Abstract

The purpose of this research was to perform the energy efficiency and GHG emissions of persimmon production. The data supplied from research were collected from 72 different farms by face to face surveys with simple random sampling method. According to the research findings, the energy inputs in persimmon production were computed respectively as 20,950.42 MJ ha−1 (44.04%) chemical fertilizers, 6370.74 MJ ha‑1 (13.39%) chemicals energy, 5200.08 MJ ha−1 (10.93%) human labour energy, 3479.76 MJ ha−1 (7.31%) machinery energy, 3376.80 MJ ha−1 (7.10%) electricity energy, 3029.48 MJ ha−1 (6.37%) diesel fuel energy, 2608.20 MJ ha−1 (5.48%) irrigation water energy and 2556.00 MJ ha−1 (5.37%) farmyard manure energy. Energy use efficiency, specific energy, energy productivity and net energy calculations were computed respectively as 1.57, 1.21 MJ kg−1, 0.82 kg MJ−1 and 26,908.52 ha−1. The consumed total energy input in persimmon production can be classified as 29.88% direct, 70.12% indirect, 21.79% renewable and 78.21% non-renewable. Total GHG emissions were calculated as 4440.00 kgCO2‑eqha−1. The results of the study showed that the share of human labor in total GHG emissions was the highest (1857.17 kgCO2‑eqha−1), chemical fertilizier (1698.85 kgCO2‑eqha−1) and herbicide (1177.35 kgCO2‑eqha−1) held the second and third.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Persimmon is a fleshy fibrous tropical, deciduous fruit belonging to Ebenaceae family. It is commonly cultivated in warm regions of the world including China, Korea, Japan, Brazil, Turkey, and Italy (Itamura et al. 2005; Yokozawa et al. 2007). While persimmon (Diospyros kaki L.) is known as “Trabzon persimmon” in Turkey, it is also known as “Asian” or “Japanese apple” in South America (Çelen 2019; Karakasova et al. 2013).

Diospyros sp., to which persimmon is a member, includes approximately 400 varieties, most of them are found naturally in tropic and subtropical climate zones and only 4 varieties are commercially grown (Spongberg 1977; Kitagawa and Glucina 1984; Erdoğan et al.).

Persimmon fruit contains 79% water, 0.7% pectin, 0.4% protein, and crude fiber (Radha and Mathew 2007). Vitamin C contents vary from 7.5 to 70 mg per 100 g (1 oz = 28.34952 g) of the fruit flesh depending upon the variety (Kondo et al. 2004). Some varieties are as rich as satsuma mandarin and strawberry in their vitamin C contents (Nakagawa et al. 2008). It also contains various bioactive substances (Table 1) like vitamins (A, B complex, C, E, and K) and minerals (zinc, copper, iron, magnesium, calcium, and phosphorus) that are valuable for the proper physiology of human health (Shazia et al. 2016; USDA 1998). Proanthocyanidins (PAs) are potent antioxidants and show 20 and 50 times more activity than vitamins C and E, respectively (Kawase et al. 2003).

According to 2014 data, the total amount of persimmon production in the world was 5,190,624 tons and the biggest producers were China (3,803,564 tons), Korea (428,363 tons), Spain (245,000 tons), Japan (240,600 tons), Brazil (182,290 tons), Azerbaijan (140,405 tons), Italy (39,149 tons) (Anonymous 2020b). Turkey’s total persimmon production was 38,043 tons in 2017 and production was mostly in Adana (9100 tons), Izmir (4179 tons), Mersin (3403 tons) Hatay (3172 tons) and Adıyaman (2991 tons) provinces. The persimmon growing area in Adıyaman (197.5 ha) makes up approximately 8.2% of the total persimmon production area in Turkey (2393.2 ha) and the production amount makes up around 7.9% of the total production (TUIK 2018).

