Abstract

In this study, four selected commercial strains of Aspergillus oryzae were collected from soy sauce koji. These A. oryzae strains designated as NSK, NSZ, NSJ and NST shared similar morphological characteristics with the reference strain (A. oryzae FRR 1675) which confirmed them as A. oryzae species. They were further evaluated for their ability to produce γ-aminobutyric acid (GABA) by cultivating the spore suspension in a broth medium containing 0.4 % (w/v) of glutamic acid as a substrate for GABA production. The results showed that these strains were capable of producing GABA; however, the concentrations differed significantly (P < 0.05) among themselves. Based on the A. oryzae strains, highest GABA concentration was obtained from NSK (194 mg/L) followed by NSZ (63 mg/L), NSJ (51.53 mg/L) and NST (31.66 mg/L). Therefore, A. oryzae NSK was characterized and the sequence was found to be similar to A. oryzae and A. flavus with 99 % similarity. The evolutionary distance (K nuc) between sequences of identical fungal species was calculated and a phylogenetic tree prepared from the K nuc data showed that the isolate belonged to the A. oryzae species. This finding may allow the development of GABA-rich ingredients using A. oryzae NSK as a starter culture for soy sauce production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The non-protein amino acid γ-aminobutyric acid (GABA) is recognized as a principal inhibitory neurotransmitter in the mammalian central nervous system [7]. Low GABA levels in the brain are associated with several psychiatric and neurological disorders, including anxiety, depression, insomnia, and epilepsy. Clinically, GABA has also been shown to be useful for reducing blood pressure [5, 15] stimulating the immune system [26], and combating hypertension [7]. In addition, studies have also shown that GABA aids in relaxation, reduces anxiety, and promotes better sleep [25, 36]. Moreover, there is significant potential for GABA to be employed in functional food development. This potential has prompted researchers to explore various ways to enhance the GABA content of foods either by blending GABA directly into food production systems or by employing GRAS microorganisms to biosynthesize GABA during fermentation in food production systems. Some GABA-containing products include tea [1], red mold rice [29], germinated brown rice [30], tempeh [2], yogurt [27] and black raspberry juice [18]; however, blending GABA into food production systems is considered less acceptable to consumers. Thus, more focus has been given to the screening and exploitation of microorganisms that may be employed to produce GABA [18, 19, 33].

Fermentation is the most promising method to enhance the GABA content of food production systems. Thus, to develop effective starter cultures [40], selecting filamentous fungi that are able to produce large amounts of GABA is of prime importance. The metabolic versatility of filamentous fungi as mentioned by El-Enshasy [10] and Fazenda et al. [13] would aid the success of this study typically among Aspergillus species. Aspergillus oryzae was one of the first microbes recognized for its beneficial effects in the commercial production of foods such as miso, hamanatto, shoyu (soy sauce) and tempeh.

The fungus is known to possess a gene for glutamate decarboxylase (GAD, E.C. 4.1.1.15). GAD is a key enzyme in the biosynthesis of GABA [17] and is involved via the irreversible α-decarboxylation of l-glutamic acid to γ-aminobutyric acid, which requires pyridoxal 5′-phosphate as a co-factor [20]. Because A. oryzae is so widely used in the production of fermented food production systems, we became interested in studying the GABA-producing capabilities of the Aspergillus sp. In this study, four commercial A. oryzae strains were obtained from koji samples and evaluated for their GABA-producing abilities. These investigations were conducted with the goal of enhancing GABA content in fermented foods, particularly soy sauce.

Materials and methods

Koji samples

Four koji samples coded koji NSK, koji NST, koji NSJ and koji NSZ were obtained from established commercial soy sauce manufacturers in Selangor, Malaysia. The green-colored koji samples containing A. oryzae strains were transported using an icebox. The master strains were subcultured and kept in Nalgene® Cryogenic Vials (Sigma-Aldrich, Dorset, UK) and stored in −80 °C for further use. The growth of the strains was inspected regularly to avoid contamination.

Determination of GABA content in Koji samples

The GABA content of the koji samples was determined according to the method proposed by Rossetti and Lombard [31] and Yang et al. [41] with slight modification. Thirty grams of soybean koji were suspended in 90 mL of 50 mM phosphate buffer (pH 7.0) and blended for 10 min with a Stomacher (Stomacher® 400C Lab Blender). The suspension was kept at 40 °C for 1 h under gentle shaking (150 rpm) and centrifuged at 3000×g for 30 min at 4 °C. The supernatant was filtered through Whatman No. 2 filter paper and the suspension centrifuged again at 10,000×g for 10 min. Finally, the supernatant was filtered through a 0.22-μm pore-size nylon filter (Fisher Scientific Bishop Meadow, UK) before being analyzed with HPLC.

