Abstract

Two reduced-scale quick, easy, cheap, effective, rugged, and safe (QuEChERS) procedures, combined with fast gas chromatography-triple quadrupole mass spectrometry (GC-QqQ MS), were developed and then validated for the determination of 35 pesticides in different vegetable products (tomatoes, zucchini, red peppers, and lettuce). The proposed reduced-scale methods, involving the use of only 3 g of sample, were compared with an official European Union method, namely EN15662:2008, based on the use of a 10-g sample. Method validation was performed considering the following figures of merit: recovery, linearity, precision, matrix effects, and limits of detection and quantification. Specifically, recovery was in the 67–126% range, regression coefficients were between 0.991 and 0.999, and coefficients of variation were between 1 and 13% (at the 50 μg kg−1 level), while limits of quantification were always below European legislation residue limits. Additionally, the measurement of matrix effects confirmed the necessity of matrix-matched calibration. The developed QuEChERS GC-QqQ MS method is both simple and rapid (analysis of six samples in 2.5 h) and is sensitive enough for EU regulation purposes. To demonstrate the applicability of the proposed reduced-scale method, multi-residue analysis was performed on 20 samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pesticides are extensively used in agriculture to increase crop yield, but with concerns about the presence of residues in foods and in the environment. As a consequence, many countries have passed laws regulating the presence of residues in or on a food (González-Rodríguez et al. 2011). Maximum residual concentrations are defined as maximum residue levels (MRLs) in Europe and Japan [Regulation (EC) No 396 2005; The Japan Food Chemical Research Foundation 2005] and as tolerances in the USA (Administrator of the Environmental Protection Agency 2014).

The use of green (or greener) and rapid sample preparation methods is currently a major issue in the analytical chemistry field, with the obvious reason being the reduction of costs in terms of reagents, solvents, and time (De La Guardia and Armenta 2011). Miniaturization is a popular way to reach such a goal: smaller sample amounts are easy to handle (and store) in the lab and lead to a decreased necessity of solvents and reagents.

In recent decades, a series of well-accepted miniaturized extraction and pre-concentration techniques have been developed, such as single-drop microextraction (SDME) (Andraščíková et al. 2015), stir-bar sorptive extraction (SBSE) (Camino-Sánchez et al. 2014), dispersive liquid-liquid microextraction (DLLME) (Andraščíková et al. 2015), miniaturized solid-phase extraction (SPE) (Wen et al. 2014), etc. On the other hand, the use of miniaturized approaches is much more limited in the case of solid samples, a factor probably due to a more demanding extraction process (viz., matrix structure disruption, efficient solvent penetration, satisfactory recovery of target compounds). Even so, miniaturized versions of existing extraction technologies have been applied, such as matrix solid-phase dispersion (MSPD) (Wen et al. 2014), pressurized liquid extraction (PLE) (Ramos 2012), ultrasound-assisted extraction (USE) (Ramos 2012), and quick, easy, cheap, effective, rugged and safe (QuEChERS) (Andraščíková et al. 2015, Ramos 2012).

The QuEChERS approach appeared for the first time in 2003 and was developed by Anastassiades et al. (2003). The method proposed by Anastassiades et al. was based on salting-out extraction with an organic solvent, followed by dispersive solid-phase extraction (d-SPE). The original method was applied to the analysis of target analytes in a wide variety of matrices, in particular for pesticides in foods (Anastassiades et al. 2003; Bruzzoniti et al. 2014; Martínez-Domínguez et al. 2014; Sapozhnikova and Lehotay 2015a). Adjustments have been made to the original QuEChERS approach, leading to two official methods: one based on the use of a citrate buffer [European Committee for Standardization (CEN) Standard Method EN 15662] (CEN 2008) and the other on the use of an acetate buffer (AOAC Official Method 2007.01) (Lehotay 2007), with the latter possessing a greater buffering capacity. The main purpose of the use of a buffer is to extend the applicability of the approach to specific pesticides, which undergo ionization and/or degradation during extraction, depending on the pH of the matrix. In both cases, the pH is adjusted to about 5, which is a compromise to extract pesticides sensitive to either acidic or basic conditions. Other noteworthy changes have concerned the d-SPE cleanup step, involving the use of different amounts or new combinations of adsorbent materials and solvents, with the objective to attain cleaner extracts (Mastovska et al. 2010; Wilkowska and Biziuk 2011; Berlioz-Barbier et al. 2014).

