Abstract

Despite the use of refrigeration, improved packaging, adsorbents, and ethylene receptor blockers, on average, nearly 40% of all fruits and vegetables harvested in the US are not consumed. Many plant products, especially fruit, continue to ripen after harvesting, and as they do so, become increasingly susceptible to mechanical injury, resulting in increased rot. Other plant products during transportation and storage are susceptible to chill injury (CI). There is a real need for products that can delay ripening or mitigate the effects of CI, yet still permit full ripeness and quality to be achieved. Preliminary results are discussed where catalyst derived from cells of Rhodococcus rhodochrous DAP 96253, grown under conditions that induced high levels of nitrile hydratase, were able to extend the ripening and thus the shelf-life of selected climacteric fruits (banana, avocado, and peach). A catalyst, when placed in proximity to, but not touching, the test fruit delayed the ripening but did not alter the final ripeness of the fruit tested. Organo-leptic evaluations conducted with control peaches and with peaches exposed to, but not in contact with, the catalyst showed that the catalyst-treated peaches achieved full, natural levels of ripeness with respect to aroma, flavor, sweetness, and juice content. Furthermore, the results of delayed ripening were achieved at ambient temperatures (without the need for refrigeration).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The US Department of Agriculture estimates that on average 40% of all produce harvested in the US is not eaten because it is considered unsuitable/unfit for consumption by the consumer. A major cause of this problem is that ripening-events result in a loss of mechanical integrity, which renders the produce more susceptible to mechanical injury, and thus to decay. The major approach to addressing this problem has been through the use of refrigeration and/or controlled atmospheres. While refrigeration is of long-standing use, chill-injury (CI) is a major problem with this approach, where many fruit/vegetables experience deleterious changes when exposed to low, non-freezing temperatures. Recent approaches to extending ripening have been through the use of chemicals such as the ethylene analog 1-methylcyclopropene (MCP) [13], which serves to competitively and irreversibly block the ethylene receptor in plants [1–3, 7, 20]. Genetic engineering approaches to either alter ethylene synthesis or render the plant more insensitive to ethylene [9, 10], or through the use of chemical absorbents/reactants. None of these recent approaches is either universally applied or appropriate. While MCP is used in conjunction with >80% of the apples grown in the US, certain apple varieties such Pink Lady and Fuji do not respond to MCP [14]. It is also noted, for example, that where MCP is used with apples, no additional benefits to ripening are noted because MCP binds irreversibly to the ethylene receptor [12]. As a result, full ripening (and therefore taste, aroma, etc.) is not generally achieved, affecting consumer appeal. Of additional concern, where MCP is used with apples, refrigeration (with its attendant increased energy consumption and cost) is still employed. Genetic engineering approaches, in general, have issues related to consumer perception. Absorbents/reactants must be present in sufficient quantity to work effectively or they will fail.

In a recent survey conducted by The Sterling-Rice Group [22], involving 1,552 consumers designed to determine why despite the appeal of fresh fruit and vegetables, peach consumption was actually down in California, showed that lack of taste, softening, and decay were the major factors for consumers not selecting peaches.

There is a clear need/utility for approaches that delay/extend the natural ripening process, thereby improving transportation and distribution but without altering or reducing consumer appeal and also that do not raise issues of perception by the consumer.

Recently we have discovered methods and approaches [16–18] derived from natural, environmental soil microorganisms to prepare biologically derived catalysts that delay the plant ripening process but which permit full ripeness to be obtained. This study presents the results of our investigation into and the potential utility of this catalyst to delay plant ripening using selected fruit (peaches, bananas, and avocados).

Materials and methods

Unless otherwise stated, all chemicals were obtained from Sigma–Aldrich (St. Louis, MO).

Maintenance and cultivation of cells

Cells of Rhodococcus rhodochrous DAP 96253 were grown on YEMEA medium (ISP medium 2 as recommended by Dietz and Thayer [5] supplemented with urea (7 g/l), cobalt (as CoCl2 at 10–50 ppm) and asparagine (1,000 ppm), cells were then harvested and reconstituted to a 20× cell concentrate and used to prepare fresh catalyst or stored frozen at −20 or −80°C until needed.