Isolation of A. oryzae strains

A sterile cotton swab was dipped into sterile distilled water before it was rolled and pressed on the surface of a koji sample to harvest the spores of Aspergillus sp. The cotton swab was then gently rolled on the surface of potato dextrose agar (PDA) and incubated at 30 °C for 2–5 days. Every colony suspected to be A. oryzae was transferred to a fresh PDA. The single spore isolation technique was employed to isolate pure culture fungi according to the method of Bueno et al. [3] with some modifications. A loopful of A. oryzae spores was grown on PDA and then transferred to a test tube containing 10 mL of sterile distilled water. The tube was shaken and poured onto a plate of 1.5 % water agar, which was prepared 24 h in advance.

The plate was rotated, and the excess liquid was poured off. It was left overnight in a slightly inclined position to allow the excess water to collect at one end. The spores were incubated at 30 °C for 5 days. The resulting pure colonies of A. oryzae strains were transferred to PDA medium and Czapek Yeast Agar (CYA) media slants and kept as stock cultures and at −20 °C.

Morphological characterization of A. oryzae strains

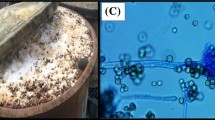

All of the strains were isolated and characterized for colony diameter, colony color, conidial color, mycelia color, colony texture, nature of spore masses and resting structure after 7 days of incubation at 25 °C in PDA and Czapek Yeast Extract Agar. The morphological characteristics of the isolated strains were compared with the reference strain RFS (A. oryzae FRR 1675), which was obtained from the Food Research Laboratory Culture Collection, North Ryde, Australia [22, 32]. For microscopic characterization, the lactophenol blue (BD chemical) or methylene blue [37] staining process was carried out according to the method proposed by Leck [22]. An appropriate amount of each isolate was immersed in a drop of 70 % alcohol placed on the microscope slide and left to semi-dry. Then a drop of lactophenol blue was applied, and the specimen was covered with a glass slide for observation. The specimen was observed under a light microscope (Nikon Ys-100) at 40× magnification to allow the observation of microscopic structures, such as conidia, conidial head, metulae (primary stigmata) and phialides (secondary sterigmata). The entire stained sample was compared with the reference strain RFS (A. oryzae FRR 1675) as suggested by Sooriyamoorthy et al. [34] with some modifications.

GABA production capability of A. oryzae strains

A small amount of spore suspension was streaked onto the surface of a sterile potato dextrose agar (PDA) slant and incubated at 30 °C for 7 days to develop spores. To harvest the spores, an appropriate amount of a sterile aqueous solution of Tween 80 (0.001 % (v/v)) was poured into the universal bottle containing the sample and was shaken by hand for 1 min. The counting of the spores was carried out using a hemocytometer (Copens Scientific, Assistant, Germany). For inocula preparation, standardized spore suspensions (approximately 1 × 104 spores/mL medium) were used for all of the experiments. The GABA-producing capabilities of the Aspergillus sp. were determined using a shake flask fermentation technique. The strains (NSJ, NSK, NST and NSZ) were cultured in the fermentation broth according to the method described by Lu et al. [23] with modifications. The basal medium consisted of glucose (5 % v/v), monosodium glutamate (0.4 v/v/27.2 mM), MgSO4.7H2O (1 g), KH2PO4 (1.5 g), yeast extract (0.6 % v/v), and CaCl2.2H2O (2 g) in 1000 mL. The 250 mL shake flask contained a standardized 1 × 104 of spore suspension in 150 mL of medium with an initial pH of 5.5. The flask was incubated at 30 °C in a rotary shaker (Sastec ST-500R) and agitated at 200 rpm. The fermentation process was carried out for 5 days, and the GABA content was analyzed using HPLC (Shimadzu LC 20AT, Japan) according to the method described by Yang et al. [42] and Yang et al. [41] with slight modification.

Effect of cultivation time on GABA production

The effect of cultivation time on GABA production was investigated in triplicate over 10 days while the culture medium and other parameters remained the same. During fermentation, the levels of glucose, cell mass, pH, GABA and glutamic acid were monitored at various time intervals.

