Abstract

3-Phenyllactic acid (PLA) is an antimicrobial compound with broad and effective antimicrobial activity against both bacteria and fungi. Enzymatic production of PLA can be carried out from phenylpyruvic acid by lactate dehydrogenase (LDH); however, the enzymatic reaction is accompanied by NADH oxidation that inhibits PLA biotransformation. Here, NADH regeneration was achieved using the formate dehydrogenase from Ogataea parapolymorpha and introduced into the d-PLA production process using the d-LDH from Pediococcus pentosaceus. Optimum PLA production by dual enzyme treatment was at pH 6.0 and 50 °C with both enzymes at 0.4 μM. Using 0.2 mM NADH, d-PLA production by NADH regeneration system reached 5.5 mM, which was significantly higher than that by a single-enzyme reaction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

3-Phenyllactic acid (2-hydroxy-3-phenylpropanoic acid or β-phenyllactic acid, PLA) is an antimicrobial compound with broad spectrum activity against both bacteria and fungi (Mu et al. 2012). It can therefore be used to extend the shelf life of food products by reducing the contamination of food-borne pathogens and food spoilage (Dieuleveux and Gueguen 1998; Lavermicocca et al. 2000). PLA also can be used as a feed additive to replace antibiotics in livestock feeds, and it exerts some positive effects to the immune system of laying hens (Wang et al. 2009b) and growing pigs (Wang et al. 2009a). Therefore, PLA production has attracted the attention of many researchers, due to its wide use in food and feed industries.

3-Phenyllactic acid can be produced through chemical or biotechnological approaches. By chemical synthesis, for example, PLA can be obtained by catalytic hydrogenation in presence of Raney-Ni catalyst or Pd–C alloy catalyst (Morita and Mori 1996). However, all the reported methods of chemical PLA synthesis have the disadvantages of extreme reaction conditions and environmental pollution. Therefore, the biological technology is preferred for industrial application of PLA production. The fed-batch fermentation of Lactobacillus sp. SK007 with feeding of the substrate, phenylpyruvic acid (PPA), and pH-control produced 17.4 g PLA l−1 with a production rate of 0.24 g l−1 h−1 (Mu et al. 2009). Whole cells of Bacillus coagulans SDM converted PPA to 37.3 g l−1 (PLA) with a productivity of 2.3 g l−1 h−1 (Zheng et al. 2011). Microbial technology can, however, produce a complex mixture of products and therefore creates a purification problem. Theoretically, enzymatic production of PLA from PPA using lactate dehydrogenase (LDH) can simplify the downstream processing of PLA. So far, many LDHs have been characterized to convert PPA to PLA. But LDH is an NAD(P)H-dependent dehydrogenase and does not have reduction activity if the cofactor is oxidized.

NADH regeneration by formate dehydrogenase (FDH, EC 1.2.1.2), which irreversibly catalyzes the oxidation of formate to CO2 accompanied by the reduction of NAD+, has been widely used for dehyrogenase-based synthesis of optically-active compounds, such as tert-l-leucine (Bommarius et al. 1995), l-lactic acid (Jayabalan et al. 2012), and aromatic alpha-keto esters (Kratzer et al. 2008). In this study, d-PLA was, for the first time, produced by enzymatic production with NADH regeneration by Pediococcus pentosaceus d-LDH and Ogataea parapolymorpha FDH.

Materials and methods

Chemicals

d-Phenyllactic acid (d-PLA) was from Sigma. PPA was from National Engineering Research Center for Biochemistry, Nanjing University of Technology (Nanjing, China).

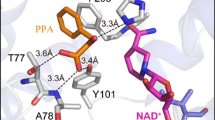

Preparation of d-lactate dehydrogenase (d-LDH) from P. pentosaceus and formate dehydrogenase (FDH) from Ogataea parapolymorpha

Pediococcus pentosaceus d-LDH (Yu et al. 2012) and O. parapolymorpha FDH (Yu et al. 2013) have been previously overexpressed, purified, and characterized in our laboratory. Accordingly, P. pentosaceus d-LDH and O. parapolymorpha FDH were overexpressed as 6× his-tagged fusion proteins by IPTG, using pET-22b(+) and E. coli BL21(DE3) as expression vector and host cell, and then purified by Ni-affinity column chromatography (Yu et al. 2012 and 2013).

d-3-Phenyllactic acid production by Pediococcus pentosaceus d-lactate dehydrogenase by adding NADH intermittently

Bioconversion of PPA into d-PLA was performed by single enzyme of P. pentosaceus d-LDH with intermittently supplementing PPA. The experiments were at 45 °C in 20 ml reaction system containing 0.4 μM enzyme, 15 mM PPA, and 0.2 mM NADH in 50 mM sodium acetate buffer (pH 5.5), and was supplemented with 40 μl 100 mM NADH every 6 min.