Alternatively, cells were grown on either the R2A or R3A media of Reasoner and Geldreich [19], modified by supplementation with urea, cobalt, and asparagine as above, and with proteose peptone and casamino acids being replaced by Hy-cotton® 7803 (Quest International, Hoffman Estates, IL) and yeast extract, respectively, to provide an animal-free medium.

The microorganism reported in this study, Rhodococcus rhodochrous DAP 96253, has been deposited with the ATCC (Manassas, VA) [16–18] and has been subsequently assigned the strain designation ATCC 55889.

Immobilization of whole cells

Cells of Rhodococcus rhodochrous strain DAP 96253 were immobilized with glutaraldehyde based upon the methods of DeFilippi [6] and Lopez-Gallego et al. [11] to obtain a matrix comprising glutaraldehyde cross-linked DEAE cellulose.

Appropriately grown (induced or non-induced cells) were harvested by centrifugation (8,000 rpm for 10 min and 4°C), resuspended in two volumes of sterile 50 mM phosphate buffer (pH 7.2) and re-centrifuged, as above two more times. Packed cell wet weight was determined after the final centrifugation, and the cells were then resuspended to achieve a 20× cell concentrate. Aliquots of resuspended cells were subjected to loss on drying at 105°C to determine dry cell weights, which were correlated with the packed cell weights. Equal amounts of cells and DEAE-cellulose were mixed and resuspended in DI water. Glutaraldehyde (25% solution) was added, with continuous stirring, to achieve a final glutaraldehyde concentration of 0.5%. Upon achieving the desired glutaraldehyde concentration, the solution was allowed to mix for an additional hour. Four volumes of DI water were then added. While this solution was still mixing, polyethylenimine (50% solution of MW 750,000, PEI) was added slowly until flocculation. The immobilized cells were filtered and then extruded through an orifice to obtain pieces of nominal 2–3 mm diameter. The particles were allowed to dry overnight prior to use.

Enzyme assays

Nitrile hydratase (acrylonitrile specific NHase)

NHase was quantified using 1,000 ppm (v/v) acrylonitrile. Cells, equivalent to [40 mg of cells (packed wet wt.)], were suspended into 1 ml of 50 mM phosphate buffer (pH 7.2) and combined with a 9-ml reaction solution containing the acrylonitrile and mixed for 2 min at 30°C. For glutaraldehyde immobilized cells, the reaction mixture was filtered through a 0.45-μm filter. For cells, the reaction mixture was acidified to pH 2 to stop the reaction, and then the solution was neutralized and centrifuged for 2 min at 13,000 rpm. The supernatant was pipetted into clean Eppendorf® tubes.

To ensure complete amide conversion to acid and ammonia, commercial amidase (1,000 units/440 μl, stored at −20°C) was added. A working amidase solution was prepared by making a 1:50 dilution of the original amidase solution, 10 μl of this working solution was added to each sample to affect the rapid conversion of the amide to its corresponding acid and ammonia, followed by vortexing for 30 s. These tubes were incubated at 37°C for 30 min.

Ammonia was determined by modification of the method by Fawcett and Scott [8]. The converted amide solution was transferred to 15-ml glass test tubes to which 2 ml of sodium phenate was added followed by the addition of 3 ml 0.1% aqueous sodium nitroprusside and 3 ml 0.02 N sodium hypochlorite (Clorox, 6.15%). This resulting solution was mixed by vortexing lightly. Color development was achieved by incubation of the tubes in the dark at 27°C for 30 min. After color development, the tubes were vortexed again and the OD was read at 630 nm for 10 s using a microplate reader (Victor 1420 multilabel counter, Perkin-Elmer Life Sciences, Shelton, CT). Each sample was read in triplicate and the data then averaged.

Amidase and asparaginase

Amidase and asparaginase activity were measured using a modification of the method of Fawcett and Scott [8] for the determination of ammonia as described above except that 1,000 ppm acrylamide and 1,000 ppm asparagine, respectively, were used as substrate.