Molecular characterization of A. oryzae strain

The strain with the highest GABA production was further identified through the biomolecular technique proposed by Oliveira et al. [8] with slight modification. Biological material (50 mg) was ultrasonically homogenized in 600 µL of lysis buffer (0.1 M of Tris-hydrochloric acid pH 8.0, 0.1 M Ethylenediaminetetraacetic acid (EDTA) and 0.06 M of sodium chloride) for 10 min in a 2-mL centrifuge tube. After homogenization, 60 µL of 10 % sodium dodecyl sulfate was added, and the tube was maintained in a water bath at 60 °C for 1 h. Alcalase working solution (60 µL) was added, and the tube was maintained in a water bath at 60 °C for an additional hour. Following this, 30 µL of potassium acetate (3 M) was added, and the tube was maintained for 15 min in an ice bath (0 °C). Following that, 300 µL of chloroform was added to the tube, and it was mixed gently for 10 min. The tube was centrifuged at 9168 g for 10 min, and the supernatant was transferred to a fresh microtube. The DNA/protein concentration ratio (A260/A280) was determined using a spectrophotometer (U2800 Hitachi, Japan). The ITS 1 and ITS 2 ribosomal DNA of the isolate was amplified by polymerase chain reaction following the method proposed by Tamura et al. [35] and Wang et al. [39]. The primer sequences employed were 5′-TCCGTAGGTGAACCTGCGG-3′ (ITS1) and 5′-TCCTCCGCTTATTTGATATGC-3′ (ITS4). The reaction was performed in a mixture (50 µL) containing 200 µM of each of the deoxynucleoside triphosphates, 1 µM of each of the two primers, 2.5 U of Taq DNA polymerase, and 0.2 µg of genomic DNA. The reaction mixture was overlaid with mineral oil to avoid evaporation. PCR was carried out with an Eppendorf Mastercycler gradient (Eppendorf Hamburg, Germany) programmed for the following first five cycles: a denaturation step at 95 °C for 1 min; an annealing step at 40 °C for 2 min; an extension step at 72 °C for 3 min; 25 cycles each consisting of 95 °C for 1 min, 55 °C for 2 min, and 72° C for 3 min. These cycles were preceded by an extended denaturation for 5 min at 95 °C and concluded by a final extension for 5 min at 72 °C. The PCR products were electrophoresed on a 0.9 % agarose gel containing 2 µL of ethidium bromide in 100 mL and 1 time Tris–acetate-EDTA buffer (40 mM Tris–acetate and 2 mM EDTA). The gel was visualized under a UV transilluminator and photographed.

Development of phylogenetic tree

A phylogenetic tree was prepared by calculating the evolutionary distance (K nuc) between sequences of identical fungal species using the neighbor-joining (NJ) method [14] in Molecular Evolutionary Genetics Analysis (MEGA) software version 4.0. Fungi with the closest evolutionary distance (K nuc) to the isolate were classified as the same species.

Analytical methods

Determination of GABA and glutamic acid

The cell suspension was separated from the fermentation broth by filtering through Whatman No. 2 filter paper, followed by centrifugation of the suspension at 10,000×g for 10 min. The supernatant was filtered through a 0.22-μm pore-size nylon filter (Fisher Scientific, Bishop Meadow, UK). A 100-uL aliquot of supernatant (or GABA standard solution) was dried under vacuum. The residue was dissolved in 20 µL of ethanol–water-triethylamine (2:2:1 v/v) and evaporated under vacuum until dry. A 30-µL volume of ethanol–water-triethylamine-PITC (7:1:1:1 v/v/v) was added to the residue and allowed to react for 20 min at room temperature to form PTC-GABA. The excess reagent was then removed under vacuum. The dry residue containing PTC-GABA was dissolved in 200 µL of the mobile phase (a mixture of 60 % solution A (aqueous solution of 8.205 g sodium acetate, 0.5 mL triethylamine and 0.7 mL acetic acid in 1000 mL) adjusted to pH 5.8, 28 % solution B (deionized water), and 12 % solution C (acetonitrile). Gradient HPLC separations were performed on a Shimadzu LC 20AT apparatus, consisting of a pump system, a CT0-10ASVP model oven with 20-µL injection loop injector, and a Model SPD-M20A PDA detector in conjunction with a DELL model DELL Optiplex integrator. A Hypersil Gold C-18 column (250 × 4.6 mm I.D., particle size 5/um; Thermo Scientific, Meadow, UK) was used for separation purposes. The mobile phase for gradient elution was pumped at 0.6 mL/min, at room temperature; detection was monitored at 254 nm.

Determination of glucose

Glucose concentration was determined using dinitro salicylic acid (DNS) method as described Frost [14]. The DNS reagent was prepared by mixing 2-g phenol, 0.5-g sodium sulfite and 200-g potassium sodium tartrate in 700-mL distilled water. The mixture was continuously stirred before 200 mL of sodium hydroxide and 3, 5 DNS were added slowly. The reagent was stirred in a dark room for 8 h. A 10-step dilution was made on each fermentation broth to determine glucose content. Next, the following components were mixed together and boiled at 100 °C for 5 min: 1 mL of DNS reagent, 1 mL of diluted sample and 2 drops of sodium hydroxide. A 10-mL portion of distilled water was added to the solution after it was cooled under running tap water. The solution was left for 20 min at room temperature, and the absorbance was measured at 540 nm. A standard curve of absorbance versus glucose concentration in the range of 0.2–1.2 g/L was constructed. Glucose concentration was expressed as gram per litre.