Energy analysis of agricultural production is a significant approach for the classification and definition of the agricultural systems in terms of energy consumption (Sabah 2010; Karaağaç et al. 2019). Energy efficiency improvement is a key indicator for sustainable energy management; for enhancing the energy efficiency it must be attempted to increase the production yield or to conserve the energy input without affecting the yield level. Intensive energy consumption as well as reducing the known energy resources is the key factor to develop the philosophy of optimum energy consumption. Optimum use of energy helps to achieve increased production and contributes to the economy, profitability and competitiveness of agricultural sustainability of rural communities (Singh Singh et al. 2004; Mousavi-Avval et al. 2011). A greenhouse gas (GHG) is a gas in the atmosphere that absorbs and spreads radiation within the thermal infrared range. The greenhouse gas (GHG) emissions of agriculture come from several sources such as machinery, diesel fuel, chemical fertilizers, chemicals and electricity. So, the rise in energy inputs can cause a rise in the greenhouse (GHG) emissions in agricultural action (Nabavi-Pelesaraei et al. 2016).

Many studies were done on energy efficiency in several types of agricultural products. such as on energy efficiency activities of almond (Beigi et al. 2016), apple (Aydın et al. 2019; Çelen et al. 2017), olive (Gökdoğan and Erdoğan 2018), pear (Aydın et al. 2017), vetch (Baran 2017), walnut (Baran et al. 2017), groundnut (Baran et al. 2019), nectarine (Oğuz et al. 2019), citrus (Yilmaz and Aydin 2020), mandarin (Karabat and Aydın 2018). Several studies on greenhouse gas emissions were done on horticulture crops such as olive (Rajaeifar et al. 2014), nectarine (Qasami-Kordkheili and Nabavi-Pelesaraei 2014), peach (Nikkhah et al. 2017), pomegranate (Özalp et al. 2018), apple (Taghavifar and Mardani 2015), watermelon (Nabavi-Pelesaraei et al. 2016), grape (Mardani and Taghavifar 2016), strawberry (Khoshnevisan et al. 2013) and different fruits (Eren et al. 2019).

Although many experimental studies were defined on energy balance on agriculture, there was no study on the energy use efficiency and greenhouse gas emissions (GHG) of persimmon production in Turkey. In this study, it has been aimed to define the energy use efficiency and greenhouse gas emissions (GHG) of persimmon production in Adıyaman province in Turkey.

Materials and Methods

Description of the Study Area

Southern part of the Adıyaman province is hot and dry during summer months and rainy and cold during winter months. Central Adıyaman is located at 37° 45′ north latitude and 38° 16′ eastern longitude. Adıyaman’s elevation from sea level is 672 m. The daily difference between highest temperature and lowest temperature is about 10 °C (Anonymous 2016). This research has been performed for 2017–2018 production season in Adıyaman province of Turkey in dry conditions in 2018. The data supplied from research have been collected from 72 different farms by face to face surveys with simple random sampling method proposed by Çiçek and Erkan (1996). In the formula (1) n : is the required sample size; N : the number of total enterprises in the area; s, standard deviation; t: the reliability coefficient (1.96 which represents 95% confidence); d: acceptable error (5% deviation). The acceptable error value has been defined to be 5%, and the sample size has been computed as 72 farms, to achieve 95% reliability.

By calculating the agricultural input energies and output energies were used in persimmon production and the energy use efficiency was determined. Human labour energy, machinery energy, farmyard manure energy, chemical fertilizers energy, chemicals energy Electricityity energy, irrigation energy and diesel fuel energy were computed as inputs and yield was computed as output.

The units shown in Tables 2 and 3 are the inputs of persimmon production. Previous energy balance and greenhouse gas emissions (GHG) studies were evaluated when defining the energy equivalent and greenhouse gas emissions (GHG) coefficients.

The total energy equivalent was computed by adding energy equivalents of all inputs in MJ unit. In order to compute the energy input-output in persimmon production, energy use efficiency, energy productivity, specific energy and net energy were computed by using the following formulates (Mandal et al. 2002; Mohammadi et al. 2008, 2010).