Apart from the use of miniaturized sample preparation methods, there is also a tendency to reduce gas chromatography (GC) separation times (Sapozhnikova and Lehotay 2015b). In this respect, the use of short microbore columns enables a drastic reduction of GC analyses times with little or no loss in terms of resolution; the well-known reduced sample capacity of reduced-ID columns is, for the main part, counterbalanced by the generation of narrower peaks (due to less band broadening) (Donato et al. 2007).

Within the aforementioned analytical context, the main scope of the present research was to evaluate a reduced-scale QuEChERS approach, followed by fast GC analysis, for the extraction and separation of target pesticides in vegetable products (tomatoes, zucchini, red peppers, and lettuce). More specifically, two different QuEChERS methods were applied in relation to the matrix type. Highly sensitive tandem mass spectrometry (MSMS) was used for qualitative and quantitative purposes (Tranchida et al. 2013a, b, c). The results attained were compared to those derived through the (QuEChERS) official CEN Standard Method EN 15662. A series of GC-amenable pesticides, with a wide MRL range, were selected from the Regulation (EC) No 396 (2005) of The European Parliament (European Parliament 2005).

The miniaturization of the QuEChERS approach has already been proposed by Berlioz-Barbier et al. for the analysis of 35 emerging pollutants in benthic invertebrates and by DeArmond et al. for the analysis of methomyl and aldicarb in blood and brain tissue (Berlioz-Barbier et al. 2014; DeArmond et al. 2015). Both works reported the use of a liquid chromatography separation step, prior to MS analysis.

The aim of this study was to evaluate a miniaturized version of QuEChERS, followed by fast GC combined with triple-quadrupole (QqQ) MS, by using four representative vegetables.

Experimental

Materials, Solvents, and Standards

The phytosanitary compounds listed in Table 1 were kindly provided by Supelco/Sigma-Aldrich (Bellefonte, USA), with purity higher than 98%.

All the solvents used were HPLC grade. Acetonitrile (ACN), ethyl acetate (EtOAc), formic acid (FA), and n-hexane (n-hex) were obtained from Supelco/Sigma-Aldrich. Stock solutions of the phytosanitary compounds (from 548 to 1260 mg L−1) were prepared in EtOAc and stored in dark vials at −20 °C, between optimization and validation experiments. Stock solutions were used for 2 weeks, for the purposes of method optimization and validation. Stock solutions of triphenylphoshate (TPP) and anthracene (An), used as internal standard (ISTD) and quality control (QC) standard, were prepared in EtOAc and stored in dark vials at −20 °C at concentrations of 2000 and 1000 μg L−1, respectively (CEN 2008).

Calibration standard solutions were prepared in EtOAc (solvent calibration) and in blank vegetable extracts (matrix matched calibration). Blank samples of zucchini, red pepper, lettuce, and tomato (for use in validation experiments and to prepare matrix matched standards) were previously extracted with the official QuEChERS method and subjected to analysis by fast GC coupled to QqQ MS to confirm the absence of target pesticides; concentration ranges for each kind of matrix are reported in Table 1 and Table S1. Samples were homogenized with an Ultra-Turrax T 25 digital homogenizer (Janke & Kunkel GmbH & Co., IKA Labortechnik, Wilmington, NC, USA).

A standard mixture of pesticides at the 10,000 μg L−1 level, in EtOAc with 0.05% FA, was used for high (≈100 μg kg−1) and medium (≈50 μg kg−1) spiking levels; a mixture at the 1000 μg L−1 level was used for the low (≈10 μg kg−1) spiking level. The three solutions were used to measure recovery.

For sample preparation, commercial QuEChERS (Supel™ QuE Citrate) containing 4 g MgSO4, 1 g NaCl, 0.5 g NaCitrate dibasic sesquihydrate, and 1 g NaCitrate tribasic dehydrate was used. For d-SPE cleanup, pre-weighed mixtures containing 150 mg of primary and secondary amine (PSA) and 900 mg of MgSO4 (Supel™ QuE PSA), or 150 mg of primary and secondary amine, plus 45 mg of graphitized non-porous carbon (ENVI-Carb) and 900 mg of MgSO4 (Supel™ QuE PSA/ENVI-Carb) were used. These materials were provided by Supelco/Sigma-Aldrich.

Samples and Sample Preparation

Five samples for each type of vegetable, namely zucchini, red pepper, lettuce, and tomato, were purchased from retailers located in Messina (Italy).

