Abstract

This paper presents the experimental study on stabilization of fine-grained soils using waste calcitice marble powder (CMP) and dolomitic marble powder (DMP). Unconfined compressive strength (UCS) tests were conducted on both the pure and stabilized soil specimens with the percentages of 5, 10, 20, 30, and 50% waste marble powder (MP) by weight. The soil specimens mixed with two types of waste MP were cured for 7, 30, and 60 days and also subjected to freezing and thawing with 1, 3, 5, 7, and 11 cycles to investigate the effect of curing time and freezing–thawing on unconfined compressive strength (qu) and undrained elastic modulus (Eu). Besides, mass losses (ML) of soil specimens were calculated after freezing–thawing cycles. According to the test results, the values of qu and Eu of stabilized soil specimens increased sharply at waste MP content of 5% and then decreased with increasing of MP in highly plastic silt (MH) with plasticity index of 21. qu and Eu increased with curing time dependent on the waste marble type and content in both soil type of specimens. As a result of this study, the waste MP contributed the fine-grained soils more resistant to freezing–thawing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, marble production has increased to 100 million tons per year and main marble production takes place in China, Italy, India, Iran, Turkey, Brazil, Egypt, Greece, and Portugal [1]. Turkey has marble reserves of 40% of the world and has 5 billion cubic meters of marble [2, 3]. Turkey, due to its geological location, has numerous marble deposits in which 250 different colors and patterns of marble types are available [4]. The Turkish marble export sector, which is high ranked in world markets, became the country having the largest amount of exports in 2009 [5].

Marble powder is a waste material generated from cutting and grinding processes and approximately 25% of the processed marble turns into powder [2, 6]. Leaving waste material directly to the environment has negative effects on many environmental factors such as air, water, and life habitat [7, 8]. Disposal of the marble powder is also an environmental problem today [6, 9]. Gurbuz [10] stated that the consumption of waste materials creates new sources of material and helps to reduce harmful effects on the environment. Tunc [8] stated that using produced waste in industry contributes significant output to the national economy. The waste marble powder still exists to be reused despite of being used in many industries areas [8, 11].

In recent years, the use of industrial wastes for stabilization of fine-grained soils has been the subject of widespread research [10, 12, 13]. Industrial wastes as a stabilizer in poor soils have been studied extensively by researchers to eliminate soil problems such as bearing capacity, swelling, and consolidation [14,15,16,17]. Okagbue and Onyebi [18] stated that the usage of marble powder as additive improved significantly some geotechnical parameters of red tropical soils. Palaniappan and Stalin [19] found that using marble powder as a stabilizer for expansive soil was applied successfully. Arora et al. [20] showed that marble powder is an excellent material to stabilize cohesive soils. Saygili [13] mentioned that utilizing waste marble dust in problematic soils in terms of geotechnics provides great contribution to the economy and protection of resources and this can be an alternative solution in highly active clayey zones. Öncü and Bilsel [21] indicated that marble powder as an industrial waste can be used utilized in soil stabilization of road sub-base materials in semi-arid climates.

Soils are subjected to freeze–thaw cycles every year in cold climates. These cycles result in changes on the engineering properties of fine-grained soils and cause significant damages on the structures such as road, railroad, pipeline, and light building. Fine-grained soils are well known as frost susceptible. Therefore, stabilization of the fine-grained soils exposed to freezing–thawing becomes inevitable [22,23,24]. Yarbasi et al. [25] emphasized that stabilized soils with lime, fly ash, and cement have good durability of freeze–thaw resistance in terms of strength properties.

Al-Mala Yousif [26] emphasized that the best performance would be achieved with sufficient curing time for stabilization. Eskioglou [27] conducted a laboratory study to examine effectiveness of marble dust as a stabilizer. It was observed that characteristics of soil were improved using marble dust and the values of unconfined compressive strength after 28 days with the addition of marble dust increased. Zorluer and Demirbas [11] indicated that additive ratio, the curing time, compaction energy, and a number of freeze–thaw cycles are important factors to control the improvement strength of the soil. Pousette et al. [28] found that freeze–thaw cycles detrimentally affect the strength of stabilized peat soils and also mentioned that freezing and thawing needs to be further studied. Yıldız and Soğancı [29] investigated the influence of freezing–thawing on strength and permeability of lime-stabilized clays and the test results showed that the strength of stabilized clay increased at the end of curing time, whereas the strength of stabilized clay decreased after freeze–thaw cycles. Yilmaz et al. [30] studied the effect of stone wastes on freezing–thawing in soil stabilization and found that the wastes are helpful against freezing–thawing effect.

