Abstract

Pollution of waters by azo dyes is a major global issue because some azo dyes have carcinogenic and mutagenic effects. Therefore, advanced methods are required to remove those pollutants from wastewater. For instance, electrochemical oxidation processes have been developed using various approaches to remove azo dyes from wastewater. Here, we review electrochemical processes for the oxidative degradation of azo dyes. Processes include anodic oxidation, electro-Fenton, photo-electro-Fenton, and solar photo-electro-Fenton. The influence of various parameters including process design, design of reactors, and the characteristic degradation products and their toxicity, are discussed. Low molecular weight carboxylic acids are mainly formed as by-products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid population growth and urbanization in the twentieth century and early twenty-first century contributed greatly to the environmental pollution problems. Among the problems associated with environmental pollution, water pollution with persistent organic pollutants is the most critical one. The discharge of industrial wastewater containing organic compounds has led to the pollution of aquatic ecosystems. The problem of water pollution with various toxic/persistent organic pollutants such as pesticides, pharmaceutical and human care products, dyes, and chlorinated phenols has been the subject of a large number of studies (Nidheesh et al. 2013; Bokare and Choi 2014; Asghar et al. 2015; Elkacmi and Bennajah 2019; Paździor et al. 2019; Wang et al. 2021; Brillas 2022).

Among the classes of organic pollutants, synthetic dyes are widely used in various industries such as textile, pharmaceutical, food and cosmetics. The most considerable contribution to wastewater containing synthetic dyes comes from the textile industry (Nidheesh et al. 2022b). Dyes are organic compounds with a complex structure that give color to various products. Dyes and their degradation products have a direct toxicological effect on different living organisms and humans (Copaciu et al. 2013). Currently, there are a large number of dyes used worldwide and their production reaches more than 900,000 tons per year. Azo dyes are the most widely dyes used in various industries. More than 60% of the dyes produced in the world are azo dyes (Gürses et al. 2016), and over 70% of the dyes used in industries are also azo dyes (Berradi et al. 2019). According to various sources, about 4–12% azo dyes are released into the environment along with the industrial wastewater generated during their production and dyeing processes (Pearce et al. 2003; Srivastava et al. 2022). As a result, about 280,000 tons of dyes per year are released globally with wastewater (Jin et al. 2007).

To date, various physicochemical methods such as adsorption (Ayati et al. 2016; Raval et al. 2016), coagulation (Luo et al. 2019), chemical oxidation and reduction (Selvaraj et al. 2021), non-thermal plasma treatment (Tarkwa et al. 2019b) and membrane filtration (Katuri et al. 2009) are used to treat wastewater containing azo dyes. Many studies are devoted to the use of biological methods for treating wastewater containing azo dyes (Solanki et al. 2013; Bhatia et al. 2017; Shah 2019). Most of the existing methods have severe limitations for practical use, such as the high cost of the technology, low removal efficacy, formation of secondary waste to be further treated, and formation of more toxic products than the parent pollutant.

Among advanced oxidation processes, electrochemical advanced oxidation processes for the removal of azo dyes from wastewater received great interest (Sirés et al. 2014; Brillas and Martínez-Huitle 2015; Moreira et al. 2017; Garcia-Segura et al. 2018; Ghime and Ghosh 2019; Selvaraj et al. 2021; Rodríguez-Narváez et al. 2021). Electrochemical methods are quite easy to operate and can be referred as “green technologies”; since wastewater treatment does not require additional chemical compounds and does not generate harmful organic intermediate products, because organic pollutants can be oxidized until the mineralization stage (transformation to CO2) before being released into the environment (Nidheesh and Gandhimathi 2012; Titchou et al. 2021a).

One of the most used electrochemical methods for azo dye removal is anodic oxidation process (Panizza and Cerisola 2009; Jiang et al. 2021; Martínez-Huitle 2021). This process is based on the direct oxidation of azo dyes on the surface of an appropriate anode via hydroxyl radical (·OH)-mediated oxidation. In this case, the anode material plays a crucial role (Peralta-Hernández et al. 2012; El Aggadi et al. 2021; Cornejo et al. 2021; Clematis and Panizza 2021; Karim et al. 2021; Ganzoury et al. 2022). During electrochemical oxidation, azo dyes can be partially oxidized with the formation of intermediate organic products that are generally biodegradable (Cornejo et al. 2021; Nidheesh et al. 2022a), or they can be completely mineralized with the formation of carbon dioxide, water, and other inorganic ions (Garcia-Segura et al. 2018; Nidheesh et al. 2019; Titchou et al. 2021a). Electrochemical processes for dye removal are based on the generation of various oxidants such as hydroxyl radical, hydrogen peroxide, and hypochlorite ion (Titchou et al. 2021a; Ganzoury et al. 2022) during electrolysis for the indirect oxidation of dyes (Särkkä et al. 2015; Nidheesh et al. 2018).

In contrast, the indirect electrochemical oxidation of azo dyes includes the generation of homogeneous reactive oxygen species in the bulk solution. Production of ·OH through electrochemically generated Fenton’s reagent via electro-Fenton process is the best example for indirect electrochemical oxidation process (Lahkimi et al. 2007; Brillas et al. 2009; Oturan and Oturan 2018; Nidheesh et al. 2023a,b). Photo-electro-Fenton, sono-electro-Fenton, electro-peroxone, peroxicoagulation and bioelectro-Fenton are the other examples of indirect electrochemical oxidation process. Recently, electrochemical generation of sulfate radical via decomposition of persulfate or peroxymonosulfate and direct conversion of sulfate ions are also received much attention (Srivastava et al. 2021; Syam Babu and Nidheesh 2022; Araújo et al. 2022). At the same time, combined methods are used to increase the efficiency of electrochemical processes. A large number of papers on the use of combined methods for the removal of azo dyes from real and simulated wastewater have been published. Combined methods include the combination of electrochemical oxidation with adsorption, ultrasonic treatment, UV light irradiation, photo-catalysis, biological oxidation and ozonation (Ganzenko et al. 2014; Martínez-Huitle et al. 2015; Patidar et al. 2020; Qiao and Xiong 2021; Koulini et al. 2022).

This review considers the most important aspects of electrochemical oxidation of azo dyes, which comprise one of the largest groups of dyes used in various industries. Characteristics, classification and toxicity of azo dyes and their intermediates are briefly discussed to understand how to prevent water pollution. The main directions of research in the field of electrochemical oxidation are given, and the prospects for the development of electrochemical methods, which are considered as the most environmentally friendly methods of wastewater treatment, are outlined.

Characteristics of azo dyes

Azo dyes constitute the largest group of synthetic dyes and are widely used due to ease of use, various properties, and a wide range of colors from yellow to black. They are highly light-resistant and used in multiple industries such as textile, printing, paint and varnish to dye various products. Azo dyes can color most natural, artificial and synthetic materials, including leather, plastic, and rubber products. Most of the azo dyes are water soluble, and the coloration of various materials is associated with their physical adsorption, absorption, or mechanical fixation (Bafana et al. 2011).

Azo dyes are characterized by the presence of the functional azo group (–N=N–) included in two or more symmetrical or asymmetrical aromatic groups (Bafana et al. 2011). The azo group can be linked to benzene rings, naphthalene, aromatic heterocycles, or aliphatic groups, which give color with various shades and intensities to the dye (Benkhaya et al. 2020b). In terms of the number of azo bonds in the molecule, azo dyes can be classified into monoazo, diazo, and polyazo dyes. In accordance with the international classification of dyes, azo dyes have color index (C.I.) numbers from 11,000 to 39,000 (Selvaraj et al. 2021). The color index number is indicated after the name of the dye, which reflects the dye technical classification and color (Kiernan 2001). For example, Reactive Black 5 (C.I. 20,505) is a black dye belonging to the group of reactive azo dyes.

The most water-soluble azo dyes, which can subsequently get into the environment with wastewater, are acid, direct, reactive, basic (cationic) and mordant ones. Acid and reactive azo dyes, mainly mono- and diazo ones, make up more than half of the currently used azo dyes (Benkhaya et al. 2017). Acid dye molecules contain sulfonic groups, which define the solubility and acidic properties of the dye. Protein fibers are colored using acid azo dyes, and the colors are characterized by brightness and purity of the hue. As a rule, acid dyes are sodium salts, which form colored anions in the solution (Benkhaya et al. 2020a). The class of reactive azo dyes includes the dyes that form a covalent bond with cellulose, protein and similar fibers during their dyeing. As a result, the dye becomes a fiber component, providing high color fastness.

Currently, there is a rapid introduction of reactive dyes into the technologies for the textile industry due to their valuable dyeing properties including high color fastness to wet treatment comparable to the color fastness of vat dyes as well as more excellent brightness of colors compared to direct, acid, and basic dyes (Alsantali et al. 2022). Direct azo dyes are mainly belong to diazo and polyazo compounds. They contain many hydroxylamino groups and nitrogen heterocycles. As a result, they form hydrogen bonds between the dye groups and are used for dyeing cellulose fibers (Bafana et al. 2011). The basic azo dyes are cationic in nature, which can color fibers containing acid groups. The molecules of these dyes have free or alkylated amino groups and do not contain either sulfonic or carboxyl groups (Kiernan 2001).

