Abstract

The persistent edaphic stress on microbial succession due to dynamic changes during composting was explored for selection of multi-stress tolerant microbe(s) desirable for ethanol production. A total of 23 strains were isolated from mango compost using four successive enrichments in YP broth (g l−1): glucose, 100; 150; 250 with ethanol (40) and cycloheximide (0.4) at 40 °C, pH 6.0. Based on multi-gene ribotyping, 14 yeasts (61 %) of Saccharomycetaceae, 2 filamentous fungi (8.6 %) and 7 bacteria (30.4 %) were obtained. Phenetic and phylogenetic analysis of the 14 yeasts revealed 64.3 % tolerant to 500 g l−1 glucose, growth at 45 °C and resemblance to Candida sp. (14.3 %), Kluyveromyces marxianus (35.7 %), Pichia kudriavzevii (21.4 %) and Saccharomyces cerevisiae (28.6 %). Assessment of the 14 yeasts in glucose fermentation medium (pH 4.5 at 40 °C) showed ethanol productivity of ≥92 % by 12 yeasts with theoretical yields of 90–97 %. Fermentation of molasses (150 g l−1 glucose equivalent) by P. kudriavzevii D1C at 40 °C resulted in 73.70 ± 0.02 g l−1 ethanol and productivity of 4.91 ± 0.01 g l−1 h−1. Assessment of P. kudriavzevii D1C revealed multi-stress tolerance towards 5-hydroxymethyl furfural, ethanol (20 %, v/v), high gravity and H2O2 (0.3 M) indicating suitability for ethanol production using high gravity molasses and pre-treated lignocellulosic biomass fermentation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Global energy crisis and environment security from the excessive use of fossil fuels has driven unprecedented spurts in renewable resources for the production of ‘green’ bio-based fuels (Balat and Balat 2009). Fermentative production of ethanol using Saccharomyces cerevisiae is reported earlier for its proven industrial process robustness and exceptional physiological and x-omics characterization for improved lignocellulosics utilization (Nevoigt 2008). However, Saccharomyces-based ethanol production is limited due to its lack of multi-stress tolerance to (i) polycyclic aromatic compounds generated during biomass pre-treatment, (ii) high fermentative temperatures (≥40 °C), (iii) low pH and (iv) high sugar concentrations. Consequently, Saccharomyces-based fermentation demonstrated inadequate (i) substrate utilization spectrum, (ii) genetic stability, (iii) ethanol productivity and (iv) ethanol tolerance (Chaudhari et al. 2012). On the contrary, tailor-made multi-stress tolerant genetically modified ethanologens for high ethanol productivity are impractical at present. Alternatively, exploration of naturally endowed ethanologen(s) from the vast biodiversity of extreme environments with desired attributes for ethanol production are anytime superior and preferred. Based on this, several earlier reports attempted to screen ethanologens from a wide variety of ecological habitats viz. soils (Kiransree et al. 2000a; Limtong et al. 2007), hot spring drainage (Ryohei et al. 2003), sugar mills (Anderson et al. 1986), sugarcane juice (Dhaliwal et al. 2011), traditional brews and wines (Blieck et al. 2007; Pereira et al. 2010), Long-pang (Laopaiboon et al. 2009), bioethanol plants (Pereira et al. 2010), etc. However, very few reports exist on isolation of ethanologens with both thermo- and osmo-tolerant peculiarities (Brooks 2008; Kiransree et al. 2000a, b; Watanabe et al. 2010). Hence, the major impetus for the exploration of ethanologenic yeasts from various habitats stems to search desirable yeasts for ethanol production.

Compost, an artificial extreme environment entails dynamic microbial succession predominantly due to changes in temperature, oxygen concentration, moisture content and nutrient availability in the decomposition of high-solid organic matter. The composition and selection of microbial biodiversity involved in composting is dependent on the (i) choice of organic material and (ii) alternate mesophilic and thermophilic phases (≥60 °C) (Ryckeboer et al. 2003). The mango peel and pulp waste material consists of high levels of residual polyphenolics and carbohydrates (Ajila et al. 2007) imposing a unique milieu for selection of microbes tolerant to phenolics, high C5 and C6 sugars, complex organic content, high temperatures (≥60 °C), low pH and a w during composting. Although, various compost material have been explored for ecological and functional biodiversity but no reports exist about microbial consortium in mango-fruit waste compost. Hence, the mango (Mangifera indica L.) peel and pulp compost was identified as a potential habitat for selection of multi-stress-tolerant fermentative microbes.

In view of these requirements desirable for ethanol production, the present study examined the mango pulp–peel compost to selectively screen and isolate robust, ethanologenic, multitude stress factor (osmo-, thermo-, ethanol and inhibitor) resistant microbes (yeast, bacteria and molds) for fermentative production of ethanol using glucose and molasses as simple and complex substrates.

Materials and methods

Sampling

Compost samples (n = 5) were collected from the mango pulp composting unit of a near-by fruit-pulp manufacturing industry (Lat, Lon: 20°56′41″N, 75°33′12″E). Composting heaps (90 days old) were excavated at a depth of 1.5 m from top to collect sample (~100 g) and composite sample was processed immediately for enrichment.

Media, enrichment and isolation

Enrichment of indigenous microflora was performed using modified procedure of Peres et al. (2001). Compost sample (25 g) was suspended in 225 ml YPD10 medium consisting of (g l−1) yeast extract, 10; peptone, 20; dextrose, 100; pH 6.0 and incubated at 40 °C, 160 rpm for 48 h. The culture broth repeatedly grown for two times in YPD10 medium was successively transferred (5 %) in each Erlenmeyer flask (500 ml capacity) containing YP medium supplemented with (i) step 1: dextrose (150 g l−1; YPD15); (ii) step 2: dextrose (150 g l−1) and ethanol (40 g l−1); (iii) step 3: dextrose (150 g l−1), ethanol (40 g l−1) and cycloheximide (0.4 mg ml−1) to enrich bacteria, molds and antibiotic resistant yeast; and (iv) step 4: dextrose (250 g l−1), ethanol (40 g l−1) and cycloheximide (0.4 mg ml−1) and incubated at 40 °C for 36–48 h on rotary shaker (150 rpm). Triplicates of different dilutions (1:10, 1:100 and 1:1,000) from each medium from each step was spread on to corresponding agar medium and incubated at 40 °C for 48 h. Each isolated colony differing in morphological characteristics was sub-cultured and maintained at 5 °C on same medium.

