Abstract

This paper describes an on-line sample preparation method for the simultaneous determination of 48 pesticides in grapes, baby food and wheat flour matrices. Target pesticides were selected to represent a wide variety of chemical structures and three typical matrices were selected. Turbulent flow chromatography was applied for on-line sample cleanup directly coupled to LC–MS/MS. The aim of the method was to reduce total analysis time, eliminate manual laboratory work, provide clean extracts and achieve reproducible results. Single laboratory method validation was conducted establishing limits of detection between 0.8 and 6.0 ng g−1 for baby food, and 0.8–10.3 ng g−1 for other matrices. Within-day precision values varied between 4 and 18 %, while between-day precisions were in the range 5–22 %. Method recovery ranged from 67 to 124 %, and method accuracy was demonstrated by analysis of external quality control samples. The method was also tested on 24 different survey samples from both bio and organic origin. The method was shown to be convenient, fast and fit for purpose in meeting regulatory requirements for pesticide residue monitoring.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pesticide residue analysis continues to be a challenging area of food testing and therefore benefits from new analytical method development. The need for easier, faster, less laborious, but on the other hand precise and robust multi-residue methods with high recovery and high sample throughput remains a priority for pesticide residue monitoring. However, development of new methods is challenging in view of the large number of target analytes with different chemical structures and the diversity of food matrices. In addition, harmonised limits for pesticide residues have been recently established by the European Commission, setting values for the usage and application of pesticides in agricultural commodities as well as maximum residue limits (MRLs) to control and minimise the dietary intake for human, especially infant, consumers [1]. The lowest MRL values were formerly set at 10 ng g−1 for baby food matrices, but for some (in a recent paper, non-targeted) pesticides even lower (4–6 ng g−1) levels have recently been introduced, demanding more selective and sensitive analytical methods for residue analysis in foods [2].

The most suitable chromatographic approaches for sensitive pesticide determination in food matrices are GC and LC techniques. Since LC can be effectively applied for thermally labile and less volatile compounds with different polarity, it has proved to be one of the most powerful techniques especially when coupled to tandem mass spectrometer (LC–MS/MS) [3, 4]. The most common approach in the past few years was coupling to triple quadrupole [5, 6], time of flight (TOF) [7] or quadrupole-ion trap mass analysers [8] and operating with soft ionisation, mostly with electrospray ionisation (ESI), to achieve only few ions and maximum sensitivity [9–11].

Sample preparation is a crucial, but often neglected, part of method development and receives less attention than chromatographic separation or detection stages. Traditional sample preparation methods for the determination of pesticides are based on liquid–liquid extraction and partition [12], or nowadays preferably on solid–liquid extraction due to its simplicity and lower organic solvent consumption. Solid-phase extraction (SPE) with different types of sorbents [13], solid-phase microextraction (SPME) [8] or matrix solid-phase dispersion (MSPD) [14] have been widely employed.

Dispersive solid-phase extraction (DSPE) offers a cost-effective way to apply the benefits of solid-phase extraction and has provided the basis for a quick, easy, cheap, effective, rugged and safe (QuEChERS) method [15], which has become the mostly widely used pesticide sample preparation method for multi-residue pesticide analysis. The QuEChERS method is, undoubtedly, a very effective and simple method, but requires many manual sample manipulation steps, making sample preparation labour-intensive and consequently increasing possible error sources when large numbers of samples have to be analysed. It is therefore attractive to consider options to replace those by (semi-) automated multi-residue methods, which would offer a faster and cost-effective analysis with reduced error sources and so improved repeatability and robustness parameters.

On-line sample preparation techniques are potential options for improved automated cleanup. Singer et al. [16] developed an on-line SPE method using functionalised polymeric sorbent with N-vinylpyrrolidone functional groups for the determination of several biocide pesticides. Chen et al. [17] developed a rather complex, but fully automated microwave-assisted extraction-SPE-LC on-line coupled system for the determination of organochlorine pesticides in rice, wheat, bean and corn matrices with 91–98 % recoveries and 4–8 % precision values at 80 ng g−1 spike level within a 30 min analysis time. A further undoubted advantage of this on-line coupled method was that solid samples could directly be analysed without any manual sample manipulation steps. In other on-line coupled methods, solid samples must be chopped, homogenised and extracted before injection. Restricted access materials (RAM), combining size-exclusion mechanisms for removal of matrix components and reversed phase retention mechanisms in the pores to retain target analytes, have been developed. This approach can remove protein matrix components [18], but such systems have been rarely applied in food laboratories, probably because of the greater complexity of food matrices. Turbulent flow (TurboFlow™) chromatography (TLX) is an on-line sample preparation technique which applies high flow rates (1.5–5.0 mL min−1) through relatively large particle columns (50–60 μm) resulting in a turbulent flow profile. Effective separation of macromolecules from smaller target analytes can be achieved primarily based on their different diffusion coefficients [19], which results in less matrix load on the chromatographic column and less matrix effects in the detector. Similar to RAM materials, TurboFlow™ columns can also act as a size-exclusion phase restricting further penetration of matrix compounds into the pores embedded with active reverse or normal phase extraction sites and reducing further co-extraction of matrix components. TurboFlow™ chromatography has been increasingly used in clinical chemistry [20, 21], but only a very limited number of published food applications have been reported such as the TurboFlow™ method developed by Mottier et al. [22] for the determination of 16 fluoroquinolones in honey or analysis of flavonoids and resveratrol in wine by Presta et al. [23]. Asperger et al. [24] developed a quantification method for 11 and Koal et al. [25] for 30 pesticides in water using Turboflow technology with APCI–MS/MS detection.