Measurement of growth

The growth of the culture (expressed in dry weight of mycelium) was measured according to Wan et al. [38]. The dry cell weight (DCW) from the harvested A. oyrzae fermentation process was estimated by filtering a 10 mL sample through a pre-dried and weighed GF/C filter (Whatman Ltd., UK) using a Buchner funnel filter set attached to a water pump, followed by repeated washing (three times) of the mycelial biomass with distilled water, Mili-Q® Advantage A10 (Millipore, Bedford, MA, USA). The mycelial filter cake was pre-dried for 2 min in an overnight dryer or a microwave oven (650 W). Next, it was cooled in a desiccator for 24 h before weighing. Calculation of the DCW was done by subtraction of pre-weighed filter mass from the mass with the filtrate and multiplied by the dilution factor to get DCW in gram per litre. All values are taken based on averages of a least three independent trials.

Determination of GAD enzymes activity

GAD enzyme activity of the isolates (A. oryzae NSK, NSJ, NST and NSZ) was determined according to the method proposed by Lu et al. [23]. One unit (U) of GAD enzyme activity from the pellets (mycelia) was defined as the formation of 1 μmol of GABA per hour at 37 °C and the results were expressed as Units/g cells.

Growth kinetics

To better describe the growth kinetics, some stoichiometric parameters related to batch fermentation have been used to evaluate the growth of A. oryzae strains NSK, NSZ, NSJ and NST. Maximum specific growth rate (U max) is described by Eq. (1) and can be obtained by plotting ln (X t − X 0) against time. The resulting slope, U max . X t refers to the cell concentration at a given time and X i is the initial cell concentration.

The growth yield coefficient was determined by the following equation:

where S i is the initial substrate concentration (g/L) and S 0 is the residual substrate concentration at the end of fermentation.

In addition, the yields Y p/s and Y p/x are determined by measuring the maximum GABA and cell concentrations and the total amount of substrate consumed.

and

P max in this equation refers to the maximum product concentration, and P i is the initial product concentration. Overall productivity, P (mg/L/h), was determined by measuring the total amount of biomass formed over a period of time.

Statistical analysis

All analysis were conducted in triplicate and the respective mean ± SD determined using the software, Statistical Analysis System (SAS University Edition, 2012) and shown as error bars. If the error bars do not appear, it is assumed that they are smaller than the size of the symbol. A t-test was used for the plotting of fermentation graphs. One-way ANOVA and post-test (Duncan’s new multiple range test, MRT) were used for kinetic parameters comparison.

Results and discussion

Morphological characteristics of A. oryzae

The morphological characteristics of the isolated strains were compared with the reference strain, RFS. The results revealed that all of the isolates shared similar features in terms of the colony, conidia and mycelia color, nature of spore mass, colony diameter, conidial head, and vesicle structure (observed after 7 days of incubation at 25 °C on PDA and CYA). In addition, there were no significant differences between the A. oryzae isolates and the reference strain. Further microscopic examination showed that the conidial heads and vesicle within the conidiophores of the strains were in radiate and sub-globose forms; however, the type of phialides and conidia formed on the surface of A. oryzae NSK vesicle was significantly different from the other strains (NSJ, NSZ, NST) and from the reference strain. A. oryzae NSK phialides were classified as uniseriate, while its conidia were in the form of sub-globose. These findings are in agreement with the features described by Samson et al. [32]. Specifically, it was found that the conidiophores structure of A. oryzae exist in two different forms. Phialides that are born directly on the vesicle surface are called uniseriate, while phialides that are born on the top of metulae in conidiophores structure are called biseriate. The morphological features of A. oryzae NSK, A. oryzae NSJ, A. oryzae NSZ and A. oryzae NST were in agreement with Samson et al. [32], Sooriyamoorthy et al. [34] and Elbashiti et al. [11]; therefore the entire strains were identified as A. oryzae sp.

GABA concentration of Koji samples

It has been reported that A. oryzae possess the glutamate decarboxylase (GAD) gene, which is capable of producing γ-aminobutyric acid (GABA) [17] by irreversible decarboxylation of glutamic acid. It has also been postulated that the presence of GABA in certain fungi-derived fermented foods could be the results of GABA-biosynthesizing activity of the fungi present. Hence, in this study, four commercial koji samples were analyzed for GABA content. The results revealed that all of the koji samples contained appreciable amounts of GABA (223–443 mg/kg). Since only fungal species are able to survive in low water activity of solid state koji fermentation, the presence of GABA in all the samples strongly indicated that GABA was biosynthesized by the fungi during koji fermentation. As the raw material (soybean) for koji contains substantial amounts of protein and carbohydrate, these substrates could have been hydrolyzed by the endogenous and exogenous enzymes present in the fungus. The fungus may have converted these proteins and carbohydrates into simple building blocks that were subsequently converted into GABA by the naturally present glutamate decarboxylase enzyme produced by the A. oryzae.