Evaluation of catalyst for delayed ripening activity

Fruit samples

Banana, avocado, and peach were used to evaluate the delayed ripening activity of the bacterial-derived catalyst. All bananas and avocados used in the studies were obtained from readily available commercial sources. Documentation regarding the processing history and transportation conditions (including nature of controlled atmosphere) was not available for either bananas or avocados. Bananas were either obtained in large hands (with 12–16 bananas each) and then split into two equal hands or in hands of 6–8 bananas, which were grouped to achieve similar appearance, color, etc., and then representative hands were used as controls or as experimentals accordingly. Avocados were grouped accordingly to size, shape, color, and overall appearance, and then split equally into control and experimental groups. Peaches (through the assistance of the Georgia Peach Council and the Georgia Agribusiness Council) were obtained directly from the growers/distributors. Peaches were picked and processed the same morning the fruit went on test. With respect to all Georgia peaches evaluated, extensive documentation was available regarding where the peach varieties came from, growing conditions, all processing steps and conditions, and grading. When evaluating peaches, only a single variety was evaluated at a time. Grade 1 peaches, of consistent size, shape, color, and with no blemishes or imperfections were used to provide similar peaches for controls and experimentals.

Imaging ripening changes

Digital color images were obtained over the course of an experiment for all fruit evaluated. Imaging was achieved using a Nikon F3 Digital camera with fruit samples illuminated using OTT (×32 natural light bulbs).

Other fruit measurements

Representative peaches were also evaluated for skin surface strength upon receipt with the aid of a stand-mounted Effegi Penetrometer (Model 011, QA Supplies, Norfolk, VA) according to the method of Crisosto and Garner [4] and the manufacturer. Rapid loss of skin integrity/flesh strength in the control peaches resulted in penetrometer values well below the accepted range for the penetrometer, and as a result, skin strength test measurement could not be used over the course of the experiment to gauge loss of integrity. Representative peaches were taken over the course of the experiment and cut open in order to obtain longitudinal slices according to the methods outlined by Crisosto and Garner [4] in order to obtain representative juice samples for both pH and Brix determinations. Brix was determined by using an AO model 253 refractometer (AO, Rochester, NY) according to the method of Crisosto and Garner [4].

Determination of carbohydrate in fruit by the anthrone method

Carbohydrate in fruit was determined by the anthrone method using a variant of the Spiro [21] modification of the method of Ludwig and Goldberg [12], which was adapted from the method of Morris [15].

Triplicate longitudinal samples (10 g) were taken from each fruit placed in a 50-ml tube on ice containing 10 ml of DI water and the sample crushed. The sample was then centrifuged at 4,000 rpm in a Sorvall RC2b centrigure for 10 min at 4°C. Triplicate 1.0 ml samples of the supernatant were transferred to 1.5 ml Eppendorf® tubes and centrifuged for 10 min at 13,000 rpm in an Eppendorf® microcentrifuge. The supernatant was transferred to fresh tubes and serial dilutions were made (up to 103). Glucose, 100 μg/ml prepared from a 1 mg/ml stock solution, was used as the standard.

Anthrone reagent was prepared fresh by dissolving 200 mg of anthrone in 100 ml of 75% sulfuric acid. Samples (1 ml) to be analyzed were placed in glass tubes to which 5 ml of the anthrone reagent was added with mixing. The tubes were placed in a 100°C water bath for 3.5 min, removed, allowed to cool, and then the absorbance was read at 625 nm.

Only a limited number of tests were performed using avocados as the entire avocado had to be sacrificed (cut in half) to obtain an image that clearly showed the effects of ripening on the avocado.

Viability of glutaraldehyde-immobilized cells

Duplicate samples (1 g) of immobilized cells (2–3 mm particles) were ground and then re-suspended with 10 ml of sterile 50 mM phosphate buffer (pH. 7.0). Both dilutions and actual ground matter (triplicate) were plated, in duplicate on to YEMEA and R2A agars. Dilutions were plated by spread-plate technique and ground matter was plated by pour-plate techniques. Plates were incubated at 30°C for 14 days. The above procedure was repeated with three separate batches of glutaraldehyde-immobilized cells. Viable cells of R. rhodochrous DAP 96253 were not recovered from any of the samples (data not shown).