This paper aims to fill this gap and establish the performance characteristics of a quantitative TurboFlow™ chromatographic method for multi-residue pesticide analysis in different food matrices. For this purpose, 48 polar, mid- and non-polar pesticides and 3 different matrices representing (semi-) liquid (grape) and solid (wheat flour as well as carrot-based puree baby food) matrices were selected. Method performance parameters were established using an in-house validation process; the method was used for different survey samples and method performance parameters were compared to currently used methods.

Experimental

Chemicals, Materials and Standards

Optima LC/MS-grade solvents water and methanol used as mobile phases, HPLC-grade acetone, acetonitrile and isopropanol used for column wash purposes and formic acid (FA) for LC–MS as mobile phase additive were from Thermo Fisher Scientific GmbH (Langenselbold, Germany).

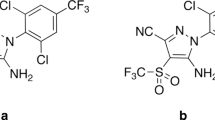

Pesticide and internal standards used in the study—abamectin, ametryn, azinphos-me, azoxystrobin, bifenazate, carbaryl, carbendazim, carfentrazone-ethyl, chlormequate, clofentezin, cymoxanil, cypermethrin, dazomet, diazinon, dimethoate, dimethomorph A, dimethomorph B, ediphenfos, fenazaquin, fluazifop P, fluzilazol, hexithaizox, imazalil, imidacloprid, isoproturon, isoxaben, lactofen, malathion, metalaxyl, methomyl, metribuzin, myclobutanyl, omethoate, oxadyxil, oxamyl, pethoxamid, profenofos, promecarb, propoxur, pymetrozin, piperonil butoxide, pyrimethanyl, quinoxifen, spirodiclofen, tebuconazol, thiacloprid, triadimefon, trifloxistrobin, d 4-imidacloprid, d 6-isoproturon, d 6-primicarb and d 10-parathion-ethyl—were purchased from Sigma-Aldrich GmbH (Munich, Germany). External quality control samples FAPAS No: 963, FAPAS No: 966 and FAPAS No: 19110 were obtained from FERA (York, UK). Grapes, baby food puree (carrot based) and wheat flour samples as blank matrices as well as survey samples were purchased in local retail stores in Germany.

The 0.2 μm PTFE filters and 2 mL centrifuge tubes were from Thermo Fisher Scientific (Langenselbold, Germany).

Preparation of Calibration Solutions

Standard stock solvent mixtures of pesticides (2 μg mL−1) were gravimetrically prepared in acetonitrile. Working internal standard solution containing 100 ng mL−1 d 4-imidacloprid and d 6-isoproturon, 1,000 ng mL−1 d 6-primicarb and 70 μg mL−1 d 10-parathion-ethyl were gravimetrically prepared and directly used for spiking of samples and calibration solutions. Matrix-matched calibration standard solutions were prepared prior to extraction and injection by appropriate dilution of aliquots of the standard stock solution and internal standard working solution in the relevant blank matrix. Standard stock solvent and working internal standard solutions were stored in freezer at −20 °C and were demonstrated to be stable under those conditions for 3 months (stability test was performed weekly and monitored in a control chart). All daily used working solutions were freshly prepared from the stock standards prior to use.

Sample Preparation

A representative sample of 10–15 individual red and white grapes (GR) were selected from a bunch and chopped and homogenised in a Ultra-Turrax homogeniser equipped with a G25 dispergator (Thermo Fisher Scientific, Langenselbold, Germany). Carrot-based baby food (BF) and wheat flour (WF) samples were taken directly from the original package after vigorous mixing with a spatula. 0.5 g homogenised samples (GR, BF or WF) were taken in a 2 mL centrifuge tube and 900 μL acetonitrile (to wheat flour 500 μL water and 400 μL acetonitrile) with 100 μL working internal standard solution was added. Consequently, the added internal standard quantities (per mL) were 10–10 ng d 4-imidacloprid and d 6-isoproturon, 100 ng d 6-primicarb and 7 μg d 10-parathion-ethyl in all samples. The mixture was vigorously shaken on a Vortex mixer for 10 min and sonicated in an ultrasonic bath (both from Thermo Fisher Scientific, Langenselbold, Germany) for an additional 5 min. The mixture was centrifuged on a Heraeus Fresco 17 Microcentrifuge (Thermo Fisher Scientific, Langenselbold, Germany) at 5,000 rpm for 2 min and the supernatant was collected and filtered through 0.2 μm PTFE filter into HPLC vials.