The aim of the this paper involves demonstrating the utilization of two different waste marble powders on data of unconfined compressive strength test of stabilized fine-grained soil specimens prepared with various freeze–thaw cycles and curing time. Compressive strength tests conducted in various properties in which the MP was utilized are presented in detail. The effect of freezing–thawing on the engineering properties of fine-grained soil stabilized with waste marble powder has not been adequately and extensively investigated in the literature. There are a limited number of studies examining freezing–thawing and curing effects on the engineering properties of fine-grained soil stabilized using the different types of waste marble powders in the same study in literature. Therefore, current study is expected to make significant contribution to the environment, waste industry, and economy.

Test material and laboratory tests

Materials

In this study, two types of fine-grained soils and waste marble powders (CMP and DMP) were used for conducting tests as materials and additives. Both fine-grained soil samples were supplied by commercial firm. The waste sludge samples of CMP and DMP were taken from marble processing plants in Afyon and Aydın, Turkey [31]. A series of laboratory tests were performed on both the virgin soil specimens and stabilized soil specimens in the Geotechnical Engineering Laboratory of Civil Engineering Department, University of Niğde Ömer Halisdemir, Turkey.

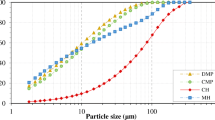

In this study, grain size distribution tests based on laser diffraction on dry samples were conducted on the pure soils and the waste marble powders and the results of the tests are shown in Fig. 1. In addition, pycnometer test [32], liquid limit test of cone penetrometer method [33] and plastic limit test [34], and unconfined compression test [35] were carried out on the soil specimens. The fine-grained soils were employed to be stabilized in tests and were classified as highly plasticity clay (CH) and highly plasticity silt (MH) according to the unified soil classification system.

The mineralogical and chemical compositions of materials employed in the tests were determined by performing the XRD and XRF analyses in the central laboratory of Niğde Ömer Halisdemir University. MH sample consisted of kaolinite (51%), dicite (41%), and kristobalite (8%) minerals. CH sample included clay (46%), sanidin (39%), and kuvars (9%) minerals. CMP and DMP were composed of fully calcite (100%) and, dolomitice (98%) and calcite (2%) minerals, respectively. The chemical properties of the materials used in the experimental work are given in Table 1.

The virgin specimens represent the soil specimen not stabilized with any waste marble powder, while the stabilized specimens represent the soil specimen stabilized with any waste marble powder. The engineering properties of materials were determined and the average properties of the soil and waste marble powders samples are given in Table 2.

Test program and procedures

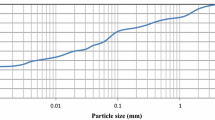

Three sets of UCS tests were conducted for investigating influential factors such as the marble powder content, freeze–thaw, and curing time. The conventional UCS tests were performed on the virgin and stabilized soil specimens based on ASTM D 2166 [35] under strain-controlled conditions. The soils and waste marble powders were dried in an oven at approximately 105 ± °C for 24 h. The waste calcitice and dolomitice marble powders were mixed with both soil samples separately at the percentages of 5, 10, 20, 30, and 50% by weight of the soil sample. Thus, the stabilized soil specimens with different percentages of the wastes were obtained. The test soil specimens were prepared in manufactured split steel mold by compacting at maximum dry unit weight (γdmax) and optimum water content (wopt) determined according to the ASTM D 698-07 [36] at desired content of waste marble powder. The compaction curves for non-stabilized soil specimens are given in Fig. 2. Besides, optimum water contents and maximum dry weight for stabilized soil specimens are presented in Fig. 3. The specimens were put inside the mold in three layers to create uniform layers using static compaction. All prepared cylindrical specimens had a diameter of 50 mm and 100 mm in height (Fig. 4). Extreme care was taken during the mixing process and compaction to ensure a uniform and identical specimen. All specimen types (virgin and stabilized) were prepared in the same method due to determine unconfined compressive strength. UCS tests were performed on the soil specimens in terms of curing time and freeze–thaw cycle. The load was applied an axial strain at a rate of 1% min until specimens failed.

