Abstract

The aim of this study is to optimize energy consumption and reduce greenhouse gas (GHG) emissions in apricot production in Turkey, which has the highest share in apricot production in the world. A data envelopment analysis (DEA) approach was used to distinguish efficient and inefficient farms, based on data collected from 108 apricot farms through face-to-face surveys, in order to determine the optimum level of energy usage. Thus, the amount of GHG emissions and input energy to be saved by using the optimum energy input were determined. The results revealed that the total, pure and scale efficiencies of apricot producing farms were on average 0.797, 0.904 and 0.875, respectively. The rate of energy saving has been determined as 21.78%. This means that the current apricot production amount can be produced using 5349.12 MJ ha−1 less input energy. The highest contribution to total energy savings is made by farmyard manure with 35.24%, followed by irrigation and fertilizer with 32.82%, respectively. In this study, it was determined that the amount of GHG emissions released into the environment from apricot production can be reduced by 19.50% with energy optimization.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Due to the continuous increase in the world population and the need for a healthy diet, it is necessary to use energy efficiently, to reduce fossil fuel use and to increase the use of renewable energy in order to improve current agricultural production in terms of quantity, quality and environment (Baran et al. 2017a). In the food supply chain, energy is used in the whole cycle, starting from the production of the inputs used in agricultural production and extending to the produced products reaching the end consumer. However, the high level of energy dependence in food production worries energy-importing countries in terms of the high impact of energy prices on food prices, as well as food security and national independence.

Between 2004 and 2018, agricultural energy consumption in the European Union (EU) increased by 3%. Simultaneously with this consumption, emissions increased by around 6%. During this period, more than 50% of the energy used in agricultural production in the EU was derived from fuels such as diesel oil and gas oil. Natural gas and electrical energy were also among the important energy sources. Although the share of these resources in total energy consumption decreased, the share of renewable energy resources increased from 5 to 10% over this period. On average, 1 kg of GHG emissions can produce around 2–3 euros in production, unlike in horticultural production where it produces only 0.4 euros in production (Gołasa et al. 2021).

According to results of one study, 16–27% of all anthropogenic emissions were attributable to farms (Shukla et al. 2019). Emissions take place at every stage of agricultural production, from seed preparation to harvesting and storage of products. Recently, the evaluation of sustainability, energy use and GHG emissions of agricultural production systems from environmental aspects have gained increasing importance in many comprehensive studies. Dyer and Desjardins (2018) developed the Fruit and Vegetable Energy (FAVE) model to quantify the energy budget and fossil CO2 emissions. Fieldwork, irrigation, on-farm cooling, farm building maintenance, off-farm transport, N fertilizer supply and farm machinery were taken into account in order to estimate CO2 emission intensity.

The efficient use of energy in fruit cultivation processes is also very important. Therefore, detailed studies have been conducted on energy use for cherry (Demircan et al. 2006; Kizilaslan 2009), apricot (Esengun et al. 2007a), strawberry (Banaeian et al. 2011), peach (Aydin and Akturk 2018), orange, lemon and mandarin (Alishah et al. 2019; Mousavi-Avval et al. 2012; Ozkan et al. 2004), pear (Aydin et al. 2017), almond (Beigi et al. 2016), apple (Akdemir et al. 2012; Ekinci et al. 2019; Gokdogan and Baran 2017), nectarin (Oğuz et al. 2019), mulberry (Baran et al. 2017a), grape (Baran et al. 2017a), kiwifruit (Mohammadi et al. 2010), walnut (Baran et al. 2017c), banana (Akcaoz 2011), pomegranate (Canakci 2010; Ozalp et al. 2018), olive (Gökdoğan and Erdoğan 2018) and plum (Baran et al. 2017b).

