Abstract

In this study, energy use patterns and the functional relationship between energy inputs and output for pomegranate production were investigated in Antalya province in Turkey. It further objective to identify greenhouse gas (GHG) emissions in pomegranate production. Data were obtained from 75 farms using face-to-face interview method. The results indicated that 50,605.5 MJ ⋅ ha−1 of total energy input was required for 76,252.3 MG ⋅ ha−1 pomegranate energy output. 1.51 unit energy output was provided by using 1 unit energy input. 1 unit energy output and 1 kg pomegranate require 0.66 unit and 2.57 MJ energy input, respectively. The average CO2 emission amounts were also calculated to be 1.73 t CO2 per hectare and 88.1 kg CO2 per 1000 kg pomegranate production. Electricity, fertilizers and pesticides were the highest contributors to GHG emissions. Both total energy input usage and GHG emission amounts have been found to be decreasing as the farm size increases. Increasing scale of pomegranates orchards will not only increase energy efficiency and productivity but also decrease environmental pollution and damages. The regression analysis revealed that, excessive use of machinery and fuel inputs results in a decline in energy production in pomegranate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Turkey is within the borders of the homeland of pomegranate, and has been producing and consuming this fruit for thousands of years. Pomegranate cultivation has been popular particularly in recent years in Turkey. The production area, which was 4675 ha in 2000, reached to 30,751 ha in 2015, with an annual increase rate of 13.4%. In parallel to the increase in production area, the total pomegranate production rose from 59,000 to 445,750 tons in the same period (TUIK 2016). Antalya climbed from the tenth place to the top among provinces with an annual increase rate of 13.4%, in pomegranate production in Turkey.

Nowadays agricultural sector has become more energy intensive in order to provide not only food but also energy (biogas and electricity) for increasing population and welfare. The energy consumption in Turkish agriculture, which was 3073 Mep in 2000, increased to 5755 Mep in 2011 with an annual increase rate of 5.9% (Ozturk et al. 2015). Intensive, excessive and unconsciously energy input use in agriculture results in a decrease in profitability and an increase in human health risk. Moreover, it creates numerous environmental problems such as pollution of water by chemical fertilizer and pesticides, greenhouse gas emission (GHG) that leads to global warming. Agriculture contributes significantly to atmospheric GHG emissions, by producing 14% of the global net CO2 emission (IPCC 2007). Therefore, energy analysis and GHG emission assessments are well-established components of environmental impact assessments (Yousefi et al. 2014). Energy analyses, based on the ratios and econometrics are generally used for measuring energy efficiency and its environmental impacts. These analyses help to determine how efficiently energy is used. Thus, both the unnecessary use of energy and the damages suffered by the environment can be reduced (Goktolga et al. 2006; Barut et al. 2011). Moreover, the effective energy use in agriculture is a fundamental condition for sustainable agricultural development, since it provides financial savings and preserves natural resources by decreasing production costs and pollution (Uhlin 1998; Flores et al. 2016).

In recent years, many studies have been conducted on energy analysis of different fruits. Some of these studies are on apple production in Greece (Strapatsa et al. 2006), in Iran (Rafiee et al. 2010); sultana grape (Kocturk and Engindeniz 2009), cherry (Kizilaslan 2009), sweet cherry (Demircan et al. 2006), banana (Gundogmus 2013) production in Turkey; kiwifruit (Mohammadi et al. 2010), tangerine (Mohammadshirazi et al. 2012), peach (Royan et al. 2012), nectarine (QasemiKordkheili et al. 2013), mango production in Nigeria (Jekayinfa et al. 2013). In some particular studies, the use of energy in the production of pomegranate in Turkey is studied (Akcaoz et al. 2009; Canakci 2010). Distinctively from both studies, this study considered GHG emissions during production, econometric energy analysis and the effect of the farm groups on energy use. In addition, the differences among farm group mean values were statistically tested.

