Abstract

The location selection is a strategic decision that significantly influences revenue, level of competition, and success of companies and countries. This study aims to propose a hybrid approach for the location selection, to evaluate the potential location for the automotive manufacturing plant of Turkey, and to reveal a comprehensive analysis of weighting and multiple criteria decision-making (MCDM) methods. The proposed approach integrates different objective and subjective weighting, MCDM, and Copeland methods. Turkey has recently introduced its first automobile prototypes and has announced that the manufacturing plant will be located in Bursa. This decision is thoroughly examined via four objective weighting methods—entropy, criteria importance through inter-criteria correlation, standard deviation, and mean weight and a subjective method—analytic hierarchy process. Besides, the alternatives are evaluated based on six MCDM methods—technique for order preference by similarity to ideal solution, preference ranking organization method for enrichment evaluations, vise kriterijumska optimizacija i kompromisno resenje, organization, rangement et synthese de donnes relationnelles, elimination and choice translating reality, and the weighted sum method. The outcomes of the weighting methods and MCDM methods, the impact of the attribute weights provided by each method on rankings, the outcome of each method pair, and selection of the best location (Bursa) are thoroughly evaluated considering a real-world case with a potential outcome that makes evaluations more realistic and tangible unlike most of the other studies in the literature. In this regard, Spearman's rank correlation coefficients are considered. Also, sensitivity analysis is conducted to reveal the robustness of the methods and the impact of each weight on outcomes. Some considerable results, including the most robust method and optimal method pairs for the case, are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The decision process of plant location comprises the identification, examination, assessment, and selection of alternatives. As a location selection decision generally involves a long-term commitment of resources and requires a considerable amount of investment, the plant location choice has significant strategic impacts on the firm's competitiveness, flexibility, and timeliness. Thus, the ultimate choice of a plant location must contribute to the success of corporate strategic plans for production objectives, marketing, financing, and human resource [1].

The plant location selection is a typical multiple criteria decision-making (MCDM) problem, where competing alternatives accompanied by several opposing criteria exist. Meeting all criteria (attributes) while selecting the optimal alternative from a limited number of alternatives may not be possible. In such situations, MCDM methods produce an effective solution to the problem. The MCDM methodologies are essential tools for decisionmakers in determining the best alternative after assessing various competing and usually contradictory criteria.

MCDM techniques have become an essential branch of operations research. There have been numerous MCDM methods commonly implemented for various purposes in various fields, including location selection problems and the automotive industry. However, none of the methods is considered the most appropriate for all decision-making problems [2]. Therefore, a comparative analysis is required to determine the optimal one for a specific case. Besides, there have been several weighting methods to provide required inputs (weights) to those MCDM methods. Likewise, choosing the best approach from among them is not a predetermined process as well. Therefore, a thorough comparative analysis considering various weighting and MCDM methods is essential for the literature. Some studies proposed hybrid approaches for various location decision problems. However, most of them integrated a few methods [3,4,5]. In this study, a detailed comparative analysis is conducted and a hybrid approach is presented based on four objective weighting methods: entropy, criteria importance through inter-criteria correlation (CRITIC), standard deviation (SD), and mean weight (MW) and a widespread subjective weighting method, analytic hierarchy process (AHP), and six evaluation methods: technique for order preference by similarity to ideal solution (TOPSIS), preference ranking organization method for enrichment evaluations (PROMETHEE), vise kriterijumska optimizacija i kompromisno resenje (VIKOR), organization, rangement et synthese de donnes relationnelles (ORESTE), elimination and choice translating reality (ELECTRE), and the weighted sum method (WSM).

The reasons for selecting the methods can be explained threefold. First, commonly used objective and subjective weighting methods are selected to examine the results for the problem and to reflect the objective and subjective assessments to the ranking. The comparison of these methods reveals the correlation between them can guide future studies to select the most suitable method. Second, six of the commonly adopted MCDM methods are chosen as they belong to different family groups and have different procedures that may result in different outcomes. TOPSIS advanced by Hwang, Yoon [6] is a method to assess candidates' performance over the similarity with the ideal solution. PROMETHEE, developed by Brans, Vincke [7], Brans et al. [8], delivers a total preorder of the alternatives via an aggregation of the entering and leaving flows. WSM is one of the most popular MCDM methods due primarily to its simplicity and time efficiency [9]. ORESTE allows ranking the alternatives in a complete or partial order by considering incomparability [10]. ELECTRE interprets the outranking via a credibility index [11]. VIKOR is a compromise method for ranking alternatives by providing a maximum group utility for the majority and a minimum individual regret for the opponent [12]. Last, integrating these methods provides a comprehensive evaluation of the optimal location selection for the first time.

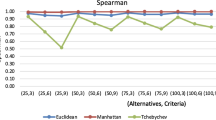

The real-life location selection problem considered in this study involves two problems indeed. The first is the problem of determining the best location for a planned manufacturing plant. The second is evaluating the decision already made by policymakers through various method pairs and analyses. The problem involves competing alternatives and conflicting criteria. One of the main objectives is to identify optimal alternative and evaluate the selected alternative location for Turkey's first own manufacturing plant. Turkey has launched its automobile prototypes recently, and the officials have announced that the plant will be located in Bursa. This strategically crucial case, whose potential optimal location is known, allows an objective and realistic analysis. In this regard, eight alternative cities: Aksaray, Istanbul, Izmir, Konya, Manisa, Bursa, Kocaeli, and Sakarya, are determined based on the literature, related news, and expressions of official authorities. Six main criteria, namely cost (C), labor characteristics (LC), quality of life (QL), infrastructure (I), economic factors (EF), and suppliers (S), and sixteen sub-criteria are determined depending on both an extensive literature review and views of expert and authorities in the automotive industry. However, this study is far beyond finding the optimal location. This study presents a unique approach for the automotive manufacturing plant location selection and comprehensive comparative analyses. In this context, each weighting method is applied to obtain the attribute weights, and these results are evaluated. Then, by using each weighting method's outcome as the input of each MCDM method, 30 different models are obtained, and the ranking results are examined. The outcomes of each model are also evaluated through Spearman's test. These evaluations are essential in revealing the weighting method's impact on the ranking results, revealing the differences among the weighting methods and MCDM methods, and providing insight into the optimal method pairs for the selected problem. Then, the results of the 30 models are integrated through the Copeland method that reflects the objective and subjective assessments for the criteria and the procedures of different MCDM methods from different groups. In addition to comparative analyses, the selection of the best location (Bursa) is also thoroughly examined based on the results obtained from 30 models and the integrated approach, and different scenarios of the sensitivity analysis.