Curing time

The soil specimens with various content of waste marble powders were cured in desiccators at 22 °C with constant optimum moisture content along 7, 30, and 60 days for unconfined compression (Fig. 5). A series of UCS tests were conducted on prepared soil specimens to determine the development of unconfined compressive strength (qu) and undrained elastic modulus (Eu) of the virgin and stabilized soil specimens with curing time. In addition, the change in microstructure was examined after curing time.

Freezing and thawing tests

Some soil specimens were subjected to freeze–thaw cycles to explore influences of the freezing–thawing on the unconfined compressive strength performance of fine-grained soils stabilized with two types of marble powders in accordance with ASTM D560. Cylindrical test specimens were exposed to 0, 1, 3, 5, 7, and 11 freeze–thaw cycles in a freeze–thaw cabinet (Fig. 6). Freezing–thawing procedure was conducted in a closed system. The effect of any external water source is removed to maintain the existing water content of the sample in closed the system. Jamshidi [37] stated that a significant impact of freezing and thawing can be observed after only three freeze–thaw cycles. The freeze–thaw specimens were placed into a digital freezing cabinet at − 20 °C for a period of 6 h, then were thawed at + 20 °C for a period of 6 h. This procedure had been previously used in literature (Roustaei et al. [24], Ghazavi and Roustaei [38]). A period of 6 h freezing at − 20 °C and a period of 6 h thawing at + 20 °C was called as 1 cycle. The same procedure was continued up to 11 cycles. UCS tests were conducted after desired freeze–thaw cycles. In addition, specimen mass loss was calculated after freeze–thaw cycles to determine the effect of freeze–thaw cycle. The mass loss (ML) of specimens is calculated as Eq. (1):

where A is initial mass of soil specimen and B is mass of soil specimen after freeze–thaw cycle.

Scanning electron microscopy tests

To prove the improvement, scanning electron microscopy (SEM) and energy dispersive X-ray microanalysis (EDAX) were carried out to observe changes in microstructure and chemical composition of stabilized soil samples with curing time at Niğde Ömer Halisdemir University central laboratory.

Test results and discussion

UCS tests were conducted to check the influence of waste marble powders on soil specimens. The results of all the experimental studies performed on stabilized soil specimens and influence of two types of waste marble powders on qu and Eu of the soil specimens in terms of curing time and freeze–thaw cycle are discussed in detail.

Effect of marble powder content on qu and Eu

Figures 7a and 8a present the axial stress (σ) versus the axial strain (ε) for both soil specimens with and without DMP and CMP, respectively. The specimens failed at axial strain of 2–3% for MH soils and at axial strain of 1.5–3% for CH soils. The axial stress–axial strain responses presented in Figs. 7a and 8a show a strain softening behavior regardless of soil type with different plasticity and waste marble type. The study reveals that the axial stress–axial strain response is affected with the content and type of marble powder.

From test results given in Figs. 7b and 8b, it can be seen that while the value of qu increased up to the marble powder content of about 5% for both waste marble powders and then decreased with increase of the marble powder content in MH specimens, whereas it decreased with increase of the marble powder content for both waste marble powders in CH specimens. The different behavior is considered to be due to distinct plasticity of soils. The values of qu from UCS tests for the MH specimens were measured as 400.20 kPa and 475.30 kPa at the CMP and DMP content of 5%, respectively, while the qu value of non-stabilized specimen was 313.80 kPa, then decreased 215.60 kPa and 183.00 kPa at the CMP and DMP content of 50%, respectively. However, those for the CH specimens decreased with increasing the marble powder content from 313.80 to 155.90 kPa and 124.70 kPa at the CMP and DMP content of 50%, respectively. DMP was more effective than CMP on the values of qu of stabilized MH specimens. A large number of studies in literature exist that qu of stabilized soils decreased with increase of the marble powder content [10, 15]. It was explained that as the addition of marble powder into the soils increases the strength of mixed material up to the marble powder content of 10% and then, the strength of the specimens begins to decrease due to the decrease in the cohesion between the soil and marble powder [10]. Okagbue and Onyeobi [18], Bansal et al. [9] and Devarajan [39] stated that increase in the value of qu is possible up to an optimum amount of marble powder value but after that it starts decreasing. There is a threshold in the positive effect of the addition at around 5% for MH with MP in this study.

