Abstract

γ-Aminobutyric acid (GABA), a hypotensive agent, can be produced by Monascus spp. Two hundred and fifteen GABA-producing Monascus strains were isolated from fermented bean curd and red-mold rice. The strain M6 with the highest production level of GABA (3.657 g/L) was isolated from fermented bean curd by using PDB with 0.5% monosodium glutamate (MSG) and identified as Monascus ruber based on morphological and ITS region sequence comparisons. The strain M6 was irradiated by UV to raise GABA production. The mutant strain of M6-13 had the highest GABA yield of 5.527 g/L, which was 1.5 times higher than that of the original strain M6. In addition, the strain M6-13 still had stable yield of GABA and no reverse mutation after sub-cultured for 15 generations. GABA production level of the mutant strain M6-13 increased to 7.826 g/L in submerged flasks culture by use of the orthogonal experiment method. Based on this, process analysis and optimization of GABA production of the strain M6-13 were studied in 3.7-L vessel fermentor and the maximum GABA yield reached 13.470 g/L.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the last decade, fundamental studies have opened a new field of research dealing with bioactive or biogenic substances derived from foods [1]. GABA, a four-carbon non-protein amino acid, is produced as a major inhibitory neurotransmitter in the mammalian nervous system [2]. The preparation and application of GABA is increasingly concerned [3–13] with the treatment of existing conditions such as epilepsy and high blood pressure. Therefore, searching GABA-rich foods becomes one of the focuses in the field of functional food research [14]. Several functional foods are manufactured: GABA-enriched green tea by anaerobic or cyclic treatments of tea leaves or shoots [3]; GABA-enriched rice germ by soaking in water [13, 14]; GABA-enriched brown rice by high pressure treatment and germination [7, 10, 11]; GABA-enriched germinated wheat through the activity of endogenous enzymes [9]; and GABA-enriched fermented beverages such as tempeh-like beverage [4], dairy products [5, 6], and red-mold rice containing the Monascus fungus [12].

However, the yields of GABA accumulated from fruit and vegetables are low [15, 16]. GABA production through fermentation believed to be convenient and efficient has been gradually applied in food industry [17]. Escherichia coli were used for producing GABA first, but many hidden troubles and dangers existed [17, 18]. In 1979, Endo in Japan found that a special matter synthesized from Monascus had hypotensive activity. This was the first report on GABA could be biosynthesized from Monascus. Since then, several microorganisms including lactic acid bacteria [19–22], Monascus [23–25], and yeast [26], generally regarded as safe, have been widely researched and applied in GABA production. Monascus spp. is a traditional fermentation fungus used on food for thousands of years in China; its special effect on, and application to, food was recorded in ancient records. The secondary metabolites produced by Monascus spp. include Monascus pigments [27, 28], monacolin K, and GABA [24, 29]. But up to now, the lack of GABA Monascus strains and fermentation process retarded the production and application of GABA in our country. Therefore, screening of higher γ-aminobutyric acid-producing Monascus and optimization of culture medium and fermentation conditions were studied. As far as know,it is the first report that Monascus produce GABA in the liquid culture.

Materials and methods

Chemicals and media

GABA was purchased from Sigma (St. Louis, Mo. USA). Agar, glucose, malt extract, peptone, yeast extract, and other chemicals were purchased from Shenggong (Shanghai Chemical Company, China). Some agro-industrial residues such as fermented bean curd, Indian meal (IM), potato dextrose (PD), rice meal (RM), red-mold rice, soybean powder (SP), sweet potato starch (SPS), and wheat flour (WF) were obtained from the local supermarket (Jinhua city, Zhejiang Province, China).

Isolation, mutagenesis, and preservation of strains were performed on Potato Dextrose Agar (PDA) medium. The seed culture medium comprised of (per liter) 50 g glucose, 20 g peptone, 10 g yeast extract, 10 g K2HPO4, 5 g MgSO4·7H2O, 5 g KCl, and 1 g FeSO4. A chemically defined medium was used for GABA production, which contained (per liter) 30 g carbon sources, 5 g nitrogen sources, 5 g monosodium glutamate (MSG),1 g K2HPO4, 0.5 g MgSO4·7H2O, 0.5 g KCl, and 0.01 g FeSO4 in distilled water. Some agricultural products were also used as carbon source in fermentor. Initial pH values of all media were adjusted to 6.0 prior to sterilization at 121 °C for 20 min.