GABA-producing capabilities of A. oryzae strain isolates

A. oryzae strain isolates were further examined for GABA-producing capability by culturing the isolates in broth media containing 0.4 % (w/w) of glutamic acid. Spore suspension was used as inoculum because it may be simply prepared and allows for consistent inoculum size. The fermentation process was carried out for 5 days; all of the strains showed rapid growth after they were sub-cultured on PDA and CYA. As shown in Table 1, the batch fermentation showed that A. oryzae NSK produced the highest GABA concentration (73.13 ± 1.77 mg/L). The GABA concentrations produced by A. oryzae NSJ (29.87 ± 1.80 mg/L), A. oryzae NST (25.75 ± 25.75 mg/L) and A. oryzae NSZ (26.78 ± 2.17 mg/L) were all similar and significantly (P < 0.05) lower than A. oryzae NSK. The results also showed that the glutamic acid concentrations in the A. oryzae NST and A. oryzae NSJ fermentation broths remained at 122.01 and 110.25 mg/L; however, the glutamic acid concentrations in the A. oryzae NSK and A. oryzae NSZ samples were 8.82 and 29.4 mg/L, respectively. It can be concluded that all the A. oryzae isolates possessed GABA-producing activity albeit at different levels.

Effect of cultivation time on GABA production

All the strains were further evaluated for their ability to produce GABA during 10 days of fermentation by cultivating the isolates in media containing glucose (5 % v/v), monosodium glutamate (0.4 v/v/27.2 mM), MgSO4 .7H2O (1 g), KH2PO4 (1.5 g), yeast extract (0.6 % v/v), and CaCl2.2H2O (5.5 g). The samples were held at a constant temperature of 30 °C and an initial pH 5.5; they were subjected to batch fermentation using 250-mL shake flasks. During fermentation, the behavior of all the isolates was monitored for GABA formation, substrate consumption (glutamic acid and glucose), cell formation and change in pH. The results are shown in Fig. 1 and are summarized in Table 2. GABA was generally produced at the maximum level either during the exponential phase or the stationary phase. As shown in Table 2, all the A. oryzae isolated strains showed a similar growth pattern and maximum cell concentration (X max); however, these strains had different glucose and glutamic acid consumption rates (Y x/s ) even though glucose and glutamic acid were consumed rapidly by all the A. oryzae strains and depleted after 2–4 days of fermentation.

However, the calculated Y x/s values showed that A. oryzae NST consumed the largest amounts of glucose and glutamic acid for each gram of cells (0.2664 g/g) compared to A. oryzae NSJ (0.2639 g/g), A. oryzae NSZ (0.2614 g/g) and A. oryzae NSK (0.2596 g/g). Exhaustion of glucose and glutamic acid was observed to be the main contributor to their short log phases. The compounds such as glucose and glutamic acid as carbon and nitrogen sources, respectively, are the crucial elements required by microorganisms to synthesize the amino acids and proteins for cell growth and energy maintenance as well as the production of metabolites during fermentation [4, 12, 24, 28]. For food processing and fermentation processes, fungi that consume the smallest amount of substrate while producing the largest amount of desirable end- products are preferable.

It is clear that A. oryzae NSK is significantly different from the other strains in terms of GABA yield and substrate consumption. A Duncan Multiple Range Test showed that A. oryzae NSK not only used less substrate (0.2596 g/g) but also synthesized the highest amount of GABA (194 mg/L) compared to the other strains. Overall, A. oryzae NSK produced 3.59 mg GABA per gram of substrate (Y p/s ) used, and each gram of NSK cells yielded 13.61 mg of GABA (Y p/x ). Therefore, A. oryzae NSK was found to be the most productive strain in terms of GABA production compared to A. oryzae NSZ, NSJ and NST. It has also been hypothesized that GABA production is related to the formation of conidia. This was reported by Kumar et al. [21], who observed high levels of GAD enzyme in mature conidia compared to mycelia.

The medium used may have favorably stimulated the formation of Aspergillus sp NSK conidia to an optimum level, which subsequently generated more GABA. It was also observed that, during the production of GABA, the pH became more acidic, and GABA was still produced even after the pH increased. The increase and decrease in pH occurred for all of the strains tested. The fluctuation in pH is probably due to the generation of ammonia by the deamination of amino acids derived from medium composition [16]. In addition to pH, time also affected the rate of GABA production. Normally, maximum GABA production was achieved after 72–96 h of fermentation [6]. For A. oryzae NSK and NSZ, the maximum concentrations of GABA were reached after 72 h, while A. oryzae NSJ and NST reached their highest levels after 96 h.

This result was due to high GAD enzyme activity of A. oryzae NSK (26.10 units/g cells), which led to higher GABA production compared to A. oryzae NSZ (8.44 units/g cells), A. oryzae NST (3.23 units/g cells) and A. oryzae NSJ (5.54 units/g cells) after 72–84 h of fermentation times. High GAD enzyme activity aided in the rapid conversion of supplemented glutamic acid to GABA before being gradually utilized as a source of nitrogen to support the increasing cell growth. After GABA achieved maximum levels, its concentration decreased naturally; GABA was no longer detected after 240 h for all A. oryzae strains investigated. The increase and decrease in GABA concentration over time could be related to the status of nitrogen levels present during fermentation in which glutamic acid supply is not only required for GABA production but also for new cell development and maintenance.