Testing of delayed ripening

Fruit to be tested was placed in bags (commercially available brown kraft paper bags). For bananas, hands containing 6–8 bananas were used. The number of peaches (6–8) used was based on the size of the peaches so that there was no contact between any of the peaches or the sides of the bag. Avocados (8) were similarly placed so that there was no contact between any of the avocados or the sides of the bag. Immobilized catalyst (prepared as described above) was placed in a small glass dish, which in turn was placed into the bags so that there was no contact between any of the peaches or the sides of the bag. The tops of the bags were folded over 3× and held in place with three metal chromatography clamps (5 cm). Humidity in the bags was maintained >90%; <100%. All tests were conducted at 25–27°C. Controls included test fruit with no catalyst present and fruit exposed to catalyst made with non-induced cells.

Initial interpretations were based on photographic images of ripening changes. Bananas and peaches were also tested for firmness using the appropriate penetrometer for that fruit [4]. In addition, peaches were tested for sugar content (BRIX) and acidity. (As BRIX and acidity measurement are destructive of the peach, all the peaches in that set were sacrificed. As a result, additional experimental and control sets for peaches had to be prepared in the beginning to account for the amount of fruit sacrificed over the course of an experiment.) Subsequently, carbohydrate by anthrone was also determined along with BRIX and acidity.

Catalyst-impregnated paper

Samples of commercially available, creped paper (100 g/mm2, 20.3-cm diameter) were impregnated with an equivalent of 120–200 mg (cell dry weight of induced or non-induced cells). The impregnated papers were then used to wrap selected peaches, which were tested as above. Non-impregnated paper was used as a control.

Results

Catalyst derived from cells of R. rhodochrous strain DAP 96253 grown on YEMEA supplemented with cobalt, urea, and asparagine showed the greatest impact in delayed ripening of the fruits tested in this study. It was also noted that cells of R. rhodochrous. strain DAP 96253 when grown on YEMEA supplemented with cobalt urea, and asparagine had the highest levels of NHase. Table 1 shows a comparison between NHase-induced and non-induced cells of strain DAP 96253 for NHase and amidase.

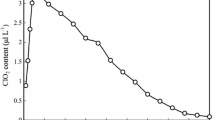

Figures 1, 2, 3, and 4 show images representative of catalyst-treated and non-treated peaches, avocados, and bananas. In all cases, those fruit exposed to the prepared microbial catalyst showed a visibly evident delayed ripening response over the controls. For all initial evaluations with peaches, firmness, as determined by penetrometer, sugar content (Brix) and pH also were measured over time. All peaches tested were picked as firm, ripe fruit, and all had acceptable penetrometer values for firm, ripe peaches (6-lbs) and Brix values ranging from 11 to 13. For all the peaches of the Big Red Variety (images shown in Fig. 1), controls and experimental, the initial firmness was 6 lbs, the pH 4.0 and Brix 11–12. However, the surface integrity/strength of the control peaches degraded rapidly to the extent that the penetrometer could not be used to reliably measure integrity/strength, making comparisons with the treated peaches not possible. The pH values for control and experimental peaches were essentially unchanged from the initial pH of 4.0. The Brix content of the control peaches achieved 13–14 and in some cases began to decline by the end of the comparison experiment (Fig. 1).

In subsequent testing involving Big Red peaches, both Brix and anthrone-carbohydrate were determined and the results compared. Prior to initiating this test, all peaches had; firmness (7 lbs), Brix (14–15), carbohydrate by anthrone (76–98 mg/ml) and pH (4). At the termination of the experiment, all control peaches had lost all firmness and were mold covered. At that point the control peaches all showed: Brix 17–18, carbohydrate by anthrone (167 mg/ml) and pH 4; whereas the peaches exposed to the catalyst had Brix 16–17, and carbohydrate by anthrone (136 mg/ml). The peaches exposed to the catalyst eventually reached Brix and anthrone levels as high if not higher than the control peaches while retaining good firmness.