On-line Coupled Turboflow™ Chromatography-LC–MS/MS

On-line chromatographic cleanup and LC–MS/MS employed a Transcend™ TLX-1 system coupled to TSQ Access Max triple quadrupole mass spectrometer (Thermo Fisher Scientific, San Jose, CA, USA) controlled by the Aria software. The operation was carried out in focus mode setup with 1:1 flow splitting via Tee piece before TSQ entrance. Focus mode setup consisted of two pumps, CTC auto-sampler and two six-port valve systems, from which one (valve A) was in-housing the TurboFlow™ (TX) column as well as a fix volume loop for storing elution mobile phase for TX (TX loop) and a connection to the second valve (valve B). Valve B was equipped with special rotor seal enabling a Tee connection and served for dilution and diverting TX effluent either to waste or to LC. The system set up and flow connections for sample loading and transfer of TX effluent onto the analytical column are shown in Fig. 1a, b.

In the final method, a polymeric based cyclone MCX-2 50 × 0.5 mm TurboFlow™ (TX) column was used as sample preparation column and Hypersil Gold 150 × 4.6 mm (5 μm) column equipped with Uniguard Hypersil Gold 10 × 4 mm (5 μm) guard column as analytical (LC) column (all from Thermo Fisher Scientific, Runcorn, UK). The transfer loop volume for storing TX eluent and consequently the TX transfer volume was 200 μL. The volume of the injection syringe was 100 μL, and the final injection volume was 10 μL. The sample holder temperature was kept at 10 °C. The injection syringe as well as injection valve were rinsed twice before and four times after injection with both 50 % methanol/water and 20 % acetone/methanol mixtures.

Detection of pesticides was carried out by electrospray (ESI) ionisation in selective reaction monitoring (SRM) mode. Ion transitions, collision energies, tube lens and skimmer values were set individually for all compounds (Table 1). All other MS parameters were kept constant during the run: cycle time was set to 0.3 s, peak width was 0.7 FWHM, collision pressure was 1.5 mTorr, and both capillary and vaporiser temperature were 310 °C. The sheath gas pressure was 60, and the auxiliary gas pressure was 15 arbitrary units. Positive polarity was applied for all compounds, and the spray voltage was kept at 3500 V.

Quantitative Analysis

Identification of analytes was confirmed for five identification points based on specific ion transitions at the corresponding retention times (Table 1), as well as the observed ion ratio values corresponding to those of the standards within legislative acceptable deviation [26]. For quantification of pesticides, internal standardisation was applied with four labelled internal standards spiked into all samples at three concentration levels by 10× dilution of working internal standard solution. Response factors (Rf = A × c IS/c × AIS where A is the area, c is concentration and index IS stands for internal standard) for quantification were determined for each of the matrices and internal standards by calculating cumulative average response factors over the whole calibration range. Quantification was based on quantifier ion intensities. Table 1 gives an overview on both quantifier and qualifier ions.

Results and Discussion

Optimisation of On-line Sample Preparation

Optimisation of both TX and LC conditions is necessary for method development. Solid-phase column materials and operating parameters as well as loading, washing (for TX) and elution conditions are key optimisation parameters. The transfer step is a crucial point in the method, since all target pesticides covering ionic, polar and non-polar chemistries have to be simultaneously eluted and transferred from the TX onto the LC column ensuring they are focused on the front of the analytical column. Compatibility of TX and LX columns as well as solvent systems has to be ensured and chosen very carefully.

The chemical diversity of target substances complicated the selection of the TX column: analyte log P values (predicted by Pallas Software, Compudrug Int., Sedona, AZ, USA) ranged between −2.09 (for chlormequate) and 6.48 (for spirodiclofen). To establish load, wash and elution parameters, the TX column was directly coupled to the TSQ detector and step gradient with 3 min initial 100 % aqueous (containing 0.1 % FA) mobile phase was applied followed by a gradient run with increased methanol (containing 0.1 % FA) content up to 100 % in 10 % increments after each minute.