Enzymatic production of d-PLA by NADH regeneration with O. parapolymorpha FDH

For d-PLA production by NADH regeneration system, the experiments were carried out at 50 °C and pH 6.0 for 5 min in 20 ml reaction system containing 15 mM PPA, 0.2 M sodium formate, 0.2 mM NADH, 0.4 μM P. pentosaceus d-LDH, and different concentrations of O. parapolymorpha FDH.

Analytical methods

d-3-Phenyllactic acid was determined using HPLC using an Agilent Zorbax SB-C18 column (4.6 mm × 150 mm, 5 μm). A linear gradient was used for elution with methanol/0.05 % trifluoroacetic acid (solvent A) and water/0.05 % trifluoroacetic acid (solvent B) at 1 ml min−1 and A/B ratios of 10:90, 100:0, 100:0, and 10:90 (v/v), with run times of 0, 20, 23, and 25 min, respectively. d-PLA was detected at 210 nm (Li et al. 2007).

Results and discussion

d-3-Phenyllactic acid production by d-lactate dehydrogenase with supplementing NADH

Pediococcus pentosaceus d-LDH has already been characterized to produce d-PLA from PPA with optimally at pH 5.5 and 45 °C (Yu et al. 2012). d-PLA production by d-LDH from PPA is NADH-dependent; therefore, production cannot proceed if the cofactor is oxidized. When NADH is consumed, the reaction stops, but can be restarted by supplementing fresh NADH. Figure 1 shows d-PLA production by P. pentosaceus d-LDH with seven runs of intermittent NADH supplementation. In each run, d-PLA production tended to equilibrium and stopped after a time because of the exhaustion of NADH; and the reaction could be continued by adding extra NADH. Although NADH supplement can improve d-PLA production, it is impossible to be adopted in practical application in industry because NADH is very expensive. A useful approach is to perform the NADH regeneration by another dehydrogenase converting NAD+ to NADH.

d-3-Phenyllactic acid production by d-lactate dehydrogenase coupled with NADH regeneration by FDH

FDH has been widely used as NADH regeneration biocatalyst for dehydrogenase-based synthesis of optically active compounds (Tishkov and Popov 2006). O. parapolymorpha FDH has been characterized having promising properties, such as better thermostability, wide pH optimum, and high organic solvents tolerance (Yu et al. 2013). The enzyme showed wide pH optimum at 6–7 and relatively high optimum temperature at 65 °C (Yu et al. 2013). Herein, enzymatic production of d-PLA by P. pentosaceus d-LDH was carried out with NADH regeneration by O. parapolymorpha FDH (Fig. 2). The reaction conditions were simply optimized, including pH, temperature, and the enzyme ratio.

The optimum pH of P. pentosaceus d-LDH (Yu et al. 2012) and O. parapolymorpha FDH (Yu et al. 2013) are at 5.5 and 6.0–7.0, respectively. The close optimum pH between these two enzymes was helpful to d-PLA production in the dual-enzyme reaction. It exhibited relatively wide pH spectrum from 5 to 7 for d-PLA production by the dual-enzyme reaction, with the highest productivity at pH 6.0 (Fig. 3a). Maximal d-PLA production was at 50 °C but, interestingly, the temperature profile exhibited two peaks at 50 and 60 °C (Fig. 3b) and was possibly caused by the significantly different optimum temperature of the two enzymes: P. pentosaceus d-LDH (Yu et al. 2012) at 45 °C and O. parapolymorpha FDH (Yu et al. 2013) at 65 °C.

The effect of enzyme concentration on the d-PLA production by dual-enzyme reaction is shown in Table 1. When the initial NADH concentration was at 0.2 mM the single enzyme P. pentosaceus d-LDH at 0.4 μM could only produce 0.18 mM d-PLA. Adding O. parapolymorpha FDH for NADH regeneration significantly improved the (shown in Table 1). When O. parapolymorpha FDH was added at 0.4 μM, the same as P. pentosaceus d-LDH concentration, d-PLA yield reached 5.5 mM which was ~30-fold more that without adding O. parapolymorpha FDH. d-PLA production tended to balance when the O. parapolymorpha FDH was added at more than 0.4 μM, suggesting that setting the molar concentration ratio of the two enzymes as 1:1 was appropriate for the dual-enzyme reaction for d-PLA production.