Figures 7c and 8c show the variation of Eu of soil specimens with and without marble powder content. DMP had more effect on Eu of MH specimens in comparison with CMP. It increased with increase of DMP content up to content of 5% DMP then decreased in MH specimens. On the other hand, CMP had no significant change up to content of 30% DMP on the values of Eu of MH specimens (Fig. 7c). There is no significant influence of marble powder on the value of Eu of CH specimens up to content of 30%, and then decreased irrespective of waste marble powder type (Fig. 8c). The values of Eu for the MH specimens were measured as 16.08 MPa and 25.34 MPa at the CMP and DMP content of 5%, respectively, while the value of Eu of non-stabilized specimen was 16.42 MPa. Then it decreased 11.32 MPa and 10.30 MPa at the CMP and DMP content of 50%, respectively. It decreased from 16.42 to 12.07 MPa and 10.25 MPa at the CMP and DMP content of 50%, respectively, although there is no significant change up to MP content of 30% for CH specimens.

Effect of curing time on qu and Eu

Figures 9a and 10a show variation of the axial stress–axial strain for MH and CH specimens non-stabilized and stabilized with DMP and CMP after curing 7, 30 and 60 days, respectively. The specimens failed at axial strain of 2–3% for MH specimens and at axial strain of 1.5–3% for CH specimens depending on the curing time, and the failed axial strain (εf) increased with the increase in curing time. The axial stress–axial strain show a strain softening behavior like soil specimens with no curing time.

Figures 9b and 10b show the effect of curing time on qu in terms of waste marble powder content and type. As can be seen from in Figs. 9b and 10b, increase in the amount of waste marble powder reduced the value of qu for each curing time. However, the curing time clearly increased the value of qu. For instance, the values of qu at the CMP and DMP content of 30% for the MH specimens were measured as 286.40 kPa and 215.20 kPa for 0 day, 387.30 kPa and 342.40 kPa for 7 days, 416.70 kPa and 347.30 kPa for 30 day and 481.30 kPa, and 387.50 kPa for 60 days, respectively. The strength gains in MH specimens due to curing times were found to be higher than CH specimens (Figs. 9b, 10b). Okagbue and Onyebi [18] obtained similar development for the marble powder-stabilized soils. Increase in qu can be explained in terms of the action of pozzolanic reactions which take place through curing time for both soil types. The variation of the value of Eu is similar to that of qu as a general trend (Figs. 9c, 10c).

SEM analyses were conducted to determine the impact of waste MP on the samples by exploring the non-stabilized MH and CH samples, stabilized MH and CH samples with 50% CMP, and stabilized 7 days cured MH and CH samples with 50% CMP as shown in Figs. 11 and 12. Moreover, EDAX analyses were conducted on those soil specimens as shown in Fig. 13. SEM imagines of non-stabilized MH and CH samples are shown in Figs. 11a and 12a. The SEM images show the change in the microstructure by adding waste MP. It can be seen that waste materials are successful in filling the pores and bond between particles. Due to the reduction of pores causes compressive strength increases. It is apparent from SEM results in terms of curing time that MP made a positive impact on the microstructure to cause a more compact structure as a result of a pozzolanic reaction (Figs. 11b, c, 12b, c).