The aims of this study are (1) to investigate the input-output energy balances and to determine of scale effect (2) to estimate GHG emissions of pomegranate production to contribute to climate change mitigation efforts, (3) to specify a relationship between input energies and output, in addition to functional analysis of the energy inputs on pomegranate production in Antalya, Turkey.

Material and Method

Main material of this study consists of the data obtained through surveys conducted with the producers cultivating pomegranate in the sub-provinces of Antalya, almost 73.2% of the pomegranate production that takes place in Antalya. Furthermore, the information derived from previously-conducted studies is utilized. Within the scope of the study, face-to-face interviews were conducted with 75 pomegranate producers, 28 of which were from Group 1 (0.01–1.0 ha) enterprises, 16 of which were from Group 2 (1.1–2.0 ha) enterprises, 15 of which were from Group 3 (2.1–4.0 ha) enterprises, and 16 of which were from Group 4 (above 4 ha) enterprises. Sample farms were randomly selected from the villages in the region by using a stratified random sampling method. So, weighted average values represented the region. The sample size has been calculated using the Neyman method and the permissible error in the sample population have been defined to be 5% within 95% confidence interval.

Total energy input per unit area (hectare) is composed of the sum of partial energy of each input used in the production. The input categories studied consist of human labour, diesel fuel, electricity, agricultural tools and machineries, farm manure, irrigation water, chemical fertilizer (N, P, K) and agricultural pesticides. The units shown in Table 1 are used to find the quantities of the inputs used in production. Input quantities per hectare are calculated, and then such input data are multiplied by the energy equivalent factor. Energy equivalents of unit inputs are represented in Mega Joules (MJ). Total input equivalent can be calculated by summing the energy equivalents of all inputs represented in MJ.

Net energy, energy use efficiency, energy productivity and specific energy ratios are calculated using the formulas given below (Yousefi et al. 2014; Mandal et al. 2002; Houshyar et al. 2015; Sefeedpari et al. 2014):

In addition to farm size group, farm and farmers are classified with respect to their locations in sub regions ((1) Dosemealtı, (2) Kepez, Konyaaltı, Muratpasa, Aksu and (3) Serik), and education levels ((1) primary education, (2) secondary education and (3) university) in this study. The differences of the estimated mean values of the energy inputs, outputs per hectare and the energy efficiency and productivity ratios by groups are also statistically tested. Variance analysis and its non-parametric alternative, Kruskal-Wallis tests are used to statistically test. The assumptions of the one-way analysis of variance for independent samples are; (a) the dependent variable is measured has the properties of an equal interval scale; (2) that more than two (k) samples are independently and randomly drawn from the populations; (3) that the populations have a normal distribution; and (4) that the k samples have approximately equal variances (Lowry 1999; Arsham 2002). First two assumptions were achieved during the survey stage of the study. Normality assumption tested using Kolmogrov-Smirnov and Shapiro-Wilk tests (Baldwin 2002). Any failure of the assumptions Kruskal-Wallis tests was used.

CO2 emission coefficients of different agricultural inputs are used in order to quantify the GHG emissions of pomegranate cultivation. Table 1 also summarizes GHG emission equivalents and the emission amounts calculated by multiplying the input data by its corresponding emission coefficient.

In order to specify a relationship between energy inputs and energy production, a mathematical function is required. For this purpose, Cobb-Douglass production function is chosen as the best function in terms of statistical significance and expected signs of parameters. The Cobb-Douglass production function has been used by some authors to investigate the relationship between inputs and energy production (Rafiee et al. 2010; Mohammadi et al. 2010; Singh et al. 2004; Erdal et al. 2009; Samavatean et al. 2011). The Cobb-Douglass production function is expressed as follows;

This function can be expressed as a linear relationship using the following expression:

where: Yi denotes the production of the ith producer, Xij is the vector of inputs used in the production process, β0 is a constant term, βj represent coefficients of inputs which are estimated from the model and ei is the error term.

Assuming that pomegranate energy production is a function of inputs, for investigating the impact of each input on pomegranate energy production, the Eq. 6 can be expanded in the following form;

where; Yi represents pomegranate energy production, Xi (i = 1, …,7) represents physical inputs from human labour (X1), machinery (X2), diesel fuel (X3), chemical fertilizer (X4), pesticides (X5), electricity (X6), and pomegranate land (X7).