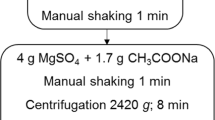

Sample preparation with the official method was based on the citrate buffer QuEChERS approach, with ACN extraction (CEN 2008). Briefly, 10 g of homogenized sample were placed into a 50-mL centrifuge tube; the matrices were spiked with adequate concentrations of standards, according to the spiking level (namely ≈10, ≈50, and ≈100 μg kg−1), the ISTD, and the QC one. After 15 min, 10 mL of ACN were added and the tube was shaken vigorously by using an IKA MS 3 basic shaker (Werke GmbH & Co. KG—Staufen, Germany) for 30 s. After, 4 g MgSO4, 1 g NaCl, 0.5 g NaCitrate dibasic sesquihydrate, and 1 g NaCitrate tribasic dehydrate were added, and the tube was shaken vigorously for 60 s. The tube was centrifuged for 5 min at 1512 rcf. Six milliliters of the acetonitrile layer were transferred into two different centrifuge tubes containing Supel™ QuE PSA for the zucchini and Supel™ QuE PSA/ENVI-Carb for the red peppers. The centrifuge tubes were shaken vigorously for 30 s and then centrifuged for 5 min at 1512 rcf. Then, 2 mL of the vegetable extract were concentrated ten times under a gentle stream of nitrogen (to a final amount of extract per volume of 10 g mL−1) and subjected to fast GC-QqQ MS analysis. The official method was used for the analysis of zucchini and red pepper samples, and the results were used for the purpose of method comparison.

With regard to the reduced-scale method, the approach was based on the same citrate buffer QuEChERS method, with ACN extraction, as described above (CEN 2008). Briefly, 3 g of homogenized sample were placed into a 12 mL centrifuge tube; adequate concentrations of standards (according to the spiking level), ISTD and the QC one, were added. For the preparation of sample blanks, 3 g of sample were spiked with internal and quality control standards only. After 15 min, 3 mL of ACN were added and the tube was shaken vigorously for 30 s. After, 1.3 g MgSO4, 0.33 g NaCl, 0.16 g NaCitrate dibasic sesquihydrate, and 0.33 g NaCitrate tribasic dehydrate were added, and the tube was shaken vigorously for 60 s. The tube was centrifuged for 5 min at 1512 rcf. One and a half milliliters of the acetonitrile layer were transferred into two different centrifuge tubes containing Supel™ QuE PSA for the tomatoes and zucchini (50 mg PSA and 300 mg MgSO4) and Supel™ QuE PSA/ENVI-Carb for the red peppers and lettuce (50 mg PSA, 15 mg ENVI-Carb, and 300 mg MgSO4). The centrifuge tubes were shaken vigorously for 30 s and then centrifuged for 5 min at 1512 rcf. Then, 1 mL of the vegetable extract was concentrated ten times under a gentle stream of nitrogen (to a final amount of extract per volume of 10 g mL−1) and subjected to fast GC-QqQ MS analysis.

Fast GC-QqQ MS Analyses

All fast GC-QqQ MS applications were carried out on a Shimadzu GC2010 instrument and a TQ8040 triple quadrupole mass spectrometer (Shimadzu, Kyoto, Japan). Automatic injection was performed by using an AOC-20i auto injector, equipped with a 10-μL syringe (injection volume range 0.1–8 μL). Data were acquired by using the GCMS solution software ver. 4.0 (Shimadzu), while the MS database used was the Pesticides GC/MS Library ver. 1.0 (Shimadzu) for initial pesticide screening.

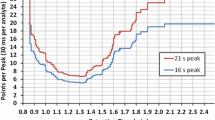

The column employed was an SLB-5ms [(silphenylene polymer, practically equivalent in polarity to poly(5% diphenyl/95% methylsiloxane)], with the following dimensions: 15 m × 0.10 mm ID × 0.10 μm d f (Supelco, Bellefonte, USA). GC temperature program: 50 °C–350 °C at 20 °C min−1. He head pressure (constant linear velocity mode 50 cm s−1) was 565.5 kPa. Injection temperature, mode, and volume: 280 °C, splitless (4 min, then split 1:20), and 0.2 μL.

QqQ MS conditions: electron ionization (70 eV); full scan conditions: scan speed 10,000 amu s−1; mass range 40–360 m/z. Interface and ion source temperatures: 220 and 220 °C. Ar (200 kPa) was employed as collision gas. For multiple reaction monitoring (MRM) transitions and collision energies (CEs), see Table 1.