Turkey ranks first in the world in apricot production. It also ranks first in dried apricot exports and holds 80% of this market. Important importing countries are Russia, USA, England and Germany. In Turkey, intensive apricot cultivation is carried out in the Malatya (50%) and Elazig, Erzincan, Sivas, İcel (Mut), Antalya, Hatay, Kars and Igdır regions. Approximately 55% of Turkey’s fresh apricot production and 85% of dried apricot production is carried out in Malatya. A very significant part of the dried apricots produced is exported. According to data of the Turkish Statistical Institute for the year 2020, apricot production was carried out on 132,747.8 ha in Turkey. Apricot production is carried out in an area of 84,987.1 ha in Malatya. Of a total of 17,649,835 apricot trees in Turkey, 7,789,791 are located in Malatya. Of a total of 833,398 tons of apricot production, 352,050 tons takes place in Malatya province. The apricot yield is at the level of 47 kg per tree in Turkey and it is at the level of 47 kg per tree in Malatya province. Considering these figures, 64% of apricot production areas and 44.14% of apricot trees in Turkey are located in Malatya province, and 42.24% of Turkey’s total apricot production takes place in Malatya (TSI 2020).

The aim of this study is to optimize energy use and reduce GHG based on data obtained from face-to-face surveys with 108 apricot producers in Malatya province of Turkey. For this purpose, direct, indirect, renewable and non-renewable energy inputs were determined in apricot cultivation. Based on the determined energy inputs/outputs and product yield, energy indicators were calculated. Input usage for efficient and inefficient apricot farms was compared, optimum input levels were determined for inefficient apricot farms and the improvement of energy use and reduction of GHG emissions were discussed.

Materials and Methods

Data Collection

The research data were collected through face-to-face interviews with apricot producers in Malatya province. The number of questionnaires needed for this research was calculated by taking the sampling size into account, in other words, by using the simple random sampling method, the formula for which is given in Eq. 1 (Çiçek and Erkan 1996):

In the formula above, n is sample volume, N is total number of producers (4125 farmers), S is standard deviation, Sx is standard deviation of sample mean, (d/z), d is allowable error and z is z table value. The average apricot production area of the farms in the population was determined as 2.56 ha.

The number of samples to be surveyed in the Malatya region was determined with 5% deviation from the mean and 95% confidence level. In Malatya province (Fig. 1), a face-to-face survey was conducted with a total of 108 apricot producers, and data on energy inputs used in production processes were collected.

Energy Balance Analysis

In this study, energy forms and energy indicators were computed in accordance with the energy equivalence of inputs and outputs, which are presented in Table 1 (Demircan et al. 2006).

Calculation of Energy Equivalence and CO2 Emissions of Inputs

Energy inputs and outputs have been calculated according to Eqs. 2 and 3, respectively:

where Ei,i is energy input for i input per cultivated area (MJ/ha), ii is amount consumed of i input per cultivated area (unit/ha), EEi is energy equivalent of i input (MJ/unit) (Table 2), Eo,i is energy output for i output (MJ/ha) per cultivated area and oi is amount produced of i output per cultivated area (unit/ha).

The required energy equivalent of inputs and outputs used for apricot production are presented in Table 2. The total CO2 emission (TCO2E, kg CO2/ha) pertaining to the consumption of each input per unit production area (ha) has been determined as follows:

where TCO2‑eq is the total CO2 emission per cultivated area (kg CO2‑eq/ha) and CO2‑eq is the CO2‑eq emission of i input (kg CO2‑eq/unit).

Results and Discussion

Energy Inputs/Outputs and Energy Efficiency Indicators

Input–output quantities and energy equivalents for apricot production are given in Table 3. The highest energy input (10,321.52 MJ/ha) in apricot production is realized as a result of diesel fuel consumption. This value corresponds to 42% of the total energy consumption. Indirect energy consumption (6044.35 MJ/ha) resulting from the use of fertilizers ranks second in terms of energy input per unit production area. The share of indirect energy consumption related to fertilizer use in total energy consumption is 24.62% and corresponds to approximately one fourth of total energy consumption. Indirect energy inputs (3497.38 MJ/ha) resulting from the use of machinery in apricot production processes constitute 14.24% of total energy inputs. Indirect energy input related to labour use (265.33 MJ/ha) corresponds to 10.61% of total energy inputs.

The total energy input per unit production area (ha) for apricot production has been determined as 24,554.91 MJ. However, in a study conducted by Külekçi (2016) on apricot production in the Malatya region, the total energy input was determined as 23,265.88 MJ/ha on average. In this study, the total energy input in apricot production for the same region was determined as 1289 MJ/ha higher. On the other hand, in the studies conducted by Gezer et al. (2003) and Gündoǧmuş (2006), the total energy inputs in traditional apricot production in Turkey were determined as 22341 MJ/ha and 22,811.68 MJ/ha, respectively.