The Cobb-Douglass energy production function (Eq. 7) is estimated using Ordinary Least Square (OLS) method. The analysis is performed using the statistical software package. After the estimation of the energy production function, marginal physical productivities (MPP) of the various inputs are calculated using the βj of the various inputs as follows:

where MPPxj is marginal physical productivity of jth input, βj regression coefficient of jth input, Gm Y geometric mean of production and Gm Xj, geometric mean of jth input energy.

Results and Discussion

The average family size is 5.1 in the study. It is also found that 52.4% of the family population constituted male and 47.6% female. The average age of pomegranate farmers interviewed is 49.9. More than half of the surveyed farmers (55.1%) have primary education, 22.8% have secondary education and 22.1% have university level education. The average duration of experience of pomegranate production in the enterprises surveyed is found to be 8.1 years. The average pomegranate garden size was calculated as 0.21 hectares in the surveyed farms. The average number of trees in the orchard was 55.5. The characteristic structure of pomegranate cultivation in the research area is small family farming.

Energy Inputs and Outputs in Pomegranate Production

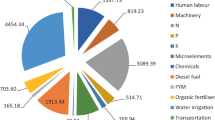

Total physical energy input consists of human labour, machinery, chemical fertilizer, farm manure, pesticides, diesel, electricity and water for irrigation. Physical energy sources and energy consumption for pomegranate production are presented in Table 2. The results revealed that, the quantity of labour and machinery power used in the pomegranate production are 912.0 h ⋅ ha−1 and 85.3 h ⋅ ha−1, respectively. Total hours of labour used in different operations are as follows: for harvesting 407.5 h, maintenance 281.8 h, irrigation 103.4 h, fertilizing 54.0 h, spraying 43.9 h and soil cultivation 21.4 h per hectare. Chemical fertilizers are typically applied 3.44 times and 549.6 kg per hectare a year. Additionally, 932.0 kg of farm manure per hectare is used. The chemical fertilizers consist of nitrogen (46.3%), phosphorus (29.9%) and potassium (23.8%). The total amount of pesticide used in pomegranate production is 69.3 kg per hectare. The share of insecticides, fungicides, herbicides and acaroids are found to be 34.8%, 34.6%, 15.9% and 14.8% respectively. Additionally, 35.7 L diesel fuel, 933.6 kWh electricity, 56.9 m3 water are used per hectare for pomegranate production.

Average pomegranate yield is 19,696.8 kg per hectare in the research area. Pomegranate yields were reported as 23,350 kg ⋅ ha−1, between 28,335–43,655 kg ⋅ ha−1 in previous studies (Akcaoz et al. 2009; Canakci 2010) and 18,691.2 kg ⋅ ha−1 in 2015 in Antalya (TUIK 2016).

With respect to the obtained results, the shares of weighted average energy consumption in pomegranate production are 35.8% chemical fertilizer, 27.9% pesticides, 19.5% electricity, 9.2% machinery, 3.5% human labour, 3.4% diesel, 0.6% farm manure and 0.1% water for irrigation. Although, percentages vary between different size groups, the general tendency is that the chemical fertilizers and pesticides are the highest energy inputs in all groups. There are percentage differences between the groups in terms of other inputs as well, but the ranking is similar to the average size groups. The results revealed that consumption of fertilizer, pesticides, electricity and machinery energy inputs is relatively high for pomegranate production in the region.

When we examine the operations in human labour, the highest energy is consumed in harvesting (44.7%) and hoeing, pruning (30.9%). Fertilization (50.1%) is the highest energy input in machinery usage. Nitrogen (85.1%) is the main fertilizer, the fungicides (36.7%) and insecticides (31.3%) are the main pesticides in pomegranate production.