EDAX analysis was performed on non-stabilized MH sample and stabilized MH samples with waste 50% CMP and 50% DMP to determine mineralogical composition. In Fig. 13, the EDAX spectrum of the stabilized soil is primarily characterized by calcium (Ca) and silicon (Si) as evidenced by the high weight percentage of these elements in the soil. Seco et al. [40] stated that the most waste materials which have the pozzolanic effect are these that contain a significant amount of reactive Ca, Si, or Al oxide. The presence of elements such as Ca and Si causes pozzolanic activity. When CMP and DMP were increased, the calcium from MP reacted with the soluble silica and alumina in the CH and MH (Eqs. 2, 3). The reactions continue as long as residual calcium is available. The pozzolanic activity contributed to formation of the fabric and structure of stabilized samples (Figs. 9, 10, 11, 12):

Effect of freeze–thaw on qu and Eu

To compare stress–strain characteristics for five different freeze–thaw cycles, axial stress–strain curves are given in Fig. 14a. Axial stress–strain curves did not have a clear peak stress, except for the waste marble content of 50% in the 1st cycle, and the soil specimens failed at axial strain of 3–4% within elastic region in MH specimens (Fig. 14a). However, CH specimens exhibited strain-softening behavior in the specimens with 1st, 3rd, and 5th cycles and it failed within elastic region in the specimens with 7th and 11th cycles. The specimens failed at axial strain of 2–4.5% for CH specimens. The failure modes of soil specimens with DMP and CMP are similar in terms of waste material type (Fig. 14a). The fact is that the type of fine-grained soil used in stabilization directly affects the failure type due to the plasticity difference of the soils. The soil specimens showed the brittle failure during loading as seen from pictures on Fig. 14a.

The values of qu and Eu versus number of freeze–thaw cycles for MH and CH specimens with and without DMP and CMP are shown in Fig. 14b, c, respectively. It was found that qu increased with increasing freeze–thaw cycle for both fine-grained soils and the gain in strength and stiffness in MH specimens due to freeze–thaw cycle was higher than CH specimens. Eu exhibited similar trend to qu. The strength and stiffness were not significantly affected by waste marble type and content for MH specimens except for qu with marble powder content of 50%. On the other hand, the waste marble type and content had perceivable effect on the strength and stiffness of CH (Fig. 14b, c).

The mechanical behavior of the freeze–thawed specimens behaves very differently according to the non-freeze–thawed specimens. The non-freeze–thawed specimens with and without curing time exhibit a remarkably clear peak on the curves from the UCS test, followed by some strain softening. These peaks are very clear due to structural inter-particle bonding. The samples showed a ductile behavior (Figs. 7, 8). The freeze–thawed specimens without curing time did not exhibit a peak on the curves obtained from the UCS test and failed in the elastic region due to the freeze–thaw effect. The samples showed a ductile behavior except for 1st, 2nd, and 3th cycles in CH samples as shown in Fig. 14a. It can be attributed that the CH samples in the 1st, 2nd, and 3th cycles did not gain sufficient re-structuring effect caused by freeze–thaw due to high plasticity. The samples with freeze–thaw gained strength and stiffness in MH specimens was higher than CH specimens due to soil type. Similar results have been found in the literature. Leroueil et al. [41] could not detect the peak after freeze–thaw in a clay. As a general trend, it was found that qu and Eu increased with the increasing freeze–thaw cycle for both fine-grained soils in this study (Fig. 14b, c). Similar results have also been found in the literature. Yaling and Binbin [42] also found that freezing and thawing action makes the soil cohesion higher but there is no significant change in the internal friction angle. Ono and Mitachi [43] exposed to the samples a single freeze–thaw cycle, which increased both stiffness and shear strength. The authors proposed a re-structuring effect due to freeze–thaw. Besides, Qi et al. [44] stated that freeze–thaw causes degradation of structure in natural fine-grained soils such as clays, but structure improvement in reconstituted normally consolidated clays. It is thought that the increase in strength obtained in this study can be caused by the re-structuring effect or improvement in soil structure. As another reason, it is thought that the freeze–thawed cycle is a short period to dissolve the frozen water in the sample. In other words, insoluble ice in the sample causes an increase of the strength of the samples.