Isolation and identification

The traditional Monascus-fermented foods, red bean curd and red-mold rice were collected from different areas in China. Samples were taken and spread on to the PDA medium. After incubation at 30 °C for 72 h, single colonies were cut out and inoculated on PDA plates. The purified Monascus strains were preserved in petri dish at 23 °C and sub-cultured every three months [30].

CYA, MEA, CY50G, WA media [31] were used as identification medium. It was identified by the morphological character of Monascus strain on these media. Fresh mycelia obtained from fermentation broth were grinded into powder with liquid nitrogen. Monascus genomic DNA was extracted by the traditional cetyltrimethyl ammonium bromide (CTAB) method. Fragments containing the ITS region were amplified by using primers ITS1 (5′-TCCGTAGGTGAACCTGCGG-3′) and ITS4 (5′-TCCTCCG CT T AT TGATATGC-3′). To identify genus and species of M6, the ITS sequences were analyzed with the BLAST program of NCBI (National Center for Biotechnology Information, Bethesda, MD, USA).

Mutagenesis of Monascus

The highest GABA production Monascus strain was used as a parental one. Spore suspensions were prepared in 105 CFU mL−1 by washing the 10-day-old culture with sterile distilled water. Ten milliliters of spore suspensions was exposed to UV light for 5 min. After incubation at 30 °C for 72 h, single colonies were cut out.

Cultivations

Erlenmeyer flasks (500 mL) each containing 100-mL seed culture were inoculated with 5% of the spore suspension and incubated at 30 °C at 120 rpm for 72 h in a reciprocal shaker. The submerged fermentations for GABA production were carried out in 500-mL Erlenmeyer flasks and a 3.7-L vessel fermentor (Switzerland, Bioengineering). Cultivations in the 500-mL flasks containing 100 mL sterilized medium were performed for 72 h at 30 °C and 120 rpm. Fermentations in the 3.7-L vessel fermentor containing 2 L sterilized medium and 5% seed culture broth were performed for 120 h at 35 °C and 180 rpm with the aeration rate of 100 L/h.

Determination of GABA and biomass

One milliliter of fermentation broth during culture was taken and put in centrifuge tube. The centrifuge tube with fermentation broth was boiled for 10 min and then centrifuged at 12,000 rpm for 15 min. GABA concentration of the supernatant was determined by HPLC (Waters, Milford, MA, UK).

The 10 mL of culture broth was put through a 0.45-μm Millipore cellulose filter. The harvested mycelia were washed with sterile distilled water and then dried in an oven at 80 °C until the dry weight was not changed. This was the dry cell weight (DCW).

Optimization of fermentation conditions in shake flasks

Various carbon sources (30 g/L) and nitrogen sources (5 g/L) were added individually in order to determine the effect on GABA production. The culture substrate and fermentation conditions of the strain were optimized by means of single-factor experiment and L9 (33) orthogonal tests. The effects of single factors including carbon sources (soluble starch, dextrose, MSG, sodium succinate, sucrose), nitrogen sources (beef extract, sodium nitrate, peptone, ammonium biphosphate, yeast extract), incubation temperature (24 °C, 27 °C, 30 °C, 33 °C, 35 °C, and 38 °C), the initial solution pHs (4.0, 4.5, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5), and shaking speed (0 rpm, 60 rpm, 120 rpm, and 180 rpm) on GABA production in a submerged culture in 500-mL Erlenmeyer flasks were analyzed. A three-level orthogonal design L9 (33) (9 runs and 3 center points) was used. The experimental design was showed in Table 1. The experiments were replicated three times.

Optimization of fermentation conditions in 3.7-L vessel fermentor

Different inoculums sizes (2.5%, 5.0%, 7.5%, and 10%), ventilation rates (0, 50, 100, 150, 200 L/h), and agro-industrial residues (IM, PD, RM, SP, SPS, and WF) were employed to study their effects on mycelium growth and GABA production for selecting the best conditions for GABA production. Growth kinetics was studied by estimating the biomass of Monascus and by analyzing the GABA production capability of the fungus.

Data analysis

Statistical analyses were performed using the SAS program (Statistical Analysis System 9.1 version) and expressed as mean ± standard error of three replicates. P < 0.05 was considered to be statistically significant. When P values for the repeated ANOVA were significant, differences in means were determined using Duncan’s multiple range tests.