Therefore, using FDH as a NADH-regeneration catalyst improved the d-PLA yield. The next step, the co-expression of the two enzymes will be tried in a single host cell and whole cells harboring the two enzymes will be used to produce d-PLA. This way would simplify the preparation of the enzymes and would be applicable for large-scale production of d-PLA.

Conclusions

Enzymatic production of d-PLA by P. pentosaceus d-LDH depended on NADH that could be regenerated using O. parapolymorpha FDH. The optimum pH and temperature for the dual-enzyme reaction were at 6.0 and 50 °C. Compared to the single-enzyme reaction, d-PLA production by dual-enzyme reaction was significantly improved with a 30-fold higher yield.

References

Bommarius AS, Schwarm M, Stingl K, Kottenhahn M, Huthmacher K, Drauz K (1995) Synthesis and use of enantiomerically pure tert-leucine. Tetrahedron Asymmetry 6:2851–2888

Dieuleveux V, Gueguen M (1998) Antimicrobial effects of d-3-phenyllactic acid on Listeria monocytogenes in TSB-YE medium, milk, and cheese. J Food Prot 61:1281–1285

Jayabalan R, Sathishkumar M, Jeong ES, Mun SP, Yun SE (2012) Immobilization of flavin adenine dinucleotide (FAD) onto carbon cloth and its application as working electrode in an electroenzymatic bioreactor. Biores Technol 123:686–689

Kratzer R, Pukl M, Egger S, Nidetzky B (2008) Whole-cell bioreduction of aromatic alpha-keto esters using Candida tenuis xylose reductase and Candida boidinii formate dehydrogenase co-expressed in Escherichia coli. Microb Cell Fact 7:37

Lavermicocca P, Valerio F, Evidente A, Lazzaroni S, Corsetti A, Gobbetti M (2000) Purification and characterization of novel antifungal compounds from the sourdough Lactobacillus plantarum strain 21B. Appl Environ Microbiol 66:4084–4090

Li X, Jiang B, Pan B (2007) Biotransformation of phenylpyruvic acid to phenyllactic acid by growing and resting cells of a Lactobacillus sp. Biotechnol Lett 29:593–597

Morita H, Mori H (1996) Process for production of phenyllactic acid derivative. European Patent No. EP0696566

Mu W, Liu F, Jia J, Chen C, Zhang T, Jiang B (2009) 3-Phenyllactic acid production by substrate feeding and pH-control in fed-batch fermentation of Lactobacillus sp SK007. Biores Technol 100:5226–5229

Mu W, Yu S, Zhu L, Zhang T, Jiang B (2012) Recent research on 3-phenyllactic acid, a broad-spectrum antimicrobial compound. Appl Microbiol Biotechnol 95:1155–1163

Tishkov VI, Popov VO (2006) Protein engineering of formate dehydrogenase. Biomol Eng 23:89–110

Wang JP, Yoo JS, Lee JH, Jang HD, Kim HJ, Shin SO, Seong SI, Kim IH (2009a) Effects of phenyllactic acid on growth performance, nutrient digestibility, microbial shedding, and blood profile in pigs. J Anim Sci 87:3235–3243

Wang JP, Yoo JS, Lee JH, Zhou TX, Jang HD, Kim HJ, Kim IH (2009b) Effects of phenyllactic acid on production performance, egg quality parameters, and blood characteristics in laying hens. J Appl Poult Res 18:203–209

Yu S, Jiang H, Jiang B, Mu W (2012) Characterization of d-lactate dehydrogenase producing d-3-phenyllactic acid from Pediococcus pentosaceus. Biosci Biotechnol Biochem 76:853–855

Yu S, Zhu L, Zhou C, An T, Zhang T, Jiang B, Mu W (2013) Promising properties of a formate dehydrogenase from a methanol-assimilating yeast Ogataea parapolymorpha dl-1 in His-tagged form. Appl Microbiol Biotechnol. doi:10.1007/s00253-013-4996-5

Zheng Z, Ma C, Gao C, Li F, Qin J, Zhang H, Wang K, Xu P (2011) Efficient conversion of phenylpyruvic acid to phenyllactic acid by using whole cells of Bacillus coagulans SDM. PLoS One 6:e19030

Acknowledgments

This work was supported by the 973 Project (No. 2012CB720802), the 863 Project (No. 2011AA100904), and the NSFC Project (Nos. 21276001 and 31171705).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, S., Zhu, L., Zhou, C. et al. Enzymatic production of d-3-phenyllactic acid by Pediococcus pentosaceus d-lactate dehydrogenase with NADH regeneration by Ogataea parapolymorpha formate dehydrogenase. Biotechnol Lett 36, 627–631 (2014). https://doi.org/10.1007/s10529-013-1404-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-013-1404-2