As an output in apricot production, a total yield of 7778.43 kg is obtained, of which 7386.87 kg of apricot fruit and 391.56 kg of apricot kernels are obtained from the unit production area (ha). Energy output per unit production area (ha) in apricot production was calculated as 17,559.13 MJ, 14,035.05 MJ for fruit production and 3524.08 MJ/ha for apricot kernel production. According to these calculations, 79.93% of the energy outputs from apricot production are fruits and 20.07% are kernels.

Energy use efficiency indicates the amount of energy gained from the production area versus the amount of energy used in the unit production area (ha). The energy use efficiency in apricot production was determined as 0.72. This means that for apricot production, 0.72 MJ of energy is gained against 1 MJ of energy consumption. However, in some studies on apricot production in Turkey, energy use efficiency was determined as 3.27 (Gezer et al. 2003), 1.45 (Gündoǧmuş 2006) and 1.28 (Esengun et al. 2007b). In this study, the energy use efficiency in apricot production was determined to be lower than the previous studies on this subject.

Energy productivity (MJ/kg) indicates the amount of product (kg) obtained from the production area versus the amount of energy consumed (MJ) per unit production area (ha). Energy productivity in apricot production was determined as 0.30. In this case, 0.30 kg of product is produced for 1 MJ of energy consumption for apricot production.

The concept of energy concentration or certain energy (MJ per mass of food produced) is proposed to assess efficient energy use in the food chain. Specific energy (MJ/kg) is the inverse of energy productivity and indicates the amount of energy consumed (MJ) versus the amount of product (kg) obtained from the unit production area (ha). The specific energy in apricot production was determined as 3.32. In this case, 3.32 MJ of energy is consumed for 1 kg of apricot production.

Net energy (MJ) demonstrates the net energy amount (MJ) achieved from the unit production area, after the amount of energy consumed for production is deducted from the amount of energy obtained from the unit production area. The net energy in apricot production is negative and determined as −6995.78 MJ. In this case, 6995.78 MJ less (17,559.13 MJ) energy is gained for apricot production, against a total energy consumption of 24,554.91 MJ per ha.

Technical and Scale Efficiencies of Apricot Farms

In this section, the contents of technical efficiency (TE), pure technical efficiency (PTE) and scale efficiencies (SE) scores that have been obtained by executing the most generic data envelopment analysis (DEA) model, namely, Charnes–Cooper–Rhodes (CCR), were provided and discussed. Table 4 provides the frequency distribution of TE, PTE and SE scores and their descriptive statistics. The mean values of TE, PTE and SE have been found to be 0.797, 0.904 and 0.875, respectively. It was found that the minimum values of TE, PTE and SE were 0.326, 0.514 and 0.427, respectively. From Table 4, it was observed that TE scores range between 0.326 and 1, and their mean and standard deviation (SD) is 0.214.

It is seen that the mean value of the PTE score is 0.904 (with SD of 0.138) and varies between 0.514 and 1. The results show that the 10.6 points of technical inefficiency in Malatya apricot farms is due to inappropriate management practices originating from farm managers and occurring in the organization of inputs. The remainder of the technical inefficiency is due to the farm operating below optimal scale sizes. This means that the majority of technical inefficiency in Malatya apricot farms is due to pure technical inefficiency and a relatively small part of it is due to scale inefficiency.

SE gives the efficiency resulting from the scale size of the farms. It is calculated as the ratio of TE to PTE. A value equal to 1 indicates that the farm is operating at the most efficient scale size (MPSS), where constant returns to scale equal variable returns to scale. This magnitude is the point at which the long-run average cost curve is minimum. An SE of less than 1 means that the farm is operating at a smaller than optimal scale size. In Table 4, it was determined that the mean SE score of apricot farms was 0.875 (with 0.161 SD) and ranged from 1 to 0.427.