Energy uses per hectare have been found 29.1% higher on the smallest size group farms than the largest size group. These results are consistent with the results for cotton production by Yilmaz et al. (2005). Moreover, in this study in all categories of energy inputs, least energy is being used in the largest size group. In general, differences in all means of energy inputs have been found statistically significant with respect to farm size groups. However, there are no significant differences with respect to sub regions and farmer education levels.

The average energy input, output and the amount of net energy have been calculated as 50,605.3 MJ ⋅ ha−1, 76,252.3 MJ ⋅ ha−1 and 25,647.1 MJ ⋅ ha−1, respectively in this study. However, energy use and net energy per hectare is 45.2% higher on the largest size group farms than the smallest size group because of the scale effect. It is also reported that large farms used energy in the best possible way to achieve maximum yield (Singh et al. 1996). Variance analysis results show that there are significant differences only in terms of total energy outputs with respect to sub regions (p = 0.03). However, the differences in terms of total energy and net energy outputs with respect to size groups and farmer education levels have not been found statistically significant.

The energy inputs and outputs for pomegranate production in previous studies in Turkey were 53,764.6 MJ ⋅ ha−1 and 56,040 MJ ⋅ ha−1 (Akcaoz et al. 2009), and between 32,619–44,462.7 MJ ⋅ ha−1 and 63,395–82,945 MJ ⋅ ha−1 (Canakci 2010), respectively. In literature, the results showed that total energy input were 48,667.0 MJ ⋅ ha−1 for cherries production in Turkey (Kizilaslan 2009), 42,819.3 MJ ⋅ ha−1 for apple production in Iran (Rafiee et al. 2010), between 192,652.6–168,783.9 and 76,433.3–42,995.6 MJ ⋅ ha−1 for plum production in Iran (Tabatabaie et al. 2012), 15,015.2 and 20,400 MJ ⋅ ha−1 for mango production in Nigeria (Jekayinfa et al. 2013).

Estimated energy productivity and efficiency indicators were given in Table 3 based on the ratios. In our study, average energy use efficiency (output/input) ratio has been found to be 1.51. In other words, 1.51 unit energy output is provided by using 1 unit energy input. In the research area, energy productivity is 0.39 kg ⋅ MJ−1. Thus, in order to produce 0.39 kg pomegranate, 1 unit energy is consumed. In addition, according to research results, energy input/output ratio is 0.66, and specific energy is 2.57 MJ ⋅ kg−1. In other words, 1 unit energy output requires 0.66 unit energy input, and 1 kg pomegranate requires 2.57 MJ energy input. In previous studies conducted in the same region, energy use efficiency ratios were calculated to be 1.04 (Akcaoz et al. 2009), and between 1.91 and 2.84 (Canakci 2010). In these studies, energy productivity was calculated to be 0.43 (Akcaoz et al. 2009), and between 0.66 and 1.02 (Canakci 2010). The energy use efficiency ratio was found to be 1.24–1.31 in the apricot (Esengun et al. 2007) and 2.69 in the apple (Yilmaz et al. 2010) in Turkey.

According to the results, energy use efficiency and energy productivity indicators increase as farm size increases, with the highest efficiency and productivity on large farms. Unlike energy use, efficiency and energy productivity, energy input/output ratio and specific energy decrease as farm size increases. Thus, these results indicate that energy inputs have been used more efficiently and productive in large farms in pomegranate production. Although there are differences in energy use efficiency, energy productivity, energy input/output ratio and specific energy with respect to size groups, sub regions and farmer education levels, they have not been found statistically significant.

