism of two different species of Citrobacter. Though, chlorophenols are not the fragments of lignin; it is a priority pollutants that has been used widely as a general biocide in commercial wood treatment (Lee and Wang 2006). The data obtained from mixed culture treatment revealed that the presence of the each bacterial strain in culture medium showed cumulative enhancing effect for growth and lignin degradation rather than inhibition.

Conclusion

This study highlights that developed mixed bacterial culture was found more effective for lignin decolorization as compared to axenic culture. This aerobic treatment could reduce 82% COD, 79% color, 79% AOX and lignin 60%, respectively after 144 h of incubation period. It was also observed that mixed bacterial culture produced the optimum level of peroxidase compared to axenic bacterial strain. Further, the HPLC and GC–MS analysis of bacterial degraded samples of black liquor revealed that decrease in color intensity might be largely attributed to the bacterial peroxidase action. In addition, compounds 2,4,6-trichlorophenol, 2,3,4,5-tetrachlorophenol and pentachlorophenol were detected in axenic degradation. These chlorophenols were completely absent in black liquor degraded by mixed culture. This concluded, that developed mixed bacterial culture was capable to degrade the black liquor utilizing its constituents as sole source of carbon, nitrogen and energy and could be useful for the decolorization and degradation of black liquor.

References

APHA (2005) Standard methods for the examination of water and wastewater, 21st edn. American Public Health Association, Washington, DC

Boer CG, Obici L, D’Souza CGM, Peralta RM (2006) Purification and some properties of Mn peroxidase from Lentinula edodeds. Process Biochem 41:1203–1207

Chandra R, Rai A, Purohit HJ, Kapley A (2007) Characterization and optimization of three potential aerobic bacterial strains for kraft lignin degradation from pulp paper waste. Chemosphere 67:839–846

Daniel G, Nilsson T (1998) Developments in the study of soft rot and bacterial decay. In: Bruce A, Palfreyman JW (eds) Forest products biotechnology. Taylor & Francis, London, UK, pp 37–62

Dick GJ, Torpey JW, Beveridge TJ, Tebo BM (2008) Direct identification of a bacterial manganese (II) oxidase, the multicopper oxidase MnxG, from spore of several different marine Bacillus species. Appl Environ Microbiol 74:1527–1534

Diez MC, Castillo G, Aguilar L, Vidal G, Mora ML (2002) Operational factor and nutrient effect on activated sludge treatment of Pinus radiata kraft mill wastewater. Bioresour Technol 83:131–138

Grover R, Marwaha SS, Kennedy JF (1999) Studies on the use of an anaerobic baffled reactor for the continuous anaerobic digestion of pulp paper mill black liquors. Process Biochem 34:653–657

Gupta VK, Minocha AK, Jain N (2001) Batch and continuous studies on treatment of pulp mill wastewater by Aeromonas formicans. J Chem Technol Biotechnol 76:547–552

Hammel EK, Cullen D (2008) Role of fungal peroxidase in biological ligninolysis. Curr Opn Plant Biol 11:349–355

Hernandez M, Hernandez-Coronado M, Bell AS, Arias ME (2001) Degradation of alkali-lignin residues from solid-state fermentation of wheat straw by streptomycetes. Biodegradation 12:219–223

Isik M, Sponza DT (2003) Effect of oxygen on the decolourization of azo dyes by Escherichia coli and Pseudomonas species sp. and fate of aromatic amines. Process Biochem 38:1183–1192

Jeffries TW, Choi S, Kirk TK (1981) Nutritional regulation of lignin degradation by Phanerochaete chrysosporium. Appl Environ Microbiol 42:290–296

Jokela JJ, Pellinen M, Salkinoja-Salonen M, Brunow G (1985) Biodegradation of two tetrameric lignin model compounds by a mixed bacterial culture. Appl Environ Microbiol 23:38–46

Khalid A, Arshad M, Crowley DE (2009) Biodegradation potential of pure and mixed bacterial cultures for removal of 4-nitroaniline from textile dye wastewater. Water Res 43:1110–1116

Kirk TK, Schulz E, Connor WL, Lorenz LF, Zeikus JG (1978) Influence of cultural parameters on lignin metabolism by Phanerochaete chrysosporium. Arch Microbiol 117:227–287

Ko JJ, Shimizu Y, Ikeda K, Kim SK, Park CH, Matsui S (2009) Biodegradation of high molecular weight lignin under sulfate reducing condition: lignin degradability and degradation by-products. Bioresour Technol 100:1622–1627

Ksibi MM, Amor SB, Cherif S, Elaloui E, Houas A, Elaloui M (2003) Photodegradation of lignin from black liquor using UV/TiO2 system. J Photochem Photobiol A: Chem 154:211–218

Lara MA, Malaver-Rodriguez AJ, Rojas OJ, Holmquist O, Gonzalez AM, Bullon J, Penaloza N, Araujo E (2003) Black liquor lignin biodegradation by Trametes elegans. Int Biodter Biodegrade 52:167–175

Lee YCM, Wang CC (2006) Isolation and physiological characterization of the pentachlorophenol degrading bacterium Sphingomonas chlorophenolica. Chemosphere 62:709–714

Lundquist K, Kirk TK (1971) Acid degradation of lignin. Acta Chem Scand 25:889–894

Oliveira LPD, Duarte MCT, Ponezi AN, Durrant LR (2009) Purification and partial characterization of manganese peroxidase from Bacillus pumilus and Panibacillus sp. Braz J Microbiol 40:818–826

Perestelo F, Falcon MA, Perez ML, Roig EC, de la Fuente Martin G (1989) Bioalteration of kraft pine lignin by Bacillus megaterium isolated from compost piles. J Ferment Bioeng 68:151–153

Pokhrel D, Viraraghavan T (2004) Treatment of pulp and paper mill wastewater—a review. Sci Total Environ 333:37–58

Raj A, Reddy MMK, Chandra R (2007) Identification of low molecular weight aromatic compounds by gas chromatography-mass spectrometry (GC-MS) from kraft lignin degradation by three Bacillus sp. Int Biodter Biodegrade 59:292–296

Roan TM, Josephson KL, Peppar IL (2001) Dual bioaugmenation strategy to enhance remediation of contaminated soil. Appl Env Microbial 67:3208–3215

Shin KS, Lee YJ (1999) Depolymerization of lignosulfonate by peroxidase of the white-rot basidiomycetes, Pleurotus ostreatus. Biotechnol Lett 21:585–588

Ugurlu M, Gurses A, Dogar C, Yalcın M (2008) The removal of lignin and phenol from paper mill effluents by Electrocoagulation. J Environ Mang 87:420–428

Wang H, Su JQ, Zheng XW, Tian Y, Xiong XJ, Zheng TL (2009) Bacterial decolorization and degradation of the reactive dye reactive red 180 by Citrobacter sp. CK3. Int Biodter Biodegrade 63:395–399

Zaied M, Bellakhal N (2009) Electrocoagulation treatment of black liquor from pulp paper industry. J Hazard Mater 163:995–1000

Acknowledgments

The financial assistance from Department of Biotechnology and CSIR under SIP08 is highly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chandra, R., Abhishek, A. Bacterial decolorization of black liquor in axenic and mixed condition and characterization of metabolites. Biodegradation 22, 603–611 (2011). https://doi.org/10.1007/s10532-010-9433-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-010-9433-1