Comparison of Input and Output Energies of Efficient and Inefficient Apricot Farms

Input and output energies of efficient and inefficient apricot farms are compared in Table 5. The total energy input is at the level of 19,663.02 MJ/ha for productive farms, while it is at the level of 26,521.99 MJ/ha for inefficient farms. Energy inputs of inefficient farms are 34.88% higher than efficient farms. This indicates that total energy inputs can be reduced by about 35% in inefficient farms. The highest difference in energy input between efficient and inefficient farms occurs in the use of irrigation water, farmyard manure (FYM) and machinery, respectively. These inputs specified in inefficient farms are used in higher amounts at the rates of 149.61%, 141.59% and 99.8%, respectively. Energy inputs related to the use of chemical fertilizers and biocides in inefficient farms are higher at 58.02% and 19.56%, respectively, compared to efficient farms. The lowest difference (9.75%) in energy input between efficient and unproductive farms occurs in diesel fuel consumption. The energy input for diesel fuel consumption is 9659.71 MJ/ha for efficient farms and 10,601.49 MJ/ha for inefficient farms.

The total energy output is 24,823.5 MJ/ha for efficient farms and 16,146.20 MJ/ha for inefficient farms. The energy output of inefficient farms is 34.96% lower than efficient farms. This indicates that the total energy output on inefficient farms can be increased by about 35%. The energy output for apricot fruit production is 17,873.22 MJ/ha in efficient farms, while it is 13,016.78 MJ/ha in inefficient farms. The energy output for apricot fruit production in inefficient farms is 27.17% lower than in efficient farms. This indicates that apricot yield can be increased by 27.17% in farms that are inefficient in terms of fruit production.

Optimum Energy Requirement and Energy Saving for the Apricot Production

Optimum energy requirements and energy savings for apricot production are given in Table 6.

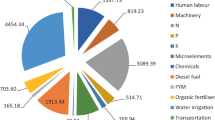

While the optimum energy requirement in apricot production is 19,205.8 MJ/ha, in the current situation 24,554.91 MJ/ha energy is consumed. In this case, there is an opportunity to save a total of 5349.12 MJ/ha of energy for apricot production. This amount corresponds to the level of 21.78% as a share. In other words, there is a potential to save 21.78% of the total inputs used in apricot production in the Malatya region. The input items with the highest saving potential in input use are FYM (35.24%), irrigation water (33.00%) and chemical fertilizer (32.82%), respectively. In other words, there is an opportunity to save around one third in the use of water and chemical/farm fertilizers for apricot production. This means that approximately the same amount of savings can be achieved from GHG emissions. Saving potentials in labour, biocides and machinery usage are 22.59%, 21.97% and 18.04%, respectively. The input with the lowest saving potential for apricot production is the use of diesel fuel (15.87%). While the optimum energy output for apricot production is 18,514.1 MJ/ha, currently 17,559.13 MJ/ha energy is gained. In this case, there is an opportunity to gain a total of 954.97 MJ/ha of energy for apricot production.

The variation of the energy saving rates that can be achieved depending on the total inputs used in apricot production is given in Fig. 1. The highest energy savings can be achieved in the use of chemical fertilizers, with a rate of 37.09%. The second highest energy saving input is the use of diesel fuel (30.63%). In this case, there is the potential to save the highest rates from diesel fuel consumption in direct energy use and chemical fertilizer consumption in indirect energy use for apricot production. The savings rates that can be achieved from the use of machinery, labour and biocides were determined as 11.8%, 11% and 6.79%, respectively. In the total energy savings that can be achieved for apricot production, FYM is the input with the lowest saving potential (0.40%).

Improvement of Energy Indicators in Apricot Production

Improvement potential of energy indicators in apricot production are given in Table 7. In apricot production, 52.64% (12,926.85 MJ/ha) of the current energy use is direct energy inputs, 45.84% (11,256.21 MJ/ha) is indirect energy inputs, 10.86% (2666.17 MJ/ha) is renewable energy inputs and 87.63% (21,516.89 MJ/ha) is non-renewable energy inputs. Non-renewable energy inputs constitute the highest rate (87.63%) of energy consumption in apricot production, and renewable energy inputs constitute the lowest rate (10.86%). On the other hand, in the research conducted by Esengun et al. (2007b) on apricot production in the same region, it was determined that 75% of the total energy inputs consisted of non-renewable and 25% renewable energy inputs. The rate of renewable energy consumption (87.63%) determined in this study is higher than the rate (75%) determined by Esengun et al. (2007b), while the rate of non-renewable energy consumption (10.86%) is lower. The distribution of energy inputs in the production of fruits other than apricots in Turkey were found to be 34.48% direct, 54.91% indirect and 16.34% renewable for sweet cherry (Demircan et al. 2006), 30% direct and 70% indirect for kiwi (Mohammadi et al. 2011) and 47.17% direct, 52.83% indirect, 15.38% renewable and 74.62% non-renewable energy inputs for apple. In this study, the rates of non-renewable and direct energy inputs determined for apricot production (87.63% and 52.74%) were determined to be higher than the values determined in the above-mentioned studies for the production of various fruits, while the share of renewable energy inputs (10.86%) was determined to be lower.