Reactive azo dyes are mainly used for dyeing cellulose fibers. The mechanism of dyeing materials with reactive dyes involves the formation of covalent bonds between the dye molecules and the fibers, which are more resistant to various conditions of use. Reactive substituents of these azo dyes can also react with the hydroxyl groups present in the dye bath due to the alkaline environment, and as a result, part of the hydrolyzed dyes can no longer react with the fiber. Thus, from 10 to 50% of the initial dye charge will be present in the dye bath effluent, resulting in a strongly colored effluent (Al-Degs et al. 2000). It should be noted that reactive dyes have a toxicological effect on living organisms (Salazar and Ureta-Zañartu 2012). They reduce the amount of ammonium-oxidizing bacteria in the soil, which may limit the efficiency of using nitrogen by plants, thereby decreasing the productivity of land ecosystems (Topaç et al. 2009).

Direct azo dyes are the cheapest and easiest to use. Most direct azo dyes are diazo and polyazo compounds. The disadvantage of direct azo dyes is their poor recovery from the dye bath, and therefore, about 30–60% of the dye enters the wastewater. Direct azo dyes are mainly used to dye cellulose fibers, and they link with the fibers by hydrogen bonding and van der Waals interactions. Therefore, direct azo dyes have low color fastness to wet treatment, and they are currently less used (Bafana et al. 2011). It should be noted that direct azo dyes, like other groups of azo dyes, have a pronounced toxicological effect on populations of living organisms in ecosystems (Hernández-Zamora and Martínez-Jerónimo 2019a, 2019b).

Azo dyes have mutagenic properties (Hashemi and Kaykhaii 2022), and they are difficult to oxidize under aerobic conditions at biological treatment plants (Senthil Rathi and Senthil Kumar 2022). Under certain conditions, their degradation can result in toxic products (Gottlieb et al. 2003; Rawat et al. 2016). In addition, mammal microbiota, including skin or intestinal microflora, can turn the azo dyes into carcinogenic metabolites (Feng et al. 2012). The toxicological effect of selected azo dyes is presented in Table 1.

Many of the azo dyes, products of their reductive splitting as well as chemically related aromatic amines are reported to affect human health by causing allergies and other human diseases. Some azo dyes exhibit toxic effects. For example, Acid Orange 10 or Orange G is a monoazo dye used mainly for dyeing silk and woolen products, paper and industrial ink, and is also used in the manufacture of pencils and dyeing cell structures in biochemical research. Acid Orange 10 has shown genotoxicity and may also be hazardous to human health (Jović-Jovičić et al. 2010). Monoazo dye Acid Red 14 is used for dyeing woolen fabrics, silk and polyamide fibers (see the structural formula in Table 2). Acid Red 14 is also used in the food industry and is known as carmoisine or food additive E122. According to the European Food Safety Agency, the hyperactive-child syndrome may be associated with the ingestion of carmoisine (Thiam et al. 2015c). Acid Red 27 or amaranth food color is a water-soluble monoazo dye. Acid Red 27 is added during the manufacture of various food products, giving them a distinctive red color (Rovina et al. 2017). Some countries have banned the use of Acid Red 27 in food and beverages because its toxicological effect was scientifically proven (Barros et al. 2014; Rovina et al. 2017). Therefore, Acid Red 27 removal from aqueous solutions by various methods, including electrochemical oxidation, was reported (Fan et al. 2008).

To date, most dyes are not controlled for toxicity and are considered nontoxic. However, supposedly nontoxic azo dyes have functional groups that can impart mutagenic and carcinogenic properties upon degradation. For example, they can lead to the formation of degradation products such as β-naphthylamine, aniline, triazine, p-phenylenediamine, and β-amino-α-naphthol, which are well-known genotoxicants (Brüschweiler et al. 2014; Rawat et al. 2016). It should also be noted that diazo, triazo and polyazo dyes are the most toxic among azo dyes (Golka et al. 2004). When assessing toxicity of azo dyes, attention is focused only on a laboratory study. Their possible degradation under the influence of various environmental factors, including biological oxidation at biological treatment plants or in natural water, is not taken into account. The formation of toxic degradation products of azo dyes has been shown in many works (Brüschweiler et al. 2014). In particular, the formation of carcinogenic 3,3’-dimethoxybenzidine during the degradation of Direct Blue 15 azo dye is reported (Golka et al. 2004). Degradation of Acid Orange 7 and Reactive Black 5 dyes, which are considered to be non-toxic, also leads to the formation of hazardous aromatic amines (Gottlieb et al. 2003).

The concentration of azo dyes in dyeing wastewater can widely range from 5 to 1500 mg/L, depending on the material to be dyed. The resistance of azo dyes to biodegradation requires their pre-treatment using various physicochemical methods. Physicochemical and biological methods for treating wastewater containing azo dyes are primarily used to remove the color of solutions. Each of the method for color removal has its own advantages and disadvantages, including factors such as the nature of the dye, the composition of wastewater, concentration, toxicity, the cost of used chemicals, as well as the cost of processing of unit volume of wastewater and the equipment. These factors determine the economic feasibility of each method for wastewater treatment of azo dyes effluents (Selvaraj et al. 2021). The oxidation or reduction by-products play a significant role in evaluating the effectiveness of the method for treating wastewater containing azo dyes. It should be noted that using a single method for removing azo dye might be insufficient. In view of this, the study of the processes of azo dye removal has become an urgent task, and the search for environmentally sound methods of dye removal in order to reduce an anthropogenic load on ecosystems associated with the discharge of wastewater containing azo dyes is currently ongoing.

In this context, the interest of researchers in developing methods for azo dye removal from wastewater is increasing (Salazar and Ureta-Zañartu 2012; Jáger et al. 2019). In recent years, many studies have been carried out on developing electrochemical methods for removing azo dyes of different colors (Almomani and Baranova 2012, 2013). Among azo dyes, acid, reactive, and direct dyes are of the greatest interest to researchers. Table 2 lists different azo dyes and their removal by electrochemical approach. Most of the studied azo dyes belong to monoazo and diazo compounds, and they are characterized by the formation of various aromatic fragments during electrochemical oxidation (Bafana et al. 2011). Electrochemical oxidation has been used to remove azo dyes from solutions due to their toxic properties. In particular, much attention has recently been paid for the removal of various food colors from wastewater because of their effects on human, especially on the child (Parsa et al. 2014; Thiam et al. 2015a, 2016; Rahmani et al. 2015; Malakootian and Moridi 2017; Ben Hafaiedh et al. 2020).

Electrochemical oxidation of azo dyes

Electrochemical methods for azo dye removal attract much attention as they are environmentally friendly since the leading reagent that oxidizes azo dyes is an electron transferred from the surface of various electrode materials (Shukla and Oturan 2015). Oxidation of azo dyes during electrolysis is also associated with the generation of ·OH on the surface of the electrodes during oxidation of water (anodic oxidation) and in the bulk of the electrolyte upon adding a catalyst and in situ generation of hydrogen peroxide during electrolysis (electro-Fenton). Electrochemical oxidation removes azo dyes with high chemical oxygen demand ranging from 0.1 to 100 g/L from wastewater (Sirés et al. 2014). On the other hand, electrochemical advanced oxidation processes can be used as a pre-treatment process to increase the biodegradability of azo dyes containing wastewater for a biological post-treatment (Ganzenko et al. 2014).

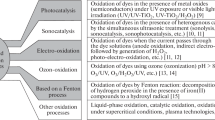

Other oxidation processes for removing azo dyes have limitations and disadvantages compared to electrochemical advanced oxidation processes. The chemical oxidation processes, such as ozone oxidation and hypochlorite ion oxidation, and advanced oxidation processes such as Fenton's reagent, photo-Fenton, and photo-catalytic oxidation also lead to decolorization of azo dye solutions (Deng et al. 2020). However, applying these methods for wastewater treatment and azo dyes removal is limited due to some disadvantages. For example, the main disadvantage of the Fenton's reagent and related advanced oxidation processes is the formation of an iron-containing sludge and the process is effective only at acidic pH (Oturan and Aaron 2014; Deng and Brillas 2023). Oxidation processes based on ozone have the disadvantage of a short half-life of ozone molecules (Javaid and Qazi 2019). The use of hypochlorite ions as oxidants leads to incomplete destruction of azo dyes with the formation of aromatic amines (Isaev and Magomedova 2022), which can be more toxic than the original azo dyes (Gottlieb et al. 2003). Photo-catalytic methods also have limited application due to high rates of recombination of the photo-generated electrons and holes (Ge et al. 2016). However, the use of advanced oxidation processes for removing azo dyes compared to other physicochemical methods such as adsorption or coagulation does not lead to the secondary pollution associated with the transfer of azo dyes from one phase to another (Ma et al. 2021).