Method Validation

The developed method was in-house validated following the SANTE/11945/2015 guidelines (SANTE 2015). First, the reduced-scale approach was evaluated through a comparison with the official method, in terms of recovery and precision, as reported in van Zoonen et al. (1999). Recovery experiments, performed on zucchini and red pepper, were carried out at three different spiking levels (≈10, ≈50, and ≈100 μg kg−1), for both methods, and also considering both d-SPE procedures. Both the t test (to evaluate if the average results differ significantly) and the F test (to evaluate the difference between the standard deviations) were performed to compare the methods. The solvent calibration solutions (≈10, ≈50, ≈100, and ≈1000 μg L−1) were also used to evaluate the matrix effect (ME) for each analyte in all four samples. ME values were calculated as the difference between the slope of the matrix-matched (MM) calibration curve and the solvent-only (SO) calibration curve, divided by the slope of the solvent-only calibration curve; the derived value was then expressed as a percentage: %ME = [(MM calibration curve slope − SO calibration curve slope)/SO calibration curve slope] × 100. Intra-day precision was evaluated at the 50 μg kg−1 level (approximately), by performing eight replicates, and expressed as %CV. Limits of detection (LoD) and quantification (LoQ) were calculated by multiplying the standard deviation of the analyte area, relative to the sample blank fortified at the lowest concentration level (n = 4), three and ten times, respectively, and then by dividing the result by the slope of the calibration curve. Matrix-matched linearity was tested at six levels in the 10–5000 μg kg−1 range (at the ≈10, ≈50, ≈100, ≈500, ≈1000, and ≈5000 μg kg−1 levels), performing four replicates at each level. Calibration curves were then constructed using the least squares method to estimate the regression line; the linearity and the goodness of the curve used were confirmed using Mandel’s fitting tests. The significance of the intercept was established running a t test. All the statistical tests were carried out at the 5% significance level. For absolute quantification purposes, matrix-matched calibration was used.

Results and Discussion

Fast GC-QqQ MS Optimization

The fast GC method developed was characterized by a total run time of 15 min. The GC oven required 2 min to cool down from 350 to 50 °C, giving a total analysis time of 17 min. The column employed was a low-polarity high-resolution one, capable of generating circa 150,000 theoretical plates if used under ideal conditions. A constant He linear velocity of 50 cm s−1 was applied. The temperature program gradient, namely 20 °C min−1, was derived on the basis of a 10 °C/void time value, advised and reported in the literature (Blumberg and Klee 1998).

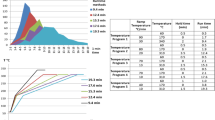

A standard solution containing all the target analytes was injected (concentration range 1128–6400 μg L−1) in the full scan mode to determine the retention times and the most significant ions of the target compounds. A time-consuming series of experiments was performed to determine the precursor and the product ions and the relative ion ratios, along with optimum CE values (Table 1). MRM transitions were all defined at a CE value of 20 eV; for CE optimization, the 5–40 eV range was evaluated at intervals of 5 eV. As recommended by SANTE guidelines (SANTE 2015), each targeted compound was characterized by four parameters: retention time, two MRM transitions, and the ratio between the product ions. Fast GC-QqQ MS traces, relative to the analysis of a spiked zucchini at the ≈10 μg kg−1 level, are shown in Fig. 1. The average percent of ion ratios (qualifier/quantifier), along with the related standard deviation (SD) values, are listed in Table 1 (zucchini and red pepper) and Table S1 (lettuce and tomato). The overall chromatographic separation can be considered more than sufficient, allowing an accurate quantification of all analytes. Just in one case, namely for the cyproconazole isomers, the separation obtained did not allow the quantification of the single isomers, and for such a reason, they were quantified as sum. The isomers could have probably been resolved by tuning the oven temperature program. However, due to the fact that the European MRL considers the sum of isomers, the oven temperature program was not modified. The MRL values of all target analytes are reported in Table 1 and Table S1, for each kind of sample. In 25 cases, the MRLs are the same for all the samples, while in other cases, the values are very different, up to two orders of magnitude. The higher MRL values are those reported for boscalid and dimethomorph isomers: 30,000 and 15,000 μg kg−1 in lettuce, respectively.