Polymer- (cyclone P) and silica-based (C18) reversed phase materials were first selected both in 50 × 0.5 mm dimension (Thermo Fisher Scientific, Runcorn, UK); however, these represent very similar separation selectivity mechanisms when coupling to the commonly used RP-LC columns in pesticide analysis. Both tested columns showed satisfactory retention for most of the target substances; however, small polar and ionic compounds like omethoate, dimethoate, cymoxanil, oxamyl, carbendazim, methomyl and chlormequate were eluted in the void time even under the weakest initial (aqueous) elution conditions. Therefore, based on the cationic and weak basic character of some target substances, MCX and MCX-2 mixed mode ionic exchange columns (both 50 × 0.5 mm and from Thermo Fisher Scientific, Runcorn, UK) were also tested with both 100 % water and 100 % water at pH 3 (adjusted with FA) loading solvents. MCX gave more focused and retained peaks for pymetrozin and carbendazim compared to the cyclone P column; however, other substances showed the same retention and peak shape. In contrast, the MCX-2 column retained dimethoate, cymoxanil, oxamyl, carbendazim, methomyl and chlormequate together with the other retained substances on cycP and/or on MCX (Fig. 2).

Retention and elution profile of selected 500 ng ml−1 polar and weak basic compounds on a cyclone P and b on MCX-2 TX columns. Elution conditions: after initial aqueous (pH 3 with formic acid) mobile phase for 3 min, step gradient with 20 % MeOH/H2O (5 mM ammonium formate + 0.1 % formic acid) between 3 and 4 min, 40 % between 4 and 5 min and 90 % between 5 and 6 min was applied

The only partially (~30 %) retained substance was omethoate; however, the chemical structure of dimethoate and omethoate differ only in substitution of oxygen with sulphur. The retention difference can be explained by different hydrophobic interactions based on their different polarity and log P values, representing −1.14 for omethoate and 0.96 for dimethoate. The most polar and ionic chlormequate as well as few weak basic compounds like myclobutanyl, pymetrozin, quinoxifen, triadimefon, trifloxistrobin, thiacloprid, imazalil or pyrimethanil were retained via hydrophobic and ionic interactions, while other compounds were retained mostly based on hydrophobic interactions. Elution from the TX column occurred in 20 % organic/aqueous mobile phase (pH 3) for the least retained compounds imidacloprid, cymoxanil, methomyl, chlormequate, dimethoate, oxamyl and omethoate. All other compounds eluted with 40 % organic mobile phase composition, and 90 % organic ratio was strong enough to elute all target compounds completely from the MCX-2 column. Therefore, this TX eluent solvent mixture was chosen as the transfer solvent. The transfer solvent was stored in the 200 μL fixed volume transfer loop and was directed onto the TX column by switching valve A into the proper (in-line) position. Maximum injection volume (breakthrough limit) was determined on the TX column to be 30 μL as a compromise. This volume was limited due to the small number of low retained polar and ionic substances; however, for the other compounds a much higher breakthrough volume with a greater enrichment factor and consequently a higher sensitivity could have been achieved.

Optimisation of Transfer and Analytical Separation

Solvent incompatibility, analyte solubility, solvent strength effects and viscosity mismatch can lead to distorted peaks during the transfer step. Taking into account that complete elution from the TX column was observed with RP-LC fully compatible methanol/aqueous solvent system, the first two effects were not considered to be an issue; however, solvent strength and viscosity effects were of concern. The high organic content of TX effluent leads to unsatisfactory focusing and consequently total breakthrough of target compounds on the analytical column. Therefore, dilution with aqueous solvent was necessary to reduce solvent strength and achieve focusing and acceptable peak shapes on the analytical column. Dilution was carried out in valve B equipped with rotor seal containing a Tee connection enabling mixing of high organic content TX effluent and 100 % aqueous solvent based on flow rate differences between the two flow channels. Efficient focusing of even the most polar substances occurs with the lowest possible initial organic phase concentrations. Therefore, 5–10 % initial organic content was selected, since higher (20 % or more) initial organic content on LX column resulted in distorted peaks with splitting or fronting (Fig. 3).

Method optimisation: effect of unsatisfactory dilution during transfer on to the LC column. Imidacloprid (left) shows peak fronting when too strong initial eluent is applied, while methomyl (right) was not affected. The concentration of both analytes was 500 ng ml−1 (gradient conditions and so retention times differ from the final method)

Also, the transfer time limited the dilution step in terms of overall method efficiency (total run time) and peak broadening. By keeping the transfer time to a minimum, the speed and efficiency of the method can be increased. Simultaneously, distribution of the eluted peak is reduced, and therefore the highest possible flow rate required for TX elution can be applied. However, extremely high flow rates from the dilution channel and the resulting total flow rate can cause low separation efficiency, especially on higher particle size (3–5 μm) columns due to decreased theoretical plate number (C term of van Deemter plot). Additionally, high pressures can make the method incompatible with HPLC systems with pressure limits below 600 bar.

For these reasons, 5 % initial organic phase (18× dilution) on the LC column with 1 min transfer time would require 1.9 mL min−1 total flow rate, which would result in unnecessarily high flow rates and unacceptably high pressures on small particle size (sub-2 μm or sub-3 μm) columns. Therefore, 10 % initial organic phase concentration was selected and tested with a setting of 100 μL min−1 flow rate on TX and 900 μL min−1 flow rate on dilution (LC) channels resulting in a 2 min transfer time.