Koçtürk and Engindeniz (2009) reported that, the input energy is also classified into direct and indirect, and renewable and non-renewable forms. The indirect energy consists of pesticide and fertilizer, while the direct energy includes human and animal labour, diesel and Electricityity used during the production process. On the other hand, non-renewable energy includes petrol, diesel, Electricityity, chemicals, fertilizers, machinery, while renewable renewable energy consists of human and animal labour (Mandal et al. 2002; Singh et al. 2003).

Energy use efficiency was conducted by using Microsoft Excel program; before, the results were tabulated Table 4 and related to persimmon production input-output values and the relevant calculations were provided in Table 4. Energy efficiency calculations in persimmon production were given in Table 5, energy inputs in the forms of energy for persimmon production were given in Table 6.

Greenhouse gas (GHG) emissions of inputs in persimmon production were given in Table 7. The greenhouse emissions (GHG) (kg CO2‑eqha−1) united with the inputs to growing 1 ha of persimmon were calculated as following, adapted by (Hughes et al. 2011).

∑ Where R(i) is the application rate of input, I (unitinputha−1), and EF (i) is the GHG emission coefficient of input i (kg CO2‑equnitinput−1). Table 3 is the GHG emissions coefficients of agricultural inputs. However, an index is determined to evaluate the amount of emitted kg CO2‑eq per kg yield as following adapted Houshyar et al. (2015) and Khoshnevisan et al. (2014). IGHG is GHG ratio, and Y is the yield as kg per ha.

Results and Discussion

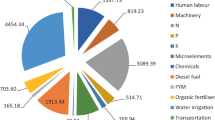

During the studies in the persimmon producers, the average amount of persimmon produced per hectare for 2018 production seasons was computed as 39200 kg. As it can be seen in Table 4, energy inputs in persimmon production were as follows, respectively: 20,950.42 MJ ha−1 (44.04%) chemical fertilizers, 6370.74 MJ ha−1 (13.39%) chemicals energy, 5200.08 MJ ha−1 (10.93%) human labour, 3479.76 MJ ha−1 (7.31%) machinery energy, 3376.80 MJ ha−1 (7.10%) electricity energy, 3029.48 MJ ha−1 (6.37%) diesel fuel energy, 2608.20 MJ ha−1 (5.48%) irrigation water energy and 2556.00 MJ ha−1 (5.37%) farmyard manure energy. Total input energy was computed as 47,571.48 MJ ha−1. Production output persimmon yield was computed as 74,480.00 MJ ha−1.

Persimmon yield, energy input, energy output, energy efficiency, specific energy, energy productivity and net energy in Persimmon production were computed as 39200 kg ha−1, 475,571.48 MJ ha−1, 74,480.00 MJ ha−1, 1.57, 1.21 MJ kg−1, 0.82 kg MJ−1 and 26,908.52 MJ ha−1, respectively (Table 5). In previous agricultural studies, Kaltsas et al. (2007) determined (organic olive) energy output/input ratio as 3.31, Gündoğmuş (2006) determined (organic apricot) energy output/input ratio as 1.45, and Gökdoğan et al. (2017) determined (organic mulberry) energy output/input ratio as 5.62, Beigi et al. (2016) determined (walnut) energy output-input ratio as 0.62–1.12, Baran et al. (2017) determined (walnut) energy output-input ratio as 0.61 and Gökdoğan and Erdoğan (2018) determined (olive) energy output-input ratio as 2.72.

The consumed total energy input in persimmon production was classified as 29.88% direct, 70.12% indirect, 21.79% renewable and 78.21% non-renewable (Table 6). Similarly, in previous agricultural studies, almond (Beigi et al. 2016), walnut (Baran et al. 2017), olive (Gökdoğan and Erdoğan 2018) the ratio of non-renewable energy was higher than the ratio of renewable energy.