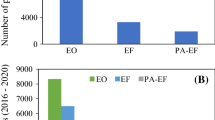

Electrochemical oxidation of azo dyes has advantages over other physical and chemical methods. For example, electrochemical removal of azo dyes can be carried out under relatively mild conditions at ambient temperature and pressure without additional chemicals. Electrochemical methods are highly efficient, do not produce secondary waste, are easily automated, and can be supplemented by other methods for dye removal (Särkkä et al. 2015; El-Kacemi et al. 2017; Cui et al. 2021). The disadvantages of a typical electrochemical process implemented by anodic oxidation include high energy consumption for the treatment of wastewater with a low concentration of organic pollutants, heterogeneous nature of the electrochemical process (mass transfer limitation), and a decrease in the activity of the electrode surface due to adsorption of azo dye degradation products (Garcia-Segura et al. 2018). To compensate disadvantages of this process, various approaches including indirect electrochemical oxidation with the generation of oxidizing agents such as active chlorine species, persulfate (called mediated oxidation) (Panizza and Cerisola 2009), and photo-electrochemical oxidation were developed. On the other hand, the electro-Fenton process and related techniques such as heterogeneous electro-Fenton, photo-electro-catalysis, photo-electro-Fenton and solar photo-electro-Fenton take the advantages to generate hydroxyl radicals homogeneously in the bulk solution, in addition of heterogeneous hydroxyl radical formed on the anode surface, to increase the process efficiency (Titchou et al. 2021a). Figure 1 summarizes the main electrochemical methods used for the removal of azo dyes from wastewater. The main parameters affecting the efficiency of electrochemical oxidation of azo dyes are the electrode material, current density, initial concentration of dyes, nature of the dye and the electrolyte, fluid hydrodynamics, pH, and temperature (Qiao and Xiong 2021).

Electrochemical oxidation processes for removal of azo dyes. Direct oxidation–oxidation directly on the anode surface due to electron transfer and formation of ·OH on the anode surface (Panizza and Cerisola 2009; Moreira et al. 2017); indirect oxidation–oxidation due generation of various oxidants such as H2O2, hypochlorite, and persulfate (Scialdone 2009); electro-Fenton–oxidation due homogeneous.·OH via electrochemical generated Fenton’s reagent (Oturan and Oturan 2018; Vasudevan and Oturan 2014; Nidhesh et al. 2018); photo-electro-Fenton–oxidation due electrochemical generated Fenton’s reagent with simultaneous ultraviolet or sunlight irradiation (Brillas 2020; Ganiyu et al. 2018)

The electrochemical oxidation of azo dyes has been the subject of a large number of studies. Most of the publications are devoted to electrochemical oxidation of acid and reactive azo dyes using various electrochemical methods, which is due to the wide use of both azo dyes for dyeing various materials. The efficiency of electrochemical oxidation of azo dyes can also be affected by the molecular structure of dyes. Research results show that functional groups, which reduce nucleophilicity of the azo dye, inhibit electrophilic attack of the electro-generated ·OH and, thus, reduce overall effectiveness and decolorization rate. In addition, the presence of an additional chromophore azo bond in the molecule leads to the formation of a more stable conjugated π-system, which increases the activation energy required for electrophilic attack and enhances the persistent nature of azo dyes (da Costa Soares et al. 2017).

Anodic oxidation

Anodic oxidation of organics can occur by a direct electron transfer to the anode surface and by hydroxyl radicals formed on the anode surface during water oxidation. The efficiency of producing hydroxyl radicals and, consequently, oxidation of azo dyes are depending on the anode material used in anodic oxidation process. Since the formation of ·OH is a heterogeneous process, in the case of using active metal and metal oxide anodes (so-called active anodes), chemisorption occurs on the electrode surface and the mineralization of organics is not much high (Panizza and Cerisola 2009). The formation of hydroxyl radicals is facilitated by anodes with high oxygen over-potential (called non-active anodes), such as boron-doped diamond (BDD), PbO2, and sub-stoichiometric titanium oxide (Peralta-Hernández et al. 2012; He et al. 2019; Trellu et al. 2020; Karim et al. 2021; Srivastava et al. 2021). The mechanism of oxidation of organic compounds with the formation of hydroxyl radicals has been studied in sufficient detail by many researchers (Comninellis 1994; Panizza and Cerisola 2009). In the case of active anode, heterogeneous hydroxyl radicals MOx(HO·) form mainly during water oxidation [Eq. (1)] is strongly adsorbed to the anode surface. Adsorbed radicals lead to the formation of chemisorbed oxygen [Eq. (2)] or oxygen release [Eq. (3)]. Chemisorbed oxygen can then release as gaseous oxygen [Eq. (4)]. MOx(HO·) and oxygen oxidize organic substances (noted RH), followed by catalytic regeneration of the anode surface according to Eqs. (3)–(6).

The proposed mechanism is different in the case of a non-active anode, such as BDD. The BDD(HO·) is very slightly adsorbed on the anode surface and behaves as quasi-free hydroxyl radicals. Therefore, the oxidation of organic pollutants leading to their mineralization can be summarized as follows:

Anodic oxidation of azo dyes results in the formation of low molecular weight organic compounds, such as carboxylic acids, available for biological oxidation or complete mineralization occurring with the formation of CO2, H2O, and other inorganic compounds (Alcocer et al. 2018). The efficiency of direct anodic oxidation of dyes depends on several functional groups (for example, azo bonds) in their molecules, making them electro-active for direct electron transfer (Alagesan et al. 2021).

Indirect electro-oxidation

During indirect oxidation, the reaction of anodic oxidation or cathodic reduction (of water or species present in the medium) results in the formation of intermediate products or oxidizing agents such as ozone, hydrogen peroxide, and other active species on the electrode surface under the action of external current (Nidheesh et al. 2018). In the presence of SO42−, Cl− and PO43− ions as electrolytes, oxidizing agents such as S2O82−, Cl2, HClO and P2O84− can also form (El Aggadi et al. 2021; Divyapriya and Nidheesh 2021). Oxidizing agents or active species thus formed can react with organic pollutants leading to their oxidation with the formation of various intermediate compounds (Martínez-Huitle and Brillas 2009; Martínez-Huitle et al. 2015). The initial oxidation reaction occurs on the electrode surface, and the subsequent degradation of pollutants occurs in the bulk electrolyte (Qiao and Xiong 2021).

Electro-Fenton

The electro-Fenton is one of the most popular electrochemical advanced oxidation processes along and is based on electrochemically assisted Fenton reaction. In contrast to the classical Fenton system in which Fenton’s reagent (mixture of H2O2 and Fe2+) is externally added to the solution to be treated, the electro-Fenton process does not use chemicals except a catalytic amount of ferrous iron (Oturan et al. 2000; Brillas et al. 2009). H2O2 is formed by a two-electron reduction of O2 [Eq. (10)] on a suitable cathode. Formed H2O2 reacts with externally added catalyst (Fe2+) to form ·OH homogeneously via Fenton reaction [Eq. (11)].

Continuous generation of ·OH is then ensured by the electro-regeneration of Fe2+ [Eq. (12)) from the reduction of Fe3+ formed in Fenton reaction [Eq. (11)].·OH further reacts with organic pollutants leading to their oxidation to biodegradable species, which can be further removed by a biological post-treatment (Olvera-Vargas et al. 2016). Alternatively, organic pollutants can be mineralized to CO2 and inorganic ions as in anodic oxidation (Eqs. (9) and (10)]. However, the latter option needs longer treatment time and more energy.

The most widely used cathode materials for the efficient production of H2O2 are based on carbon materials (carbon felt, reticulated vitreous carbon (RVC), carbon sponge, carbon nanotubes (CNT) or graphite) (He and Zhou 2017; Ganiyu et al. 2018; Divyapriya and Nidheesh 2020; Sopaj et al. 2020). The performance of the electro-Fenton process was strongly improved with the use of non-active anodes, mainly BDD anode. The use of BDD as an anode in the electro-Fenton process allows for the simultaneous production of homogeneous ·OH in the bulk solution [Eq. 11] and heterogeneous BDD(·OH) on the anode surface (Oturan et al. 2012).

The electro-Fenton process is optimal at acidic pH of about 3. To overcome this pH dependency and to recover the catalyst used in the process, several modifications were recently done by developing heterogeneous electro-Fenton process including various solid catalysts, and catalyst loaded on cathode surface. The various advancements in electro-Fenton process are explained in detail in previous research and review articles (Barhoumi et al. 2017: Heidari et al. 2021; Meijide et al. 2021; Gopinath et al. 2022; Krishnan et al. 2022; Nidheesh et al. 2022c; Nidheesh et al. 2023a, b).

Photo-electro-catalysis

Photo-electro-catalysis is a rapidly developing method for removing azo dyes from aqueous solutions (Garcia-Segura and Brillas 2017; Brillas and Garcia-Segura 2023). This is due to the increased efficiency of organic dye removal through the synergistic effect of photo-catalysis and electro-catalysis (Laghrib et al. 2020). The main advantage of photo-electro-catalytic oxidation of azo dyes is the high rate of charge separation compared to photo-catalysis and low energy consumption compared to electrochemical oxidation of azo dyes, especially when using sunlight as an energy source (Zhang et al. 2023; Brillas 2023). In this case, the main disadvantage of photo-catalytic oxidation of azo dyes, rapid recombination of photo-generated electrons and holes (e−/h+), can be eliminated by applying an external potential during photo-electro-catalytic oxidation of azo dyes (Ma et al. 2020). For photo-electro-catalytic oxidation of azo dyes, semiconductor electrodes, that capable of reacting to UV or sunlight, are used and applied onto various substrates. The absorption of a photon by the semiconductor photo-electrode with energy exceeding its band gap results in charge separation, generating electrons (e−) in the conduction band and holes in the valence band [Eq. 13] (Rajput et al. 2021).