The literature review (Tables 1 and 2) reveals some research gaps, and this study extends the previous research by concentrating on the following issues:

-

A real-world decision problem that involves the selection of the optimal and evaluation of the selected location is considered.

-

Subjective and objective weighting methods are evaluated together for the location selection problem for the first time.

-

Some methods, including CRITIC, SD, and ORESTE, are used for the problem of location selection of the automotive manufacturing plant for the first time (Tables 1 and 2).

-

A comprehensive comparative evaluation of TOPSIS, PROMETHEE, VIKOR, ORESTE, ELECTRE, and the WSM together is presented for the first time.

-

Some method pairs, such as CRITIC-PROMETHEE and SD-ORESTE, are applied for the location selection of the automotive manufacturing plant for the first time (Tables 1 and 2).

-

Some of the decision attributes considered in this study, such as the number of automotive plants that reflect the supplier availability, are also original, so this might be a valuable contribution to the location selection literature.

-

The sensitivity analysis can also be considered a contribution in terms of revealing the robustness of the methods and the impact of the attribute weights on the rankings.

-

The rank results of 30 models are integrated through the Copeland method. Thus, a unique hybrid approach is presented for the automotive manufacturing plant decision problem.

-

Overall, this is the first study using and evaluating all these approaches in one study.

The rest of the study is structured as follows. In the following section, the descriptions of the weighting and ranking (MCDM) methods and application of the approaches to the real case are presented. The findings and regarding discussions are presented in Sect. 3. In Sect. 4, conclusions and suggestions for future work are presented.

2 Materials and methods

The subjective method, namely AHP, and four objective methods, namely entropy, CRITIC, SD, and MW, are used for obtaining criteria weights. Also, six of MCDM methods, namely TOPSIS, PROMETHEE, VIKOR, ORESTE, ELECTRE, and WSM, are utilized for ranking alternative locations and determining the optimal one in this study. The structure and algorithm of each method are described in the following subsections.

2.1 Weighting methods

2.1.1 Analytic hierarchy process (AHP)

AHP, introduced by Saaty [49], is grounded on pairwise comparisons and a hierarchical structure. The advantages of AHP include appropriateness for complex decision problems with multiple criteria and compatibility with other MCDM techniques. AHP has been one of the most frequently implemented MCDM approaches in decision-making problems. The procedure of AHP can be explained in several steps. In the first step, a multifaceted decision problem is designed as a hierarchy. The objective, main- and sub-criteria, and alternatives are placed in a hierarchical structure that comprises at least three levels from top to bottom: the aim of the problem, multiple criteria that describe alternatives, and decision alternatives. In the second step, the pairwise comparison of the criteria regarding the objective is performed. The criteria are compared pairwise based on their impact degree. The decisionmaker utilizes a pairwise comparison mechanism using the 1–9 scale, which is shown in Table 3.

To compute the weights for criteria, the AHP method generates a pairwise comparison matrix A as follows:

where \(C = \left\{ {C_{j} |~j = ~1,2, \ldots ,n} \right\}\) represents the criteria set. The outcome of the pairwise comparison on n criteria is abridged in an evaluation matrix A(n × n), where each element aij (i,j = 1,2, …,n) is the quotient of criteria weights [51]. In the final step, the mathematical operations begin to standardize and determine the relative weights for every matrix. The relative weights are represented by the right eigenvector (w) matching to the largest eigenvalue (λmax), as

The matrix A has rank one and λmax = n if the pairwise comparisons are wholly consistent. In such a case, weights can be attained by normalizing any of the columns or rows of A.

The accuracy of the results of the AHP heavily depends on the consistency of the pairwise comparison judgments. The relation between the entries of A: aij * ajk = aik describes the consistency. The consistency index (CI) is calculated by Eq. 3.

The ultimate consistency ratio (CR) is calculated by dividing the CI by the random index (RI), as shown in the following equation:

0.1 is the acceptable upper limit of the CR. The evaluation procedure has to be done over again to obtain an acceptable consistency value in case the final CR exceeds this limit.

2.1.2 Entropy

Entropy has been used for finding objective attribute weights [6]. The procedure of the method is defined as follows:

-

(i)

The decision matrix is normalized using the following functions for benefit attributes and cost attributes, respectively.

$$ r_{{ij}} = \frac{{a_{{ij}} }}{{\mathop \sum \nolimits_{{i = 1}}^{m} a_{{ij}} }}\quad {\text{for}}\quad i = 1,2, \ldots ,m $$(5)$$ r_{{ij}} = \frac{{1/a_{{ij}} }}{{\mathop \sum \nolimits_{{i = 1}}^{m} \left( {\frac{1}{a}_{{ij}} } \right)}}\quad {\text{for}}\quad i = 1,2, \ldots ,m $$(6) -

(ii)

Entropy values are calculated through the following function.

$$ e_{j} = - \left( {\ln m} \right)^{{ - 1}} \mathop \sum \limits_{{i = 1}}^{m} r_{{ij}} \ln r_{{ij}} \quad {\text{for}}\quad j = 1,2, \ldots ,n $$(7) -

(iii)

The weights of each attribute are computed through the following formulation.

$$ w_{j} = \frac{{1 - e_{j} }}{{\left( {n - \mathop \sum \nolimits_{{j = 1}}^{n} e_{j} } \right)}}\quad {\text{for}}\quad j = 1,2, \ldots ,n $$(8)

Low entropy values indicate that the degree of disorder in the system is low, and the weight is high [52].

2.1.3 Criteria importance through inter-criteria correlation (CRITIC)

CRITIC method determines the weights of criteria considering both the standard deviation of each criterion and the correlations among the attributes. The procedure of the approach is defined as follows:

-

(i)

The decision matrix is normalized using the following equation.

$$ a_{{ij}}^{ + } = \frac{{a_{{ij}} - {\text{min}}\left( {a_{{ij}} } \right)}}{{\max \left( {a_{{ij}} } \right) - {\text{min}}\left( {a_{{ij}} } \right)}} $$(9)where \(a_{{ij}}^{ + }\) represents the normalized value of the ith design on the jth response.