Fast GC-QqQ MS chromatograms relative to the analysis of a spiked zucchini sample at the ≈10 μg kg−1 level. For peak assignment, refer to Table 1

Method Optimization

The main object of the present research was the evaluation of a reduced-scale method. The entire extraction process was performed using circa one third of the sample (3 g instead of 10 g, paying attention to properly homogenize the sample prior to extraction), extraction solvent (3 mL instead of 10 mL), and sorbent material (2.1 g instead of 6.5 g for the extraction step, 0.35 g instead of 1.05 g for the Supel™ QuE PSA step, and 0.36 g instead of 1.09 g for the Supel™ QuE PSA/ENVI-Carb stage) compared to the official method, thus saving a considerable amount of solvents, sorbent material, and sample. It was highly important to reach sufficient sensitivity for European regulation requirements (European Parliament 2005), and thus a concentration step at the end of the cleanup process was found necessary; specifically, the sample solution was concentrated by a factor of 10 under a gentle stream of nitrogen (the use of the ISTD and the QC one allows to control this process carefully). In fact, as previously mentioned, one of the main disadvantages relative to the use of microbore columns is the lower sample capacity compared to conventional ID ones; such a drawback is, in part, counterbalanced by reduced band broadening. To evaluate the possible loss of volatiles during the concentration process, a comparison was made between a pesticide solution at the 100 μg L−1 level, concentrated 10 times, and one at the 1000 μg L−1 concentration level. A t test was performed between the areas of the two solutions, showing that there were no significant losses of volatile compounds (p > 0.05).

After the concentration process, the recovery of the reduced-scale QuEChERS extraction procedure was subjected to evaluation through a comparison with the official CEN Standard Method EN 15662. Specifically, recoveries were measured for both d-SPE cleanup steps (PSA and PSA/ENVI-Carb) by using spiked matrices, namely red pepper and zucchini. Such experiments were performed at the ≈10, ≈50, and ≈100 μg kg−1 concentration levels (n = 4), with the presence of the internal standard (TPP). The t test and F test were performed at each concentration level to evaluate significant differences (p < 0.05) in the average and SD results, respectively. Considering the 35 pesticides evaluated at three concentration levels, a total of 105 comparisons of the average recoveries were performed running the t test. Of these, 39 and 60 were significantly different (p < 0.05) between the official and the reduced-scale method using the PSA and the PSA/ENVI-Carb cleanup processes, respectively. While, comparing the SD values running the F test, 30 and 9 results were significantly different (p < 0.05) between the official and the reduced-scale method using the PSA and the PSA/ENVI-Carb cleanup processes, respectively. The most critical pesticide, using the PSA cleanup step, resulted to be cyfluthrin isomer 1 (26) with significantly lower results, at all three concentration levels, when applying the scaled-down method. Considering the PSA/ENVI-Carb cleanup step, significantly higher (p < 0.05) recoveries were obtained using the scaled-down method for the following pesticides: cyproconazole isomer II (14), mepronil (15), bromuconazole isomer II (22), boscalid (28), difenoconazole isomer II (32), and dimethomorph isomer I (33) and II (34). Spiromesifen (17) showed significantly higher recoveries using the scaled-down method, except for the lowest level (L1). With regard to the official method, recovery was in the range 70–122% (on average 93%), with %CV values in the range 1–18% (on average 7%), for the PSA cleanup process (zucchini); for the PSA/ENVI-Carb (red pepper) cleanup step, recovery was in the range 71–116% (on average 90%), with %CV values in the 2–13% range (on average 5%). With regard to the reduced-scale method, recovery was in the 67–124% range (on average 94%), with %CV values in the range 1–16% (on average 4%), for the PSA cleanup process; for the PSA/ENVI-Carb cleanup step, recovery was in the 70–126% range (on average 97%), with %CV values in the range 2–13% (on average 5%).

Only in a single case that the recovery value for the official PSA method exceeded 120%, namely for fenvalerate isomer II (30) at the 50 μg kg−1 concentration level; however, an average value of 117% considering the three spiking levels was observed. With regard to the reduced-scale method, using the PSA cleanup process, recoveries were always satisfactory apart from desmedipham (2) (slightly higher than 120%) at the 50 and 100 μg kg−1 concentration levels (an average value of 122% was calculated for the three spiking levels), for spiromesifen (17) (slightly lower than 70%) at the 100 μg kg−1 level (an average value of 73% was calculated for the three spiking levels), for captafol (18) at all concentration levels (an average value of 122% was calculated), for flurtamone (23) (slightly higher than 120%) at the 50 μg kg−1 level (an average value of 121% was calculated for the three spiking levels), for fenvalerate isomer II (30) (slightly higher than 120%) at the 50 μg kg−1 level (an average value of 104% was calculated for the three spiking levels), and difenoconazole isomer I (31) (slightly higher than 120%) at the 10 and 100 μg kg−1 levels (an average value of 115% was calculated for the three spiking levels). Comparison of the recoveries of targeted compounds in spiked zucchini samples at ≈10 (expressed as L1), ≈50 (expressed as L2), and ≈100 (expressed as L3) μg kg−1 levels are reported in Fig. 2 (the first columns refer to the official method). Significant differences (p < 0.05) obtained running the t test and F test are highlighted in Fig. 2 with the symbols * and §, respectively.