Under the influence of an external applied potential, the photo-generated e− can move towards the counter electrode, leading to redox reactions on the electrode surfaces (Cao et al. 2017). Simultaneously with the electrolysis process, direct azo dyes oxidation reactions occur on the photo-catalyst surface, forming highly active oxygen-containing particles (Feng et al. 2021). The combination of electro-catalytic and photo-catalytic processes reduces the rate of electron–hole pair recombination and increases the lifetime of holes (Zarei and Ojani 2016). The resulting h+ has a strong oxidizing ability and can migrate to the surface for direct interaction with azo dyes or react with H2O/OH− to form hydroxyl radicals, which also oxidize organic pollutants [Eq. 14]. Photo-generated electrons can react with dissolved oxygen to form active oxygen-containing particles according to Eq. 15 (Garcia-Segura and Brillas 2017).

In addition to photo-catalytic processes, electrochemical oxidation of azo dye can also occur on oxide–metal semiconductors. Anodic oxidation of azo dye can occur by direct electron transfer to the surface of the anode and ·OH formed on the surface of the anode during water oxidation. The efficiency of hydroxyl radical formation and thus the oxidation of azo dyes depend on the anode material. Since the formation of ·OH is a heterogeneous process, the use of active metal and metal oxide anodes leads to chemisorption of oxidation products of azo dyes on the electrode surface and their low activity in the oxidation process (Panizza and Cerisola 2009). Anodes with high oxygen evolution over-potential, such as BDD, PbO2, and others, promote the formation of hydroxyl radicals (Peralta-Hernández et al. 2012; Alimirzaeva et al. 2019; He et al. 2019; Karim et al. 2021).

Photo-/solar photo-electro-Fenton

Photo-electro-Fenton process consists of light (UV or visible) irradiation of electro-Fenton reactor. This process implemented first by Brillas’ team allows for increasing mineralization efficiency of electro-Fenton process. The short-chain carboxylic acids formed during electro-Fenton oxidations are complexed by Fe3+ present in the medium and become recalcitrant to ·OH, resulting in low mineralization rates. On the other hand, UV or visible light irradiation can destroy this complex and thus facilitate the mineralization of carboxylic acids. For example, Eq. (16) shows the destruction of Fe(III)-carboxylic acid complex with the regeneration of Fe2+ (catalyst). The photo-generated Fe2+ ion can subsequently catalyze the Fenton reaction, which results in the formation of Fe3+ and ring closure [Eq. (11)]. Additionally, photo-reduction of Fe3+ generated in Fenton reaction allows the formation of additional ·OH [Eq. (17)] (Brillas et al. 2009; Oturan and Aaron 2014; Ganiyu et al. 2018; Divyapriya et al. 2021).

Although the photo-electro-Fenton in practice provides high oxidation/mineralization power, the use of artificial light makes the process costly. Therefore, solar photo-electro-Fenton process have been developed to remediate this inconvenient (Bedolla-Guzman et al. 2016; Salazar et al. 2019; Brillas 2020; Wang et al. 2021). This process is effective for completely mineralizing synthetic azo dyes and real wastewater (Brillas 2022) with higher mineralization power and lower energy consumption than conventional electro-Fenton processes.

Electrochemical oxidation of various azo dyes

Various electrochemical processes are used to remove azo dyes from wastewater: direct and indirect electrochemical oxidation, electro-Fenton, photoelectrocatalysis, photo-electro-Fenton, solar photo-electro-Fenton, and a combination of electrochemical processes with other physical–chemical or biological treatments. The combination of electro-oxidation with various types of physical and chemical treatment increases the efficiency of color and chemical oxygen demand removal. For example, this enhancement has been demonstrated during oxidative degradation of Reactive Black 5 by ultrasonic treatment coupled with electrochemical oxidation (Johin et al. 2019), sono-electro-Fenton in the presence of electrochemically generated hydrogen peroxide (Şahinkaya 2013), and photo-electro-Fenton with UV or sunlight irradiation in the presence of electrochemically generated hydrogen peroxide and semiconductor materials (Wang et al. 2008b; Sala et al. 2016). Electro-catalytic oxidation of Methyl Orange in a hybrid self-powered electrochemical cell has also been reported to be a variant of creating an energy-independent technology for wastewater treatment from azo dyes (Yang et al. 2013).

Electrochemical generation of Fenton’s reagent is used as an effective and potentially practical method for removing azo dyes from wastewater (Isarain-Chávez et al. 2013). The rate of Methyl Orange oxidation is higher for electro-Fenton process as compared to anodic oxidation with electro-generated hydrogen peroxide (do Vale-Júnior et al. 2018). The addition of heterogeneous catalysts, such as magnetically separable nano-Fe3O4 (Sasidharan Pillai and Gupta 2016) and Fe2(MoO4)3-kaolin-based iron molybdate (He et al. 2014) to Methyl Orange solution for hydrogen peroxide decomposition, leads to an increase in the rate of ·OH generation and, accordingly, an increase in the rate of decolorization and chemical oxygen demand removal (Jiang et al. 2016).

Among acid azo dyes, electrochemical oxidation of Methyl Orange was extensively studied by several researchers. Methyl Orange is used as a model compound for studying the activity of various electrode materials and in determining the effectiveness of new electrochemical methods. Direct anodic oxidation of Methyl Orange and its indirect electrochemical oxidation are also studied with the generation of active chlorine on the anode or hydrogen peroxide on the cathode (Zhang et al. 2015) in solutions with a high NaCl concentration (Yu et al. 2015). These authors showed that a high current density, an acid environment, and an increase in the concentration of NaCl have a positive effect on the electro-oxidation rate of Methyl Orange. It should be noted that the electrochemical oxidation of Methyl Orange in chloride-containing solutions does not lead to the formation of intermediate organochlorine compounds (Pillai et al. 2015).

Acid Orange 7 is mainly used in printing and textile industries and hardly degrades by biological and other wastewater treatment methods. When dissolved in water, Acid Orange 7 can form three types of molecules with different charges depending on the solution pH (Chou et al. 2011). AO7 electrochemical oxidation in various electrolytes and using various approaches have been studied in sufficient detail (Chou et al. 2011; Qiao et al. 2015; Wu et al. 2016). An increase in the efficiency of electrochemical oxidation for complete removal Acid Orange 7 can be achieved by combining electrochemical oxidation with other treatment methods. Acid Orange 7 electrochemical oxidation results in the accumulation of toxic aromatic fragments, which can be removed using subsequent sorption (Li et al. 2015). The overall efficiency of Acid Orange 7 electrochemical oxidation using granular activated carbon as electrodes and in combination with coagulation reduces chemical oxygen demand and color to 99% and 87%, respectively (Xiong et al. 2001). Bio-electrochemical treatment of the solutions containing Acid Orange 7 azo dye has also been reported, which leads to complete decolorization of the solution with an additional mineralization of toxic products formed during azo dye oxidation (Pan et al. 2017).

During the Acid Orange 7 indirect electrochemical oxidation through the generation of hydrogen peroxide, the cathode material plays an important role. The cathode material was subjected to various modifications to increase the efficiency of hydrogen peroxide production yield. Modifying a carbon air-diffusion cathode with nanoparticles of tungsten oxide resulted in increased hydrogen peroxide yield and azo dye oxidation (Paz et al. 2018). In a polypyrrole framework, lignin-based composites deposited on graphite felt was also used as the cathode in Acid Orange 7 electrochemical oxidation (Sun et al. 2015). When the powdered sludge carbon resulted from pyrolysis reaction at 800 °C was used as the cathode, the Acid Orange 7 removal from the solutions occurred efficiently due to simultaneous adsorption and electro-oxidation (Sun et al. 2015). Besides, when an electrochemically active tubular carbon-graphite membrane was used as the cathode, Acid Orange 7 electro-oxidation was supplemented with dynamic filtration technology (Liang et al. 2016). The electrochemical oxidation of Acid Orange 7 took place rapidly in anodic oxidation with PbO2-coated RVC composite cathode (RVC/PbO2/TiNT) and an industrial stainless steel mesh anode (Ramírez et al. 2016). Combining the processes of ozonation and electrolysis with the formation of H2O2 on the cathode led to an increase in the efficiency of the azo dye oxidation process. In this case, complete decolorization and total organic carbon removal at the level of 95.7% were obtained after 4 and 45 min of treatment, respectively (Bakheet et al. 2013).

The use of the electro-Fenton process also refers to Acid Orange 7 indirect electrochemical oxidation. Acid Orange 7 oxidation in the electro-Fenton process occurs with the formation of electro-generated ·OH, leading to the complete oxidative degradation of the dye up to its complete mineralization. H2O2 and Fe2+ ions are catalytically electro-generated on a carbon felt cathode (Özcan et al. 2009). The new cathode for electro-Fenton based on reduced graphene oxide deposited on the carbon felt surface makes it possible to decolorize the Acid Orange 7 solution after 5 min of electrolysis (Le et al. 2015). Electro-Fenton is the most efficient method for Acid Orange 7 removal. A comparison of two cathode materials, unidirectional carbon fiber and reticulated vitreous carbon, showed that the former electrode was more efficient in generating hydrogen peroxide and subsequent oxidation of Acid Orange 7 (Ramírez-Pereda et al. 2018).