-

(ii)

The multiplicative aggregation function given below is applied to find the amount of information contained in the jth response.

$$ C_{j} = \sigma _{j} \mathop \sum \limits_{{k = 1}}^{n} \left( {1 - r_{{jk}} } \right) $$(10)where \(\sigma _{j}\) designates the standard deviation of the jth response and \(r_{{jk}}\) designates the correlation coefficient between two different responses.

-

(iii)

The objective weights (wj) are computed through the following function.

$$ w_{j} = \frac{{C_{j} }}{{\mathop \sum \nolimits_{{k = 1}}^{m} C_{k} }}. $$(11)

2.1.4 Standard deviation (SD)

The SD method finds the weights of criteria based on their standard deviations, as follows:

2.1.5 Mean weight (MW)

The MW is the most basic weighting approach that assumes all the criteria are equally important through the following equation.

2.2 Methods for ranking alternatives

Each MCDM method has its algorithm, advantages, and disadvantages. The algorithm and description of MCDM methods are summarized in Table 4. The main principle in TOPSIS is that the optimal alternative has the minimum length from the positive-ideal solution (PIS) and the maximum length from the negative-ideal solution (NIS). In PROMETHEE, the alternatives are pairwise compared based on each criterion depending on the decisionmaker's preferences, resulting in local scores. Then, these local scores are combined to a global score that leads to the PROMETHEE I or PROMETHEE II ranking [7, 8]. PROMETHEE I deliver the partial ordering of the decision alternatives, while PROMETHEE II provides the alternatives' full ranking. In this study, PROMETHEE II is implemented. WSM is one of the best known and most straightforward MCDM techniques to evaluate several alternatives based on several decision criteria. WSM, especially in single-dimensional problems, can be the most commonly used approach [53]. In VIKOR, presented by Opricovic [54], compromise ranking is realized by comparing the measure of closeness to the ideal solution [55]. ELECTRE was presented by Roy [11]. ELECTRE III has been broadly exploited because of its ability to process unclear information [56]. Therefore, ELECTRE III is preferred for the problem of this study. ORESTE, introduced by Roubens [57], is an integrated ranking method that comprises two main steps: the calculation of the utility values to obtain weak ranking of alternatives and then the derivation of the PIR relations through conflict analysis.

2.3 Implementation of the Methods for Manufacturing Plant Location Selection

Although there have been some automotive manufacturing plants in Turkey, none of them are Turkish brands. Turkey has introduced its national automobiles recently. Also, the officials have chosen Bursa to manufacture these automobiles in two years. By considering this real and strategical significant case, various methods are evaluated in this study. In this context, eight locations are assessed. The methodology for location selection and evaluation of the optimal location for the manufacturing plant is described in Fig. 1.

First, the most effective criteria are determined based on a comprehensive literature review and expert knowledge. Thus, six main criteria namely cost, labor characteristics, infrastructure [69], quality of life [70], economic factors, and suppliers [71], and sixteen sub-criteria namely labor cost [72], land cost [73], unemployment rate, education level, average age, climate [74], schools, well-being index, availability of airway, highway, railroad, and water transportations, investment and tax incentives [69], regional price level index, number of suppliers and automotive plants [75] are determined. Second, the hierarchy of criteria, in which the first level and second level of the hierarchy comprises six main criteria and sixteen sub-criteria, respectively, as shown in Table 5, is formed. In this table, the descriptions of sub-criteria and the objective of them are also provided. In the context of AHP, the main and sub-criteria weights are computed by forming the pairwise comparison matrix (Table 6) and the normalized matrix of main criteria (Table 7) and sixteen sub-criteria pairwise comparison matrices (Table 8) depending on the expert knowledge and literature. It is assured that the CR of each comparison matrix formed is less than 0.1.

Then, the decision matrix is formed by collecting data from different sources, namely the Turkish Statistical Institute, Turkish State Meteorological Service, Turkish Council of Higher Education, Automotive Suppliers Association of Turkey, and [76], as presented in Table 9 and each objective weighting method is implemented to find attribute weights.

Next, the outcome of each method is evaluated in terms of Spearman's correlation coefficients. Then, location alternatives are evaluated through the TOPSIS, PROMETHEE, VIKOR, ORESTE, ELECTRE, and WSM techniques. Eight location alternatives, namely Aksaray, Bursa, Istanbul, Izmir, Kocaeli, Konya, Manisa, and Sakarya, are evaluated against each criterion by utilizing the MCDM techniques. The values of each criterion are used as the input for these methods. Then, the outcome of each MCDM method is compared with others to present a comprehensive analysis and to reveal the optimal location alternative. In this regard, Spearman's rank correlation coefficient (rs) is utilized. It is calculated by using the following equation.

where n denotes the number of alternatives and di is the difference between the ranks of the two methods. Then, the ranking results of 30 models are integrated through the Copeland method to determine the optimal alternative location. The selected location (Bursa) is evaluated based on a variety of models, including the proposed approach. Finally, the sensitivity analysis is conducted considering various scenarios to evaluate the robustness of the priority ranking and observe the impact of attribute weights. In this context, seven scenarios containing 42 cases are developed. Each MCDM method used is evaluated based on the results of the sensitivity analysis. The outcomes of these methods are also evaluated in terms of the selected city.

3 Results and discussion

The weights of the main and sub-criteria obtained through AHP are given in Table 10. The results in the table indicate that cost and suppliers have the two highest weights, respectively. However, labor characteristics and quality of life have the lowest weights among all the main criteria. Specifically, the results indicate that the two most significant factors are the number of suppliers and land cost. The expert evaluation reveals the importance of suppliers.

Besides, the criteria weights also computed through objective methods, namely entropy, CRITIC, SD, and MW, are given in Table 11. The results of the entropy, CRITIC, and SD methods indicate that land cost, which is evaluated as the second important in AHP, is the essential factor. Also, as expected, the results of MW reveal that all criteria have equal weights.