The results of greenhouse gas (GHG) emissions of persimmon production were tabulated in Table 7. The total GHG emissions were calculated as 4440.00 kg CO2‑eqha−1. The results of the study showed that the share of human labor in total GHG emissions was the highest (1857.17 kg CO2‑eqha−1), chemical fertilizier (1698.85 kg CO2‑eqha−1) and herbicide (1177.35 kg CO2‑eqha−1) held the second and third. GHG ratio (per kg) was determined as 0.18. In similar a study, (Taghavifar and Mardani 2015) calculated the total GHG emission of apple production as 1200 kg CO2‑eqha−1, (Özalp et al. 2018) calculated the total GHG emission of pomegranate production as 1730 kg CO2‑eqha−1 and (Mardani and Taghavifar 2016) calculated the total GHG emission of grape production as 860 kg CO2‑eqha−1.

Conclusion

As a result, in this study, the energy efficiency of persimmon production was determined. According to the results, the profitability of persimmon production was determined to be low in terms of energy efficiency (1.57). The energy inputs in persimmon production were computed, respectively, as 20,950.42 MJ ha−1 (44.04%) chemical fertilizers, 6370.74 MJ ha‑1 (13.39%) chemicals energy, 5200.08 MJ ha−1 (10.93%) human labour energy, 3479.76 MJ ha−1 (7.31%) machinery energy. Total input energy was computed as 47,571.48 MJ ha−1. Energy values of yield were computed as 74,480.00 MJ ha−1. Energy use efficiency, specific energy, energy productivity and net energy calculations were computed respectively as 1.57, 1.21, MJ kg−1, 0.82 kg MJ−1 and 26,908.52 MJ ha−1. The consumed total energy input in persimmon production can be classified as 29.88% direct, 70.12% indirect, 21.79% renewable and 78.21% non-renewable. Farmyard manure should be used instead of the chemical fertilizers in order to increase the energy use efficiency and renewable energy ratio in persimmon production. The total greenhouse gas (GHG) emissions were determined as 4440.00 kg CO2‑eqha−1 and 0.18 of GHG ratio (per kg). The results of the study showed that the share of human labor in total GHG emissions was the highest (1857.17 kg CO2‑eqha−1), chemical fertilizier (1698.85 kg CO2‑eqha−1) and herbicide (1177.35 kg CO2‑eqha−1) held the second and third. Energy use efficiency and GHG emissions were increased because the usage of farmyard manure was used instead of chemical fertilizers. Çelen (2016) reported that reducing the usage of nitrogen by lowering erosion, leakage, and evaporation, using more bio-nitrogen, using farmyard manure and other bio-fuels, implementing waste and left-over management in harvest residues and having minimum soil processing are compulsory.

References

Anonymous (2016) The Adıyaman Governorship, Available: http://www.adiyaman.gov.tr/iklim. Accessed 15 May 2016

Anonymous (2020a) Native-persimmons. https://www.fatsecret.com/calories-nutrition/usda/native-persimmons. Accessed 2 Oct 2020

Anonymous (2020b) Maps of world. https://www.mapsofworld.com/world-top-ten/persimmon-producing-countries.html. Accessed 2 Jan 2020

Aydın B, Aktürk D, Ozkan E, Hurma H, Kiracı MA (2017) Armut üretiminde karşılaştırmalı enerji kullanım etkinliği ve ekonomik analiz: Trakya Bölgesi örneği. Turk Tarim Gida Bilim Teknol Derg 5(9):1072–1079 (in Turkish)

Aydın B, Aktürk D, Özkan E, Hurma H, Kiracı MA (2019) Comparative energy use efficiency and economic analysis of apple production in Turkey: case of Thrace region. Erwerbs-Obstbau 61:39–45

Baran MF (2017) Energy and economic analysis of vetch production in Turkey: a case study from Thrace region. Fresenius Envıron Bull 26(3):1996–1972

Baran MF, Gökdoğan O, Oğuz HI (2017) Determining the energy usage efficiency of walnut (Juglans regia L.) cultivation in Turkey. Erwerbs-Obstbau 59:77–82

Baran MF, Karaağaç HA, Bolat A, Çil A, Çil AN (2019) Determining energy usage efficiency in groundnut production (the case of Adana province). Eur J Sci Technol 15:103–111

Beigi M, Torki-Harchegani M, Ghanbarian D (2016) Energy use efficiency and economical analysis of almond production: a case study in Chaharmahal-Va-Bakhtiari province, Iran. Energy Effic 9:745–754