According to the literature data, the efficiency of anodic oxidation and electro-Fenton processes of Acid Red 27 depends on the electrolyzer configuration, current density, electrolyte type, and electrodes used (Zhang et al. 2012). The solutions of food azo dye were processed using different anode materials at different temperatures and solution flow rates, which ensured the color and chemical oxygen demand removal of more than 75% (Elaissaoui et al. 2019). When Ir-Sn-Sb mixed-oxide anode was used in the electro-Fenton and photo-electro-Fenton processes, the efficiency of Acid Yellow 36 oxidation increased compared to anodic oxidation. Oxidation of the dye occurred mainly by heterogeneous M(·OH) and generated active chlorine species (Aguilar et al. 2017). In situ electrochemical generation of H2O2 has also been used to oxidize the Acid Yellow 36 azo dye (Cruz-González et al. 2010). In this case, H2O2 continuously formed in the dye solution from electro-reduction of dissolved molecular oxygen (Isaev and Aliev 2012; Rodríguez De León et al. 2019).

Using other physicochemical methods combined with electrochemical oxidation increases the efficiency of Acid Red 14 removal. The electro-Fenton process promotes about 60–70% of Acid Red 14 mineralization, while photo-electro-Fenton can mineralize Acid Red 14 more efficiently (total organic carbon removal of more than 94%) even at low current densities, due mainly to the contribution of UV light irradiation (Wang et al. 2008a). The addition of TiO2 to the Acid Red 14 solution significantly enhances the dye degradation (Shen et al. 2002), and the addition of Fe3O4 nanoparticles leads to heterogeneous Fenton-like processes of dye oxidation on the catalyst surface (Es’haghzade et al. 2017). Acid Red 14 electrochemical degradation in a plasma flow (Barrera et al. 2020) is also more efficient than anodic oxidation (Wang et al. 2010). In the case of a plasma-stimulated oxidation process, the formation of hydrogen peroxide occurs in a plasma discharge, which enhances dye degradation, and the introduction of iron ions (Fe2+/Fe3+) into the solution leads to the formation of an enormous amount of ·OH through Fenton reaction (Barrera et al. 2020).

The combination of electrochemical oxidation of Methyl Orange with the subsequent adsorption of degradation products increased the process efficiency due to the synergistic effect between electrolysis and adsorption (Liu et al. 2022). The combination of the AO16 electro-oxidation process with the subsequent adsorption process has also been reported, resulting in an increase in chemical oxygen demand removal efficiency (Zakaria et al. 2015). Comparatively treated the Acid Red 1 solutions by anodic oxidation with electro-generated H2O2 (anodic oxidation-H2O2), electro-Fenton and photo-electro-Fenton processes at constant current density and oxidation power was found in the following sequence: anodic oxidation-H2O2 < electro-Fenton < photo-electro-Fenton. Faster and similar decolorization efficiency was achieved in electro-Fenton and photo-electro-Fenton owing to the quicker destruction of aromatics with hydroxyl radicals produced in bulk (Fig. 2).

Dissolved organic carbon (DOC) abatement: a and color removal vs. electrolysis time for the degradation of Acid Red 1 (AR1) solutions, b using a Pt/air-diffusion cell (open symbols) or a boron-doped diamond (BDD)/air-diffusion cell (solid symbols). Method: (○,●) Anodic oxidation with formation H2O2 (AO-H2O2), (□,■) electro-Fenton (EF) with 0.5 mM Fe2+ and (∆,) photo-electro-Fenton (PEF) with 0.5 mM Fe2+ and 6 W ultraviolet light of λmax = 360 nm. Poor dissolved organic carbon (DOC) removal of the AR1 solution by AO-H2O2 with Pt, only reaching 16% mineralization at the end. The alternative use of a BDD anode causes a much faster DOC decay; up to attain 93% mineralization at 360 min. The slow DOC removal found for EF with Pt at long electrolysis time. The faster degradation process under the action of ·OH in the bulk can also be observed in EF with BDD, primordially during the first 180 min of treatment where 80% DOC reduction was already achieved. When the PEF process was applied, less influence of the anode material was found due to the potent action of UVA irradiation. PEF yielded a very fast mineralization of the AR1 solution to yield almost total mineralization (> 96% DOC removal) after 300 min using Pt, and in a shorter time of 240 min for BDD. Reprinted by permission from Florenza et al. (2014a).

The highest efficiency of dye oxidation by electro-oxidation process was reported in the case of the use of high oxygen over-potential anodes in combination with other oxidation processes, such as oxidation with electro-generated hydrogen peroxide (Vahid and Khataee 2013), electro-generated sodium hypochlorite (Akrout and Bousselmi 2013), electro-Fenton (El-Desoky et al. 2010b; Rahmani et al. 2016; Zhang et al. 2019a, b), photo-electro-Fenton (Almeida et al. 2012, 2014; Pacheco-Álvarez et al. 2019), heterogeneous photo-catalysis (Santos et al. 2015; Morales et al. 2018), addition of persulfates (dos Santos et al. 2020b, a), and biological oxidation (Cui et al. 2020). Color removal ranges from 80% to complete decolorization, chemical oxygen demand from 60% to over 90% and total organic carbon from 50 to 80%. Table 3 shows comparative data on electrochemical oxidation of various azo dyes.

Effect of electrode materials on the electrochemical degradation of azo dyes

Various electrode materials have been used to remove azo dyes from water using electrochemical oxidation. Using electrode materials with high oxygen over-potential makes it possible to treat azo dyes containing solutions effectively. On metal oxide electrodes, Methyl Orange oxidation proceeds mainly with the generation of hydroxyl radicals (Mais et al. 2020). When comparing the efficiency of the process of Methyl Orange electrochemical oxidation on various electrode materials, complete removal of color and chemical oxygen demand has been achieved only using the BDD anode, while residual chemical oxygen demand was in the solution treated with PbO2 anode, and TiRuSnO2 anode allows only partial oxidation (Labiadh et al. 2015). The use of heterostructures of various metal oxides as electrodes with additional treatment using ultrasound and UV light makes it possible to increase the efficiency of Methyl Orange oxidation due to the synergistic effect of various processes (He et al. 2010; Peng et al. 2013). Methyl Orange electrochemical oxidation on PbO2 deposited on Ti/SnO2–Sb substrate and doped with P25–TiO2 has been studied (Xu et al. 2013a). In this case, a synergistic effect was observed between electrochemical oxidation and photo-catalysis on P25-TiO2 under UV light irradiation. The same synergistic effect was also observed for the composite electrode based on TiO2 and BDD (Pacheco-Álvarez et al. 2018). PbO2 nanospheres deposited on SnO2 nanowires and deposited on a titanium substrate (PbO2 nanospheres @ SnO2 nanowires/Ti) also indicated high efficiency of Methyl Orange oxidation. During 60 min of electrolysis, chemical oxygen demand decreased by 92.7% at 25 °C and pH 5.0 under a current density of 15 mA/cm2 (Li et al. 2014b).

The anode material plays a vital role in Acid Orange 7 electrochemical oxidation. When BDD is used as the anode, complete decolorization of the Acid Orange 7 solution and chemical oxygen demand removal by more than 90% were observed (Fernandes et al. 2004). When comparing the activity of platinum and BDD anodes, BDD shows a higher rate of Acid Orange 7 mineralization with the formation of end oxidation products such as CO2 and inorganic ions such as sulfate, nitrate, and ammonium (Hammami et al. 2008; Zhang et al. 2014a). At the same time, it can be noted that Acid Orange 7 oxidation on BDD leads to the formation of polymer intermediates at low pH values (Chen and Chen 2006). The formation of inorganic compounds as end products of Acid Orange 7 oxidation also occurs when PbO2 is used as the anode. The PbO2 anode modified with neodymium and cerium also shows a high efficiency upon Acid Orange 7 oxidation (Qiao et al. 2018).

Comparison of SnO2–Sb, PbO2–F, and BDD anodes showed that a higher decolorization rate was obtained using the SnO2–Sb and PbO2–F anodes in dilute Acid Orange 7 solutions, while a higher rate of chemical oxygen demand removal from concentrated Acid Orange 7 solutions was obtained using BDD and SnO2–Sb electrodes (Mao et al. 2008). Ti/SnO2-Sb doped with titanium nitride (TiN) nanoparticles also had a higher Acid Orange 7 decolorization efficiency than Ti/Sb-SnO2 (Duan et al. 2014). It was found that BDD was much more active than Ti/Sb2O5-SnO2 electrodes during Acid Orange 7 oxidation (Chen et al. 2003). Ta2O5 coating is an effective method for improving surface morphology and electrochemical characteristics of Ti/TiO2/PbO2 nanotubes. The degradation efficiency of Acid Orange 7 and total organic carbon removal using the Ti/TiO2 NT/Ta2O5-PbO2 anode was almost 100 and 98.3%, respectively, compared to the Ti/PbO2 anode at the same electrical charge consumption 3 A·h/L (Gui et al. 2019). When TiO2-modified β-PbO2 was used as the anode material in photo-electro-catalysis, the maximum efficiency of Acid Orange 7 removal was reached at pH of 2.29 (Li et al. 2006a). In this case, Acid Orange 7 was oxidized due to the formation of hydroxyl radicals and direct electron transfer, as well as the hole generation on TiO2 upon UV light irradiation (Li et al. 2006b, 2014a).