Identification and characterization of the microbes

Yeast isolates were characterized morphologically and biochemically for utilization of carbon and nitrogen sources and each test was interpreted as per Kurtzman et al. (2011). The genotypic characterization of yeast and mold isolates was performed as per Kurtzman and Robnett (1998) after sequencing internal transcriber spacers (ITSs) (ITS1-5.8S-ITS2) and the D1/D2 domain of 26S (LSU) ribosomal DNA (rDNA). Additionally, the 18S rDNA was also sequenced in order to compare them with the previously reported ethanologenic microbes. Similarly, bacterial isolates were characterized based on 16S rDNA gene sequence.

Genomic DNA extraction

Genomic DNA extraction of the yeast isolates was performed using modified Bust n’ Grab protocol (Harju et al. 2004). The growth medium was replaced by YPD15 for each yeast isolate and additional freeze-thaw cycles (3x, −80 to 80 °C at 15 min intervals) followed by treatment of 60 μl lyticase (2.5 mg ml−1) and incubation at 37 °C for 2 h. DNA extraction of the mold isolates was performed with initial vortex treatment with sterile glass beads and replacing lyticase with 40 μl of chitinase. The bacterial genomic DNA isolation was performed by single colony lysis as per Ausubel et al. (2003). The DNA was quantified and assayed for purity spectrophotometrically (Nanodrop ND1000 UV/VIS spectrophotometer) and visualized by 0.7 % agarose gel electrophoresis. All the chemicals and reagents were procured from Sigma Aldrich, USA.

PCR amplification and DNA cycle sequencing

All the three potentially informative sequences of rDNA (18S, ITS1-5.8S-ITS2 and D1/D2 domain of LSU) were sequenced for phylogenetic analysis. The primers and the PCR conditions used for amplification of the target rDNA gene used in the study are summarized in Tables S1 and S2, respectively. The PCR conditions and primers used for sequencing the D1/D2 domain of LSU were as per Kurtzman and Robnett (1998). The partial 18S rDNA was amplified using Taq DNA polymerase (Qiagen) and the primers NS1 and NS8 in a reaction mixture (25 μl) containing 2 μl template DNA, 1.25 μl of each primer (100 pmol), 2.5 μl dNTP (0.25 mM) and 2.5 μl Taq buffer (MgCl2, pH 8.0). The ITS region was PCR amplified in 25 μl reaction mixture containing the same components as for 18S rDNA except the primer sets ITS1 and ITS4 as per White et al. (1990). Bacterial 16S rDNA (~960 bp) was PCR amplified from total chromosomal DNA using 530F (5′-GTGCCAGCMGCCGCGG-3′) and 1490R (5′-GGTTACCTTGTTACGACTT-3′) primers in a reaction mixture (25 μl). All the PCR amplifications were carried out using Applied Biosystems 9700 Thermal Cycler. Sequencing reaction of each PCR product was performed as per manufacturer’s instructions using a fluorescence-based BigDye™ v3.1 Cycle Sequencing Kit (Applied Biosystems, USA) and respective internal primers. Reaction products were purified using BigDye® X-Terminator™ Purification Kit (Applied Biosystems, USA). Single strand sequencing was performed on fully automated Applied Biosystems ABI 3730 DNA Analyzer.

Sequence, phylogenetic analysis and nucleotide sequence accession numbers

All sequences were base called and analyzed for quality (Sequence Scanner v1.0, Applied Biosystems, CA). Each nucleotide sequence was searched and compared with available sequences in NCBI GenBank database using BLAST to determine phylogenetic affiliation and sequence similarities. Phylogenetic analysis of the molecular dataset was carried out using sequences of the related taxa acquired from NCBI GenBank database using MEGA v5.04 Software (Tamura et al. 2011). Each sequence was deposited to NCBI GenBank (accession numbers JF715166–201 and HM357878–86, n = 45).

Growth and CO2 release by yeast strains

Biomass (15 g dry wt l−1) of each isolate was inoculated separately into 125 ml capacity bottles filled with 80 ml YPD15 and fermentation medium (150 g l−1 dextrose), sealed, purged with nitrogen (99.9 %) and incubated at 40 °C for 48 h. Total gas evolved was measured in an inverted measuring cylinder connected to the bottles, while CO2 (%) production was estimated by headspace gas chromatography (GC, Nucon 5765 Gas Chromatograph, New Delhi) using standard CO2 (Alchemie, Mumbai). Absolute CO2 (ml) was calculated as a product of total gas evolved (ml) at 24 and 48 h and CO2 (%) estimated from headspace GC divided by 100.

Growth and fermentation conditions

The batch fermentative performance of each isolate was examined initially in 100 ml fermentation medium consisting of (g l−1): dextrose, 150, ammonium sulphate, 2 and yeast extract, 1.0 at pH 4.5 and 40 °C under static condition with an initial cell concentration of 14 g dry wt l−1. For this purpose, each pre-grown culture was cultivated separately to 10 ml and subsequently to 100 ml YPD15 medium in 500 ml Erlenmeyer flask under aerobic condition (150 rpm) at 40 °C for 24 h and finally, cell mass was grown in 200 ml YPD15 medium for another 18 h at 40 °C, 150 rpm. The pellet was harvested (5,000×g, 10 min), washed thrice with sterile distilled water and used as inoculum for batch fermentation.

Similarly, batch fermentation was conducted in 100 ml fermentation medium containing pre-treated molasses (MFM15) at pH 4.5 and 40 °C under static conditions. Appropriate dilutions using Pearson-square method were prepared for the fermentation medium to achieve 150 g l−1 total reducing sugar (TRS) content and supplemented with ammonium sulfate (2 g l−1) and final pH of 4.5. All the isolates were pre-acclimatized to the molasses fermentation medium by repeated inoculations (Banerjee et al. 1981).