To evaluate the weight results of the methods, Spearman's correlation coefficients are obtained as given in Table 12. The results of the tests indicate that there is a significant relationship between entropy and CRITIC, entropy and SD, and CRITIC and SD. However, the relationships between AHP and entropy, AHP and CRITIC, and AHP and SD are very weak. The results reveal the differences between subjective and objective weighting methods. In this regard, using only one of these can lead to wrong decisions.

The weights provided by each method are used as the input of the MCDM methods. After the implementation of the procedure of each approach, the final ranking of the alternatives is determined based on outcomes (utilities) of the methods, whose results are partly given in Table 13, as an example.

The rankings are obtained for each method, as given in Table 14. The results indicate that SD-based ORESTE, MW-based ELECTRE, and VIKOR, AHP-based ORESTE suggest Bursa as the most suitable location for the automotive manufacturing plant location. As mentioned earlier, Bursa was announced by the authorities to be the location of the manufacturing plant. Thus, it can be inferred that SD-based ORESTE, MW-based ELECTRE, and VIKOR, AHP-based ORESTE methods can be used for this kind of location selection. Even though it may be hard to generalize this result, it may be an indicator of this kind of case. Also, it is seen that the methods chosen for finding attribute weights and for ranking alternatives significantly determine the outcome. To illustrate the impact of attribute weights and the method chosen for weighting on ranking results, Fig. 2a–f is presented.

Based on the figures, the following observations can be highlighted:

-

PROMETHEE recommends the same best alternative, regardless of the method chosen to find attribute weights (Fig. 2c).

-

The alternative, which is ranked seventh, can be ranked first depending on the method chosen for obtaining attribute weight (Fig. 2d). Similarly, the alternative, which is ranked first, can be ranked fifth depending on the method chosen for attribute weights. These results prove the impact of attribute weights and methods selected for that.

-

The objective methods (including the same weights for all criteria)-based WSM provide the same alternative as the best, however, different from the subjective method-based WSM. This point proves the difference between subjective and objective methods.

To evaluate the impact of the methods used for finding attribute weights on the MCDM outcomes, Spearman's rank correlation coefficients are calculated (Tables 15, 16, 17, 18, 19 and 20). Table 15 reveals that the results of entropy-based ELECTRE are highly correlated with CRITIC-based ELECTRE. Similarly, the results of CRITIC-based ELECTRE are highly correlated with SD-based ELECTRE. However, correlations between entropy-based ELECTRE and MW-based ELECTRE, and MW-based ELECTRE and AHP-based ELECTRE are moderate.

Table 16 shows that the correlation between the results of entropy-based ORESTE and CRITIC-based ORESTE is very strong. Overall, the correlation coefficients are higher than 0.6, meaning that the correlations are strong.

Table 17 reveals that the correlation between entropy-based PROMETHEE and SD-based PROMETHEE is negative and very weak. Though, the correlation between SD-based PROMETHEE and MW-based PROMETHEE is very strong.

Table 18 shows that the correlation between CRITIC-based TOPSIS and SD-based TOPSIS is very strong. However, the correlation between entropy-based TOPSIS and MW-based TOPSIS is negative and very weak.

Table 19 indicates that the correlation between CRITIC-based VIKOR and SD-based VIKOR is very strong. However, the correlation between entropy-based VIKOR and MW-based VIKOR is weak.

Table 20 shows that the correlation between SD-based WSM and MW-based WSM is very strong. However, the correlation between entropy-based WSM and MW-based WSM is weak.

To determine the optimal alternative location, the ranking results of all models are integrated through the Copeland method. Thus, the subjective and objective evaluations of the criteria and the ranking results of different MCDM methods from different groups are integrated. To put it more broadly, the proposed approach is important in the following aspects. First, considering the impact of weighting methods on the ranking results, utilizing five of them is essential. Thus, the effect of subjective evaluations that may be biased is minimized and different objective evaluations based on four methods are taken into account. In addition, MCDM methods provide different ranking results for different problems and based on different criteria weights. Therefore, basing the optimal decision on a single MCDM method can lead to deceptive decisions. Instead, using and integrating different MCDM methods from different groups increases the accuracy of the ranking. To be noted, the comparative analysis in this study reveals and proves all these issues. Therefore, before implementing the proposed approach, the comparative analyses presented earlier are crucial.

The Copeland method scores alternatives based on how many times an alternative is dominant over others in terms of ranking. To find the scores, pairwise comparison matrices are formed for each model. Here, a value of one is given for all other alternatives that rank below the alternative considered; otherwise, a zero value is given to the corresponding matrix value. Once all values for each matrix are obtained, the column sum and row sum for each alternative are calculated. The final Copeland score of an alternative is found by taking the difference between the row and column sums [77]. The Copeland calculations and scores are presented in Table 21.

Based on the calculations, the final consensus ranking of the alternatives is given in Table 22. The results indicate that Konya is the best location, followed by Kocaeli, Bursa, Izmir, Sakarya, Istanbul, Aksaray, and Manisa. Based on this final consensus ranking, it can be inferred that PROMETHEE can be preferred if one has to be chosen among methods considered in the present study. PROMETHEE recommends Konya as the most optimal location based on all the weighting methods considered in the study. In other words, PROMETHEE has been found to be the most robust method as it suggests the same alternative location as the best regardless of the weighting method. In addition, the selected location (Bursa) is ranked third by the proposed approach. This difference may be due to the attributes considered. Further analyses are conducted to examine.

Cost, specifically land cost, is one of the crucial attributes in location selection problems. However, in the considered case, differently from usual location selection problems, the weight of land cost attribute may be neglected as the country does not need to pay for its lands. To reflect this issue to the results, to reveal the degree of subjectivity of the AHP results, and to examine the stability of the priority ranking, different cases under different scenarios are formed and analyzed in the context of sensitivity analysis. The analysis is conducted for AHP weights. Hence, a weight of 90% is assigned to one criterion, and the remaining 10% is distributed among the other criteria based on the ratio of the weights calculated in the original case. This process is performed for each criterion, respectively. Also, the weight of land cost is set to zero, and a weight of 100% is allocated to other criteria in an additional scenario. In this regard, seven scenarios are formed, and the procedure of each MCDM method is processed again, and rankings are obtained from each method. Thus, 42 cases are analyzed in total, and the results of each of 42 cases of the sensitivity analysis are illustrated in Table 23.