Organo-leptic evaluation was conducted using those peaches exposed to (but not in contact with) the catalyst. The organo-leptic evaluations of the catalyst-treated peaches indicated levels of sweetness, aroma, taste, and texture consistent with that seen in naturally full-ripened peaches. These organo-leptic evaluations were seen on catalyst-treated peaches up to one full week after the control peaches had to be discarded.

While the results of the experiments employing avocados were encouraging, only a limited number of experiments were conducted. Because the ripening of avocados was not really apparent from the external appearance of the fruit, it was necessary to sacrifice the entire fruit to obtain an internal image. As a result, many avocados were required for each experimental set.

Conclusions

The preliminary tests as performed clearly showed that non-replicating immobilized (glutaraldehyde cross-linked) cells made from NHase-induced cells of R. rhodochrous strain DAP 96253, clearly delayed the ripening of avocados, bananas, and peaches. Most importantly, the catalyst did not have to be in contact with the test fruit samples to affect delayed ripening. The results also showed that cells induced for NHase (as described above) had the greatest effect on delayed ripening for all fruit tested versus catalyst derived from cells of R. rhodochrous strain DAP 96253 grown with other growth conditions.

Where multiple varieties of peach were evaluated, the tests all showed that those peaches either treated with or exposed to catalyst showed a ripening delay of 5–7 days over that of the control peaches. While these preliminary experiments are very encouraging, experiments using larger numbers of samples are needed in order to establish statistical significance. These larger evaluations, in addition to all of the tests performed in this study, will also include chemical analysis of the flavor and aroma compounds and titratable acidity. Organo-leptic evaluations involving peaches where the catalyst was in proximity to the peach but where there was no contact, showed that the catalyst-treated peaches achieved a level of ripeness (as determined by taste, aroma, texture, sweetness, and level of juice) consistent with that seen in naturally fully ripened peaches. Additional appropriate organo-leptic evaluations will be conducted after IRB (human subjects) approval has been obtained for those samples where the catalyst and produce are in direct contact.

This catalyst does not need to touch the fruit or produce to affect delayed ripening. Experiments conducted over several seasons with multiple varieties of peaches have clearly shown that the shelf life can be extended from 7 to 10 days over that seen with control peaches. Furthermore, those peaches exposed to the catalyst achieve full ripeness and desirability. A most interesting observation from the experiments conducted was that the delayed ripening was achieved at ambient temperatures. The potential energy/cost savings for holding and transporting fruits and vegetables could be quite significant if refrigerated condition, at current practice levels, is not required.

Additional work is also required to further optimize the catalyst production and performance. Finally, experiments that fully elucidate the mechanism(s) by which the induced Rhodococcus cells delay ripening in climacteric plants must be completed.

Because of their essentially year-round availability and for the readily apparent visual documentation of ripening and decay changes, bananas served as a routing model fruit for our experiments. However, because of the lack of documentation/processing history and source information available for the commercial bananas, the results of the experiments with bananas must be interpreted with care. As a result, commercial bananas were used to establish trends and general conditions. For experimental purposes, the fresh peaches obtained in Georgia were preferred because of the full documentation as to source, processing, grading, handling, transportation conditions, and packaging.

References

Blankenship SM, Dole JM (2003) 1-Methylcyclopropene: a review. Post Harvest Biol Technol 28:1–25

Candan AP, Graell J, Crisosto CH, Larrigaudiere C (2006) Improvement of storability and shelf-life of “Blackamber” plums treated with 1-methylcyclopropene. Food Sci Tech Int 15:437–444

Cliff M, Lok S, Lu S, Toivonen PMA (2009) Effect of 1-methylcyclopropene on the sensory, visual, and analytical quality of greenhouse tomatoes. Postharvest Biol Technol 53:11–15