Comparison of the recoveries of the 35 targeted compounds in spiked zucchini samples at the ≈10 (expressed as L1), ≈50 (expressed as L2), and ≈100 (expressed as L3) μg kg−1 levels. The first column refers to the official method, while the second column refers to the reduced-scale one. For pesticide assignment, refer to Table 1. The symbols asterisk and section sign highlight significant differences (p < 0.05) obtained running the t test and F test, respectively

With regard to the reduced-scale method, using the PSA/ENVI-Carb cleanup step, recoveries were always satisfactory apart from metolachlor (7) (slightly higher than 120%) at the 10 μg kg−1 level (an average value of 91% was calculated for the three spiking levels) and chloridazon (16) (slightly higher than 120%) at the 100 μg kg−1 level (an average value of 112% was calculated for the three spiking levels). Comparison of the recoveries of targeted compounds in spiked red pepper samples at ≈10, ≈50, and ≈100 μg kg−1 levels are reported in Fig. 3. Significant differences (p < 0.05) obtained running the t test and F test are highlighted in Fig. 3 with the symbols * and §, respectively.

In general, all recovery values can be considered as acceptable, namely within the 60–140% range, on the basis of indications of the European Commission (European Parliament 2005). The results obtained using the reduced-scale methods appear to be in general agreement with the official methods; for such a reason, validation of both PSA and PSA/ENVI-Carb reduced-scale methods was performed.

Method Validation

The parameters considered for method validation were as follows: ME, LoQ and LoD, linearity, recovery, and repeatability. The performances of the proposed method are reported in Table 1 for zucchini and red pepper and in the supplementary material (Table S1) for lettuce and tomatoes.

The extent of MEs was calculated for each sample, since specific co-extracted compounds may cause either ion suppression or the opposite effect, leading to inaccurate results. Obviously, MEs are dependent on the nature of the matrix and the efficiency of the sample preparation step. MEs calculated for all analytes are reported in Table 1 and Table S1 for the four types of samples, with values exceeding 20% highlighted in bold (in total 28). The results indicated that the degree of signal suppression/enhancement varied with the type of matrix and compound. For the zucchini, %ME values ranged from −67% for dimethipin (3) to 66% for desmedipham (2), with an average value, considering absolute values, of 23%; for the red peppers, %ME values ranged from −33% for fenamidone (21) to 39% for desmedipham (2), with an average value of 14%; for lettuce, %ME values ranged from −56% for dimethipin (3) to 38% for cyfluthrin isomer I (26), with an average value of 16%; and finally, for the tomatoes, %ME values ranged from −33% for chlorfenapyr (12) to 47% for prosulfocarb (6), with an average value of 13%. %ME values of the analytes were variable within the same sample, but, in several cases, in good agreement for the same pesticides among the different samples. For instance, the %ME values for cyproconazole isomer I (12) were 14, 20, 20, and 18%; −7, −6, −5, and −2% for bromuconazole isomer II (22); and 38, 24, 20, and 27% for difenoconazole isomer II (32) in zucchini, red pepper, lettuce, and tomato, respectively. The results confirm the importance of using matrix-matched calibration for the purpose of quantification.

LoDs ranged from 0.1 to 2.6 μg kg−1 for zucchini, from 0.2 to 4.3 μg kg−1 for red pepper, from 0.1 to 3.3 μg kg−1 for lettuce, and from 0.2 to 3.2 μg kg−1 for tomatoes; the LoQ values ranged from 0.3 to 8.6 μg kg−1 for zucchini, from 0.6 to 14.2 μg kg−1 for red pepper, from 0.4 to 11.0 μg kg−1 for lettuce, and from 0.6 to 10.8 μg kg−1 for tomatoes. The obtained values were always below European legislation residue limits (European Parliament 2005).

Linearity was measured using matrix-matched solutions for each sample and evaluated with the Mandel’s fitting test (Fcalc < Ftab) in the 10–5000 μg kg−1 range for most compounds. In some cases (15), the upper limit of linearity was ≈1000 μg kg−1 (see Table 1 and Table S1). Calibration curves were characterized by regression coefficients (R 2) ranging from 0.995 to 0.999 for zucchini, from 0.992 to 0.999 for red peppers, from 0.995 to 0.999 for lettuce, and from 0.991 to 0.999 for tomatoes.