Depletion of glutamic acid after 72 and 96 h caused the isolate to utilize its own secondary metabolites i.e. GABA by catabolizing the GABA produced via the GABA shunt where GABA is transaminated to succinic semialdehyde (SSA) and succinate by 4-aminobutyrate transaminase (GABAT) and succinic semialdehyde dehydrogenase to produce α-ketoglutarate following the TCA cycle [9]. The release of both enzymes is under the control of UGA1 and two genes [9]. After the removal of α-ketoglutarate amino group by the transamination steps, the ammonia formed is undergoing the nitrification process before being absorbed as a nitrogen source in the form of nitrate [21]. The catabolism process to release nitrogen compound from GABA is thermodynamically unfavorable since it involves an extensive and complex pathway i.e.: GABA shunt and TCA cycle; hence, GABA is not utilized immediately after it has been produced [20, 21].

Molecular characteristics of A. oryzae strain NSK

A. oryzae NSK was selected as the best GABA-producing strain for biomolecular identification and construction of the genetic tree. Therefore, genomic DNA of A. oryzae NSK was extracted, and a polymerase chain reaction process was conducted to amplify the partial region of A. oryzae NSK rDNA using ITS 1 and ITS 4 primers. The amplified sequence was a combination of two complete genes of 5.8S ribosomal RNA, an internal transcribed spacer 2 and two partial sequences of an internal transcribed spacer 1 and 28S ribosomal RNA. From the result, a product of approximately 1200 bp was successfully amplified (Fig. 2), sequenced and aligned with the related species based on NCBI BLAST. A.oryzae NSK sequence was found to be similar to A. oryzae and A. flavus with 99 % similarity. Subsequently, the evolutionary distance (K nuc) between sequences of identical fungal species was calculated using Molecular Evolutionary Genetics Analysis (MEGA) software version 4.0 for further identification [35]. A phylogenetic tree was prepared using the neighbor-joining (NJ) method [35] from the K nuc data using the same software (Fig. 3). The K nuc values showed that the isolate was closely related to the A. oryzae BS-A4 compared to the A. flavus strain. The morphological characteristics confirmed the identity of this fungus as belonging to A. oryzae (strain NSK).

Neighbor-joining phylogenetic tree showing the relationships of Aspergillus sp. isolate (strain NSK) and related species based on 18S rRNA gene sequences. Aspergillus flavus strain SK20 = DQ467973.1, Aspergillus oryzae strain BS-A4 = HQ285531.1, Aspergillus flavus strain 13 = DQ467970.1, Aspergillus flavus strain ATCC 20043 = AY939782.1, Aspergillus oryzae strain AS-A8 = HQ285525.1, Aspergillus oryzae strain AD-B5 = HQ285522.1, Aspergillus oryzae strain SRRC 2103 = AY373857.1, Aspergillus oryzae NRRL 506 = AF459735.1, Aspergillus flavus isolate ucb021 = EF409787.1. Bar 0.0005 K nuc

Conclusion

In this study, we evaluated the GABA-producing abilities of four commercial strains of Aspergillus sp, namely A. oryzae NSK, NSJ, NST and NSZ isolated from koji. All the strains shared similar morphological characteristics in terms of colony color, texture and diameter as well as mycelia color, conidial color, conidial head structure and vesicle structure; however, they had different GABA-producing capabilities; highest GABA productivity was demonstrated by A. oryzae NSK compared to A. oryzae NSJ, NSZ and NST. Molecular identification was performed to confirm the A. oryzae NSK species and to construct its phylogenetic tree. The results showed that the isolated DNA scored the highest percentage of sequence coverage’s similarity (77 % coverage) to the A. oryzae strain FH4 (EU409806.1). Further analysis was conducted by calculating the evolutionary distance (K nuc) between sequences using Molecular Evolutionary Genetics Analysis (MEGA); the results confirmed that the isolate belonged to the species A. oryzae. The GABA-production potential of A. oryzae NSK can be further improved through optimization of its physical (pH and temperature) and nutritional conditions (carbon and nitrogen sources). These improvements may allow the development of an innovative functional food material rich in GABA particularly soy sauce.