The use of spent activated carbon (resulted from adsorption of wastewater with heavy metals) for electrochemical decolorization of the Acid Orange 7 solution in the presence of peroxydisulfate is reported by Li et al. (2016). Granular activated carbon electrode is able to decompose peroxymonosulfate and peroxydisulfate, which leads to the formation of sulfate radicals (SO4·−) and ·OH (Li et al. 2017a). Catalysts based on iron and cobalt supported by mesoporous silica lead to an increase in electrochemical activation of peroxydisulfate with the formation of SO4·−, which leads to effective chemical oxygen demand and total organic carbon removals from the solution of Orange II (Cai et al. 2014). The same effect on Acid Orange 7 electrochemical oxidation by peroxydisulfate is also observed in the presence of Fe3O4 (Lin et al. 2014). Activated carbon fiber can be used as an in situ regenerated cathode-adsorbent during Acid Orange 7 electrochemical oxidation in the presence of Fe3+ ions and peroxymonosulfate. The azo dye adsorbed on the cathode surface is able to completely degrade and mineralize the dye, leading to an in situ regeneration of the adsorbent (Sun et al. 2020).

Acid Orange 7 electrochemical oxidation is promoted by the presence of chlorides in the solution. The formation of active chlorine contributes to faster indirect oxidation of the dye molecules. The degree of total organic carbon removal using Ti/RuO2-Pt electrode was 79.48% with complete decolorization of the solution (Zhang et al. 2014b). In chloride-containing solutions, decolorization proceeds faster upon increasing chloride concentration, but complete mineralization of Acid Orange 7 is not achieved when anodes with low oxygen over-potential are used (Scialdone et al. 2014). A more considerable chemical oxygen demand decrease for Acid Orange 7 solutions is observed using BDD (Scialdone et al. 2014).

Acid Orange 10 electrochemical oxidation has been studied using various electrode materials and approaches (Radha et al. 2012; Lounis et al. 2016; Hamous et al. 2020, 2021). In particular, Acid Orange 10 degradation on a platinum electrode was studied in detail by Hamous et al. (2020). The mechanism of Acid Orange 10 oxidation in chloride and sulfate electrolytes differs. The presence of chlorides in the solution leads to accelerated oxidation of Acid Orange 10 molecules, just as for other azo dyes, which is associated with the formation of hypochlorite ions and indirect oxidation of the azo dye. Non-active electrodes, such as Ti/SnO2–Sb (Sarafraz et al. 2015) and Ti/PbO2 (Bonyadinejad et al. 2016), are able to produce hydroxyl radicals through water oxidation. Under optimal electrolysis conditions, complete decolorization of the dye solution was achieved, and chemical oxygen demand/total organic carbon removal was 61.3/43.9% for Ti/SnO2–Sb and 63/60% for Ti/PbO2, respectively (Sarafraz et al. 2015; Bonyadinejad et al. 2016). Modification of the Ti/SnO2–Sb2O5–RuO2 anode with tantalum improves electro-catalytic properties during Acid Orange 10 oxidation due to an increase in the ability to generate ·OH (Zhao et al. 2022). Only partial Acid Orange 10 oxidation was observed on a titanium anode coated with IrO2/TaO2/RuO2 (Muthukumar et al. 2007). Ti/TiO2-based semiconductor anodes enable the oxidation of Acid Orange 10 upon UV light irradiation (Xie and Li 2006). In this case, the dye oxidation can occur through photo-electro-catalysis, electro-oxidation, and electro-Fenton processes.

Among the studied anode materials, BDD was proved to be the most potent anode for Acid Red 27 oxidation because of high oxygen over-potential and the formation of hydroxyl radicals slightly adsorbed on its surface, as compared to Pt (Jain et al. 2009) and PbO2 (Elaissaoui et al. 2016, 2019). On the other side, anode materials such as Ti/IrO2-Ta2O5 (Fajardo et al. 2016), IrO2-Ru2O-SnO2-TiO2/Ti, Ru2O-SnO2-TiO2/Ti (Salazar-Gastélum et al. 2013) and Ti/Pt-SnSb (Fajardo et al. 2017) are preferred as anodes in Acid Red 27 oxidation due to their relatively low cost, even though the dye oxidation efficiency is lower as compared to BDD (Fajardo et al. 2016).

Methyl Red electrochemical oxidation was studied by different groups (Panizza and Cerisola 2007; Santos et al. 2020a, b). It was noted that the degree of chemical oxygen demand removal depended on the anode material and decreased in the following order: Si/BDD > Ti/PbO2 > Pt > Ti/Ti0,50Ru0,45Sn0,05O2 (Panizza and Cerisola 2007). Under the optimal conditions, the electro-Fenton process (Zhou et al. 2008) led to decolorization of the solution with a concentration of 20 mg/L in 20 min, while at a higher dye concentration (100 mg/L) only 74% decolorization was achieved. In addition, Methyl Red electrochemical oxidation was studied using other anode materials such as PbO2 and BDD (Panizza and Cerisola 2008), Ti/Ru0.34Ti0.66O2 (Morais et al. 2013), RuO2-IrO2-TiO2 (Sathishkumar et al. 2017), Zn(OH)2 and ZnO thin films (Ahmad et al. 2022). Its oxidative degradation was also carried out by electro-Fenton process oxidation along with the generation of active chlorine species (Ma and Zhou 2009; Sathishkumar et al. 2017). Finally, Tavares et al. (2012) reported the electro-catalytic activity of two anode materials, Ti/Ru0.3Ti0.7O2 and Ti/Pt, during direct and indirect electrochemical oxidation of Methyl Red with the determination of the resulting oxidation products.

Under optimal conditions, when PbO2 is used as anode, continuous oxidation of the Acid Red 18 dye occurs, leading to the removal of 99.9% of the dye and 80.0% of chemical oxygen demand after 180 min of electrolysis (Rahmani et al. 2015). The electro-Fenton process is a relatively fast and efficient method for Acid Red 18 removal from industrial wastewater (Malakootian and Moridi 2017). Complete mineralization is achieved after 15 min of electrolysis using heterogeneous catalysts such as magnetite (Fe3O4) and hematite (Fe2O3) (Ben Hafaiedh et al. 2020). Simultaneous ozone exposure and electrochemical oxidation synergistically affect Acid Red 18 removal from aqueous solutions (Parsa et al. 2014). Table 4 shows the results of processing Reactive Black 5 solutions using various electrode materials.

Electrochemical oxidation of Reactive Orange 16 azo dye was mainly carried out using BDD. A systematic study on the influence of various supporting electrolytes and various current densities on simultaneous ozone exposure and electrochemical oxidation synergistically affects Acid Red 18 removal from aqueous solutions of Reactive Orange 16 dye with BDD was made by Lanzoni Migliorini et al. (2017). A higher rate of Reactive Orange 16 oxidation was observed in the K2SO4 solution at pH 10, which was associated with the effect of deprotonation of the dye molecule, which contributed to the destruction of the dye molecule, in particular, of the azo bond. In addition, a higher concentration of hydroxyl ions promoted the generation of hydroxyl radicals on BDD (Migliorini et al. 2011). Comparison of the efficiency of Reactive Orange 16 oxidation on Ti–Pt/β-PbO2 and BDD using a filter-press reactor showed that BDD was more effective in decolorizing the solution than Ti–Pt/β-PbO2; complete decolorization was achieved by passing 1.0 Ah/L and 2.0 Ah/L, respectively. The presence of NaCl led to a decrease in the time for complete decolorization due to the electro-generation of active chlorine (Andrade et al. 2009).

The use of a platinum wire as an anode in Reactive Orange 16 oxidation showed lesser efficiency. After 4 h of electrolysis by chronoamperometry, the degree of decolorization of the dye solution was only 40% in an acidic medium and 18% in an alkaline medium (Aggadi et al. 2021). At the same time, 93% decolorization of the Reactive Orange 16 solution was achieved in a flow cell on a Pt electrode after 60 min at 2.2 V/SHE using 1.00 g/L NaCl as electrolyte (Gomes et al. 2011). A thin Pt film on a titanium substrate (Pt/Ti) (Gomes et al. 2009) and an anode based on platinum oxide (Mijin et al. 2015) also showed good efficiency in Reactive Orange 16 oxidation. For Pt electrode, a 93% decolorization was obtained after 60 min at 2.2 V/SHE using 0.017 M NaCl solution and 0.5 M H2SO4 solution as an electrolyte. For Pt/Ti electrode, the color removal was 98% under the same conditions (Gomes et al. 2009). The use of thin-film TiO2 electrodes led to the complete decolorization of the Reactive Orange 16 solution after 20 min of photo-electro-catalysis (Carneiro et al. 2004). The efficiency of Reactive Orange 7 oxidation in the flow mode was 90.91% (Basiri Parsa et al. 2015). Reactive Orange 7 oxidation was also studied using the C/PbO2, Pb + Sn/PbO2 + SnO2, Pb/PbO2 electrodes. At 25 °C and in the presence of 4 g/L NaCl, almost complete Reactive Orange 7 oxidation was achieved using these electrodes after 15 min (97.66%, 95.33, and 94.60% for C/PbO2, Pb + Sn/PbO2 + SnO2 and Pb/PbO2 electrodes, respectively) at pH of 2.54 and current density of 25 mA/cm2 (Ghalwa et al. 2012).