Mass losses in the freeze–thaw specimens were calculated after 1, 3, 5, 7, and 11 cycles to examine the effect of the CMP and DMP on the durability behavior of the stabilized soil (Fig. 15). It can be clearly seen from Fig. 15 that the mass losses of stabilized soils decreased with increasing waste powder content for each freezing–thawing cycles regardless the type of marble powder and soil type. However, the mass losses increased with increasing freezing–thawing cycles up to 7 cycles, then decreased slightly at 11 cycles. It was observed that there was no significant influence of MP type on mass losses and the average mass loss was found to be 4–6% and 11–14% at 1 and 11 cycles for CH specimens and 4–7% and 16–25% at 1 and 11 cycles for MH specimens based on MP content. Similar trend was obtained in literature [10]. Zaimoglu [22] also stated that mass losses around 10–15% do not significantly affect soil strength of closed to the surface at the end of the 12 freeze–thaw cycles. This study proved that adding marble powder helps to make the soil more resistant to freezing–thawing (Fig. 15).

Conclusions

MH sample with plasticity index of 21 and CH sample with plasticity index of 49 were mixed separately with two type of waste marble powders in portion varying between 0 and 50%. UCS tests in the laboratory were performed on the un-stabilized and stabilized soil specimens to examine the variations in the values of qu and Eu in terms of the freeze–thaw cycle of 1, 3, 5, 7, and 11 and curing time of 0, 7, 30, and 60 days. Depending on the test results obtained from the current study, the following conclusions can be made;

-

The axial stress–strain response showed a strain-softening behavior regardless of soil specimens with different plasticity index and waste marble type and it was affected with the content and type of marble powder without curing and freeze–thaw.

-

The addition of waste marble powder to fine-grained soils, in general, gave rise to decrease in the values of qu and Eu of stabilized soil specimens after increase in the certain marble content dependent on the mineral composition of soil specimen and marble powder type and content without curing and freezing–thawing.

-

The value of qu went down with increasing waste marble powder content for each curing time and but the curing time clearly increased qu. The variation of Eu with curing time also exhibited similar trend of qu.

-

The axial stress–strain curves of soil specimens exposed to freeze–thaw had no a clear peak stress, except for MP content of 50% in the first cycle, and the soil specimens failed within elastic region in MH specimens. On the other hand, CH specimens displayed strain-softening behavior in the specimens up to 5 cycles and it failed within elastic region in the specimens higher than 5 cycles. The failure mode of soil specimens exposed to freeze–thaw showed similarity in terms of waste marble type and the type of soil used in stabilization directly affected the failure type. The soil specimens also displayed the brittle failure during loading.

-

The value of qu increased with increasing freeze–thaw cycle for both soil types and the gain in strength and stiffness in MH specimens due to freeze–thaw cycle was higher than CH specimens. Eu exhibited the same trend as qu. The strength and stiffness were not significantly affected by waste marble type and content for CH specimens except for qu with MP content of 50%. On the other hand, the waste marble type and content had significant effect on the strength and stiffness of CH specimens.

-

In this study, MH and CH soils with different plasticity exhibited different behaviors for the usage in practice. Therefore, the effect of the waste CMP and DMP is also different. It was determined that 5% of waste MP rate for MH is the threshold in the positive effect without curing and freeze–thaw effects. However, the threshold value of waste ratio for CH cannot be mentioned for the same conditions.

-

As a general trend, the most prominent increase in strength caused by the pozzolanic effect occurred after 7 days for both soils with MP. For this reason, it should be considered that the pozzolanic effect occurs after 7 days for the practice usage. Besides, the strength gains in MH specimens due to curing time were found to be higher than CH specimens.

-

The mass losses of stabilized soils decreased with increasing waste powder content for each freezing–thawing cycles regardless the type of marble powder and soil type, and; however, increased with increasing freezing–thawing cycles. As a result, the marble powder made the soil more resistant to freezing–thawing.