Aliquots of each sample were withdrawn at an interval of 5 h for determination of ethanol concentration, residual sugar (Miller 1959) and cell mass (gravimetric). Ethanol from fermentation broth was recovered by distillation as per AOAC (Horwitz 1975).

Batch fermentation kinetics

The data for kinetic analysis of batch culture were analyzed in terms of growth yield (Y x/s ) and ethanol yield (Y p/s ). Ethanol productivity (P) was expressed as gram ethanol produced per gram of TRS utilized per hour calculated from the final ethanol concentration (Eq. 1). Ethanol yield (Y p/s ) was calculated as grams of ethanol produced (E max ) to per gram of sugar concentration (TRS o ) (Eq. 2). Ethanol yield (% of theoretical) was calculated from Gay-Lussac’s equation for ethanol yield for the theoretical maximum fermentative conversion of glucose to ethanol by yeast (0.511, Eq. 3). Growth yield (Y x/s ) pertaining the growth associated with fermentation was calculated as the ratio of increase in biomass during the course of fermentation to the corresponding substrate concentration in the fermentation medium (Eq. 4). Thus,

where t f is the time to achieve complete fermentation (h), X and X o are the initial and final amounts of biomass (dry wt, g l−1) and TRS o and TRS are the initial and corresponding TRS content of the fermentation broth.

Stress tolerance

Ethanol and oxidative stress tolerance towards H2O2 were assessed using YPD15 medium using modified procedures described by Lewis et al. (1997) separately by inoculating the yeast cells (3 × 107 ml−1) in YPD15 broth containing 20 % (v/v) ethanol and H2O2 (0.3 M) each for 1 h at 45 °C in triplicates. Ethanol stress was alleviated by 10-fold dilution in YPD15 medium while cell pellets were washed (thrice) for relieving H2O2 stress. Tolerance towards acetic and formic acid, furfural, guaiacol and vanillin was estimated separately by incorporating different concentration of each inhibitor in YPD15 broth. Cell count of treated and untreated (control) samples was estimated by plating on YPD15 agar medium at 40 °C.

Analytical methods

Residual sugar content in each sample was determined using 3,5-dinitrosalicylate reagent (Miller 1959). Physico-chemical characterization of mango peel–pulp compost material was performed in conformity to APHA (Eaton et al. 2005).

The CO2 released during the fermentation in medium (YPD15 and fermentation medium) was estimated using GC by injecting headspace gas sample (0.5 ml) collected at 24 and 48 h intervals into Porapak Q (80–100 mesh) column, eluted with helium as a carrier gas and monitored with thermal conductivity detector. Temperature at injector was ambient, column at 60 °C and detector at 150 °C. Data was measured by WinChrome06Ex Advanced Chromatography Software v2.0.

Each fermentation wort sample was centrifuged to separate the biomass and distillate was mixed with one volume of isopropanol. Calibration curves of absolute ethanol (slope = 0.19) were used to determine the ethanol content of distillate sample. For GC analysis, each distillate sample was injected into Porapak Q column, nitrogen (99.99 %) at 30 ml min−1 flow rate (1.96 bars) and monitored using FID detector. Temperature at injector was 175 °C, column oven at 200 °C and detector at 250 °C. GC responses of each distillate were measured by the same software. The retention time for ethanol and isopropanol was estimated to be 1.7 and 2.8 min, respectively under similar conditions. GC analysis of each distilled sample was performed in duplicate.

HPLC analysis of 5-hydroxymethyl furfural (5-HMF) in MFM15 medium (0 and 50 h fermentation) was performed by injecting 20 μl of each sample in a Young Lin Acme 9000 HPLC isocratic system equipped with a UV visible detector using mobile phase of methanol:water (44:55, v/v) and NeoSphere C-18 (5μ, 250 × 4.6 mm, stainless steel) stationary reverse phase column at a flow rate of 0.8 ml min−1. Reduction in peak area of 50 h sample as compared to control and reference 5-HMF (Hi-media, Mumbai) was analysed.

Statistical analysis

All experiments were performed in triplicates unless otherwise mentioned. Means and standard deviations were calculated using Microsoft MS-Excel Spreadsheet Software.

Results and discussion

Characteristics of mango-fruit pulp compost

The composition of microbiota during composting is determined by many factors. Heat evolved during composting may per se inhibit microbes through enzyme inactivation or oxygen unavailability. The yeasts are generally less tolerant to high temperature during composting (Ryckeboer et al. 2003). At 60 °C, yeasts are either killed or transiently persist as ascospores and recur when temperature drops down to 54 °C (Choi and Park 1998; Peters et al. 2000; Ryckeboer et al. 2003). The proliferation of yeast during thermophilic composting was attributed to composition of food waste and low pH (Choi and Park 1998). The direct isolation of microbes from composting may possibly favor (i) natural selection of ethanologens for desirable attributes, (ii) high temperature (61–67 °C) metabolism of carbohydrates at varying rates and (iii) screening for polyphenols degradation activity. The chemical analysis of mango pulp–peel compost sample was performed for various parameters and summarized in Table 1. Earlier report about analysis of mango peel showed the presence of 21–28 % total carbohydrates and 54–109 mg g−1 polyphenols in different varieties of mango fruit (Ajila et al. 2007). The presence of carbohydrate (glucose and fructose) and low pH in mango peel–pulp compost may likely offer protection to yeast cells against thermal inactivation. Thus, compost of mango-fruit pulp and peel may be suitable for selection of better thermo-tolerant ethanologens due to the presence of (i) high temperature, (ii) carbohydrates and (iii) acidic pH during composting process. Hence, compost material of mango pulp and peel was predicted as a fertile habitat for screening ethanologens of interest.