Hypersil GOLD C18 and C18aq, 50 × 2.1 mm (1.9 μm) columns (Thermo Fisher Scientific, Runcorn, UK) were first tested, but due to the pressure restriction of the pump (600 bar) a maximum 450 μL min−1 total flow was achievable, meaning 45 μL min−1 elution flow rate on TX column and ~4.5 min transfer time. Taking into account an average separation time for sub-2 μm columns, the sample transfer time was nearly the same time as the analytical separation itself. Additionally, some peaks eluted in a distorted form and thus these LC columns were replaced by a base deactivated Hypersil BDS C18, 3 μm column (Thermo Fisher Scientific, Runcorn, UK). To keep the same column efficiency (N ~ 16.000), a 100 × 3 mm column was installed. The BDS column improved peak shapes for all substances and enabled higher total flow rates (~1 mL min−1) and shorter (2 min) transfer times. However, long-term usage at higher pressure (pressure partially above 500 bar at viscosity maxima of 40–50 % methanol–water binary solvent) damaged the column sealing. Thus, this column was replaced and finally Hypersil Gold C18 150 × 4.6 mm, 5 μm (Thermo Fisher Scientific, Runcorn, UK) column was installed representing similar theoretical column efficiency (~15.000). With this relatively high particle size column, even 1.8 mL min−1 total flow rate generated tolerable pressure, and transfer within 1.1 min was achievable giving sharp, symmetrical peaks. To reduce peak broadening based on C term of van Deemter curve, finally a 1.6 mL min−1 total flow was applied on this column resulting in a 0.16 mL min−1 flow rate for transfer and 1.44 mL min−1 flow rate for the dilution with 1.33 min transfer time. Under these conditions, a tenfold dilution was achieved resulting in 9 % initial organic mobile phase content for LC. Peak shapes were satisfactory for all compounds when applying aqueous pH 3 loading solvent, and only chlormequate eluted in a broader peak (w 0.1 = 0.7 min). The peak width for chlormequate could be decreased significantly with application of pure water as loading solvent; however, other peaks became distorted or disappeared because of modified retention on the TX column. For this reason, aqueous loading solvent adjusted to pH 3 (with formic acid) was finally selected.

The final optimised method and the corresponding method programme is shown in Table 2.

The sample load and elution of matrix compounds occurred in step 1 under turbulent flow conditions in 100 % water at pH 3 (adjusted with formic acid) for 1 min. Washing of the TX column for 1 min with 5 % organic (methanol) content for further matrix component elution occurred in step 2 and in the meantime the LC column was equilibrated with water containing 5 mM ammonium formate +0.1 % formic acid at reduced flow. Step 3 represents a transfer step from the TX onto the LC column by switching the loop in line and Tee in valve B in line with LC transfer position. In step 4, the TX column was washed with 20 % acetone, 40 % acetonitrile and 40 % isopropanol mixture diverting to waste. The gradient run started on the LC column with a steep water–methanol (containing 5 mM ammonium formate and 0.1 % formic acid) gradient. In step 5, the transfer loop was filled with TX elution solvent for the next run and the gradient run was performed with a less steep gradient on the LC column. In step 6, the TX column was regenerated and equilibrated, while the LC gradient reached 100 % methanol in 3.6 min and kept isocratic for 1 min to complete elution of all transferred compounds. Step 7 represents the equilibration step for both TX and LC columns.

The total run time of the final method with TX sample preparation, analytical separation and column regeneration steps was 13 min. The chromatographic peak shapes (Fig. 4), average plate numbers (N) and resolution values were satisfactory for all compounds except N for chlormequate based on the above-mentioned reasons. Isobaric compounds were baseline separated for fenazaquin–quinoxifen and imazalil–oxadyxil–pethoxamid critical pairs; R s = 1.3 was measured for clofentezin–diazinon pairs. Dazomet and methomyl were not resolved (R s < 1). However despite lack of chromatographic resolution, MS specificity was sufficient to distinguish them unambiguously, so no further modification of gradient was carried out and thus unnecessary longer run time was avoided.

Method Validation

Single laboratory validation was carried out on all matrices and target pesticides according to IUPAC and AOAC guidelines [27, 28] as well as EC recommendations for quality control of pesticide residue methods [29]. To prove enhanced performance of on-line sample cleanup against off-line methods, method performance parameters were compared to data available in literature for the off-line methods.

Method Selectivity

Compound identification and method selectivity were based on the presence of specific ion transitions at the corresponding retention time (5 identification points). To ensure that the matrix was free of any interferences at the expected retention time window of the target analytes, six independent blank (nonspiked) matrix samples were injected and the recorded chromatograms were visually inspected. In all cases, the chromatograms were flat and free of any peaks exceeding 30 % of the analyte’s LOQ value in the close vicinity of the expected retention time indicating high method selectivity for the analytes. The only extra peak that was evident was well separated and eluted immediately before cypermethrin (Fig. 4), which was assumed to be the known isomer.