Results and discussion

Screening and identification

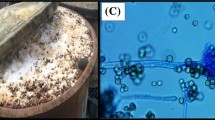

About 215 Monascus strains were isolated from the fermented bean curd and red-mold rice. The GABA production ability of Monascus was focused on in this study. Some screening results were showed in Fig. 1. The strain M6 (isolated from the red bean curd) had the highest GABA production ability (3.657 g/L) in PDB incubation at 30 °C for 72 h was acquired.

There existed some differences among different common Monascus in morphological characters including hypha, conidium, cleistothecium, ascospores, and so on, which served as deposing the evidences to classify and to identify Monascus. The strain M6 was identified as Monascus ruber based on morphological and physiological characters. The application of molecular techniques provided more scientific evidences in identification. According to ITS region sequence comparisons, the strain M6 (HQ659500) showed high homology (99%) to Monascus ruber, and the result was concordant with morphological identification.

UV treatment of high GABA production strain

UV treatment was a common method for improvement of Monascus spp. The strain M6 was used as original strain and irradiated by UV to raise GABA production. One of the mutant strains, M6-13, provided half as much again increase in the concentration of GABA. After 15 generations, the GABA production of the mutant strain M6-13 was stabilized and no reverse mutation (Table 2). Therefore, the fermentation conditions of the mutant strain M6-13 in both flasks and fermentor were further optimized.

Optimization of medium and fermentation conditions in a flask

The culture medium and fermentation conditions of the strain M6-13 were optimized by means of single-factor experiment and L9 (33) orthogonal test. In the single-factor experiments, the effect of different carbon sources and nitrogen sources to biomass, and secondary metabolites was studied. The results (data were not showed) indicated that soluble starch was beneficial to both GABA production and DCW, besides beef extract was proved to be the best nitrogen source.

An orthogonal experiment was designed to investigate optimum culture conditions taking account of three factors: cultivation temperature, Initial pH, and shaking speed. The results of orthogonal experiment and analysis were showed in Tables 3 and 4, respectively. By experiments, the optimum fermentation conditions of M6-13 were cultured at 35 °C, initial solution pH 5.0 and 120 rpm. Under above conditions, the highest production level of GABA has reached to 7.826 g/L. What’s more, cultivation temperature had highest significance on GABA production among the three factors.

Growth profile and GABA production of the strain M6-13 in batch culture

GABA productions during fermentation were quantitatively analyzed by HPLC. A typical batch-mode fermentation time-course of the strain M6-13 in PDB medium containing 0.5% MSG, the stirrer speed of 180 rpm, and the aeration rate of 200 L/h (standard conditions for mixing and aeration) was showed in Fig. 2. The growth kinetics was estimated by the dry biomass at different incubation periods. It was evident that its lag phase was for the first 40 h. When DCW increased, the level concentration of GABA in the culture started to increase correspondingly. The incubation period from 60 h showed decreased fungal growth, and the concentration of GABA reached maximal level of 8.899 g/L at 84 h.

Effect of ventilation rates and inoculums concentration on GABA production

GABA synthesis was closely related to the amount of ventilation rates and inoculums during the fermentation. The effects of ventilation rates on GABA production of the strain M6-13 were showed in Fig. 3. The GABA yield reached a maximum value of 11.558 g/L when the aeration rate was 100 L/h and decreased thereafter.

Four inoculation concentrations were analyzed, and the results were showed in Fig. 4. Inoculation concentrations have a great effect on the time-span of lag phase and GABA production. Higher inoculums volumes (7.5% and 10.0%) can bring a shorter lag phase of about 56 h and a lower GABA production ability (10.613 g/L). On the other hand, lower inoculums volumes have a longer lag phase of about 68 h and a higher GABA production ability (13.174 g/L, Fig. 5). But, the fermentation at inoculums volume 5.0% finally showed higher GABA production than others. Considering all aspects, a 5.0% inoculation volume is the best one for research and industrial production.

Selection of agricultural products

Synthetic media at industrial scales were not economical since the cost used was still high. Therefore, the study on development of low-cost processes was necessary. Some agricultural products such as Indian meal, potato dextrose, rice meal, soybean powder, sweet potato starch, and wheat powder were compared for selecting the best substrate for GABA production. The results showed that the successive order of agricultural products affecting the GABA production was IM (7.762 g/L), PD (9.841 g/L), RP (6.945 g/L), SP (4.866 g/L), SPS (10.341 g/L), and WP (13.474 g/L) (Fig. 6). Hence, wheat powder was used for subsequent studies.