Greenhouse Gases Emissions

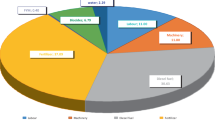

Table 4 shows the CO2 emission for pomegranate production according to the energy usage. The average CO2 emission amount is 1.73 t CO2eq ⋅ ha−1 in this study. Results indicate that electricity had the highest share in CO2 emission (32.7%) followed by chemical fertilizers (22.5%), pesticides (19.5%) and machinery (19.1%). It can be seen in Table 4, the total amount of CO2 emission ranges from 1.42 to and 1.96 t CO2 per hectare by size group. Parallel to total energy input, the CO2 emission decreases as farm size increases, with the smallest amounts of CO2 emission on large farms. The CO2 emission analysis for different products given in the literature is as follows; the total GHG emission was 1.2 t CO2eq ⋅ ha−1 for apple production (Taghavifar and Mardani 2015), 0.86 t CO2eq ⋅ ha−1 for grape production (Mardani and Taghavifar 2016), 3.3 and 3.6 t CO2eq ⋅ ha−1 for organic and conventional avocado orchards, respectively, in Mexico (Astier et al. 2014), 1.5, 1.6, 4.7, 3.1, 0.4, 1.8 and 2.3 t CO2eq ⋅ ha−1 for Andean blackberry, avocado, Golden berry, lulo, mango, passion fruit and pineapple production, respectively, in Colombia (Graefe et al. 2013).

An average GHG emission for 1 t pomegranate production is 88.1 kg CO2 in this study. The GHG emissions also range between 72.5–97.6 kg CO2 per production of 1 ton pomegranate with respect to size groups (Table 4). This value was 1400 kg CO2 ⋅ t−1 for corn (Yousefi et al. 2014), 263 kg CO2 ⋅ t−1 for soybean (Knudsen et al. 2010), 303.4–467 kg CO2 ⋅ t−1 for canola (Khojastehpour et al. 2015), 84.6 kg CO2 ⋅ t−1 for tomato (Houshyar et al. 2015), 30–62 kg CO2 ⋅ t−1 for potatoes (Gomiero et al. 2008).

Cobb-Douglass Energy Production Function Estimation

To investigate the relationship between the inputs and output, the Cobb-Douglas energy production function was estimated by using the physical inputs measures and pomegranate energy production per farm. The independent variables explained 90.1% of the variation in pomegranate energy production. The respective coefficients are provided in Table 5.

In this study presence of autocorrelation has been tested using the Durbin-Watson statistic test. Test results have revealed that, Durbin-Watson value is 1.90, indicating that there is no autocorrelation at the 1% significance level in the estimated model.

The estimated outcomes have revealed unexpected results; physical inputs of machinery and diesel use show negative effect on pomegranate energy production. These results are likely related to the excessive use of inputs. The intensive and excessive use of machinery and diesel can also be reason of low energy productivity. Consequently, machinery and diesel inputs should be used carefully by farmer to increase pomegranate energy productivity and efficiency in the research area.

Estimated coefficients except machinery and diesel indicate that the impact of inputs could be considered positively on pomegranate energy production. Human labour, farm electricity and land inputs coefficients were found statistically insignificant. The regression results have revealed that the contribution of pesticide is significant at the 1% level. Also, the impacts of chemical fertilizer and diesel are significant at 5% level. The estimated coefficients also indicate efficiency characteristics regarding production practices, and represent production elasticities. Therefore, the most important input in terms of production elasticity is pesticides (1.010), which mean an increase of 1% in pesticides usage, results in 1.010% energy production increase. The second important input has been found to be fertilizer with the elasticity of 0.236. The overall elasticity of inputs was close to unity (1.036), suggesting nearly constant return to scale relationship between the physical inputs and energy production.

The MPP value of the model variables is shown in the last column of Table 5. It can be seen that MPP of pomegranate land, pesticides, and chemicals fertilizer inputs have been found as 3.25, 2.45 and 0.40, respectively. These results indicate that last 1 unit of land, pesticides, and chemicals fertilizer used in pomegranate energy production provided 3.25, 2.45 and 0.40 MJ energy, respectively. The MPP values of machinery and diesel have been found negative, which indicates overuse of inputs.