Using a titanium electrode modified with ZnO and carbon nanotubes, the maximum efficiency of Reactive Orange 7 oxidation for the dye mixture removal was only 25.9% (Mahmoudian et al. 2021), while using Ti/nano ZnO–CuO under optimal conditions, the color decreased by 99.16% and chemical oxygen demand by 66.66% after 60 min of electrolysis (Akbari et al. 2022). Complete oxidation of Reactive Orange 107 (RO107) azo dye using composite electrode materials Ce0,8Gd0,2O2, Ce0,8Nd0,2O2 and Ce0,8Sm0,2O2 was also reported (Rajkumar et al. (2015). Results obtained for the electrochemical oxidation of some reactive azo dyes are given in Table 5.

Electrochemical oxidation of Congo Red was studied using BDD (Jalife-Jacobo et al. 2016), Pb/PbO2 (Chen et al. 2021), graphite (Kaur and Kaur 2016), Ti/RuO2-IrO2 (Sathishkumar et al. 2019), multiwalled carbon nanotubes—MnO2/Ni (Zhu and Chen 2021) and polyaniline-/graphene-modified anode (Li et al. 2022). Complete removal of total organic carbon during oxidation of direct azo dyes requires long electrolysis time, which is associated with the formation of a larger number of aromatic fragments produced upon breaking the –N = N– bond (Faouzi et al. 2006; Shetti et al. 2019). During Congo Red oxidation using BDD, a qualitative analysis by spectrophotometry showed different behaviors of Congo Red molecules during ozonation and electrochemical degradation. During ozonation, a rapid decolorization of the solution was observed, while the color remained until the end of the galvanostatic electrolysis. This is due to the difference in the oxidation mechanisms of the two processes. Simultaneous degradation of azo groups and subsequent degradation during electrochemical oxidation using BDD with complete removal of chemical oxygen demand and total organic carbon are assumed during ozonation (Faouzi Elahmadi et al. 2009). The better ability of β-PbO2 to generate ·OH contributed to the Congo Red removal (68.62%) from its initial concentration of 20 mg/L and at current density of 8 mA cm−2 for 20 min (Chen et al. 2021).

A comparative study of Direct Red 23 oxidation in aqueous solutions by electro-Fenton process using various anodes: carbon-graphite, Ti4O7 Magneli phase, BDD and DSA, was reported by Titchou et al. (2021b). The highest total organic carbon removal efficiency was achieved using BDD anode at a current density of 5 mA/cm2. When treating a Direct Red 23 solution with an initial concentration of 60 mg/L, total organic carbon removal was about 86% at 6 h electrolysis and in the presence of NaCl and Na2SO4 electrolytes. Using BDD anode led to the complete decolorization and 50.2% mineralization during electrochemical degradation of Direct Blue 71 dye operated in flow mode and under galvanostatic conditions, at a current density of 7.75 mA/cm2 and a flow rate of 600 mL/min (Xu et al. 2022). The presence of chloride ions accelerated the oxidation of direct azo dyes (Kupferle et al. 2006; Jalife-Jacobo et al. 2016) including Congo Red (Jalife-Jacobo et al. 2016) and Direct Red 83 (Kupferle et al. 2006). Complete decolorization of the Direct Blue 71 triazo dye solution was achieved after 90 min of electrolysis with Pt anode, and complete mineralization occurred after 120 min in a laboratory electrochemical reactor (Parsa et al. 2009).

Electrochemical treatment is able to achieve almost complete chemical oxygen demand removal from wastewater with high current yield (Vaghela et al. 2005). When treating wastewater containing a mixture of active azo dyes by electrocoagulation in combination with electrochemical oxidation processes, in particular electro-Fenton process, complete removal of turbidity and color and 97% removal of total organic carbon were achieved. In this case, energy consumption for decolorization of wastewater was 0.45–1.5 kWh/kg of removed total organic carbon depending on the current density (Zazou et al. 2019).

Studies on the treatment of wastewater containing azo dyes have been carried out using various anode materials such as Ti/Pt (Wang et al. 2009), RuO2/IrO2/TaO2 (Bhaskar Raju et al. 2009), graphite (Bhatnagar et al. 2014), Ti–Pt/β-PbO2 and Ti/Ti0,7–Ru0,3O2 (Aquino et al. 2014), BDD (Zhu et al. 2011), and Ti/RuO2/IrO2 (Raghu et al. 2009). Notably, higher efficiency in chemical oxygen demand and total organic carbon removals were observed for metal oxide electrodes and BDD. The use of electrochemical process for oxidative degradation of organic azo dyes made it possible to bring the indices of wastewater to the standard level for its discharge into the environment without further treatment (Gallios et al. 2012).

Factors controlling the performance of the electrochemical oxidation of azo dyes

Various factors, including pH, applied current or voltage, hydrogen peroxide generation rate (in the case of electro-Fenton process), electrode material, initial dye concentration, electrolyte type and concentration, electrode spacing and electrolysis time, affect the removal of azo dyes by electrochemical oxidation processes (Vasudevan and Oturan 2014; Nidheesh et al. 2018; Rodríguez-Narváez et al. 2021; Qiao and Xiong 2021; Sun et al. 2022). The transition to a more complex structure of the dye molecule led to a decrease in the rate of electrochemical decolorization. It was shown (Chen et al. 2020) that the degradation rate changed downward in the following series: fuchsine acid–Reactive Red 2–Acid Orange G–Alizarin Red–Acid Blue 92–Reactive Orange X-GN–Orange II–Reactive Blue 19. The use of the electro-Fenton process led to a significant acceleration of oxidation yield of reactive azine azo dyes. For example, the decrease in total organic carbon for Acid Red 2 during 3 h of electrolysis was 87% (Lei et al. 2015). The use of ultrasound also significantly enhanced electro-oxidation of reactive azo dyes (Somayajula et al. 2012).

Among reactive dyes, electrochemical oxidation of Reactive Orange 7 attracted the most attention of researchers. The effect of the initial dye concentration, solution pH, electrolyte concentration, and current density on the efficiency of Reactive Orange 7 removal using Ti/Sb-SnO2 anode has been studied. Under the optimal conditions, complete decolorization was achieved after 5 min; chemical oxygen demand reduction was up to 70.3% after 90 min (Basiri Parsa et al. 2013). Depending on the type of anode and cathode materials, the type of process and the electrolyte, acid azo dye Acid Red 18 can be degraded due to a single or combined action: direct anodic oxidation, indirect (mediated) oxidation near the anode or in the bulk of the solution by the homogeneously generated ·OH and by indirect oxidation with active chlorine (Thiam et al. 2015a, 2016).

The efficiency of Methyl Orange removal from solutions by electrolysis is affected by current density, electrolyte concentration and solution pH (Oukili and Loukili 2019). Aeration of Methyl Orange solutions during electrochemical oxidation increases the process efficiency, which is associated with the formation of hydrogen peroxide on the cathode (Li et al. 2013b; Zhang et al. 2015). The introduction of halogen salts to the solution increased the rate of Methyl Red mineralization as follows: control < NaCl < NaBr < NaF. The use of a titanium plate anode led to the formation of an anatase film on its surface, which enhanced the Methyl Red oxidation due to the synergistic effect resulting from the combination of electrochemical oxidation and photo-catalysis on a titanium anode (Martín de Vidales et al. 2020).

Acid Orange 7 electrochemical degradation combined with a photo-catalytic process led to a higher dye conversion (Kusmierek and Chrzescijanska 2015). The use of a TiO2 coating consisting of 29% rutile, 9% anatase and 62% Ti7O13 on a stainless steel substrate as a photo-anode and an air-diffusion cathode to produce H2O2 in a photo-electrochemical cell under sunlight irradiation resulted in the complete decolorization of the solution after 120 min under optimal conditions. The photo-anode made by immobilizing a TiO2 film on activated carbon fibers (TiO2/AC) was also used to remove Orange II (Hou et al. 2009). Good results were obtained during AO7 photo-electrochemical oxidation using a composite electrode made of exfoliated graphite and bismuth vanadate (EG-BiVO4) (Orimolade and Arotiba 2019).

Using different anode materials and different electrochemical cell design options, the effect of different operating parameters, such as the anode material (Oliver-Tolentino et al. 2014; Popli and Patel 2015; Sowmiya et al. 2016; Soni et al. 2017), solution pH (Yavuz and Shahbazi 2012; Radi et al. 2012), nature of the electrolyte (Sakalis et al. 2005; Rivera et al. 2011; Vasconcelos et al. 2016b), initial dye concentration (Navarro et al. 2010; Li et al. 2019), cathode material (Méndez-Martínez et al. 2012; Aveiro et al. 2018), current density (Singh et al. 2017; Koulini et al. 2022), electrode potential (Cerón-Rivera et al. 2004) and applied voltage (Jović et al. 2013), on the efficiency of Reactive Black 5 removal was optimized. Several authors noted that color removal, current efficiency, chemical oxygen demand and/or total organic carbon decrease, and specific energy consumption are mainly depend on the above parameters (Rao et al. 2006; Bansal et al. 2013; Jager et al. 2018; Mengelizadeh et al. 2019; Saxena and Ruparelia 2019). In addition, the structure of the reactive azo dye can also affect the oxidation efficiency, as reported during electrochemical oxidation of four reactive azo dyes (Reactive Orange 91, Reactive Red 184, Reactive Blue 182, and Reactive Black 5) using a Ti/Pt electrode (Sakalis et al. 2005).