Selective enrichment and isolation of ethanologens

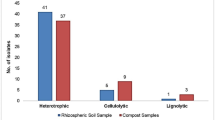

Several approaches like metagenomic libraries and high-throughput solid-phase screening were explored for selection of desired microbes from different ecological niches (Banat et al. 1992; Fracchia et al. 2006; Gardner et al. 2012). Furthermore, earlier investigations employed either high concentration of glucose alone or in combination with high temperature of incubation for isolation of ethanologens (Banat et al. 1992; Dhaliwal et al. 2011; Kiransree et al. 2000a). Accordingly, serial dilution with four successive transfers initially in YPD10 medium (225 ml) was used for isolation of ethanologenic microbes from mango peel compost (25 g) at 40 °C, 150 rpm and pH 6.0 for 48 h. Then the culture broth (5 %) was grown under similar conditions successively in (i) YPD15, (ii) YPD15 and cycloheximide (0.4 mg ml−1), (iii) YPD15 fortified with cycloheximide (0.4 mg ml−1) and ethanol (40 g l−1) and (iv) finally, YPD25 supplemented with cycloheximide (0.4 mg ml−1) and ethanol (40 g l−1). The culture broth (48 h) was subsequently purified on same medium at 40 °C. After 48 h incubation, a total of 78 yeasts, two molds and seven bacterial isolates were obtained. Of the 78 yeast strains showing typical microscopic yeast-like morphological forms were selected, grouped and then each strain was examined for utilization of sugar (150 g l−1) in YPD15 medium at 40 °C under aerobic condition at 150 rpm and monitored for 5 days. Strains showing meager glucose consumption within 5 days were abandoned. Among the selected 14 yeasts, 2 strains (YD1 and YD2) showed slow growth and delayed consumption of sugar (lag of 72 h), but the 12 yeast isolates utilized sugar in 60 h with increase in growth. The two mold strains too showed a similar pattern of rapid glucose consumption, while the seven bacterial isolates showed meager growth and almost negligible consumption of sugar (data not shown). Hence, yeast isolates (12) were screened and examined for further study.

Biochemical and physiological characteristics

Assessment of biochemical characteristics of ethanologenic yeast isolates further distinguished intra-species metabolic capabilities (Table S3). Yeast strains (14) of four genus were distinctly separated based on (i) growth and fermentation of carbohydrates, (ii) growth at ≤50 °C, (iii) tolerance to ≤50 % (w/v) glucose concentrations and (iv) formation of the pseudohyphae on corn meal agar by Dalmau plate technique and ascospore formation.

From Table S3, the strains Y4, Y16 and D1C were characterized as belonging to the genus Pichia based on (i) occasional pellicle formation, (ii) assimilation of ethanol and glycerol, (iii) growth at temperatures above 37 °C (observed up to 50 °C), (iv) multi-lateral budding, (v) absence of nitrate assimilation and (vi) urease production. These traits were found similar to the characteristics described by Kurtzman et al. (2011). However, the strains showed meager utilization of d-xylose, a desirable trait for ethanol fermentation from pre-treated lignocellulosic biomass (Chaudhari et al. 2012).

Similarly, the strains of Y1, Y2, Y9, Y12 and Y15 displayed distinctive intra-species differences in sugar utilization, pseudohyphae formation and growth in high gravity (50 %) d-glucose. The strains utilized hexose and pentose mono-, di-, tri- and polysaccharides. The yeast isolates showed (i) presence of multi-lateral budding, (ii) pseudomycelium formation, (iii) absence of nitrate assimilation, (iv) urease production and (v) cycloheximide resistance (0.1 %). Vigorous fermentation of d-xylose and cellobiose and tolerance to high gravity (50 %) glucose concentration were observed indicating that the yeast isolates belong to Kluyveromyces marxianus.

The strains B1M, C2M, D3A and D3C showed phenotypic characteristics similar to Saccharomyces sp. as described by Kurtzman et al. (2011). It includes (i) absence of raffinose fermentation and (ii) assimilation of maltose. However, tolerance to high temperature (50 °C) and d-glucose concentration (50 %) was observed for the strains.

The yeast isolates YD1 and YD2 exhibited distinct peculiarities like (i) maltose fermentation, (ii) growth on melezitose, (iii) formation of pseudomycelium and (iv) ring pellicle formation indicating its affiliation to Candida sp.

Phylogenetic analysis

Phenetic characteristics of isolates alone are unable to differentiate inter-species divergence among the strains. Hence, alternative approach like sequencing of rDNA is employed for molecular characterization of yeasts exhibiting slower rates of mutation and regarded as evolutionary chronometers (Kurtzman 1992). The sequences and similarity indices of the isolates are summarized in Table 2. The percent similarity differed among the yeast strains with respect to rDNA but clustered to their nearest neighboring taxa. Phylogenetic analysis of 14 yeasts revealed similar clustering pattern in three rDNA regions with variable degree of % similarity. Based on sequencing of 18S, ITS and D1/D2 domain of 26S rDNA gene, yeast isolates (61 %) delineated to the family Saccharomycetaceae and identified as members of Candida sp. (14.3 %), K. marxianus (35.7 %), Pichia kudriavzevii (21.4 %) and S. cerevisiae (28.6 %). Among the genus (i) Saccharomyces, strain B1M was found to be most distinct from the other strains but clustered with the genus Saccharomyces and (ii) P. kudriavzevii (syn. Issatchenkia orientalis; Kurtzman et al. 2008, 2011), strain D1C was most divergent but clustered with the genus Pichia clade. On the contrary, characteristic feature of each isolate was clearly inferred from the sequencing of ITS region with 99 and 97 % similarity for strain B1M and D1C with the genus Saccharomyces and P. kudriavzevii, respectively. The resemblance of the strains Y4, Y16 and D1C to previously reported ethanologenic I. orientalis MF121 (Hisamatsu et al. 2006) was 98 % (Y4) and 99 % (Y16 and D1C), 99 % with I. orientalis YS22 (Rao et al. 2008), 98 % (strain Y16) and 99 % (Y4 and D1C) with P. kudriavzevii Y1-N-10 (Dhaliwal et al. 2011) with the respective 18S, ITS and 26S rDNA sequences and hence, may be different from the previously reported strains.