Repeatability was calculated at the ≈50 μg kg−1 level by analyzing the spiked matrices, eight times consecutively. The %CV values ranged from 1 to 10% for zucchini, from 2 to 11% for red peppers, from 1 to 13% for lettuce, and from 1 to 13% for tomatoes.

Real-World Samples

The validated reduced-scale fast GC-QqQ MS method was used for the analysis of 35 phytosanitary compounds in 20 samples, five for each type of vegetable (zucchini, red pepper, lettuce and tomato), purchased from local retailers. Three replicates for each sample were performed. Of the 20 samples tested, none presented a contamination level higher than that allowed by current legislation (European Parliament 2005). In all, eight different pesticides were determined in eight different samples, with none detected in the tomato samples. The most frequently found pesticide was boscalid (also at the highest concentrations), it being determined in six samples in concentrations ranging from 3.5 to 757.7 μg kg−1, with an average value of 109.9 μg kg−1. The highest concentration level was found in a sample of lettuce, even though it was well below the European MRL of 3000 μg kg−1 (European Parliament 2005). The sample with the highest number of pesticides detected was a zucchini sample, with a total of 10 different pesticides detected.

Conclusions

The multi-residue method proposed proved to be suitable for the analysis of 35 pesticides in four different vegetables and, at the same time, being more environmentally-friendly and cheaper than the official QuEChERS method. The use of fast GC enabled a considerable time reduction of the pre-separation step. The sample preparation process required approx. 20 min/sample, with six samples treated simultaneously. Overall, the analysis of the six samples was performed in 2.5 h, without considering data processing. Having demonstrated the general validity of the approach herein described, future research will be focused on an increase in the number of pesticides included in the method. Although extra-care was applied during the homogenization step to assure representativeness of the entire sample, it is noteworthy that further work is needed to verify that the 3-g samples are representative of the original 1-kg vegetable samples collected (Lehotay and Cook 2015).

References

Administrator of the Environmental Protection Agency (2014) Code of Federal Regulations, Protection of Environment. https://www.gpo.gov/fdsys/pkg/CFR-2014-title40-vol24/xml/CFR-2014-title40-vol24-part180.xml

Anastassiades M, Lehotay SJ, Štajnbaher D, Schenck FJ (2003) Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J AOAC Int 86:412–431

Andraščíková M, Matisová E, Hrouzková S (2015) Liquid phase microextraction techniques as a sample preparation step for analysis of pesticide residues in food. Sep Purif Rev 44:1–18

Berlioz-Barbier A, Buleté A, Faburé J, Garric J, Cren-Olivé C, Vulliet E (2014) Multi-residue analysis of emerging pollutants in benthic invertebrates by modified micro-quick-easy-cheap-efficient-rugged-safe extraction and nano liquid chromatography–nanospray–tandem mass spectrometry analysis. J Chromatogr A 1367:16–32

Blumberg LM, Klee MS (1998) Method translation and retention time locking in partition GC. Anal Chem 70:3828–3839

Bruzzoniti MC, Checchini L, De Carlo RM, Orlandini S, Rivoira L, Del Bubba M (2014) QuEChERS sample preparation for the determination of pesticides and other organic residues in environmental matrices: a critical review. Anal Bioanal Chem 406:4089–4116

Camino-Sánchez FJ, Rodríguez-Gómez R, Zafra-Gómez A, Santos-Fandila A, Vílchez JL (2014) Stir bar sorptive extraction: recent applications, limitations and future trends. Talanta 130:388–399

De La Guardia M, Armenta S (2011) Green analytical chemistry. Elsevier, Oxford

DeArmond PD, Brittain MK, Platoff GE Jr, Yeung DT (2015) QuEChERS-based approach toward the analysis of two insecticides, methomyl and aldicarb, in blood and brain tissue. Anal Methods 7:321–328

Donato P, Tranchida PQ, Dugo P, Dugo G, Mondello L (2007) Rapid analysis of food products by means of high speed gas chromatography. J Sep Sci 30:508–526

European Committee for Standardization (CEN) Standard Method EN 15662 (2008) Food of plant origin. Determination of pesticide residues using GC–MS and/or LC–MS/MS following acetonitrile extraction/partitioning and clean-up by dispersive SPE. QuEChERS method, (www.cen.eu)

González-Rodríguez RM, Rial-Otero R, Cancho-Grande B, Gonzalez-Barreiro C, Simal-Gándara J (2011) A review on the fate of pesticides during the processes within the food-production chain. CRC Cr Rev Food Sci 51:99–114

Lehotay SJ (2007) Determination of pesticide residues in foods by acetonitrile extraction and partitioning with magnesium sulfate: collaborative study. J AOAC Int 90:485–520