BioGrace-II (2015) Harmonised calculations of biofuel greenhouse gas emissions in europe. http://www.biograce.net. Accessed 2 June 2015

Çelen I (2016) An evaluation of energy use in agricultural applications. Electronic Journal of Vocational Colleges 2016:18–29

Çelen S (2019) Effect of microwave drying on the drying characteristics, color, microstructure, and thermal properties of Trabzon persimmon. Foods 8:84. https://doi.org/10.3390/foods8020084

Çelen İ, Baran MF, Önler E, Bayhan Y (2017) Determination of energy balance of apple (Malus domestica) production in Turkey: a case study for Tekirdag province. Anadolu J Agric Sci 32:40–45

Çiçek A, Erkan O (1996) Agricultural economics research and sampling methods. Lesson Notes No: 6, vol 12. Gaziosmanpaşa University, Agriculture Faculty Publishing, Tokat

Clark S, Khoshnevisan B, Sefeedpari P (2016) Energy efficiency and greenhouse gas emissions during the transition to organic and reduced-input practices: student farm case study. Ecol Eng 88:186–194

Eren Ö, Baran MF, Gökdoğan O (2019) Determination of greenhouse gas emissions (GHG) in the production of different fruits in Turkey. Fresenius Environ Bull 28(1):464–472

Gökdoğan O, Erdoğan O (2018) Evaluation of energy balance in organic olive (Olea Europaea L.) production in Turkey: a case study of Aydın-Karpuzlu region. Erwerbs-Obstbau 60(1):47–52

Gökdoğan O, Oğuz HI, Baran MF (2017) Energy input-output analysis in organic mulberry (Morus spp.) production in Turkey: a case study Adıyaman-Tut region. Erwerbs-Obstbau 59(4):325–330

Gündoğmuş E (2006) Energy use on organic farming: a comparative analysis on organic versus conventional apricot production on small holdings in Turkey. Energy Convers Manag 47:3351–3359

Houshyar E, Dalgaard T, Tarazgar MH, Jorgensen U (2015) Energy input for tomato production what the economy says, and what is good for the environment. J Clean Prod 89:99–109

Houshyar E, Mahmoodi-Eshkaftaki M, Azadi H (2017) Impacts of technological change on energy use efficiency and GHG mitigation of pomegranate: application of dynamic data envelopment analysis models. J Clean Prod 162:1180–1191

Hughes DJ, West JS, Atkins SD, Gladders P, Jeger MJ, Fitt BD (2011) Effects of disease control by fungicides on greenhouse gas emissions by UK arable crop production. Pest Manag Sci 67:1082–1092

Itamura H, Zheng Q, Akaura K (2005) Industry and research trend of Japanese persimmon. Acta Hortic 685:37–44

Kaltsas AM, Mamolos AP, Tsatsarelis CT, Nanos GD, Kalburtji KL (2007) Energy budget in organic and conventional olive groves. Agric Ecosyst Environ 122(2):243–251. https://doi.org/10.1016/j.agee.2007.01.017

Karaağaç HA, Baran MF, Mart D, Bolat A, Eren Ö (2019) Determination of energy usage efficiency and greenhouse gas (GHG) emissions in chickpea production (the case of Adana province). Eur J Sci Technol 16:41–50

Karaağaç MA, Aykanat S, Çakır B, Eren O, Turgut MM, Barut ZB, Oztürk HH (2011) Energy balance of wheat and maize crops production in Hacıali undertaking. 11th International Congress on Mechanization and Energy in Agriculture Congress, Istanbul, Turkey, 21–23 September, pp 388–391

Karabat S, Aydın B (2018) İyi tarım uygulamalarının mandarin üretiminde enerji kullanım etkinliği ve ekonomik analiz üzerine etkisi: İzmir ili örneği. Toprak Su Dergisi 7(1):1–10 (in Turkish)

Karakasova L, Babanovska-Milenkovska F, Lazov M, Karakasova B, Stojanova M (2013) Quality proparties of solar dried persimmon (Diospyros kaki). J Hyg Eng Des 4:54–59