While the optimum use amount for direct energy in apricot production processes is 10,700 MJ/ha, currently 12,926.85 MJ/ha energy is used. In this case, there is a potential to reduce direct energy consumption by 17.23%. The main input that can directly improve energy consumption in apricot production is the use of diesel fuel. On the other hand, while the optimum use amount for indirect energy in apricot production processes is 8256.68 MJ/ha, currently 11,256.21 MJ/ha is used. There is a 26.65% improvement potential in indirect energy consumption. The main applications that can improve indirect energy consumption in apricot production are the use of chemical fertilizers and machinery. There is an improvement potential of 22.88% and 21.45%, respectively, in renewable and non-renewable energy uses in apricot production.

While the optimum energy use efficiency in apricot production processes was 0.96, it was determined as 0.72 in the current situation. In this case, there is a 34.8% improvement potential in energy use efficiency. In terms of optimum energy productivity, 0.73 kg of apricots should be produced for 1 MJ of energy consumption, while 0.30 kg of apricots are currently produced. In this case, there is the potential to improve current energy productivity by 142.92%. In terms of optimum specific energy, while it is necessary to consume 1.37 MJ for 1 kg of apricot production, 3.32 MJ is currently consumed. In this case, there is the potential to improve the available specific energy by 58.83%. Although the optimum net energy is −691.7 MJ, it is currently determined as −6995.78 MJ. It has the potential to improve the current net energy value by 90.11%.

GHG Emission Mitigation in Apricot Production

Optimum and current GHG emissions and GHG mitigations in apricot production are given in Table 8. Currently, total GHG emissions in apricot production are calculated as 1653.6 kg CO2‑eq/ha. For the production of fruits other than apricots in Turkey, GHG emissions were found to be 1730 kg CO2‑eq/ha for pomegranates (Ozalp et al. 2018) and 1464.07 kg CO2‑eq/ha and 1344.27 kg CO2-eq/ha for apples in conventional and organic production, respectively (Ekinci et al. 2019). In the present study, total GHG emissions determined for apricot production (1653.6 kg CO2‑eq/ha) are lower than the value determined for pomegranate production by Ozalp et al. (2018) and higher than the values determined for apple production by Ekinci et al. (2019).

The concept of the GHG intensity (kg CO2‑eq per mass of food produced) is introduced to measure sustainability in the food chain. Based on the fruit yield (7386.87 kg) and GHG emissions (1653.6 kg CO2‑eq/ha) taken from the unit production area (ha) in apricot production, it was determined that 0.224 kg CO2‑eq GHG emissions was realized for 1 kg of apricot fruit production. For 1 kg of pomegranate production, 0.0881 kg of CO2‑eq GHG emissions occur (Ozalp et al. 2018). In this case, 0.1359 kg CO2‑eq more GHG emissions occur for 1 kg of apricot fruit production compared to 1 kg of pomegranate production. Therefore, it is necessary to increase the use of renewable energy inputs in apricot production.