The mold isolates (02) showed growth rapidly at 40 °C (within 48 h), however, meagerly fermenting 150 g l−1 as well as 250 g l−1 glucose containing YPD medium. Analysis of 18S rDNA gene sequencing revealed phylogenetic affiliation to Aspergillus and Rhizopus sp. sharing 98 % similarity with Aspergillus fumigatus (AB008401) and the zygomycete, Rhizopus microsporus var. chinensis CCTCC M201021 (EU410422).

Ethanol production by yeast isolates

Preliminary screening

Multi-stress resistance towards elevated temperature, alcohol concentrations, enzyme inhibitors, low external pH, high sugar concentrations, weak organic acids (lactic and acetic) and furfurals are considered as desirable traits in ethanologenic microbe(s) (Chaudhari et al. 2012). Yeasts are generally better candidates for higher ethanol productivity in the presence of multitude stress factors. Initially, all isolates viz. yeasts (14), bacteria (07) and molds (02) were analyzed for sugar utilization in YPD15 medium under aerobic conditions (150 rpm) at 40 °C. Except bacterial isolates, the efficiency of sugar utilization was found to be above 90 % in 5 days. Of the 14 yeast isolates, 02 strains of Candida sp. showed (i) growth after 3 days and (ii) slow glucose consumption (below 40 %). While, mold isolates (02) exhibited better utilization of glucose at 40 °C but produced negligible ethanol (data not shown).

The CO2 production for the selected 12 yeast isolates was investigated in 125 ml capacity sealed bottles containing YPD15 and fermentation medium with 150 g l−1 glucose using 15.0 g dry wt l−1 biomass at 40 °C under static condition for 24 and 48 h. The results are shown in Fig. 1. The absolute CO2 evolution was found more than 90 and 135 ml with K. marxianus Y15 and P. kudriavzevii Y4, Y16 and D1C and S. cerevisiae B1M in YPD15 medium after 24 and 48 h. On the contrary, pattern of absolute CO2 evolution was more than 114 ml observed with P. kudriavzevii Y4, Y16, D1C and strains of S. cerevisiae in fermentation medium (glucose, 150 g l−1) after 24 h. Interestingly, CO2 evolution was so vigorous after 48 h that the bottles violently de-sealed and poised the GC measurement.

Fermentation of d-glucose at 40 °C by yeast isolates

The preliminary screening of 12 yeast isolates showed ethanol production from fermentation medium (pH 4.5) containing glucose (150 g l−1). Accordingly, each isolate was pre-grown in YPD15 medium to 14.0 g dry wt l−1 for fermentation at 40 °C. The results obtained are set out in Fig. 2 and Table 3. From the results, it was clear that yeast isolates (12) showed ethanol production with fermentation efficiencies >92 % and ethanol productivity in the range of 0.82–7.43 g l−1 h−1.

Fermentative performance of yeast isolates a K. marxianus, b P. kudriavzevii and c S. cerevisiae on fermentation medium containing 150 g l−1 glucose at 40 °C showing residual TRS (circles), ethanol produced (squares) and biomass, dry weight (g l−1, triangles). Figure a showing strain Y1 (red), strain Y2 (green), strain Y9 (blue), strain Y12 (black) and strain Y15 (orange) of K. marxianus. Figure b showing strain Y4 (red), strain Y16 (green) and strain D1C (blue) of P. kudriavzevii. Figure c showing strain B1M (red), strain C2M (green), strain D3A (blue) and strain D3C (black) of S. cerevisiae

Among the K. marxianus strains, isolate Y9 achieved (i) the highest ethanol productivity (P) of 2.50 g l−1 h−1, (ii) ethanol concentration (E max ) of 74.6 g l−1, ethanol yield (Y p/s ) of 50.8 g g−1 and (iii) fermentation efficiency of 99.80 % (of theoretical) in 30 h. The P of Y12, Y1, Y15 and Y2 strains was found in the range 0.82 < 0.85 < 0.63 < 0.96 g l−1 h−1, respectively. While, the growth yield (Y x/s ) of the strain Y2 was minimum (0.002 g g−1) compared to Y15 strain (0.079 g g−1). Ethanol production of most strains of K. marxianus is reported to be <60 g l−1 while fermenting glucose (150 g l−1) at 40 °C (Banat et al. 1998; Limtong et al. 2007). Recently, Pang et al. (2010) observed 69 g l−1 ethanol using mutant strain GX-UN120 of K. marxianus.

In contrast to the strains of K. marxianus, the strains of S. cerevisiae (D3C, D3A, B1M and C2M) showed a considerably higher % theoretical ethanol yield (97–98 %) with E max ≥74.72 g l−1. The maximum E max of 74.98 g l−1 was shown by the strain B1M. However, P of strain B1M was much lower (1.87 g l−1 h−1) than that of strain D3A (2.99 g l−1 h−1). The Y p/s was almost same (0.496–0.498 g g−1) which can be attributed to the negligible growth yield (≤0.008 g g−1) of all the strains.

The strains of P. kudriavzevii namely, Y4, Y16 and D1C showed better P than the strains of K. marxianus and of S. cerevisiae (except strain D3A) at 40 °C. The P was significantly higher with strain D1C (7.43 g l−1 h−1) compared to strains Y4 (2.95 g l−1 h−1), Y16 (2.86 g l−1 h−1), the strains of K. marxianus and S. cerevisiae. The E max of 74.31 g l−1 was attained within 10 h by strain D1C with ethanol yield of 0.494 g g−1 close to the strains Y4 (0.509 g g−1) and Y16 (0.5 g g−1). While, the E max of 73.76 and 71.49 g l−1 by strain Y4 and Y16, respectively were attained in 25 h. The Y p/s of 0.509 g g−1 with 99.99 % theoretical yield was noticed with strain Y4, but produced 73.76 g l−1 ethanol lower than strain D1C and the strains of S. cerevisiae. The strain D1C was therefore, found to be best performing with respect to the shortest fermentation time (10 h) and E max close to theoretical ethanol yield than the strains of K. marxianus and S. cerevisiae with d-glucose as a substrate at 40 °C. These results are in accordance with Dhaliwal et al. (2011) and Oberoi et al. (2012) where galactose adapted P. kudriavzevii Y1-N-10 cells produced 71.95 g l−1 ethanol with P of 4.0 g l−1 h−1 within 18 h at 40 °C in fermentation wort containing 166 g l−1 cane sugar and ethanol production decreased to 58.53 g l−1 at 45 °C. Previous studies with P. kudriavzevii have indicated emerging multi-stress tolerant non-Saccharomyces yeast for ethanol production. Transformant TTK316 of I. orientalis MF121-bgl1 produced ethanol in repeated batch fermentation of glucose (100 g l−1) at 40 °C, pH 2.5 within 12 h (Kitagawa et al. 2010). In contrast, Hisamatsu et al. (2006) screened I. orientalis MF121 to produce 90 g l−1 ethanol in fermentation medium containing 200 g l−1 glucose and 50 g l−1 sodium sulphate at 30 °C, pH 6.0 and the strain further showed lower P (~95 g l−1) at 30 °C after 5 days. But Gallardo et al. (2011) noticed ethanol production up to 45 g l−1 by I. orientalis 195B on YPD10 containing 100 g l−1 glucose at 42 °C in 30 h.