Abbreviations

- P :

-

GABA concentration (mg/L)

- S :

-

Substrate concentration (g/L)

- S 0 :

-

Initial substrate concentration (g/L)

- t :

-

Fermentation time (h−1)

- X :

-

Cell concentration (g/L)

- X m :

-

Maximum cell concentration (g/L)

- X 0 :

-

Initial cell concentration (g/L)

- Y p/s :

-

Yield factor for product on cell (mg/g)

- Y x/s :

-

Yield factor for cell on substrate (g/g)

- K s :

-

Monod growth saturation coefficient (g/L)

- μ m :

-

Maximum specific growth rate (h−1)

References

Abe Y, Umemura S, Sugimoto KI, Hirawa N, Kato Y, Yokoyama N, Yokoyama T, Iwai J, Ishii M (1995) Effect of green tea rich in γ-aminobutyric acid on blood pressure of Dahl salt-sensitive rats. Am J Hypertens 8:74–79

Aoki H, Furuya Y, Endo Y, Fujimoto K (2003) Effect of γ-aminobutyric acid-enriched tempeh-like fermented soybean (GABA-tempeh) on the blood pressure of spontaneously hypertensive rats. Biosci Biotechnol Biochem 67:1806–1808

Bueno DJ, Silva JO, Oliver G (2004) Fungal isolation and enumeration in foods. Methods Mol Biol 268:127–131

Chaerun SK (2009) Tempeh waste as a natural, economical carbon and nutrient source: ED-XRF and NCS study. HAYATI J Biosci 16:120

Chen CY, Bechtold AG, Tabor J, Bonham AC (2009) Exercise reduces GABA synaptic input onto nucleus tractus solitarii baroreceptor second-order neurons via NK1 receptor internalization in spontaneously hypertensive rats. J Neurosci 29:2754–2761

Coleman ST, Fang TK, Rovinsky SA, Turano FJ, Moye-Rowley WS (2001) Expression of a glutamate decarboxylase homologue is required for normal oxidative stress tolerance in Saccharomyces cerevisiae. J Biol Chem 276:244–250

D’Andrea G, Granella F, Cataldini M, Verdelli F, Balbi T (2001) GABA and glutamate in migraine. J Headache Pain 2:s57–s60

de Oliveira V, Felipe L, Wallau GdL, Silva Loreto EL (2009) Isolation of high quality DNA: a protocol combining “rennet” and glass milk. Electron J Biotechnol 12:11–12

Deacon JW (2013) Fungal biology. Blackwell, Malden

El-Enshasy HA (2007) Filamentous fungal cultures—process characteristics, products, and applications. Bioprocess Value Added Prod Renew Resour New Technol Appl 9:225–261

Elbashiti T, Fayyad A, Elkichaoui A (2010) Isolation and identification of Aspergillus oryzae and the production of soy sauce with new aroma. Pak J Nutr 9:1171–1175

Fazenda ML, Dias JM, Harvey LM, Nordon A, Edrada-Ebel R, LittleJohn D, McNeil B (2013) Towards better understanding of an industrial cell factory: investigating the feasibility of real-time metabolic flux analysis in Pichia pastoris. Microb Cell Fact 12:1

Fazenda ML, Seviour R, McNeil B, Harvey LM (2008) Submerged culture fermentation of ‘‘higher fungi’’: the macrofungi. Adv App Microbiol 63:33–103

Frost LD (2004) Glucose assays revisited: experimental determination of the glucose concentration in honey. Chem Educ 9:239–241

Inoue K, Shirai T, Ochiai H, Kasao M, Hayakawa K, Kimura M, Sansawa H (2003) Blood-pressure-lowering effect of a novel fermented milk containing γ-aminobutyric acid (GABA) in mild hypertensives. Eur J Clin Nutr 57:490–495

Jiang D, Ye Y, Hou J (2011) Studies on screening of higher γ-aminobutyric acid-producing Monascus and optimization of fermentative parameters. Eur Food Res Technol 232:541–547

Kato Y, Kato Y, Furukawa K, Hara S (2002) Cloning and nucleotide sequence of the glutamate decarboxylase-encoding gene gadA from Aspergillus oryzae. Biosci Biotechnol Biochem 66:2600–2605

Kim JY, Lee MY, Ji GE, Lee YS, Hwang KT (2009) Production of γ-aminobutyric acid in black raspberry juice during fermentation by Lactobacillus brevis GABA100. Int J Food Microbiol 130:12–16

Komatsuzaki N, Shima J, Kawamoto S, Momose H, Kimura T (2005) Production of γ-aminobutyric acid (GABA) by Lactobacillus paracasei isolated from traditional fermented foods. Food Microbiol 22:497–504

Kumar S, Punekar NS (1997) The metabolism of 4-aminobutyrate (GABA) in fungi. Mycol Res 101:403–409

Kumar S, Punekar NS, SatyaNarayan V, Venkatesh K (2000) Metabolic fate of glutamate and evaluation of flux through the 4-aminobutyrate (GABA) shunt in Aspergillus niger. Biotechnol Bioeng 67:575–584

Leck A (1999) Preparation of lactophenol cotton blue slide mounts. Community Eye Health 12:24

Lu W, Sun L, Zhang X, Sun J (2010) Properties of glutamate decarboxylase of Aspergillus oryzae and its application for biotransformation of glutamate into gamma-aminobutyric acid. In: Bioinformatics and biomedical engineering (iCBBE), 2010 4th international conference on IEEE, pp 1–5