Linearity

Calibration was carried out for both solvent and matrix-matched calibration standards prepared individually by spiking samples before extraction. The linearity of calibration curves was assessed at six calibration levels (and blank) in duplicate analysis over the range from 10 to 500 ng g−1. Calibration levels were 0 (blank), 10, 25, 50, 100, 250 and 500 ng g−1, respectively, and calibration solvents were injected in random order over the sequence. Linearity was assured for both cases based on linearity test according to Mandel, for determination of regression coefficients’ relative intensities of target analytes, and internal standards (A/A IS) were plotted against relative concentrations of target and internal standard compounds. Additionally, visual observation of residual plots was also applied. The linearity was confirmed and correlation coefficients of linear functions were better than 0.985 for all cases. Residual plots were free of any trends and distributed evenly around the average value.

Precision

The injection precision of the instrument was tested by repeated injection of 100 ng mL−1 standard pesticide mixture in six replicates randomly over the day. Despite the use of gradient elution, the repeatability values for retention times were very satisfactory, being below 1.5 %. Method within-day (precision) and between-day repeatability (intermediate precision) values were determined for each matrix at 100 ng g−1 spiking level each in six replicates and expressed as % RSD over 3 days with independently prepared samples. Mean precision values were determined as average of the three individual days’ mean precision, while intermediate precision was expressed as mean of the overall precision data. Measured precisions varied between 4 and 18 %, and intermediate precisions between 5 and 20 % for most of the compounds fulfilling legislation criteria. Only a few compounds (azoxystrobin, clofentezin, fenazaquin and isoproturon in GR, cymoxanil in BF and dazomet in WF) showed slightly higher intermediate precision values (max. 22 %) over 3 days. The measured values are detailed in Table 3.

The measured intermediate precision values are in good agreement with published manual method precision values [30]; however, literature data often refer only to repeatability conditions and neglect investigation of intermediate precision. Based on this, it can be concluded that the TLX method provides higher precision by eliminating manual steps from the sample preparation.

Accuracy and Recovery

Method accuracy was assessed by recovery studies using blank matrix extracts spiked at three concentration levels in six independently prepared replicates. Samples were spiked prior to any sample manipulation steps with target analytes at 10, 100 and 250 ng g−1 concentration levels and internal standards. Relative recovery values were established after quantification (by using internal standardisation) and expressed as ratio of calculated and nominal spiked amount ×100.

Calculated recovery values and relative standard deviation (% RSD) values are shown in Table 4.

The target range for satisfactory recovery values were 70–125 %, which was achieved for all compounds with the exception of abamectin, oxamyl and triadimefon at the lower spiking levels, although still greater than 60 %. Recovery values show equivalent or even better method accuracy as described in literature for manual methods [31] (e.g. for pymetrozin [32] or omethoate [33] in grape matrix). Since LOD value of chlormequate exceeded the lowest spiking level concentration in GR and WF matrices, consequently no recovery value could be established for this compound at 10 ng g−1 spiking level. Recovery value was established for BF matrix, since 10 ng g−1 spiking level was equal to the lower limit of quantification (LLOQ) value; however, this represents an indicative value only. Similarly, for clofentezin, cypermethrin, omethoate (in GR and WF), hexithiazox (in WF) and pethoxamid (in GR), the lowest spike levels were in all cases between the LLOQ and LOQ values; the indicative recovery value was calculated and shown in Table 4. Additional accuracy was established by analysing FAPAS sample numbers 963 (pasta), 966 (maize flour) and 19110 (lettuce puree) external quality control test materials. All measured concentrations of the spiked relevant compounds (diazinon, tebuconazole, trifloxistrobin, malathion, azoxystrobin and dimethomorph) were within the defined satisfactory ranges indicating no bias of the method for these compounds (Table 5).

Limit of Detection and Limit of Quantification

The limits of detection and quantification were estimated following the IUPAC approach, which consisted of analysing the blank sample to establish noise levels and then testing experimentally estimated LODs and LOQs for signal/noise 3 and 10, respectively. The lowest MRLs for the target compounds were defined for baby food matrices (10 ng g−1) and targeted to meet the LOQ level. Measured LOD values in the BF matrix ranged between 0.8 ng g−1 (pyperonyl-butoxide) and 6 ng g−1 (chlormequate) indicating satisfactory sensitivity of method for legislative applications; however the LOQ exceeded legislation limit for chlormequate (20 ng g−1) based on the earlier discussed peak broadening effect. For grapes and wheat flour matrices, piperonyl butoxide showed the lowest (0.8 ng g−1 for both) and chlormequate the highest (10.3 ng g−1 in grapes and 9.2 ng g−1 in wheat flour) LOD values, while the LODs for all other compounds were between 0.9 and 5.0 ng g−1 in grapes and between 0.9 and 4.5 ng g−1 in wheat flour matrices. The detailed description of the measured LOD and LOQ values are summarised in Table 6.