While the total optimum GHG emissions per hectare (ha) in apricot production is 322.42 kg CO2‑eq, it is currently 1653.6 kg CO2‑eq. There is a potential to reduce total GHG emissions by 1331.18 kg CO2‑eq per unit production area (ha). In this case, there is the potential to reduce total GHG emissions by 19.5%. Currently, the highest greenhouse gas emissions occur in the use of diesel fuel with a value of 505.91 kg CO2‑eq/ha. While the optimum GHG emissions resulting from the use of diesel fuel are 80.29 kg CO2‑eq/ha, it is currently 505.91 kg CO2‑eq/ha. In this case, there is a potential to reduce GHG emissions related to the use of diesel fuel by 425.61 kg CO2‑eq per hectare and by 84.13%. In terms of GHG emissions, labour and use of machinery rank second and third with 478.54 kg CO2‑eq/ha and 248.31 kg CO2‑eq/ha, respectively. There is the potential to reduce GHG emissions related to machine use by 81.96% and GHG emissions related to labour use by 77.44%. While the optimum GHG emissions related to the use of chemical fertilizers in apricot production are 42.21 kg CO2‑eq/ha, it is currently determined as 128.17 kg CO2‑eq/ha. There is a potential to reduce GHG emissions related to the use of chemical fertilizers at the level of 85.96 kg CO2‑eq/ha and 67.07% in terms of rate. It has the potential to reduce GHG emissions resulting from the use of phosphorus, nitrogen and potassium fertilizers by 71.26%, 66.82% and 58.84%, respectively. Biocides have the potential to reduce GHG emissions resulting from the use of irrigation water and FYM by 78.61%, 67% and 64.4%, respectively.

The variation of GHG savings rates that can be achieved depending on the inputs used in apricot production is given in Fig. 2. The highest emissions savings will be achieved in the use of diesel fuel, and its share in total emission savings is at the level of 31.97%. The share of emissions savings related to the use of labour within the total emissions savings is 27.83%. In this case, emissions are the second highest input labour use that can be saved. In this case, there is the potential to save the highest rates from GHG emissions related to diesel fuel consumption in direct energy use in apricot production and from GHG emissions related to labour use in indirect energy use. The share of emission savings that can be achieved from the use of machinery, chemical fertilizers, irrigation water and biocides were determined as 15.29%, 6.46% and 5.05%, respectively. The share of the saving rate that can be achieved from the GHG emissions resulting from the use of nitrogen fertilizer in apricot production is 5.76%. The input with the lowest GHG emissions saving potential (0.05%) is FYM.

Conclusions

Most energy saving measures in perennial crop production, such as fruit production, is related to fertilization, crop protection and field applications. By reducing the direct and indirect energy inputs used in apricot production, some general measures can be taken to provide energy efficiency and reduce GHG emissions: Using tractors and other tools/machines with the power suitable for the job; reducing fuel use in soil tillage and other field applications; optimizing the use of tractors and machines in garden applications; using fuel-saving power sources and carrying out their maintenance regularly; applying reduced or no tillage cultivation; using transportation vehicles rationally; ensuring the compatibility of tire sizes/pressure and front axle weight for agricultural implements and machinery; using vehicles used in production together (tool/machine combinations); improving the use of common machinery; applying fertilizer according to soil fertility and the presence of plant nutrients in the soil; reducing the use of chemical fertilizers; using multi-component (composite) fertilizers; dividing the fertilizer dose to be applied and to use it effectively; applying advanced fertilizer management related to nitrogen fertilization; increasing the use of organic fertilizers; applying organic fertilization based on nitrogen fertilizer; applying alternative food sources such as organic/green fertilizers and bioactive microorganisms; reducing pesticide use; increasing bioactive microorganism/insect applications; using the inputs used in production according to soil fertility and plant nutrient intake; applying water demand management and reducing water losses; applying energy and water-saving drip irrigation; producing high-yielding varieties; applying precision agriculture applications with variable ratio; regarding energy consumption, establishing a monitoring system such as inspection-control-data collection and conducting scientific research and market research for innovative energy-saving solutions in production.

References

Akcaoz H (2011) Analysis of energy use for banana production: A case study from Turkey. Afr J Agric Res 6(25):5618–5624

Akdemir S, Akcaoz H, Kizilay H (2012) An analysis of energy use and input costs for apple production in Turkey. J Food Agric Environ 10:473–479

Alishah A, Motevali A, Tabatabaeekoloor R et al (2019) Multiyear life energy and life cycle assessment of orange production in Iran. Environ Sci Pollut Res 26:32432–32445. https://doi.org/10.1007/s11356-019-06344-y

Aydin B, Akturk D (2018) Energy use efficiency and economic analysis of peach and cherry production regarding good agricultural practices in Turkey: A case study in Çanakkale province. Energy 158:967–974. https://doi.org/10.1016/j.energy.2018.06.087

Aydin B, Akturk D, Ozkan E (2017) Comparatively energy use efficiency and economic analysis in pear farming: Case of Thrace Region. Turkish J Agric Sci Technol 5(9):1072–1079. https://doi.org/10.24925/turjaf.v5i9.1072-1079.1288