Kawase M, Motohashi N, Satoh K et al (2003) Biological activity of persimmon (Diospyros kaki) peel extracts. Phytother Res 17(5):495–500

Khoshnevisan B, Rafiee S, Mousazadeh H (2013) Environmental impact assessment of the open field and greenhouse strawberry production. Eur J Agron 50:29–37

Khoshnevisan B, Shariati HM, Rafiee S, Mousazadeh H (2014) Comparison of energy consumption and GHG emissions of open field and greenhouse strawberry production. Renew Sustain Energy Rev 29:316–324

Kitagawa H, Glucina PG (1984) Persimmon culture in New Zealand. DSIR Information Series, vol 159. New Zealand Department of Scientific and Industrial Research, Wellington, p 74

Koçtürk OM, Engindeniz S (2009) Energy and cost analysis of sultana grape growing: a case study of Manisa, West Turkey. African Journal of Agricultural Resources 4(10):938–943

Kondo S, Yoshikawa H, Katayama R (2004) Antioxidant activity in astringent and non-astringent persimmons. J Hortic Sci Biotechnol 79(3):390–394

Kızılaslan H (2009) Input-output energy analysis of cherries production in Tokat province of Turkey. Appl Energy 86:1354–1358

Lal R (2004) Carbon emission from farm operations. Environ Int 30:981–990

Mandal KG, Saha KP, Ghosh PK, Hati KM, Bandyopadhyay KK (2002) Bioenergy and economic analysis of soybean based crop production systems in central India. Biomass Bioenergy 23:337–345

Mani I, Kumar P, Panwar JS, Kant K (2007) Variation in energy consumption in production of wheat-maize with varying altitudes in hill regions of Himachal Prades, India. Energy 32:2336–2339

Maraseni TN, Cockfield G, Maroulis J, Chen G (2010) An assessment of greenhouse gas emissions from the Australian vegetables industry. J Environ Sci Health B 45(6):578–588

Mardani A, Taghavifar H (2016) An overview on energy inputs and environmental emissions of grape production in West Azerbaijan of Iran. Renew Sustain Energy Rev 54:918–924

Mohammadi A, Rafiee S, Mohtasebi SS, Rafiee H (2010) Energy inputs-yield relationship and cost analysis of kiwifruit production in Iran. Renew Energy 35:1071–1075

Mohammadi A, Tabatabaeefar A, Shahin S, Rafiee S, Keyhani A (2008) Energy use and economical analysis of potato production in Iran a case study: Ardabil province. Energy Convers Manag 49:3566–3570

Mousavi-Avval SH, Rafiee S, Mohammadi A (2011) Optimization of energy consumption and input costs for apple production in Iran using data envelopment analysis. Energy 36:909–916

Nabavi-Pelesaraei A, Abdi R, Rafiee S (2016) Neural network modeling of energy use and greenhouse gas emissions of watermelon production systems. J Saudi Soc Agric Sci 15(1):38–47

Nakagawa T, Nakatsuka A, Yano K et al (2008) Expressed sequence tags from persimmon at different developmental stages. Plant Cell Rep 27(5):931–938

Nguyen TLT, Hermansen JE (2012) System expansion for handling co-products in LCA of sugar cane bio-energy systems: GHG consequences of using molasses for ethanol production. Appl Energy 89:254–261

Nikkhah A, Royan M, Khojastehpour M, Bacenetti J (2017) Environmental impacts modeling of Iranian peach production. Renew Sustain Energy Rev 75:677–682

Oğuz Hİ, Erdoğan O, Gökdoğan O (2019) Energy use efficiency and economic analysis of nectarine (Prunus persica var. nucipersica) production: a case study from Niğde province. Erwerbs-Obstbau 60(4):323–329

Özalp A, Yılmaz S, Ertekin C, Yılmaz I (2018) Energy analysis and emissions of greenhouse gases of pomegranate production in Antalya province of Turkey. Erwerbs-Obstbau. https://doi.org/10.1007/s10341-018-0380-z