In Table 23, in Scenario 1, the most weight is given to the cost attributes. In other words, if the cost factors are critically important, the best location will be Aksaray based on four of the MCDM method results. In Scenario 2, the most weight is given to the labor characteristics criteria meaning that the unemployment rate, education level, and average age are crucially significant. Thus, the optimal location will be Istanbul, according to four of the MCDM methods. In Scenario 3, the most weight is allocated to the quality of life factors meaning that climate, schools, and well-being index are the critical criteria. Using this as input, Istanbul is the most suitable location based on four methods.

In Scenario 4, the most weight is given to the infrastructure attributes, namely availability of airway facilities, availability of highway facilities, availability of railroad facilities, and availability of water (port) transportation. This case may be necessary as the officials often stress the availability of water transportation. The results of the five methods indicate that Izmir is the best alternative. In Scenario 5, the most weight is given to the economic factors meaning that investment and tax incentives and regional price level index are the most significant factors. In this case, Aksaray will be the best alternative based on the results of the three methods. In Scenario 6, the most weight is given to the suppliers' criteria, namely the number of suppliers and automotive plants. As a result, Kocaeli is suggested as the best location by four methods. Differently, in Scenario 7, the land cost factor is neglected, considering the country does not need to pay for its lands. 100% of the weights are allocated to the other criteria based on their initial weights in the original case. Thus, the optimal alternative is Istanbul, according to three of the methods.

One of the focus points is Bursa in this study, as it is selected as the best location by the officials. The results of the sensitivity analysis are examined further in terms of this alternative. In this context, the sum of rankings of each alternative in terms of each MCDM method is illustrated in Fig. 3. In the figure, the lower the sum of rankings of an alternative, the better alternative it is. Admittedly, the usual selection of the best alternative is selecting the one that is suggested by the method considered. However, in this study, six of the MCDM methods are utilized, and 42 cases are formed in the sensitivity analysis. Therefore, this approach may be preferable to reveal the best method if one has to be chosen. To be specific, it can be inferred that ORESTE is the best method for this selection problem since the sum of the best location (Bursa) has the lowest value among all others.

The mean rankings of each alternative based on all cases of the sensitivity analysis are demonstrated in Fig. 4. Considering that 42 cases exist in the analysis, and each method provides different outcomes in each of these cases, it may be reasonable to consider the mean rankings. The lower the ranking of an alternative, the more suitable location it is. Thus, Bursa is the most appropriate location for the manufacturing of the automotive plant. This outcome is the same as officials declared.

Overall, it can be summed that the differences between the results of the MCDM methods may have resulted from the differences in structure, procedure, the capability of ranking, and selecting of the methods. The VIKOR and TOPSIS are utility value-based MCDM approaches. They consider the distances between the alternatives and the PIS or NIS in terms of their performance values. They are not able to detect the complex relationships between alternatives. However, as an outranking method, PROMETHEE can derive the ranking set and acquire the complex relationships between alternatives [34]. The WSM transforms the cost criteria into benefit and implements the simple aggregation process. ELECTRE forms concordance and discordance matrices and considers uncertainty. ORESTE requires ordinal evaluations of the alternatives and the ranking of the criteria in terms of importance.

To sum up, previous studies on location selection mostly adopted one or two MCDM methods. As mentioned earlier, some studies proposed hybrid approaches. In these studies, an optimal location was found, and that location was proposed as the best. However, the present study differs in some respects from others. First, comprehensive analyses were conducted. Also, various MCDM methods from different family groups were used and various weighting methods were applied, both objective and subjective. Examining the results of these methods and their pairs is valuable. The selected location by policymakers was evaluated based on the various method pairs. Finally, the optimal location was proposed based on an integrated, comprehensive approach. In general, the work done with 42 cases in the sensitivity analysis that determines which method (ORESTE) supports the policymakers' decision and the integrated method that reveals the optimal solution for the problem and the most robust method (PROMETHEE) can be considered as a helpful and valuable decision support approach.

4 Conclusions

In this study, a hybrid approach and comprehensive analysis are presented considering the automotive manufacturing plant location selection representing a real-world decision problem. In this regard, five commonly used methods, namely AHP, entropy, CRITIC, SD, and MW, are utilized for finding attribute weights. Six MCDM methods, namely TOPSIS, PROMETHEE, ELECTRE, VIKOR, PROMETHEE, and WSM, are utilized to rank the alternatives. These methods are also widely used for various decision-making problems in numerous industries. However, this study is the first in terms of using and integrating all of them for a real-world case in one study. Also, based on several tests and analyses, this study reveals several worthwhile and contributing results explained as follows.

-

1.

Spearman's correlation test performed for the results of attribute weight methods indicate that there is a significant relationship between entropy and CRITIC, entropy and SD, and CRITIC and SD.

-

2.

The outcome of each method used for finding attribute weight is utilized as the input of each of the MCDM methods. The results designate that SD-based ORESTE, MW-based ELECTRE, and VIKOR, AHP-based ORESTE suggest Bursa as the most suitable location. Since Bursa was announced to be the location of the manufacturing plant by the officials, it can be inferred that these method pairs are the most appropriate for this problem.

-

3.

The evaluations of the impact of the attribute weight methods reveal substantial results. The results validate the fact that the attribute weights prominently affect the ranking outcomes of the MCDM methods. For instance, the rank of the alternative changes from seventh to first depending on the method chosen for obtaining attribute weight. Also, the results reveal that, as an exception, PROMETHEE recommends the same best alternative, regardless of the weighting method chosen. Furthermore, the objective methods—WSM pairs provide the same alternative as the best. However, the subjective method-based WSM suggests a different alternative as the optimal. This point proves the difference between subjective and objective methods.

-

4.

The evaluation of the results of each method pairs using Spearman's correlation coefficients demonstrates valuable results. First, entropy-based ELECTRE is highly correlated with CRITIC-based ELECTRE. Similarly, the results of CRITIC-based ELECTRE are highly correlated with SD-based ELECTRE. Also, the correlation between entropy-based ORESTE and CRITIC-based ORESTE; SD-based PROMETHEE and MW-based PROMETHEE; CRITIC-based TOPSIS and SD-based TOPSIS; CRITIC-based VIKOR and SD-based VIKOR; and SD-based WSM and MW-based WSM is very strong.

-

5.