Conclusions

Monascus spp were largely used in a variety of fermented foods, especially for the manufacture of red-mold rice with functional properties. The screening of Monascus based on their capacity for synthesizing GABA may open new perspectives on production of GABA-enriched functional products. To our knowledge, just a few reports have concerning the screening of higher GABA production Monascus.

In this study, 215 GABA production Monascus strains were isolated from fermented bean curd and red-mold rice. The strain M6 isolated from fermented bean curd showed the highest GABA production ability (3.657 g/L) in PD with 0.5% monosodium glutamate. The strain M6 was identified as Monascus ruber by morphological and ITS region sequence comparisons. The strain M6-13 mutagenized by UV had the highest GABA production yield of 5.527 g/L which was 1.5 times higher than that of original strain. The GABA production ability of the strain M6-13 was optimized by orthogonal experiment method and increased to 7.836 g/L.

Ventilation rates at 100 L/h and inoculation concentrations at 5.0% using wheat flour as the main component were the best fermentation conditions for the strain M6-13 in the 3.7-L vessel fermentor at 35 °C, and the final GABA yield of the strain M6-13 reached 13.174 g/L at the optimized conditions.

References

Cho YR, Chang JY, Chang HC (2007) Production of γ-aminobutyric acid (GABA) by Lactobacillus buchneri isolated from kimchi and its neuroprotective effect on neuronal cells. J Microbiol Biotechnol 17:104–109

Leventhal AG, Wang Y, Pu M, Zhou Y, Ma Y (2003) GABA and its agonists improved visual cortical function in senescent monkey. Science 300:812–815

Ohmori M, Yano T, Okamoto J, Tsushida T, Murai T, Higuchi M (1987) Effect of anaerobically treated tea on blood pressure of spontaneous hypertensive rats. Nippon Nogeikagaku Kaishi 61:1449–1451

Aoki H, Furuya Y, Endo Y, Fujimoto K (2003) Effect of γ-amino butyric acid-enriched tempeh-like fermented soybean (GABA tempeh) on the blood pressure of spontaneously hypertensive rats. Biosci Biotechnol Biochem 67:1806–1808

Hayakawa K, Kimura M, Kasaha K, Matsumoto K, Sansawa H, Yamori Y (2004) Effect of a γ-aminobutyric acid-enriched dairy product on the blood pressure of spontaneously hypertensive and normotensive Wistar-Kyoto rats. Br J Nutr 92:411–417

Inoue K, Shirai T, Ochiai H, Kasao M, Hayakawa K, Kimura M, Sansawa H (2003) Blood pressure lowering effect of a novel fermented milk containing gamma-aminobutyric acid (GABA) in mild hypertensives. Eur J Clin Nutr 57:490–495

Kinefuchi M, Sekiya M, Yamazaiki A, Yamamoto K (1999) Accumulation of GABA in brown rice by high pressure treatment. Nippon Shokuhin Kagaku Kaishi 46:323–328

Komatsuzaki N, Shima J, Kawamoto S, Momose H, Kimura T (2007) Production of γ-aminobutyric acid (GABA) by Lactobacillus paracasei isolated from traditional fermented foods. Food Microbiol 22:497–504

Nagaoka H (2005) Treatment of germinated wheat to increase levels of GABA and IP6 catalyzed by endogenous enzymes. Biotechnol Prog 21:405–410

Oh SH (2003) Stimulation of gamma-aminobutyric acid synthesis activity in brown rice by a chitosan/Glu germination solution and calcium/calmodulin. J Biochem Mol Biol 36:319–325

Okada T, Sugishita T, Murakami T, Murai H, Saikusa T, Hotorino T, Onoda A, Kajimoto O, Takahashi R, Takahashi T (2000) Effect of the defatted rice germ enriched with GABA for sleeplessness, depression, autonomic disorder by oral administration. Nippon Shokuhin Kagaku Kaishi 47:596–603

Rhyu MR, Kim EY, Kim HY, Ahn BH, Yang CB (2000) Characteristics of the red rice fermented with fungus Monascus. Food Science and Biotechnology 9:21–26