References

SPO (2001) Report on building materials II (2616-O˙IK: 627). State Planning Organization, Ankara

Fırat S, Yılmaz G, Cömert AT, Sümer M (2012) Utilization of marble dust, fly ash and waste sand (Silt-Quartz) in road subbase filling materials. KSCE J Civ Eng 16(7):1143–1151. https://doi.org/10.1007/s12205-012-1526-4

MTA (2019) Mineral Research and Exploration General Directorate reports. https://www.mta.gov.tr

Bilgin N, Yeprem HA, Arslan S, Bilgin A, Günay E, Marşoglu M (2012) Use of waste marble powder in brick industry. Constr Build Mater 29:449–457. https://doi.org/10.1016/j.conbuildmat.2011.10.011

RTMEN (2019) Republic of Turkey Ministry of Energy and Natural Resources. https://www.enerji.gov.tr

Prakash T, Chhipa RC (2014) Opportunities for marble powder waste as an eco-friendly use in adaptive construction materials. IJEAR 1:8–16

Pathan VG, Pathan MG (2014) Feasibility and need of use of waste marble powder in concrete production. IOSR-JMCE 23–26

Tunc ET (2019) Recycling of marble waste: a review based on strength of concrete containing marble waste. J Environ Manag 231:86–97. https://doi.org/10.1016/j.jenvman.2018.10.034

Bansal H, Rajora V, Sidhu GS (2016) Effect of waste marble powder on UCS and free swell index of clayey soil. IJSRE 4(8):5657–5663. https://doi.org/10.18535/ijsre/v4i08.10

Gurbuz A (2015) Marble powder to stabilise clayey soils in sub-bases for road construction. Road Mater Pavement Des 16(2):481–492. https://doi.org/10.1080/14680629.2015.1020845

Zorluer I, Demirbas A (2013) Use of marble dust and fly ash in stabilization of base material. Sci Eng Compos Mater 20(1):47–55. https://doi.org/10.1515/secm-2012-0074

Singh PS, Yadav RK (2014) Effect of marble dust on index properties of black cotton soil. IJERST 3(3):158–163

Saygili A (2015) Use of waste marble dust for stabilization of clayey soil. Mater Sci 21(4):601–606. https://doi.org/10.5755/j01.ms.21.4.11966

Bell FG (1996) Lime stabilization of clay minerals and soils. Eng Geol 42(4):223–237. https://doi.org/10.1016/0013-7952(96)00028-2

Sabat AK, Nanda RP (2011) Effect of marble dust on strength and durability of rice husk ash stabilized expansive soil. IJCSE 1:939–948

Mosaferi M, Dianat I, Khatibi MS, Mansour SN, Fahiminia M, Hashemi AA (2014) Review of environmental aspects and waste management of stone cutting and fabrication industries. J Mater Cycles Waste Manag 16(4):721–730. https://doi.org/10.1007/s10163-013-0193-y

James J, Pandian PK (2018) Strength and microstructure of micro ceramic dust admixed lime stabilized soil. J Constr 17(1):5–22. https://doi.org/10.7764/RDLC.17.1.5

Okagbue CO, Onyeobi TUS (1999) Potential of marble dust to stabilise red tropical soils for road construction. Eng Geol 53(3–4):371–380. https://doi.org/10.1016/S0013-7952(99)00036-8

Palaniappan KA, Stalin VK (2009) Utility effect of solid wastes in problematic soils. IJERIA 2:313–321

Arora RP, Ameta NK, Samar KK, Samdani KL (2014) Improvement of engineering characteristics of locally available soil mass by use of marble dust. Int Invent Multidiscip J 2:8–15

Öncü Ş, Bilsel H (2018) Utilization of waste marble to enhance volume change and strength characteristics of sand-stabilized expansive soil. Environ Earth Sci 77(12):461. https://doi.org/10.1007/s12665-018-7638-5

Zaimoglu AS (2010) Freezing–thawing behavior of fine-grained soils reinforced with polypropylene fibers. Cold Reg Sci Technol 60(1):63–65. https://doi.org/10.1016/j.coldregions.2009.07.001

Gullu H, Hazirbaba K (2010) Unconfined compressive strength and post-freeze–thaw behavior of fine-grained soils treated with geofiber and synthetic fluid. Cold Reg Sci Technol 62(2–3):142–150. https://doi.org/10.1016/j.coldregions.2010.04.001