Banaeian N, Omid M, Ahmadi H (2011) Energy and economic analysis of greenhouse strawberry production in Tehran province of Iran. Energy Convers Manag 52:1020–1025

Baran MF, Lüle F, Gökdoğan O (2017a) Energy input-output analysis of organic grape production: a case study from Adiyaman Province. Erwerbs-Obstbau. https://doi.org/10.1007/s10341-017-0322-1

Baran MF, Oğuz HI, Gökdoğan O (2017b) Determiniation of energy input-output analysis in plum (Prunus domestica L.) production. Erwerb Obstbau. https://doi.org/10.1007/s10341-017-0332-z

Baran MF, Oğuz Hİ, Gökdoğan O (2017c) Determining the energy usage efficiency of walnut (Juglans Regia L.) cultivation in Turkey. Erwerbs-Obstbau 59(1):77–82. https://doi.org/10.1007/s10341-016-0301-y

Beigi M, Torki-Harchegani M, Ghanbarian D (2016) Energy use efficiency and economical analysis of almond production: A case study in Chaharmahal-Va-Bakhtiari province, Iran. Energy Effic 9:745–754

Canakci M (2010) Energy use pattern and economic analyses of pomegranate cultivation in Turkey. Afr J Agric Res 5(7):491–499

Çiçek A, Erkan O (1996) Research and sampling method in agricultural economics vol 12. Gaziosmanpaşa University, Agricultural Faculty Press

Demircan V, Ekinci K, Keener HM et al (2006) Energy and economic analysis of sweet cherry production in Turkey: a case study from Isparta province. Energy Convers Manag 47:1761–1769

Dyer JA, Desjardins RL (2006) Carbon dioxide emissions associated with the manufacturing of tractors and farm machinery in Canada. Biosyst Eng 93(1):107–118

Dyer JA, Desjardins RL (2018) Energy use and fossil CO2 emissions for the Canadian fruit and vegetable industries. Energy Sustain Dev 47:23–33. https://doi.org/10.1016/j.esd.2018.08.006

Ekinci K, Demircan V, Atasay A, Karamursel D, Sarica D (2019) Energy, economic and environmental analysis of organic and conventional apple production in Turkey. Erwerbs-Obstbau 62:1–12. https://doi.org/10.1007/s10341-019-00462-0

Esengun K, Erdal G, Gundugmus O et al (2007a) An economic analysis and energy use in stake-tomato production in Tokat province of Turkey. Renew Energy 32:1873–1881

Esengun K, Gündüz O, Erdal G (2007b) Input-output energy analysis in dry apricot production of Turkey. Energy Convers Manag 48:592–598. https://doi.org/10.1016/j.enconman.2006.06.06

Gezer I, Acaroglu M, Haciseferoǧullari H (2003) Use of energy and labour in apricot agriculture in Turkey. Biomass Bioenergy 24(3):215–219. https://doi.org/10.1016/S0961-9534(02)00116-2

Gokdogan O, Baran MF (2017) Bestimmung der energienutzungseffizienz bei der produktion einiger Apfelsorten in der Türkei: Eine fallstudie in der Region Eğirdir. Erwerbs-Obstbau 59:13–18. https://doi.org/10.1007/S10341-016-0290-X

Gökdoğan O, Erdoğan O (2018) Beurteilung der Energiebilanz bei der ökologischen Erzeugung von Oliven (Olea Europaea L.) in der Türkei: Eine Fallstudie aus der Region Aydın-Karpuzlu. Erwerbs-Obstbau 60:47–52. https://doi.org/10.1007/S10341-017-0338-6

Gołasa P, Wysokiński M, Bieńkowska-gołasa W et al (2021) Sources of greenhouse gas emissions in agriculture, with particular emphasis on emissions from energy used. Energies 14:3784. https://doi.org/10.3390/en14133784

Graefe S, Tapasco J, Gonzalez A (2013) Resource use and GHG emissions of eight tropical fruit species cultivated in Colombia. Fruits 68:303–314. https://doi.org/10.1051/fruits/2013075

Gundogmus E (2006) Energy use on organic farming: A comparative analysis on organic versus conventional apricot production on small holdings in Turkey. Energy Convers Manag 47(18–19):3351–3359