Fermentation of molasses at 40 °C by yeast isolates

Several fermentation industries use molasses, a residue of sugar juices after sucrose crystallization as a cost-effective substrate. Currently, more than 395 distilleries operate on sugarcane molasses as the principal feedstock for ethanol production in India. Besides, sugar (>46 %), molasses contain various furfurals to inhibit ethanol production by yeasts. The ethanologenic strains were therefore, adapted in molasses medium by repeated sub-culturing prior to the fermentation in order to overcome the inhibitors (Banerjee et al. 1981).

Figure 3 and Table 3 summarizes the performance of yeast isolates on MFM15 medium. Except for the K. marxianus strain Y9, all the yeasts showed ethanol productivity ≥94 % (of theoretical). The ethanol productivity for each isolate was ranged from 1.05 < 1.13 < 1.16 < 3.27 < 4.81 g l−1 h−1 for Y9 < Y2 < Y1 < Y15 < Y12 of K. marxianus strains, respectively. While, various S. cerevisiae strains showed ethanol productivity of 1.87 g l−1 h−1 for strain D3A and B1M and 2.14 < 2.5 g l−1 h−1 for C2M and D3C respectively. But in case of strain Y12, ethanol productivity was 4.81 g l−1 h−1 on MFM15 medium better than 0.82 g l−1 h−1 on glucose which possibly may be due to the presence of activators (metal ions, vitamins etc.) and better adaptation of the strain to resist the fermentation inhibitors present in MFM15 medium. On the contrary, S. cerevisiae C2M attained ethanol yields ≥97.83 % (of theoretical) with ethanol yield and E max of 97.92 % and 74.96 g l−1, respectively by strain C2M. The performance corroborates with the ethanol productivities on glucose as a substrate with respect to E max , and ethanol yield. However, ethanol productivity of the strains C2M and D3A decreased from 2.5 to 2.14 and 2.99 to 1.87 g l−1 h−1, respectively.

Fermentative performance of yeast isolates on MFM15 medium containing 150 g l−1 TRS at 40 °C showing (g l−1) residual TRS (circles), ethanol produced (squares) and biomass, dry weight (triangles). Figure a showing strain Y1 (red), strain Y2 (green), strain Y9 (blue), strain Y12 (black) and strain Y15 (orange) of K. marxianus. Figure b showing strain Y4 (red), strain Y16 (green) and strain D1C (blue) of P. kudriavzevii. Figure c showing strain B1M (red), strain C2M (green), strain D3A (blue) and strain D3C (black) of S. cerevisiae

The ethanol productivity of strain D1C of P. kudriavzevii was 4.91 g l−1 h−1 (15 h) compared to 7.43 g l−1 h−1 (10 h) on glucose as substrate. However, marginal decrease in E max from 74.31 to 73.7 g l−1 on MFM15 medium was noticed. Relatively consistent ethanol productivities of ~2.9 g l−1 h−1 and E max (≥72.48 g l−1) were observed for strain Y4 and Y16.

The observed variation of fermentation efficiency within the strains and between the simple and complex substrates viz. glucose and molasses may be attributed to the stress factors encountered by yeasts and their adaptability to the presence of fermentation inhibitors/enzyme activators in MFM15 medium. However, at the same time, thermo-, osmotolerance and ethanol inhibition stress to all the isolates were compelling to high ethanol productivities on molasses as a substrate.

Stress tolerance

An array of yeast growth and fermentation inhibitors like weak organic acids (acetic, formic etc.), furan derivatives (furfural and hydroxymethyl furfural) and phenolic compounds (vanillin, guaiacol etc.) are reported during pre-treatment of carbohydrate feedstock (van Maris et al. 2006). The concentration of the inhibitors varies in the processed feedstock depending upon the composition and pre-treatment process adopted. In the present study, the ethanologenic P. kudriavzevii D1C was analyzed for ethanol, oxidative and 5-HMF tolerance. The strain showed (i) survival (%) of 67.57 ± 0.8 and 72.97 ± 1.5 in ethanol (20 %, v/v) and H2O2 (0.3 M) respectively and (ii) degradation of 5-HMF as evidenced from substantial decrease in peak area (retention time of 4.47 min) in fermented MFM15 medium (50 h) compared to untreated (0 h) and reference 5-HMF (retention time of 4.46 min) with emergence of additional peak in the fermented broth (retention time of 2.53) (Fig. 4). These results are in accordance with % survivors after stress in S. cerevisiae A16 (Lewis et al. 1997) and better than mutant strains of S. cerevisiae (Çakar et al. 2005). The growth of strain D1C was totally arrested at (i) 8 g l−1 acetic acid, (ii) 2 g l−1 formic acid, (iii) 2.5 g l−1 furfural, (iv) 12 mg l−1 guaiacol and (v) 12 mM concentration of vanillin. The strain D1C was also tolerant to low pH (2.0), a characteristic similar to the I. orientalis strain MF121 (Hisamatsu et al. 2006). These findings revealed ethanol, oxidative and inhibitor tolerance of P. kudriavzevii D1C thereby demonstrating as most suitable candidate for ethanol production from molasses as well as pre-treated carbohydrate feedstock.