Examples of reactive azo dyes containing azine rings are Reactive Orange 4 and Reactive Orange 13, which differ only in one substituent: -OH (Reactive Orange 4) or -NH2 (Reactive Orange 13). During oxidation using a Ti/Pt anode in a chloride-containing electrolyte, it was found that the active group had an effect on the solution decolorization efficiency. The presence of the -NH2 substituent ensured a higher decolorization rate than that of the -OH substituent (Gutiérrez-Bouzán and Pepió 2014). In this case, the dye concentration was the most significant factor in electrochemical oxidation of the both reactive dyes, Reactive Orange 4 and Reactive Orange 13 (Nordin et al. 2015; López-Grimau et al. 2018).

High energy consumption of the electrochemical method is one of the disadvantages, which prevents its large-scale application for wastewater treatment. Therefore, most studies on electrochemical oxidation of azo dyes have been carried out in laboratory conditions using individual dyes as model pollutants. However, it is essential to test the treatment of real wastewater from the textile industry, which is a complex system containing not only azo dyes, but also other related pollutants, as well as a large amount of suspended solid particles, pH varying over wide ranges, high temperature, chemical oxygen demand and various mineral salts (Chatzisymeon et al. 2006; Solís et al. 2012).

The efficiency of electrochemical treatment of real wastewater from the textile industry was evaluated in several works to determine the optimal process conditions (Fig. 3). For example, effluents from ink manufacturing contain a wide variety of pollutants such as dyes, surface-active materials, and solvents (Mukimin et al. 2017). Electrochemical oxidation of a mixture of dyes (Methylene Blue and Rhodamine B), solvents (monoethylene glycol, diethylene glycol, and glycerol), and surface-active materials (sodium dodecyl benzenesulfonate) has been studied using a single-chamber electrochemical flow cell with BDD as the anode and stainless steel as the cathode (Cañizares et al. 2007).

Energy consumption (E) and chemical oxygen demand (COD) removal of wastewater from textile industries at anodic oxidation on boron-doped diamond (AO (BDD)); anodic oxidation on PbO2 (AO (PbO2); by electro-Fenton process oxidation with use of Ti/RuO2 anode (EF (Ti/RuO2) and photo-electro-Fenton (PEF) process. The AO (BDD) process is the most effective for the COD removal, but this is accompanied by increased energy consumption. The most preferred type of electrochemical oxidation of azo dyes with efficiency of COD removal and low power consumption is PEF. The diagram is made according by the data given in Aquino et al. (2011), Hmani et al. (2012) Kaur et al. (2019) and Salazar et al. (2019)

Degradation products and their toxicity evolution during electrochemical oxidation

Toxicity reduction of dye solutions during the application of electrochemical technologies for removing azo dyes is of great importance. Degradation products of azo dyes such as aromatic amines can be mutagenic and carcinogenic (Selvaraj et al. 2021). Evaluating the toxicity of azo dye solutions after treatment using an electrochemical approach is vital for their subsequent discharge into water bodies or its use for other purposes. Incomplete oxidation of the azo dyes or their intermediates may cause the toxicity of the solution to change slightly, and sometimes may increase it because of the formation of more toxic intermediate products (Xia et al. 2020).

The possibility of toxic chlorinated organic intermediates production during the indirect electrochemical oxidation (Jager et al. 2018), which are more harmful than the original azo dyes, is a drawback of the system. Evaluation of the phytotoxicity using Vigna radiata of the initial wastewater containing azo dyes and solutions after anodic oxidation with generation active chlorine species on Ti/IrO2-RuO2-TiO2 anode with subsequent biological treatment led to the decrease of toxicity (Aravind et al. 2016). At the beginning of electrochemical oxidation on Fe-doped PbO2, toxicity of the treated Acid Orange 7 solution towards Vibrio fischeri slightly increases and then rapidly decreases to non-toxicity upon increasing electrolysis time (Xia et al. 2020). In the initial period of treatment of azo dyes by electrochemical oxidation, an increase in the toxicity of the solution was observed (Le et al. 2016). When Acid Orange 7 was oxidized by the electro-Fenton process, an increase in the toxicity up to 100% was noted, which was measured by observing the inhibition of marine bacteria Vibrio fischeri. This is due to the formation of intermediates like 1,4-benzoquinone and 1,2-naphthoquinone, which are more toxic than the initial dye. Further electrochemical treatment leads to complete mineralization and a decrease the toxicity (Le et al. 2016).

During electrochemical oxidation of azo dyes, first of all, the azo bond breaks and then benzene and naphthalene rings are gradually destroyed forming anthraquinone structures (Yang et al. 2014), which leads to the decolorization of the solution. Subsequently, the aromatic ring opening reaction results in the formation of aliphatic compounds (Fajardo et al. 2016). Sulfur in the diazo dye turned into SO42−, and nitrogen to NO3− and/or NH4+ ions, and a part of N is removed from the solution as in the form of nitrogen-containing gaseous products (Antonin et al. 2015). The oxidation of azo dyes leads to the formation of various intermediates. For example, a total of 21 aromatic intermediates and 13 hydroxylated derivatives, including diazo, monoazo, biphenyl, benzene, naphthalene and phthalic acid, were identified as intermediate products formed during the electrochemical oxidation of Congo Red dye (Solano et al. 2015). Tartaric, tartronic, acetic, oxalic and oxamic acids were identified as end-products. Like in the case of Congo Red oxidation, electrochemical oxidations of Evans blue diazo dye led to the formation of 19 aromatic intermediates and 16 hydroxylated derivatives, including diazo, monoazo, biphenyl, benzene, naphthalic, and phthalic acids (Antonin et al. 2015).

Both aromatic fragments and nontoxic carboxylic acids, such as maleic, fumaric, formic, and oxalic ones, were identified as products of electrochemical oxidation of the Methyl Orange using various methods (Márquez et al. 2020). The detection of ascorbic, benzoic, and citric acids, as well as hydroquinone and 1,4-benzoquinone, was also reported upon Methyl Orange oxidation using BDD as an anode (Guivarch et al. 2003; Isarain-Chávez et al. 2013). Various aromatic compounds and carboxylic acids are the primary intermediates during Acid Orange 7 dye oxidation (Table 6). Carboxylic acids such as maleic, tartronic, acetic, formic, oxalic, and oxamic were identified as products of Acid Orange 10 electrochemical oxidation, while ammonium and sulfate were the main inorganic ions (El-Ghenymy et al. 2014).

Up to 15 aromatic structures and carboxylic acids, including oxalic and formic acids, were identified as end products of Acid Red 14 electrochemical oxidation. Nitrates and sulfates were the main ions formed during carmoisine mineralization (Thiam et al. 2015c). Analysis of the products of Acid Red 27 oxidation by high-performance liquid chromatography coupled with mass spectroscopy showed the presence of naphthalenediol isomers in the solution of primary amines (Zhang et al. 2009). The resulting amines underwent further degradation, and phthalic acid, phthalic anhydride, benzoic acid, and phenol were found in the solution (Fig. 4). The next step involved ·OH electrophilic addition to the aromatic ring to form phenolic hydroxyl derivatives, which could be converted to aliphatic intermediates by opening the aromatic ring (Zhang et al. 2009).

The proposed decomposition pathway for the electrochemical oxidation of amaranth dye (from solutions containing 100 mg/L analyte in 0.05 M K2SO4 and adjusted to pH 12), using a boron-doped diamond anode and under 35 mA/cm2 current density for 5 h: (I) amaranth dye, m/z = 535; (II) naphthalenediol, m/z = 160; (III) phthalic acid, m/z = 166; (IV) phthalic anhydride, m/z = 158; (V) benzoic acid, m/z = 122; (VI) phenol, m/z = 94; (VII) fumaric acid, m/z = 116; and (VIII) oxalic acid, m/z = 90. Initially, the cleavage of the azo bond occurs with formation aromatic amines. In the next step, there is the elimination of sulfonic acid groups, followed by insertion of hydroxyl radical (·OH), forming a mixture of isomers (1,4 and/or 1,2-aminenaphtol). At this point occurs the NH2 elimination followed by insertion of ·OH, undergoes the naphthalenediol (II), this intermediate is in equilibrium keto-enolic (tautomers), and after addition of ·OH radical’s phthalic acid is formed (III). The phthalic acid (III) converted into phthalic anhydride (IV) (internal cyclization) and subsequently into the benzoic acid (V), after decarboxylation and hydroxylation processes, and phenol (VI) is formed as a reactive intermediate, and after the addition of ·OH radicals, the fumaric acid (VII) is identified. At the last stage, the aromatic ring opening occurs and aliphatic acids, i.e., oxalic acid (VIII) is formation. Reprinted by permission from Barros et al. (2014).