Integrating the rankings of 30 models through the Copeland method determines Konya as the optimal location. This final consensus selection is different from the selected location (Bursa). However, based on the result of the integrated approach (Konya), PROMETHEE was found to be the most robust method as it recommended the same location, regardless of the weighting method.

-

6.

Considering 42 cases within the sensitivity analysis reveal that ORESTE is the best method for this selection problem since the sum of the best location (Bursa) has the lowest value among all others. This result proves that ORESTE (used for the automotive plant location selection for the first time in this study) is a competitive and effective method. Also, based on the average ranking of the alternatives, it can be inferred that Bursa is the optimal alternative that was declared to be the actual location in real. Thus, it can be inferred that the result is consistent with the decision in practice, vice versa.

This study has already made several substantial contributions, as mentioned previously. However, future studies may examine some other MCDM and Fuzzy MCDM methods to reveal and analyze their results. Also, it may be worthwhile to evaluate more alternatives based on additional criteria. Finally, the AHP weights in this study are based on input from an expert, but the fact that a group of experts may make a more balanced contribution to the weights in AHP may be considered in future studies.

References

Yang J, Lee H (1997) An AHP decision model for facility location selection. Facilities 15(9/10):241–254. https://doi.org/10.1108/02632779710178785

Guitouni A, Martel J-M (1998) Tentative guidelines to help choosing an appropriate MCDA method. Eur J Oper Res 109(2):501–521

Abdel-Basset M, Gamal A, Chakrabortty RK, Ryan M (2021) A new hybrid multi-criteria decision-making approach for location selection of sustainable offshore wind energy stations: a case study. J Clean Prod 280:124462. https://doi.org/10.1016/j.jclepro.2020.124462

Kannan D, Moazzeni S, Sm D, Afrasiabi A (2021) A hybrid approach based on MCDM methods and Monte Carlo simulation for sustainable evaluation of potential solar sites in east of Iran. J Clean Prod 279:122368. https://doi.org/10.1016/j.jclepro.2020.122368

Wang R, Li X, Xu C, Li F (2020) Study on location decision framework of electric vehicle battery swapping station: using a hybrid MCDM method. Sustain Urban Areas 61:102149. https://doi.org/10.1016/j.scs.2020.102149

Hwang C-L, Yoon K (1981) Methods for multiple attribute decision making. In: Multiple attribute decision making. Springer, pp 58–191

Brans JP, Vincke P (1985) Note—A preference ranking organisation method. Manage Sci 31(6):647–656. https://doi.org/10.1287/mnsc.31.6.647

Brans JP, Vincke P, Mareschal B (1986) How to select and how to rank projects: the promethee method. Eur J Oper Res 24(2):228–238. https://doi.org/10.1016/0377-2217(86)90044-5

Coello Coello CA (1999) A comprehensive survey of evolutionary-based multiobjective optimization techniques. Knowl Inf Syst 1(3):269–308. https://doi.org/10.1007/bf03325101

Bourguignon B, Massart DL (1994) The Oreste method for multicriteria decision making in experimental chemistry. Chemom Intell Lab Syst 22(2):241–256. https://doi.org/10.1016/0169-7439(93)E0083-G

Roy B (1978) ELECTRE III: un algorithme de classements fondé sur une représentation floue des préférences en présence de critères multiples. Cahiers du CERO 20(1):3–24

Opricovic S, Tzeng G-H (2004) Compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur J Oper Res 156(2):445–455. https://doi.org/10.1016/S0377-2217(03)00020-1

Tavakkoli Moghaddam R, Mousavi SM, Heydar M (2011) An integrated AHP-VIKOR methodology for plant location selection. Int J Eng 24(2):127–137

Rezaian S, Jozi SA (2016) Application of multi criteria decision-making technique in site selection of wind farm—a case study of Northwestern Iran. J Indian Soc Remote Sens 44(5):803–809. https://doi.org/10.1007/s12524-015-0517-6

Vasileiou M, Loukogeorgaki E, Vagiona DG (2017) GIS-based multi-criteria decision analysis for site selection of hybrid offshore wind and wave energy systems in Greece. Renew Sustain Energy Rev 73:745–757. https://doi.org/10.1016/j.rser.2017.01.161

Chauhan A, Singh A (2016) A hybrid multi-criteria decision making method approach for selecting a sustainable location of healthcare waste disposal facility. J Clean Prod 139:1001–1010. https://doi.org/10.1016/j.jclepro.2016.08.098

Kuo M-S (2011) Optimal location selection for an international distribution center by using a new hybrid method. Expert Syst Appl 38(6):7208–7221. https://doi.org/10.1016/j.eswa.2010.12.002

Sánchez-Lozano JM, García-Cascales MS, Lamata MT (2016) Comparative TOPSIS-ELECTRE TRI methods for optimal sites for photovoltaic solar farms. Case study in Spain. J Clean Prod 127:387–398. https://doi.org/10.1016/j.jclepro.2016.04.005

Dey B, Bairagi B, Sarkar B, Sanyal SK (2017) Group heterogeneity in multi member decision making model with an application to warehouse location selection in a supply chain. Comput Ind Eng 105:101–122. https://doi.org/10.1016/j.cie.2016.12.025

Ishizaka A, Nemery P, Lidouh K (2013) Location selection for the construction of a casino in the Greater London region: a triple multi-criteria approach. Tour Manage 34:211–220. https://doi.org/10.1016/j.tourman.2012.05.003

Kharat MG, Kamble SJ, Raut RD, Kamble SS, Dhume SM (2016) Modeling landfill site selection using an integrated fuzzy MCDM approach. Model Earth Syst Environ 2(2):53. https://doi.org/10.1007/s40808-016-0106-x

Wu Y, Zhang T, Xu C, Zhang B, Li L, Ke Y, Yan Y, Xu R (2019) Optimal location selection for offshore wind-PV-seawater pumped storage power plant using a hybrid MCDM approach: a two-stage framework. Energy Convers Manage 199:112066. https://doi.org/10.1016/j.enconman.2019.112066

Villacreses G, Gaona G, Martínez-Gómez J, Jijón DJ (2017) Wind farms suitability location using geographical information system (GIS), based on multi-criteria decision making (MCDM) methods: the case of continental Ecuador. Renew Energy 109:275–286. https://doi.org/10.1016/j.renene.2017.03.041