Conclusions

This probably is the first study in which mango-fruit peel–pulp compost was scientifically examined for its composition and composting microflora. The study also demonstrated mango peel–pulp compost as a suitable source for isolation of highly fermentative microbes tolerant to multiple stress factors using a simple selective enrichment strategy. The preliminary performance of yeast isolates in batch fermentation of 150 g l−1 glucose and molasses at high temperature (40 °C) and low pH (4.5) showed better characteristics desirable for ethanol production. The isolates exhibited rapid fermentation maintaining high ethanol productivities under multitude of stress conditions. In summary, newer potential ethanologenic yeast strains were obtained from mango peel–pulp compost, but its ethanol production potential by fermenter scale-up and lignocellulosics is yet to be demonstrated.

References

Ajila CM, Bhat SG, Prasada Rao UJS (2007) Valuable components of raw and ripe peels from two Indian mango varieties. Food Chem 102:1006–1011

Anderson PJ, McNeil K, Watson K (1986) High-efficiency carbohydrate fermentation to ethanol at temperatures above 40 °C by Kluyveromyces marxianus var. marxianus isolated from sugar mills. Appl Environ Microbiol 51:1314–1320

Ausubel FM, Brent R, Kingston RE, Moore DD, Seidman JG, Smith JA, Struhl K (2003) Current protocols in molecular biology. Wiley, Hoboken

Balat M, Balat H (2009) Recent trends in global production and utilization of bio-ethanol fuel. Appl Energy 86:2273–2282

Banat IM, Nigam P, Marchant R (1992) Isolation of thermotolerant fermentative yeasts capable of growth at 52 °C and ethanol production at 45 °C and 50 °C. World J Microbiol Biotechnol 8:259–263

Banat IM, Nigam P, Singh D, Marchant R, McHale AP (1998) Review: ethanol production at elevated temperatures and alcohol concentrations: Part I—yeasts in general. World J Microbiol Biotechnol 14:809–821

Banerjee N, Bhatnagar R, Viswanathan L (1981) Development of resistance in Saccharomyces cerevisiae against inhibitory effects of Browning reaction products. Enzyme Microb Technol 3:24–28

Blieck L, Toye G, Dumortier F, Verstrepen KJ, Delvaux FR, Thevelein JM, Van Dijck P (2007) Isolation and characterization of brewer’s yeast variants with improved fermentation performance under high-gravity conditions. Appl Environ Microbiol 73:815–824

Brooks AA (2008) Ethanol production potential of local yeast strains isolated from ripe banana peels. Afr J Biotechnol 7:3749–3752

Çakar ZP, Seker UOS, Tamerler C, Sonderegger M, Sauer U (2005) Evolutionary engineering of multiple-stress resistant Saccharomyces cerevisiae. FEMS Yeast Res 5:569–578

Chaudhari AB, Dandi ND, Vadnere NC, Patil UK, Chincholkar SB (2012) Bioethanol: a critical appraisal. In: Satyanarayana T, Johri BN, Prakash A (eds) Microorganisms in sustainable agriculture and biotechnology. Springer, Berlin, pp 793–824

Choi MH, Park YH (1998) The influence of yeast on thermophilic composting of food waste. Lett Appl Microbiol 26:175–178

Dhaliwal SS, Oberoi HS, Sandhu SK, Nanda D, Kumar D, Uppal SK (2011) Enhanced ethanol production from sugarcane juice by galactose adaptation of a newly isolated thermotolerant strain of Pichia kudriavzevii. Bioresour Technol 102:5968–5975

Eaton AD, Franson MAH, American Public Health Association (2005) Standard methods for the examination of water & wastewater, 21st edn. American Public Health Association, Washington, DC

Fracchia L, Dohrmann AB, Martinotti MG, Tebbe CC (2006) Bacterial diversity in a finished compost and vermicompost: differences revealed by cultivation-independent analyses of PCR-amplified 16S rRNA genes. Appl Microbiol Biotechnol 71:942–952

Gallardo JC, Souza CS, Cicarelli RM, Oliveira KF, Morais MR, Laluce C (2011) Enrichment of a continuous culture of Saccharomyces cerevisiae with the yeast Issatchenkia orientalis in the production of ethanol at increasing temperatures. J Ind Microbiol Biotechnol 38:405–414

Gardner JG, Zeitler LA, Wigstrom WJS, Engel KC, Keating DH (2012) A high-throughput solid phase screening method for identification of lignocellulose-degrading bacteria from environmental isolates. Biotechnol Lett 34:81–89

Harju S, Fedosyuk H, Peterson KR (2004) Rapid isolation of yeast genomic DNA: Bust n’ Grab. BMC Biotechnol. doi:10.1186/1472-6750-4-8

Hisamatsu M, Furubayashi T, Karita S, Mishima T, Isono N (2006) Isolation and identification of a novel yeast fermenting ethanol under acidic conditions. J Appl Glycosci 53:111–113

Horwitz W (1975) Official methods of analysis of the association of official analytical chemists, 12th edn. Association of Official Analytical Chemists, AOAC International, Washington, DC, p 572

Kiransree N, Sridhar M, Suresh K, Banat IM, Rao LV (2000a) Isolation of thermotolerant, osmotolerant, flocculating Saccharomyces cerevisiae for ethanol production. Bioresour Technol 72:43–46

Kiransree N, Sridhar M, Rao LV (2000b) Characterisation of thermotolerant, ethanol tolerant fermentative Saccharomyces cerevisiae for ethanol production. Bioprocess Biosyst Eng 22:243–246

Kitagawa T, Tokuhiro K, Sugiyama H, Kohda K, Isono N, Hisamatsu M, Takahashi H, Imaeda T (2010) Construction of a beta-glucosidase expression system using the multistress-tolerant yeast Issatchenkia orientalis. Appl Microbiol Biotechnol 87:1841–1853