Houshyar E, Mahmoodi-Eshkaftaki M, Azadi H (2017) Impacts of technological change on energy use efficiency and GHG mitigation of pomegranate: Application of dynamic data envelopment analysis models. J Clean Prod 162:1180–1191. https://doi.org/10.1016/j.jclepro.2017.06.152

Khoshnevisan B, Shariati HM, Rafiee S et al (2013) Comparison of energy consumption and GHG emissions of open field and greenhouse strawberry production. Renew Sustain Energy Rev 29:316–324

Kizilaslan H (2009) Input-output energy analysis of cherries production in Tokat province of Turkey. Appl Energy 86:1354–1358. https://doi.org/10.1016/j.apenergy.2008.07.009

Külekçi M (2016) Determination of efficiency in apricot production in Elazig province. J Agric Fac Gaziosmanpasa Univ 33:130–130. https://doi.org/10.13002/jafag967

Lal R (2004) Carbon emission from farm operations. Environ Int 30:981–990. https://doi.org/10.1016/j.envint.2004.03.005

Mohammadi A, Rafiee S, Mohtasebi SS, Rafiee H (2010) Energy inputs-yield relationship and cost analysis of kiwifruit production in Iran. Renew Energy 35:1071–1075. https://doi.org/10.1016/j.renene.2009.09.004

Mohammadi A, Rafiee S, Mohtasebi SS, Mousavi Avval SH, Rafiee H (2011) Energy efficiency improvement and input cost saving in kiwifruit production using data envelopment analysis approach. Renew Energy 36:2573–2579. https://doi.org/10.1016/j.renene.2010.10.036

Mohammadi A, Rafiee S, Jafari A et al (2014) Energy use efficiency and greenhouse gas emissions of farming systems in north Iran. Renew Sustain Energy Rev 30:724–733. https://doi.org/10.1016/J.RSER.2013.11.012

Mousavi-Avval SH, Mohammadi A, Rafiee S, Tabatabaeefar A (2012) Assessing the technical efficiency of energy use in different barberry production systems. J Clean Prod 27:126–132. https://doi.org/10.1016/j.jclepro.2012.01.014

Oğuz Hİ, Erdoğan O, Gökdoğan O (2019) Energy Use Efficiency and Economic Analysis of Nectarine (Prunus persica var. nucipersica) Production: A Case Study from Niğde Province. Erwerbs-Obstbau 61(4):323–329. https://doi.org/10.1007/s10341-019-00434-4

Ozalp A, Yilmaz S, Ertekin C, Yilmaz I (2018) energy analysis and emissions of greenhouse gases of pomegranate production in Antalya Province of Turkey. Erwerbs-Obstbau 60:321–329. https://doi.org/10.1007/S10341-018-0380-Z

Ozkan B, Akçaöz H, Karadeniz F (2004) Energy requirement and economic analysis of citrus production in Turkey. Energy Convers Manag 45:1821–1830. https://doi.org/10.1016/j.enconman.2003.10.002

Pimentel D, Pimentel MH (2007) Food energy and society. CRC Press, Boca Raton https://doi.org/10.1201/9781420046687

Shukla P, Skeg J, Buendia E et al (2019) Climate change and land: an IPCC special report on climate change, desertification, land degradation, sustainable land management, food security, and greenhouse

TSI (2020) Turkish Statistic Institution

Funding

No funding was received to conduct this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

S. Hayran, R. Dönmez, T. Karabacak and M. Külekçi declare that they have no competing interests.

Rights and permissions

Springer Nature oder sein Lizenzgeber hält die ausschließlichen Nutzungsrechte an diesem Artikel kraft eines Verlagsvertrags mit dem/den Autor*in(nen) oder anderen Rechteinhaber*in(nen); die Selbstarchivierung der akzeptierten Manuskriptversion dieses Artikels durch Autor*in(nen) unterliegt ausschließlich den Bedingungen dieses Verlagsvertrags und dem geltenden Recht.

About this article

Cite this article

Hayran, S., Dönmez, R., Karabacak, T. et al. The Reduction of Greenhouse Gas Emissions and Energy Optimization in Apricot Production in Turkey. Erwerbs-Obstbau 65, 1207–1216 (2023). https://doi.org/10.1007/s10341-022-00767-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-022-00767-7