D’Anjou MC, Daugulis AJ (2001) A rational approach to improving productivity in recombinant Pichia pastoris fermentation. Biotechnol Bioeng 72:1–11

Mombereau C, Kaupmann K, Froestl W, Sansig G, van der Putten H, Cryan JF (2004) Genetic and pharmacological evidence of a role for GABAB receptors in the modulation of anxiety-and antidepressant-like behavior. Neuropsychopharmacol 29:1050–1062

Oh S-H, Oh C-H (2003) Brown rice extracts with enhanced levels of GABA stimulate immune cells. Food Sci Biotechnol 12:248–252

Park K-B, Oh S-H (2007) Production of yogurt with enhanced levels of gamma-aminobutyric acid and valuable nutrients using lactic acid bacteria and germinated soybean extract. Bioresour Technol 98:1675–1679

Prakash MS (2010) A simple unstructured mathematical model for ethanol fermentation by mutant Neurospora crassa. Int J Chem Eng Res 2:13–21

Rhyu MR, Kim EY, Kim HY, Ahn BH, Yang CB (2000) Characteristics of the red rice fermented with fungus Monascus. Food Sci Biotechnol 9:21–26

Roohinejad S, Omidizadeh A, Mirhosseini H, Saari N, Mustafa S, Meor Hussin AS, Hamid A, Abd Manap MY (2011) Effect of pre-germination time on amino acid profile and gamma amino butyric acid (GABA) contents in different varieties of Malaysian brown rice. Int J Food Sci Nutr 14:1386–1399

Rossetti V, Lombard A (1996) Determination of glutamate decarboxylase by high-performance liquid chromatography. J Chromatogr B Biomed Sci Appl 681:63–67

Samson RA, Hoekstra ES, Frisvad JC (2004) Introduction to food-and airborne fungi. ASM, Washington

Siragusa S, De Angelis M, Di Cagno R, Rizzello C, Coda R, Gobbetti M (2007) Synthesis of γ-aminobutyric acid by lactic acid bacteria isolated from a variety of Italian cheeses. Appl Environ Microbiol 73:7283–7290

Sooriyamoorthy S, Silva K, Gunawardhane M, Illeperuma C (2004) Isolation and identification of indigenous Aspergillus oryzae for saccharification of rice starch. Trop Agric Res 16:121–127

Tamura K, Dudley J, Nei M, Kumar S (2007) MEGA4: molecular evolutionary genetics analysis (MEGA) software version 4.0. Mol Biol Evol 24:1596–1599

Waagepetersen HS, Sonnewald U, Schousboe A (2007) Glutamine, Glutamate, and GABA: metabolic aspects. In: Lajtha A, Oja S, Schousboe A, Saransaari P (eds) Handbook of neurochemistry and molecular neurobiology: amino acids and peptides in the nervous system. Springer, New York, pp 1–21

Wan-Mohtar WAAQI, Ab Kadir S, Saari N (2016) The morphology of Ganoderma lucidum mycelium in a repeated-batch fermentation for exopolysaccharide production. Biotechnol Rep 11:2-11

Wan Mohtar WAAQI, Latif NA, Harvey LM, McNeil B (2016) Production of exopolysaccharide by Ganoderma lucidum in a repeated-batch fermentation. Biocatal Agric Biotechnol 6:91–101

Wang L, Yokoyama K, Takahasi H, Kase N, Hanya Y, Yashiro K, Miyaji M, Nishimura K (2001) Identification of species in Aspergillus section Flavi based on sequencing of the mitochondrial cytochrome b gene. Int J Food Microbiol 71:75–86

Xu D, Pan L, Zhao H, Zhao M, Sun J, Liu D (2011) Breeding and identification of novel koji molds with high activity of acid protease by genome recombination between Aspergillus oryzae and Aspergillus niger. J Ind Microbiol Biotechnol 38:1255–1265

Yang SY, Lu FX, Lu ZX, Bie XM, Jiao Y, Sun LJ, Yu B (2008) Production of gamma-aminobutyric acid by Streptococcus salivarius subsp. thermophilus Y2 under submerged fermentation. Amino Acids 34:473–478

Yang SY, Lu ZX, Lü FX, Bie XM, Sun LJ, Zeng XX (2006) A simple method for rapid screening of bacteria with glutamate decarboxylase activities. J Rapid Methods Aut Microbiol 14:291–298

Acknowledgments

We would like to extend our gratitude to the Ministry of Higher Education (MOHE) Malaysia for the financial support awarded to Prof. Dr. Nazamid Saari under the FRGS (Vot No: 5523380).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ab Kadir, S., Wan-Mohtar, W.A.A.Q.I., Mohammad, R. et al. Evaluation of commercial soy sauce koji strains of Aspergillus oryzae for γ-aminobutyric acid (GABA) production. J Ind Microbiol Biotechnol 43, 1387–1395 (2016). https://doi.org/10.1007/s10295-016-1828-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-016-1828-5