Lehotay SJ, Cook JM (2015) Sampling and sample processing in pesticide residue analysis. J Agric Food Chem 63:4395–4404

Martínez-Domínguez G, Plaza-Bolaños P, Romero-González R, Garrido-Frenich A (2014) Analytical approaches for the determination of pesticide residues in nutraceutical products and related matrices by chromatographic techniques coupled to mass spectrometry. Talanta 118:277–291

Mastovska K, Dorweiler KJ, Lehotay SJ, Wegscheid JS, Szpylka KA (2010) Pesticide multiresidue analysis in cereal grains using modified QuEChERS method combined with automated direct sample introduction GC-TOFMS and UPLC-MS/MS techniques. J Agric Food Chem 58:5959–5972

Ramos L (2012) Critical overview of selected contemporary sample preparation techniques. J Chromatogr A 1221:84–98

Regulation (EC) No 396 (2005) The European Parliament and of the council of 23 February 2005 on maximum residue levels of pesticides in or on food and feed of plant and animal origin and amending council directive 91/414/EECText with EEA relevance, off. J Eur Union L70:1–16

SANTE (2015) Guidance document on analytical quality control and validation procedures for pesticide residues analysis in food and feed. SANTE/11945/2015 30 November–1 December 2015 rev. 0

Sapozhnikova Y, Lehotay SJ (2015a) Evaluation of different parameters in the extraction of incurred pesticides and environmental contaminants in fish. J Agric Food Chem 63:5163–5168

Sapozhnikova Y, Lehotay SJ (2015b) Review of recent developments and applications in low-pressure (vacuum outlet) gas chromatography. Anal Chim Acta 899:13–22

The Japan Food Chemical Research Foundation (2005) The maximum residue limits of substance used as ingredient of agricultural chemical in foods. (MHW Notification, No. 370, 1959, amendment No. 499 2005)

Tranchida PQ, Zoccali M, Franchina FA, Bonaccorsi I, Dugo P, Mondello L (2013a) Fast gas chromatography combined with a high-speed triple quadrupole mass spectrometer for the analysis of unknown and target citrus essential oil volatiles. J Sep Sci 36:511–516

Tranchida PQ, Zoccali M, Schipilliti L, Sciarrone D, Dugo P, Mondello L (2013b) Solid-phase microextraction-fast gas chromatography combined with a high-speed triple quadrupole mass spectrometer for targeted and untargeted food analysis. J Sep Sci 36:2145–2150

Tranchida PQ, Franchina FA, Zoccali M, Bonaccorsi I, Cacciola F, Mondello L (2013c) A direct sensitivity comparison between flow-modulated comprehensive 2D and 1D GC in untargeted and targeted MS-based experiments. J Sep Sci 36:2746–2752

van Zoonen P, Hoogerbrugge R, Gort SM, van de Wiel HJ, van’t Klooster HA (1999) Some practical examples of method validation in the analytical laboratory. Trac-Trend Anal Chem 18:584–893

Wen Y, Chen L, Li J, Liu D, Chen L (2014) Recent advances in solid-phase sorbents for sample preparation prior to chromatographic analysis. Trac-Trend Anal Chem 59:26–41

Wilkowska A, Biziuk M (2011) Determination of pesticide residues in food matrices using the QuEChERS methodology. Food Chem 125:803–812

Acknowledgements

The project was funded by the “Italian Ministry for the University and Research (MIUR)” within the National Operative Project PON04a2_F “BE&SAVE” “Technologies and operational models for the sustainable food chain management through the valorization of the Biological waste for Energy use and the reduction of the Scraps generated by the Alimentary distribution and consumers, treatment for the Valorization of the Edible part of the urban solid waste and experimental development.”

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

Mariosimone Zoccali declares that he has no conflict of interest. Giorgia Purcaro declares that she has no conflict of interest. Antonino Schepis declares that he has no conflict of interest. Peter Q. Tranchida declares that he has no conflict of interest. Luigi Mondello declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Informed consent is not applicable for this study.

Electronic Supplementary Material

ESM 1

(DOCX 37 kb).

Rights and permissions

About this article

Cite this article

Zoccali, M., Purcaro, G., Schepis, A. et al. Miniaturization of the QuEChERS Method in the Fast Gas Chromatography-Tandem Mass Spectrometry Analysis of Pesticide Residues in Vegetables. Food Anal. Methods 10, 2636–2645 (2017). https://doi.org/10.1007/s12161-017-0826-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-017-0826-1