Conclusions

This study reveals the quantities of energy inputs and outputs used in pomegranate production in Antalya. The data used in the study have been obtained through face-to-face interview with producers cultivating pomegranate in Antalya. In the study, energy input and energy output in pomegranate production are calculated to be 50,605.3 MJ ⋅ ha−1 and 76,252.3 MJ ⋅ ha−1, respectively. Almost 63.7% of the energy inputs are chemical products as well as fertilizers and pesticides which are non-renewable in nature. Energy use efficiency and energy productivity ratios in the enterprises surveyed within the scope of the study are 1.51 and 0.39 kg ⋅ MJ−1, respectively. Fertilizers, pesticides and electricity are major energy inputs in all size groups of farms. The results further reveals that small farms consume more input than others. Net energy output is highest in the largest group of farms. Moreover, energy inputs are being used more efficiently and productively in large farms in pomegranate production. Small size enterprises which are one of the most important problems of agricultural structure of Turkey also exist in pomegranate production.

In this study, CO2 emission amounts are calculated to be 1.73 t CO2 per hectare and 88.1 kg CO2 per 1000 kg pomegranate production. Parallel to total energy input use, the CO2 emission decreases as farm size increases, with the smallest amounts of CO2 emission on large farms. Being a result of the study, increasing of the pomegranates orchards scales not only will increase energy efficiency and productivity but also decrease environmental pollution and damages. Furthermore, like the other agricultural crops productions, in pomegranate production the quantity of non-renewable energy input have been found higher, which arose particularly from chemical fertilizers, chemicals and equipment use. Principally, the conscious use of fertilizers and chemical inputs will ensure more efficient use of energy. According to the results of the energy production function estimation, machinery and diesel use showed negative impacts on energy production. These results are likely related to the excessive use of inputs. Consequently, machinery and diesel inputs should be used more carefully to increase energy productivity and efficiency in the research area. The variability in input use among pomegranate producing farmers was relatively high, determining the need to improve individual farm management abilities.

References

Akcaoz H, Ozcatalbas O, Kizilay H (2009) Analysis of energy use for pomegranate production in Turkey. J Food Agric Environ 72:475–480

Arsham H (2002) Statical thinking for decision making: Revealing facts from figures. http://upmail.ubalt.edu/~harsham/Business-stat/opre504.htm. Accessed 26 May 2002

Astier M, Merlin-Uribe Y, Villamil-Echeverri L, Garciarreal A, Gavito ME, Masera OR (2014) Energy balance and greenhouse gas emissions in organic and conventional avocado orchards in Mexico. Ecol Indic 43:281–287

Baldwin M (2002) Parametric test assumptions. http://users.wmin.ac.uk/~baldwim/2cog205/COG205CH14.html. Accessed 26 May 2002

Barut ZB, Ertekin C, Karaagac HA (2011) Tillage effects on energy use for corn silage in mediterranean coastal of Turkey. Energy 36:5466–5475

Canakci M (2010) Energy use pattern and economic analyses of pomegranate cultivation in Turkey. Afr J Agric Res 5(7):491–499

Canakci M, Akinci I (2006) Energy use pattern analyses of greenhouse vegetable production. Energy 31:1243–1256

Demircan V, Ekinci K, Keener HM, Akbolat D, Ekinci C (2006) Energy and economic analysis of sweet cherry production in Turkey: a case study from Isparta province. Energy Conv Manag 47(13–14):1761–1769

Dyer JA, Desjardins RL (2003) Simulated farm fieldwork, energy consumption and related greenhouse gas emissions in Canada. Biosyst Eng 85(4):503–513

Erdal G, Esengun K, Erdal H, Gunduz O (2007) Energy use and economical analysis of sugar beet production in Tokat province of Turkey. Energy 32:35–41

Erdal H, Esengun K, Erdal G (2009) The functional relationship between energy inputs and fruit yield: a case study of stake tomato in Turkey. J Sustain Agric 33(8):835–847

Ertekin C, Canakci M, Kulcu R, Yaldiz O (2011) Energy use pattern of some tuber plants cultivation over Turkey. XXXIV CIOSTA CIGR V Conference, Efficient and Safe Production Processes in Sustainable Agriculture and Forestry, Vienna

Esengun K, Gunduz O, Erdal G (2007) Input-output energy analysis in dry apricot production of Turkey. Energy Convers Manag 48:592–598