Matrix Effect

Based on the theory of TurboFlow™ chromatography, macromolecules can be removed very effectively during sample preparation reducing interfering compounds derived from the matrix. The matrices used in this study contained high number of macromolecular compounds like carbohydrates (e.g. dietary fibres), lipids (e.g. phytosterols) and proteins that can be effectively removed. To test for potential matrix effects, blank matrix extracts and solvent were spiked just before injection in the TLX system at six calibration levels. Any matrix effect was identified based on Youden plotting of relative average intensity values in matrix versus relative average intensity values in pure solvent over the whole calibration range. Moderate matrix effect was indicated when the deviation of slope of the fitted line was between 20 and 50 % from the y = x slope. Strong matrix effects were indicated above 50 % deviation (positive for ion enhancement, negative for ion suppression), while no matrix effect was indicated when the slope deviation was below 20 %. Moderate matrix effects were observed for only a few substances such as dazomet and abamectin in GR, chlormequate in BF and omethoate and fenazaquin in WF (Fig. 5) for which compounds application of matrix-matched calibration is necessary.

Determination of matrix effect by plotting deviation (%) of Youden plot slope values from the idealistic (y = x) value. Points between green lines (deviation below 20 %) indicate no matrix effect, while points between green and red lines (20–50 % deviation) refer to minor matrix effects. No points were observed outside the red lines indicating that no major matrix effect was observed (matrices: GR grape, WF wheat flour, BF baby food)

However, other compounds (96 %) indicate that the sample preparation had been effective using the TurboFlow™ column and solvent calibration was sufficient for calibration purposes.

Carryover

The level of carryover was determined by evaluating analyte peak area in blank sample injected immediately after upper limit of quantification (ULOQ) standard sample. As acceptance criteria, 20 % or less of the LOQ peak area was set. To keep carryover at a minimum level, the injector valve as well as the injector needle was washed twice prior to and after injection with both wash solvents containing 50 % methanol/water and 20 % acetone/methanol. Carryover associated with the TX column was prevented by washing the TLX column with 40–40 % acetonitrile, isopropanol and 20 % acetone directly after the transfer step. Following this procedure, no carryover above the acceptance limit was observed.

Application to Survey Samples

The method was applied to 24 different food samples including fruit-based baby food, grapes and grape-based soft drinks as well as rye, maize and wheat flour samples selected from bio and organic origin. Piperonil butoxide was found in most of fthe lour samples in the range between 98 and 145 ng g−1, although this pesticide is not regulated. Pesticides like dimethoate (1 ng g−1), ametryn (2 ng g−1), azoxystrobin (0.9 ng g−1), imazalil (3 ng g−1) and metalaxyl (1.3 ng g−1) were found in grape drink products, and pyrimethanyl (9.4 ng g−1) in grapes, but all of these residue levels were far below the MRLs. The survey nevertheless demonstrated the ability of the method to handle diverse matrices and to be able to detect even residue levels well below MRLs.

Conclusion

A pesticide residue method has been developed to enable convenient, fast and cost-effective automated determination of selected pesticides, ranging from polar to non-polar and for different matrix types. Simultaneous analysis of a high number of target compounds always requires compromises. Taking into account that this method enables determination of a large number of different chemical range of compounds, the application of mixed mode TX column gave good separation selectivity (orthogonality) for cationic or ionisable basic substances; however, most of the target compounds were retained with hydrophobic interactions reducing separation selectivity at the sample preparation stage, resulting in probable co-transfer and co-elution of different matrix compounds. However despite this, only a very limited number of moderate matrix effects were observed indicating that on-line TurboFlow™ sample preparation coupled to the analytical HPLC separation equipped with triple quadrupole detector can result in very selective and effective determination of multi-class target compounds. Despite the availability of the tremendous amount of data, a direct comparison of method performance criteria for these exact cases was not evident; however, average values for the same or similar matrices could be compared to the performance characteristic of the on-line method. This comparison proved equivalent method accuracy, sensitivity, matrix effect and even higher precision due to the elimination of manual steps from the sample preparation. For some compounds (pymetrozin, omethoate, carbendazim), even better method performance was observed with the TLX method. Due to on-line coupling, a much shorter overall run time (13 min) including cleanup and chromatographic run was achieved even when using 5 μm particle size column. However, this could be further improved when applying high pressure-resistant pumps up to 1000 bar or higher. The short analysis time enables application of method for high-throughput screening or quantitative approaches.