Kurtzman CP (1992) Minireview: rRNA sequence comparisons for assessing phylogenetic relationships among yeasts. Int J Syst Bacteriol 42:1–6

Kurtzman CP, Robnett CJ (1998) Identification and phylogeny of ascomycetous yeasts from analysis of nuclear large subunit (26S) ribosomal DNA partial sequences. Antonie Leeuwenhoek 73:331–371

Kurtzman CP, Robnett CJ, Basehoar-Powers E (2008) Phylogenetic relationships among species of Pichia, Issatchenkia and Williopsis determined from multigene sequence analysis, and the proposal of Barnettozyma gen. nov., Lindnera gen. nov. and Wickerhamomyces gen. nov. FEMS Yeast Res 8:939–954

Kurtzman CP, Fell JW, Boekhout T (2011) The yeast, a taxonomic study, 5th edn. Elsevier, New York

Laopaiboon L, Nuanpeng S, Srinophakun P, Klanrit P, Laopaiboon P (2009) Ethanol production from sweet sorghum juice using very high gravity technology: effects of carbon and nitrogen supplementations. Bioresour Technol 100:4176–4182

Lewis JG, Learmonth RP, Attfield PV, Watson K (1997) Stress co-tolerance and trehalose content in baking strains of Saccharomyces cerevisiae. J Ind Microbiol Biotechnol 18:30–36

Limtong S, Stringiew C, Yongmanitchai W (2007) Production of fuel ethanol at high temperature from sugarcane juice by a newly isolated Kluyveromyces marxianus. Bioresour Technol 98:3367–3374

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Nevoigt E (2008) Progress in metabolic engineering of Saccharomyces cerevisiae. Microbiol Mol Biol Rev 72:379–412

Oberoi HS, Babbar N, Sandhu SK, Dhaliwal SS, Kaur U, Chadha BS, Bhargav VK (2012) Ethanol production from alkali-treated rice straw via simultaneous saccharification and fermentation using newly isolated thermotolerant Pichia kudriavzevii HOP-1. J Ind Microbiol Biotechnol 39:557–566

Pang ZW, Liang JJ, Qin XJ, Wang JR, Feng JX, Huang RB (2010) Multiple induced mutagenesis for improvement of ethanol production by Kluyveromyces marxianus. Biotechnol Lett 32:1847–1851

Pereira FB, Guimarães PMR, Teixeira JA, Domingues L (2010) Selection of Saccharomyces cerevisiae strains for efficient very high gravity bio-ethanol fermentation processes. Biotechnol Lett 32:1655–1661

Peres MFS, de Sousa SR, Laluce C (2001) Obtaining strains of Saccharomyces tolerant to high temperatures and ethanol. In: Spencer JFT, Spencer ALR (eds) Food microbiology protocols. Humana Press Inc., Totowa, pp 355–367

Peters S, Koschinsky S, Schwieger F, Tebbe CC (2000) Succession of microbial communities during hot composting as detected by PCR-single-strand-conformation polymorphism-based genetic profiles of small-subunit rRNA genes. Appl Environ Microbiol 66:930–936

Rao RS, Bhadra B, Shivaji S (2008) Isolation and characterization of ethanol-producing yeasts from fruits and tree barks. Lett Appl Microbiol 47:19–24

Ryckeboer J, Mergaert J, Vaes K, Klammer S, de Clercq D, Coosemans J, Insam H, Swings J (2003) A survey of bacteria and fungi occurring during composting and self-heating processes. Ann Microbiol 53:349–410

Ryohei U, Naoko H-S, Naoto U (2003) Fermentation of molasses by several yeasts from hot spring drain and phylogeny of the unique isolate producing ethanol at 55 °C. J Tokyo Univ Fish 3:23–30

Tamura K, Peterson D, Peterson N, Stecher G, Nei M, Kumar S (2011) MEGA5: Molecular Evolutionary Genetics Analysis using maximum likelihood, evolutionary distance, and maximum parsimony methods. Mol Biol Evol. doi:10.1093/molbev/msr121

van Maris AJA, Abbott DA, Bellissimi E, van den Brink J, Kuyper M, Luttik MAH, Wisselink HW, Scheffers WA, van Dijken JP, Pronk JT (2006) Alcoholic fermentation of carbon sources in biomass hydrolysates by Saccharomyces cerevisiae: current status. Antonie Leeuwenhoek 90(4):391–418

Watanabe T, Srichuwong S, Arakane M, Tamiya S, Yoshinaga M, Watanabe I, Yamamoto M, Ando A, Tokuyasu K, Nakamura T (2010) Selection of stress-tolerant yeasts for simultaneous saccharification and fermentation (SSF) of very high gravity (VHG) potato mash to ethanol. Bioresour Technol 101:9710–9714

White TJ, Bruns T, Lee S, Taylor J (1990) Amplification and direct sequencing of fungal RNA genes for phylogenetics. In: Innis MA, Gelfand DH, Sninsky JJ, White TJ (eds) PCR protocols: a guide to methods and applications. Academic Press Inc., New York, pp 315–322

Acknowledgments

The assistance rendered by Mr. Pradeep Suryavanshi, Jain Irrigation Systems Ltd., Jalgaon, India for CO2 analysis of samples and Dr. G. S. Prasad, Microbial Type Culture Collection and GeneBank, Chandigarh, India for phenetic analysis of isolates is acknowledged. Mr. N. D. Dandi is grateful to Dr. Yogesh Shouche and Mr. Arvind Gupta, National Center for Cell Sciences, Pune, India for facilitating rDNA sequencing of the isolates under INSA Visiting Fellowship (Indian National Science Academy, New Delhi). Authors are also thankful to University Grants Commission and Department of Science and Technology, New Delhi for funding under SAP and FIST program, respectively to the institute.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dandi, N.D., Dandi, B.N. & Chaudhari, A.B. Bioprospecting of thermo- and osmo-tolerant fungi from mango pulp–peel compost for bioethanol production. Antonie van Leeuwenhoek 103, 723–736 (2013). https://doi.org/10.1007/s10482-012-9854-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10482-012-9854-4