Flores ED, Dela CRSM, Antolin MCR (2016) Environmental performance of farmer-level corn production systems in the Philippines. Int Agric Eng J 18(2):133–143

Goktolga ZG, Gozener B, Karkacıer O (2006) Energy use in peach production: case of tokat province. Gaziosmanpasa Uni J Fac Agric 2:39–44

Gomiero T, Paoletti MG, Pimentel D (2008) Energy and environmental issues in organic and conventional agriculture. CRC Crit Rev Plant Sci 27:239–254

Graefe S, Tapasco J, Gonzalez A (2013) Resource use and greenhouse gas emissions of eight tropical fruits species cultivated in Colombia. Fruits 68(4):303–314

Gundogmus E (2013) Energy use pattern and econometric models of banana production. Actual Probl Econ 3(141):233–243

Hetz EJ (1992) Energy utilization in Chilean Agriculture. Agric Mech Asia Africa Lat Am 23:52–56

Hetz EJ (1998) Energy utilization in fruit production in Chile. Agric Mech Asia Afr Lat Am 29(2):17–20

Houshyar E, Dalgaard T, Tarazkar MH, Jorgensen U (2015) Energy input for tomato production what economy says and what is good for the environment. J Clean Prod 89:99–109

IPCC (2007) Climate change; impacts adaptation and vulnerability. In: Contribution of working group II to the fourth assessment report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge, p 976

Jekayinfa SO, Adebayo AO, Afolayan SO, Daramola E (2013) On-farm energetic of mango production in Nigeria. Renew Energy 51:60–63

Khojastehpour M, Nikkhah A, Hashemabadi D (2015) A comparative study of energy use and greenhouse gas emissions of canola production. Int J Agric Manag Dev 5(1):51–58

Khoshnevisan B, Rafiee S, Omid M, Yousefi M, Movahedi M (2013) Modelling of energy consumption and greenhouse gas emissions in wheat production in Esfahan Province of Iran using artificial neural networks. Energy 52:333–338

Kizilaslan H (2009) Input-output energy analysis of cherries production in Tokat province of Turkey. Appl Energy 86:1354–1358

Knudsen MT, Yu-Hui Q, Yan L, Halberg N (2010) Environmental assessment of organic soybean (Glycine max.) imported from China to Denmark: a case study. J Clean Prod 18:1431–1439

Kocturk M, Engindeniz S (2009) Energy and cost analysis of sultana grape growing: a case study of Manisa, West Turkey. African J Agric Res 4(10):938–943

Komleh SHP, Keyhani A, Sefeedpary SRP (2011) Energy use and economic analysis of corn silage production under three cultivated area levels in Tehran Province of Iran. Energy 36:3335–3341

Lal R (2004) Carbon emission from farm operations. Environ Int 30(7):981–990

Lowry R (1999) Concepts and applications of inferential statistics. http://faculty.vassar.edu /lowry/webtext.html. Accessed 13 Mar 1999

Mandal KG, Saha KP, Ghosh PK, Hati KM, Bandyopadhyay KK (2002) Bioenergy and economic analysis of soybean based crop production systems in Central India. Biomass Bioenergy 23:337–345

Mardani A, Taghavifar H (2016) An overview on energy inputs and environmental emissions of grape production in West Azerbayjan of Iran. Renew Sustain Energy Rev 54:918–924

Mohammadi A, Rafiee S, Mohtasebi S, Rafiee H (2010) Energy inputs-yield relationship and cost analysis of kiwifruit production in Iran. Renew Energy 35:1071–1075

Mohammadi A, Rafiee S, Jafari A, Keyhani A, Mousavi-Avval SH, Nonhebel S (2014) Energy use efficiency and greenhouse gas emissions of farming systems in North Iran. Renew Sustain Energy Rev 30:724–733

Mohammadshirazi A, Akram A, Rafiee S, Avval SHM, Kalhor EB (2012) An analysis of energy use and relation between energy inputs and yield in tangerine production. Renew Sustain Energy Rev 16:4515–4521