Based on the simple on-line sample preparation technique and measured method performance parameters, samples can be analysed under controlled sample preparation conditions at low levels with fast and precise analysis achieving also an economical determination. Therefore, this method is an attractive alternative to the widely used QuEChERS method, replacing manual sample preparation steps and thereby reducing analysis time and even analysis costs. This TLX method can readily be extended also to a larger number and wider range of pesticide residues.

References

European Commission Pesticide Maximum Residue Levels Database, http://ec.europa.eu/food/plant/protection/pesticides/index_en.htm

European Commission Pesticide Residue Legislation Database, http://ec.europa.eu/food/plant/protection/pesticides/community_legislation_en.htm

Lehotay SJ, Mastovska K, Lightfield AR (2005) J AOAC Int 88:615–629

Sandra P, Tienpont B, David F (2003) J Chromatogr A 1000:299–309

Nguyen TD, Yun MY, Lee GH (2009) J Agric Food Chem 57:10095–10101

Goto T, Ito Y, Oka H, Saito I, Matsumoto H, Sugiyama H, Ohkubo C, Nakazawa H, Nagase H (2005) Anal Chim Acta 531:79–86

Gilbert-Lopez B, Garcia-Reyes JF, Mezcua M, Molina-Diaz A, Fernandez-Alba AR (2007) J Agric Food Chem 55:10548–10556

Sagratini G, Manes J, Giardina D, Damiani P, Pico Y (2007) J Chromatogr A 1147:135–143

Hernandez F, Pozo OJ, Sancho JV, Bijlsma L, Barreda M, Pitarch E (2006) J Chromatogr A 1109:242–252

Wang J, Cheung W, Grant D (2005) J Agric Food Chem 53:528–537

Pico Y, Blasco C, Font G (2004) Mass Spectrom Rev 23:45–85

Leandro CC, Fussell RJ, Keely BJ (2005) J Chromatogr A 1085:207–212

Moreno JLF, Liebanas FJA, Frenich AG, JLM Vidal (2006) J Chromatogr A 1111:97–105

Radisic M, Grujic S, Vasiljevic T, Lausevic M (2009) Food Chem 113:712–719

Anastassiades M, Lehotay SJ, Stajnbaher D, Schenck FJ (2003) J AOAC Int 86:412–431

Singer H, Jaus S, Hanke I, Lück A, Hollender J, Alder AC (2010) Environ Pollut 10:3054–3064

Chen L, Ding L, Jin H, Song D, Zhang H, Li J, Zhang K, Wang Y, Zhang H (2007) Anal Chim Acta 589:239–246

Hu L, Boos K-S, Yea M, Wua R, Zou H (2009) J Chromatogr A 1216:5377–5384

Edge T (2003) Handbook of Analytical Separations, Vol.4, p. 91

Scurati S, Robinson S, McDonnel S, Duretz B, Ashton P (2009) Toxicol Lett 189:S60

Hempen C, Glaesle-Schwarz L, Kunz U, Karst U (2006) Anal Chim Acta 560:41–49

Mottier P, Hammel YA, Gremaud E, Guy PA (2008) J Agric Food Chem 56:35–43

Presta MA, Bruyneel B, Zanella R, Kooll J, Krabbe JG, Lingeman H (2009) Chromatographia 69:167–173

Asperger A, Efer J, Koal T, Engewald W (2002) J Chromatogr A 960:109–119

Koal T, Asperger A, Efer J, Engewald W (2003) Chromatographia 57:Suppl. S-93–S-101

European Commission, Performance of Analytical Methods and Interpretation of Results, http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2002:221:0008:0036:EN:PDF

AOAC Guidelines for Single Laboratory Validation, http://www.aoac.org/Official_Methods/slv_guidelines.pdf

IUPAC Harmonised Guideline for Single Laboratory Validation, http://www.scribd.com/doc/4922271/Harmonized-Guidelines-for-Single-Laboratory-Validation-of-Methods-Of

European Commission, SANCO/12495/2011 Document, http://ec.europa.eu/food/plant/protection/pesticides/docs/qualcontrol_en.pdf

Lehotay SJ, Kyung AS, Kwon H, Koesukwiwat U, Fu W, Mastovska K, Hoh E, Leepipatpiboon N (2010) J Chromatogr A 1217:2548–2560

Lehotay SJ, de Kok A, Hiemstra M, van Bodegraven P (2005) J AOAC Int 88:595–614

Abd EL-Moneim MRA, Mahmoud AM, Hassan AEG, Emad RA (2010) J Food Agric Environ 8(2):602–606

Lesueur C, Knittl P, Gartner M, Mentler A, Fuerhacker M (2008) Food Control 19:906–914

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hollosi, L., Mittendorf, K. & Senyuva, H.Z. Coupled Turbulent Flow Chromatography: LC–MS/MS Method for the Analysis of Pesticide Residues in Grapes, Baby Food and Wheat Flour Matrices. Chromatographia 75, 1377–1393 (2012). https://doi.org/10.1007/s10337-012-2329-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-012-2329-y