Wu Y, Zhang B, Xu C, Li L (2018) Site selection decision framework using fuzzy ANP-VIKOR for large commercial rooftop PV system based on sustainability perspective. Sustain Urban Areas 40:454–470. https://doi.org/10.1016/j.scs.2018.04.024

Liu K-M, Lin S-H, Hsieh J-C, Tzeng G-H (2018) Improving the food waste composting facilities site selection for sustainable development using a hybrid modified MADM model. Waste Manage 75:44–59. https://doi.org/10.1016/j.wasman.2018.02.017

Lee H-C, Chang C-T (2018) Comparative analysis of MCDM methods for ranking renewable energy sources in Taiwan. Renew Sustain Energy Rev 92:883–896. https://doi.org/10.1016/j.rser.2018.05.007

Seker S, Aydin N (2020) Hydrogen production facility location selection for Black Sea using entropy based TOPSIS under IVPF environment. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2019.12.183

Kumar RR, Mishra S, Kumar C (2017) Prioritizing the solution of cloud service selection using integrated MCDM methods under Fuzzy environment. J Supercomput 73(11):4652–4682. https://doi.org/10.1007/s11227-017-2039-1

Hanine M, Boutkhoum O, Tikniouine A, Agouti T (2017) An application of OLAP/GIS-Fuzzy AHP-TOPSIS methodology for decision making: Location selection for landfill of industrial wastes as a case study. KSCE J Civ Eng 21(6):2074–2084. https://doi.org/10.1007/s12205-016-0114-4

Dey B, Bairagi B, Sarkar B, Sanyal SK (2016) Warehouse location selection by fuzzy multi-criteria decision making methodologies based on subjective and objective criteria. Int J Manag Sci Eng Manag 11(4):262–278. https://doi.org/10.1080/17509653.2015.1086964

Dortaj A, Maghsoudy S, Doulati Ardejani F, Eskandari Z (2020) A hybrid multi-criteria decision making method for site selection of subsurface dams in semi-arid region of Iran. Groundw Sustain Dev 10:100284. https://doi.org/10.1016/j.gsd.2019.100284

Sennaroglu B, Varlik Celebi G (2018) A military airport location selection by AHP integrated PROMETHEE and VIKOR methods. Transp Res Part D: Transp Environ 59:160–173. https://doi.org/10.1016/j.trd.2017.12.022

Mousavi SM, Tavakkoli-Moghaddam R, Heydar M, Ebrahimnejad S (2013) Multi-criteria decision making for plant location selection: an integrated delphi-AHP-PROMETHEE methodology. Arab J Sci Eng 38(5):1255–1268. https://doi.org/10.1007/s13369-012-0361-8

Wu X, Zhang C, Jiang L, Liao H (2020) An integrated method with PROMETHEE and conflict analysis for qualitative and quantitative decision-making: case study of site selection for wind power plants. Cogn Comput 12(1):100–114. https://doi.org/10.1007/s12559-019-09675-7

Safaei Ghadikolaei A, Khalili Esbouei S, Antucheviciene J (2014) Applying fuzzy MCDM for financial performance evaluation of Iranian companies. Technol Econ Dev Econ 20(2):274–291. https://doi.org/10.3846/20294913.2014.913274

Zhou F, Wang X, Samvedi A (2018) Quality improvement pilot program selection based on dynamic hybrid MCDM approach. Ind Manag Data Syst 118:144–163

Jeya Girubha R, Vinodh S (2012) Application of fuzzy VIKOR and environmental impact analysis for material selection of an automotive component. Mater Des 37:478–486. https://doi.org/10.1016/j.matdes.2012.01.022

Jain V, Sangaiah AK, Sakhuja S, Thoduka N, Aggarwal R (2018) Supplier selection using fuzzy AHP and TOPSIS: a case study in the Indian automotive industry. Neural Comput Appl 29(7):555–564. https://doi.org/10.1007/s00521-016-2533-z

Galankashi MR, Helmi SA, Hashemzahi P (2016) Supplier selection in automobile industry: a mixed balanced scorecard–fuzzy AHP approach. Alex Eng J 55(1):93–100. https://doi.org/10.1016/j.aej.2016.01.005

Gupta S, Soni U, Kumar G (2019) Green supplier selection using multi-criterion decision making under fuzzy environment: a case study in automotive industry. Comput Ind Eng 136:663–680. https://doi.org/10.1016/j.cie.2019.07.038

Moradian M, Modanloo V, Aghaiee S (2019) Comparative analysis of multi criteria decision making techniques for material selection of brake booster valve body. J Traffic Transp Eng (Engl Edn) 6(5):526–534. https://doi.org/10.1016/j.jtte.2018.02.001

Hadian H, Chahardoli S, Golmohammadi A-M, Mostafaeipour A (2019) A practical framework for supplier selection decisions with an application to the automotive sector. Int J Prod Res 58:2997–3014. https://doi.org/10.1080/00207543.2019.1624854

Dweiri F, Kumar S, Khan SA, Jain V (2016) Designing an integrated AHP based decision support system for supplier selection in automotive industry. Expert Syst Appl 62:273–283. https://doi.org/10.1016/j.eswa.2016.06.030

Kabir G, Sumi RS (2015) Hazardous waste transportation firm selection using fuzzy analytic hierarchy and PROMETHEE methods. Int J Shipp Transp Logist 7(2):115–136. https://doi.org/10.1504/IJSTL.2015.067847

Xu T, Moon DH, Baek SG (2011) A simulation study integrated with analytic hierarchy process (AHP) in an automotive manufacturing system. Simulation 88(4):450–463. https://doi.org/10.1177/0037549711407781

Sadeghzadeh K, Salehi MB (2011) Mathematical analysis of fuel cell strategic technologies development solutions in the automotive industry by the TOPSIS multi-criteria decision making method. Int J Hydrog Energy 36(20):13272–13280. https://doi.org/10.1016/j.ijhydene.2010.07.064

Wu X, Liao H (2018) An approach to quality function deployment based on probabilistic linguistic term sets and ORESTE method for multi-expert multi-criteria decision making. Inf Fusion 43:13–26. https://doi.org/10.1016/j.inffus.2017.11.008