Ozturk HH, Ertekin C, Ekinci K, Vardar A (2015) An energy consumption in Turkey’s agriculture. Turkey Agricultural Engineer VIII. Technical Congress, pp 1131–1142

QasemiKordkheili P, Kazemi N, Hemmati A, Taki M (2013) Energy consumption, input–output relationship and economic analysis for nectarine production in Sari Region, Iran. Int J Agric Crop Sci 5(2):125–131

Rafiee S, Avval SHM, Mohammadi A (2010) Modelling and sensitivity analysis of energy inputs for apple production in Iran. Energy 35:3301–3306

Royan M, Khojastehpour M, Emadi B, Mobtaker HG (2012) Investigation of energy inputs for peach production using sensitivity analysis in Iran. Energy Conv Manag 64:441–446

Samavatean N, Rafiee S, Mobli H, Mohammadi A (2011) An analysis of energy use and relation between energy inputs and yield, costs and income of garlic production in Iran. Renew Energy 36:1808–1813

Sefeedpari P, Shokoohi Z, Behzadifar Y (2014) Energy use and carbon dioxide emission analysis in sugarcane farms: a survey on Haft-Tappah sugarcane agro-industrial company in Iran. J Clean Prod 83:212–219

Singh G, Singh S, Singh J (2004) Optimization of energy inputs for wheat crop in Punjab. Energy Convers Manag 45:453–465

Singh J M (2002) On farm use pattern in different cropping systems in Haryana, India. Msc dissertation. Flensburg: Flensburg University, 118 p.

Singh RS, De D, Chandra H (2001) Energy efficiency for wheat production under irrigated condition in Madhya Pradesh. J Asian Econ Rev 43(2):236–244

Singh S, Singh S, Mittal JP, Pannu CJS (1996) Frontier energy use for the cultivation of wheat crop in Punjab. Energy Convers Manag 39:485–491

Strapatsa AV, Nanos GD, Tsatsarelis CA (2006) Energy flow for integrated apple production in Greece. Agric Ecosyst Environ 116:176–180

Tabatabaie SMH, Rafiee S, Keyhani A (2012) Energy consumption flow and econometric models of two plum cultivars productions in Tehran Province of Iran. Energy 44:211–216

Taghavifar H, Mardani A (2015) Prognostication of energy consumption and greenhouse gas emissions analysis of apple production in West Azerbayjan in Iran using artificial neural network. J Clean Prod 87:159–167

TUIK (2016) Turkish statistical institute, statistical data base. www.tuik.gov.tr. Accessed 2 Nov 2016

Uhlin H (1998) Why energy productivity is increasing: an I–O analysis of Swedish agriculture. Agric Syst 56(4):443–465

Yaldiz O, Ozturk HH, Zeren Y, Bascetincelik A (1993) Energy usage in production of field crops in Turkey. 5th International Congress on Mechanization and Energy Use in Agriculture, Izmir, pp 527–536

Yilmaz I, Akcaoz H, Ozkan B (2005) An analysis of energy use and input costs for cotton production in Turkey. Renew Energy 30:145–155

Yilmaz I, Ozalp A, Aydogmus F (2010) Determination of the energy efficiency in dwarf apple production in Antalya province: a case study for Elmali. Akdeniz Uni J Fac Agric 23(2):93–97 (In Turkish)

Yousefi M, Damghani AM, Khoramivafa M (2014) Energy consumption, greenhouse gas emissions and assessment of sustainability index in corn agroecosystems of Iran. Sci Total Environ 493:330–335

Funding

This study was supported by the Scientific Research Administration Unit of Akdeniz University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

A. Ozalp, S. Yilmaz, C. Ertekin and I. Yilmaz declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Ozalp, A., Yilmaz, S., Ertekin, C. et al. Energy Analysis and Emissions of Greenhouse Gases of Pomegranate Production in Antalya Province of Turkey. Erwerbs-Obstbau 60, 321–329 (2018). https://doi.org/10.1007/s10341-018-0380-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-018-0380-z