Saikusa T, Horino T, Mori Y (1994) Accumulation of γ-aminobutyric acid (GABA) in the rice germ during water soaking. Biosci Biotechnol Biochem 58:2291–2292

Komatsuzaki N, Tsukahara K, Toyoshima H, Suzuki T, Shimizu N, Kimura T (2007) Effect of soaking and gaseous treatment on GABA content in germinated brown rice. J Food Eng 78:556–560

Fougere F, Le Rudulier D, Streeter JG (1991) Effects of salt stress on amino acid, organic acid, and carbohydrate composition of roots, bacteroids and cytosol of alfalfa (Medicago sativa L.). Plant Physiol 96:1228–1236

Rhodes D, Handa S, Bressan RA (1986) Metabolic changes associated with adaptation of plant cells to water stress. Plant Physiol 82:890–903

Plokhov AY, Gusyatiner MM, Yampolskaya TA, Kaluzhsky VE, Sukhareva BS, Schulga AA (2000) Preparation of gamma-aminobutyric acid using E. coli cells with high activity of glutamate decarboxylase. Biotechnol Appl Biochem 88:257–265

Zhao JL (1989) Studies on gamma-aminobutyric acid production by immobilized Escherichia coli cells. Chin J Biotechnol 5:105–111

Lu XX, Chen ZG, Gu ZX, Han YB (2008) Isolation of γ-aminobutyric acid-producting bacteria and optimization of fermentative medium. Biochem Eng J 41:48–52

Park KB, Oh SH (2007) Cloning, sequencing and expression of a novel glutamate decarboxylase gene from a newly isolated lactic acid bacterium Lactobacillus brevis OPK-3. Bioresour Technol 98:312–319

Yang SY, Lu FX, Lu ZX, Bie XM, Jiao Y, Sun LJ, Yu B (2008) Production of γ-aminobutyric acid by Streptococcus salivarius sub sp. thermophilus Y2 under submerged fermentation. Amino Acids 34:473–478

Yokoyama S, Hiramatsu JI, Hayakawa K (2002) Production of γ-aminobutyric acid from alcohol distillery lees by Lactobacillus brevis IFO-1. J Biosci Bioeng 93:95–97

Kono L, Himeno K (2000) Changes in gamma-aminobutyric acid content during benikoji making. Biosci Biotechnol Biochem 64:617–619

Su YC, Wang JJ, Lin TT, Pan TM (2003) Production of the secondary metabolites gama-aminobutyric acid and monacolin K by Monascus purpureus. J Ind Microbiol Biotechnol 30:41–46

Wang JJ, Lee CL, Pan TM (2003) Improvement of monacolin K, γ-aminobutyric acid and citrinin production ration as a function of environmental conditions of Monascus purpureus MTU 601. J Ind Microbiol Biotechnol 30:669–676

Takahashi T, Furukawa A, Hara S, Mizoguchi H (2004) Isolation and characterization of sake yeast mutants deficient in γ-aminobutyric acid utilization in sake brewing. J Biosci Bioeng 97(6):412–418

Blanc PJ, Loret MO, Santerre AT, Pareilleux A, Prome D, Prome JC, Laussac JP, Goma G (1994) Pigments of Monascus. J Food Sci 59:862–865

Nimnoi P, Lumyong, S (2009) Improving solid-state fermentation of Monascus purpureus on agricultural products for pigment production. Food Bioprocess Technol. doi:10.007/s1194-009-0233-8

Chairote E, Chairote G, Niamsup H, Lumyong S (2008) The presence and content of Monacolins in red yeast rice prepared from Thai glutinous rice. World J Microbiol Biotechnol 24:3039–3047

Jiang Y, Li HB, Chen F, Hyde KD (2005) Production potential of water-soluble Monascus red pigment by a newly isolated Penicillium sp. J Agric Technol 1(1):113–126

Li ZQ, Guo F (2004) A further study of the species of Monascus. Mycosystema 23:1–6

Acknowledgments

This work was supported by National Natural Science Foundation of China (NO. 31070008), Major Science and Technology Plan of Zhejiang Province (2007C12036), and Zhejiang Provincial Natural Science Foundation of China (Grant Y3090343).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, D., ji, H., Ye, Y. et al. Studies on screening of higher γ-aminobutyric acid-producing Monascus and optimization of fermentative parameters. Eur Food Res Technol 232, 541–547 (2011). https://doi.org/10.1007/s00217-010-1413-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-010-1413-5