Nestic S, Lampón JF, Aleksic A, Cabanelas P, Tadic D (2019) Ranking manufacturing processes from the quality management perspective in the automotive industry. Expert Syst 36(6):e12451. https://doi.org/10.1111/exsy.12451

Saaty TL (1977) A scaling method for priorities in hierarchical structures. J Math Psychol 15(3):234–281. https://doi.org/10.1016/0022-2496(77)90033-5

Saaty RW (1987) The analytic hierarchy process—what it is and how it is used. Math Model 9(3):161–176. https://doi.org/10.1016/0270-0255(87)90473-8

Wang J-J, Yang D-L (2007) Using a hybrid multi-criteria decision aid method for information systems outsourcing. Comput Oper Res 34(12):3691–3700. https://doi.org/10.1016/j.cor.2006.01.017

Mohsen O, Fereshteh N (2017) An extended VIKOR method based on entropy measure for the failure modes risk assessment—a case study of the geothermal power plant (GPP). Saf Sci 92:160–172. https://doi.org/10.1016/j.ssci.2016.10.006

Triantaphyllou E, Mann SH (1989) An examination of the effectiveness of multi-dimensional decision-making methods: a decision-making paradox. Decis Support Syst 5(3):303–312. https://doi.org/10.1016/0167-9236(89)90037-7

Opricovic S (1998) Multicriteria optimization of civil engineering systems. Fac Civ Eng Belgrade 2(1):5–21

Chitsaz N, Banihabib ME (2015) Comparison of different multi criteria decision-making models in prioritizing flood management alternatives. Water Resour Manage 29(8):2503–2525. https://doi.org/10.1007/s11269-015-0954-6

Govindan K, Jepsen MB (2016) ELECTRE: a comprehensive literature review on methodologies and applications. Eur J Oper Res 250(1):1–29

Roubens M (1982) Preference relations on actions and criteria in multicriteria decision making. Eur J Oper Res 10(1):51–55. https://doi.org/10.1016/0377-2217(82)90131-X

Alinezhad A, Khalili J (2019) ELECTRE I-II–III Methods. In: Alinezhad A, Khalili J (eds) New Methods and Applications in Multiple Attribute Decision Making (MADM). Springer International Publishing, Cham, pp 167–180. https://doi.org/10.1007/978-3-030-15009-9_23

Roy BJT, Decision, (1991) The outranking approach and the foundations of electre methods. Theor Decis 31(1):49–73. https://doi.org/10.1007/bf00134132

Alinezhad A, Khalili J (2019) ORESTE method. In: Alinezhad A, Khalili J (eds) New methods and applications in multiple attribute decision making (MADM). Springer International Publishing, Cham, pp 17–21. https://doi.org/10.1007/978-3-030-15009-9_3

Alinezhad A, Khalili J (2019) PROMETHEE I-II-III Methods. In: Alinezhad A, Khalili J (eds) New Methods and Applications in Multiple Attribute Decision Making (MADM). Springer International Publishing, Cham, pp 29–39. https://doi.org/10.1007/978-3-030-15009-9_5

Abedi M, Ali Torabi S, Norouzi G-H, Hamzeh M, Elyasi G-R (2012) PROMETHEE II: a knowledge-driven method for copper exploration. Comput Geosci 46:255–263. https://doi.org/10.1016/j.cageo.2011.12.012

Zyoud SH, Fuchs-Hanusch D (2017) A bibliometric-based survey on AHP and TOPSIS techniques. Expert Syst Appl 78:158–181. https://doi.org/10.1016/j.eswa.2017.02.016

Zhang H, Gu C-l, Gu L-w, Zhang Y (2011) The evaluation of tourism destination competitiveness by TOPSIS & information entropy: a case in the Yangtze river delta of China. Tour Manage 32(2):443–451. https://doi.org/10.1016/j.tourman.2010.02.007

Alinezhad A, Khalili J (2019) VIKOR method. In: Alinezhad A, Khalili J (eds) New methods and applications in multiple attribute decision making (MADM). Springer International Publishing, Cham, pp 23–27. https://doi.org/10.1007/978-3-030-15009-9_4

Opricovic S, Tzeng G-H (2007) Extended VIKOR method in comparison with outranking methods. Eur J Oper Res 178(2):514–529. https://doi.org/10.1016/j.ejor.2006.01.020

Mulliner E, Malys N, Maliene V (2016) Comparative analysis of MCDM methods for the assessment of sustainable housing affordability. Omega 59:146–156. https://doi.org/10.1016/j.omega.2015.05.013

Si J, Marjanovic-Halburd L, Nasiri F, Bell S (2016) Assessment of building-integrated green technologies: a review and case study on applications of multi-criteria decision making (MCDM) method. Sustain Urban Areas 27:106–115. https://doi.org/10.1016/j.scs.2016.06.013

MacCarthy BL, Atthirawong W (2003) Factors affecting location decisions in international operations—a Delphi study. Int J Oper Prod Manag 23(7):794–818. https://doi.org/10.1108/01443570310481568

Coughlin CC, Terza JV, Arromdee V (1991) State characteristics and the location of foreign direct investment within the United States. Rev Econ Stat 73:675–683

McMillan TE (1965) Why manufacturers choose plant locations vs Determinants of Plant Locations. Land Econ 41(3):239–246. https://doi.org/10.2307/3144856

Schmenner RW (1982) Making business location decisions. Prentice Hall

Mehren GL (1957) Plant location in theory and in practice: the economics of space, Melvin L. Greenhut. Chapel Hill: The University of North Caro. Am J Agric Econ 39(1):193–194. https://doi.org/10.2307/1233907

Spooner D (1974) Some qualitative aspects of industrial movement in a problem region in the United Kingdom. Town Plan Rev 45(1):63

Wheeler D, Mody A (1992) International investment location decisions: the case of US firms. J Int Econ 33(1–2):57–76

PROTEMA (2016) Feasibility study automotive production in Konya.

Şahin M (2020) A comprehensive analysis of weighting and multicriteria methods in the context of sustainable energy. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-020-02922-7

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Şahin, M. Location selection by multi-criteria decision-making methods based on objective and subjective weightings. Knowl Inf Syst 63, 1991–2021 (2021). https://doi.org/10.1007/s10115-021-01588-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10115-021-01588-y