Crisosto CH, Garner D (2001) Establishing a quality control system, In: Crisoto CH (ed) Central valley postharvest newsletter. University of California Cooperative Extension, Kearney Agricultural Center, Parlier, CA. 10:1–6

Dietz A, Thayer DW (1980) In: Dietz A, Thayer DW (eds) Actinomycete taxonomy (SIM Spec Publ No. 6). Society for Industrial Microbiology, Arlington, VA. pp 227–291

DeFilippi LJ (1980) Process for preparing immobilized enzymes. US Patent 4,229,536

Fan X, Blankenship SM, Mattheis JP (1999) 1-Methylcyclopropene inhibits apple ripening. J Am Soc Hort Sci 124:690–695

Fawcett JK, Scott JE (1960) A rapid and precise method for the determination of urea. J Clin Path 13:156–159

Klee HJ, Hayford MB, Kretzmer KA, Barry GF, Kishore GM (1991) Control of ethylene biosynthesis by expression of a bacterial enzyme in transgenic tomato plants. Plant Cell 3:1187–1193

Klee HJ, Kishore GM (1996) Control of plant ripening and senescence in plants. US Patent 5,512,466

López-Gallego F, Betancor L, Mateo C, Hidalgo A, Alonso-Morales N, Dellamora-Ortiz G, Guisán JM, Fernández-Lafuente R (2005) Enzyme stabilization by glutaraldehyde crosslinking of adsorbed proteins on aminated supports. J Biotechnol 119:70–75

Ludwig TG, Goldberg HJV (1956) The anthrone method for the determination of carbohydrates in foods and oral rinsing. J Dental Res 35:90–94

Lurie S (2008) Regulation of ethylene biosynthesis in fruits by aminoethoxyvinyl glycine and 1-methylcyclopropene. Acta Hort (ISHS) 796:31–41

Marin AB, Colonna AE, Kudo K, Kupferman EM, Mattheis JP (2008) Measuring consumer response to “Gala” apples treated with 1-methylcyclopropene (1-MCP). Postharvest Biol Technol 51:73–79

Morris DL (1948) Quantitative determination of carbohydrates with Dreywood’s anthrone reagent. Science 107:254–255

Pierce GE, Drago GK, Ganguly S (2009) Induction and stabilization of enzymatic activity in microorganisms. US Patent 7,531,343

Pierce GE, Drago GK, Ganguly S (2009) Induction and stabilization of enzymatic activity in microorganisms. US Patent 7,531,344

Pierce GE, Ganguly S, Drago GK (2008) Biological-based catalyst to delay plant development processes. US Patent Application Publication 2008/0236038A1

Reasoner DJ, Geldreich E (1985) A new medium for the enumeration and subculture of bacteria from potable water. Appl Environ Microbiol 49:1–7

Sisler EC, Blankenship SM (1992) Methods of counteracting ethylene response by treating plants with diazocyclopentadiene and derivatives thereof. US Patent 5,100,462

Spiro RG (1966) Analysis of sugars found in glycoproteins. Methods Enzymol 8:3–26

Sterling-Rice Group (2005) Consumer purchase and usage patterns, when, why, and how consumers eat peaches, plums and nectarines. California Tree Fruit Agreement, Reedley, CA

Acknowledgments

The following individuals and organizations provided invaluable assistance and support for this work. Gary Black (Georgia Agribusiness Council), Charles Hall (Georgia Fruit and Vegetable Grower's Association), the Georgia Peach Council, with special thanks to Bill McGehee (Pearson Farms), Richard Dickey II, and Richard Dickey III (Dickey Farms), Duke Lane III (Lane Farms), and Will McGehee (Genuine Georgia), Georgia Agriculture, the Georgia Research Alliance, and GSURF.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pierce, G.E., Drago, G.K., Ganguly, S. et al. Preliminary report on a catalyst derived from induced cells of Rhodococcus rhodochrous strain DAP 96253 that delays the ripening of selected climacteric fruit: bananas, avocados, and peaches. J Ind Microbiol Biotechnol 38, 1567–1573 (2011). https://doi.org/10.1007/s10295-011-0947-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-011-0947-2