Özkan B, Akçaöz H, Fert C (2004) Energy input-output analysis in Turkish agriculture. Renew Energy 29:39–51

Pishgar-Komleh SH, Ghahderijani M, Sefeedpari P (2012) Energy consumption and CO2 emissions analysis of potato production based on different farm size levels in Iran. J Clean Prod 33:183–191

Qasami-Kordkheili P, Nabavi-Pelesaraei A (2014) Optimization of energy required and potential of greenhouse gas emissions reductions for nectarine production using data envelopment analysis approach. Int J Energy Environ 5(2):207–218

Radha T, Mathew L (2007) Fruit crops. Horticulture science series. Jai Baharat Press,

Rafiee S, Seyed H, Mousavi A, Ali M (2010) Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy 35:3301–3306. https://doi.org/10.1016/j.energy.2010.04.015

Rajaeifar MA, Akram A, Ghobadian B, Rafiee S, Heidari MD (2014) Energy-economic life cycle assessment (LCA) and greenhouse gas emissions analysis of olive oil production in Iran. Energy 66:139–149

Sabah M (2010) Söke Ovasında İkinci Ürün Yağlık Ayçiçeği Üretiminde Enerji Kullanımı. Çukurova Üniversitesi Fen Bilimleri Enstitüsü Tarım Makinaları Anabilim Dalı. Yüksek Lisans Tezi. Adana (in Turkish)

Shazia Y, Umar F, Afshan SI, Kashif A, Mian AM, Tusneem K, Farzana S (2016) Chemistry and Functionality of Bioactive Compounds Present in Persimmon. Journal of Chemistry. https://doi.org/10.1155/2016/3424025

Singh JM (2002) On garden energy use pattern in different cropping systems in Haryana, India. International Institute of Management University of Flensburg, Sustainable Energy Systems and Management. Master of Science

Singh G, Singh S, Singh J (2004) Optimization of energy inputs for wheat crop in Punjab. Energy Convers Manag 45(3):453–465

Singh H, Mishra D, Nahar NM, Ranjan M (2003) Energy use pattern in production agriculture of a typical village in Arid Zone India (Part II). Energy Convers Manag 44:1053–1067

Spongberg SA (1977) Ebenaceae hardy in temperate North America. J Arnold Arboretum 58(2):146–160

Taghavifar H, Mardani A (2015) Prognostication of energy consumption and greenhouse gas (GHG) emissions analysis of apple production in West Azarbayjan of Iran using Artificial Neural Network. J Clean Prod 87:159–167

TUIK (2018) Türkiye İstatistik Kurumu, Tarımsal İstatistik Verileri, Ankara. http://www.tuik.gov.tr. Accessed 5 Mar 2018

USDA (1998) Agriculture Research Service vol 44. National Agricultural Library, Beltsville, pp 47–88

Yaldız O, Öztürk HH, Zeren Y, Başçetinçelik A (1993) Energy usage in production of field crops in Turkey. 5th International Congress on Mechanization and Energy in Agriculture, Kuşadası, 11–14. October, pp 527–536 (in Turkish)

Yilmaz H, Aydin B (2020) Comparative Input-Output Energy Analysis of Citrus Production in Turkey: Case of Adana Province. Erwerbs-Obstbau 62:29–36. https://doi.org/10.1007/s10341-019-00447-z

Yokozawa T, Kim YA, Kim HY, Lee YA, Nonaka G (2007) Protective effect of persimmon peels polyphenol against high glucose-induced oxidative stress in LLCPK1 cells. Food Chem Toxicol 45:1979–1987

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

M.F. Baran declares that he has no competing interests.

Rights and permissions

About this article

Cite this article

Baran, M.F. Determination of Energy Use Efficiency and Greenhouse Gas (GHG) Emissions of Persimmon (Diospyros kaki L.) Production in Turkey (A Case Study in Adıyaman Province). Erwerbs-Obstbau 64, 499–505 (2022). https://doi.org/10.1007/s10341-022-00639-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-022-00639-0