Roustaei M, Eslami A, Ghazavi M (2015) Effects of freeze–thaw cycles on a fiber reinforced fine grained soil in relation to geotechnical parameters. Cold Reg Sci Technol 120:127–137. https://doi.org/10.1016/j.coldregions.2015.09.011

Yarbasi N, Kalkan E, Akbulut S (2007) Modification of the geotechnical properties, as influenced by freeze–thaw, of granular soils with waste additives. Cold Reg Sci Technol 48(1):44–54. https://doi.org/10.1016/j.coldregions.2006.09.009

Al-Mala Yousif M (2015) Freeze-thaw performance of low-cement content stabilized soils for containment applications. Dissertation, Dalhousie University

Eskioglou PC (1996) Influence of soil type on stabilization with marble dust for forest road construction. In: International conference on soil stabilization, Unterwaz

Pousette K, Macsik J, Jacobsson A (1999) Peat soil samples stabilized in laboratory: experiences from manufacturing and testing. In: Balkema H (ed) Mix methods for deep soil stabilization. Balkema, Rotterdam, pp 85–92

Yıldız M, Soğancı AS (2012) Effect of freezing and thawing on strength and permeability of lime-stabilized clays. Sci Iran 19(4):1013–1017. https://doi.org/10.1016/j.scient.2012.06.003

Yilmaz F, Kamiloglu HA, Sadoğlu E (2015) Soil stabilization with using waste materials against freezing thawing effect. Acta Phys Pol A 128:2B. https://doi.org/10.12693/APhysPolA.128.B-392

Sivrikaya O, Kıyıldı KR, Karaca Z (2014) Recycling waste from natural stone processing plants to stabilise clayey soil. Environ Earth Sci 71:4397–4407

ASTM D 854 (2013) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM D 854, West Conshohocken

BS 1377-2 (1990) Methods of test for soils for civil engineering purposes

ASTM D 4318 (2013) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM D 4318, West Conshohocken

ASTM D 2166 (2000) Standard test method for unconfined compressive strength of cohesive soil. American Society for Testing and Materials, West Conshohocken

ASTM D 698-07 (2013) Standard test methods for laboratory compaction characteristics of soil using standard effort. ASTM D 698-07, West Conshohocken

Jamshidi RJ (2014) Evaluation of cement-treated soils subjected to cycles of freezing and thawing. Dissertation, Dalhousie University, Halifax, NS

Ghazavi M, Roustaei M (2013) Freeze–thaw performance of clayey soil reinforced with geotextile layer. Cold Reg Sci Technol 89:22–29. https://doi.org/10.1016/j.coldregions.2013.01.002

Devarajan D (2014) Evaluation of geotechnical properties of marble dust treated clayey soil. Int J Adv Res Trends Eng Technol 1:17–22

Seco A, Ramirez F, Miqueleiz L et al (2012) Types of waste for the production of pozzolanic materials—a review. Ind Waste. https://doi.org/10.5772/36285

Leroueil S, Tardif J, Roy M, Konrad J-M (1991) Effects of frost on the mechanical behavior of Champlain Sea clays. Can Geotech J 28(5):690–697

Yaling C, Binbin H (2014) Effect of freezing and thawing on shear behavior and structural strength of artificially structural loess. EJGE. https://doi.org/10.1007/s11629-016-4005-4

Ono T, Mitachi T (1997) Computer controlled triaxial freeze–thaw-shear apparatus. Ground Freezing 97. A. A. Balkema, Rotterdam, pp 335–339

Qi J, Vermeer PA, Cheng G (2006) A review of the influence of freeze–thaw cycles on soil geotechnical properties. Permafr Periglac 17(3):245–252

Acknowledgements

This paper is benefited from the FEB 2017/10-YULTEP projects of Niğde Ömer Halisdemir University, Scientific Research Projects Unit. The authors would like to thank Niğde Ömer Halisdemir University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aydin, K., Sivrikaya, O. & Uysal, F. Effects of curing time and freeze–thaw cycle on strength of soils with high plasticity stabilized by waste marble powder. J Mater Cycles Waste Manag 22, 1459–1474 (2020). https://doi.org/10.1007/s10163-020-01035-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-01035-0