Abstract

Reactive dyeing of cotton garments involves two stages, namely exhaustion and fixation of dyes. The exhaustion stage in reactive dyeing requires high quantity of salt. After dyeing process, the highly saline coloured effluent is discharged and the treatment of this effluent at present is not economically viable and making industries look for other alternatives for usage of salt. Cationization of cotton is one of the effective alternatives to overcome the usage of the salt. The present work focuses on the exhaust method of cationization of garments at an industrial scale using 3-chloro-2-hydroxypropyl trimethylammonium chloride as a cationic agent. Two commercially popular reactive dyes namely Navy Blue and Green dyes were chosen for dyeing the garments at 10% shade. The results of dyeing were evaluated on the basis of colour strength, dyeing levelness and colour fastness. The uniformity of dye on the fabrics was evaluated based on dyeing levelness and was found to be good for cationized cotton dyed garments. The fastness properties of dyed fabrics to washing and light were good. The dye utilization in the cationized cotton dyed garments was twice as that of the conventionally dyed cotton garments. The environmental hazard posed by the highly saline coloured effluent could be easily mitigated by the salt-free reactive dyeing process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cotton fibre is the most widely used textiles for apparel production in the world due to its excellent physical and chemical properties such as dimensional stability, comfort to wear, high moisture absorbency, dyeability and biodegradability (Chattopadhyay et al. 2007). To satisfy the consumers aesthetically, cotton garments have been dyed with varieties of colour with good level of fastness properties. In industrial practice, reactive dyes are one of the most preferred colourant for dyeing cotton garments due to their brilliancy, wide gamut of colour, ease of application and high wet fastness properties (Shore 1995). However, reactive dyeing process requires a high amount of electrolyte like common salt (NaCl) or Glauber’s salt (Na2SO4) to reduce electrostatic repulsion which arises due to the surface charge on the wet cotton fabric and the anionic nature of the reactive dye molecules (Chen et al. 2015; Farha et al. 2010; Suesat 2008). Even with the required addition of salt, only 60–65% of dyes are utilized during dyeing remaining 30–35% of dyes along with added salt are removed as a coloured effluent at the end of the dyeing process (Allègre et al. 2006; Ma et al. 2015).

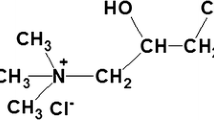

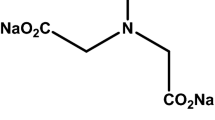

Numerous attempts have been made to reduce or eliminate the usage of salt in the reactive dyeing process. It can be summarized under these categories namely modification of dyeing machinery, dye chemistry and cotton substrate. Exhaust dyeing machines which can operate at an ultra low liquor level of 1:1 to 1:5 have led to the reduction in the water consumption and salt consumption in the reactive dyeing process to a certain extent. To further reduce the usage of salt modification of the functionality of dye was attempted and has not been commercially successful due to their higher molecular weight, poor dye migration, poor dye penetrability and poor dyeing levelness and they are restricted only to lighter shades (Aktek and Millat 2017; Taylor 2000). Cationization of cotton substrate is one of effective alternatives to eliminate the usage of salt. Various cationic agents for modification such as polyamide-based epichlorohydrin type of polymers, dendritic polymers, poly-(4-vinylpyridine) quaternary ammonium compounds, glycidyltrimethyl ammonium chloride (Glytac), chlorotriazine type quaternary compounds, choline chloride, N-methylolacrylamide, epichlorohydrin-based quaternary ammonium compounds (Aktek and Millat 2017; Khatri et al. 2015; Lewis and Mcllroy 1997) and biopolymers like chitosan, starch and their derivatives, keratin hydrolysate from chicken feather, horn and hoofs have been reported in literature (Arivithamani et al. 2014; Lim and Hudson 2004; Wang and Liu 2014; Zhang et al. 2007). Among them quaternary ammonium-based cationic agent 3-chloro-2-hydroxypropyl trimethylammonium chloride (CHPTAC) is widely used for cationization of cotton fabric as it is eco-friendly and atoxic in nature (Choudhury 2014; Varadarajan and Venkatachalam 2015; Wang and Lewis 2002). The cationized cotton fabric can be dyed with reactive dyes under neutral or mildly acidic conditions without the addition of salt. But the major limitation in the application of cationic agent to the cotton fabric is that it has to be applied by a batch process which is a time-consuming one (Hauser and Tabba 2001). It is difficult to translate at industrial scale as most of the industries adopt the exhaust method of dyeing (Montazer et al. 2007; Wang et al. 2009). The objective of the paper is to carry out cationization of garments by exhaust technique followed by reactive dyeing. The application of cationic agent by exhaust process would make the industries adopt this process without modification of existing setup.

In this study, cationization of cotton garments was carried out by exhaust method with a conventional garment dyeing machine using CHPTAC as a cationic agent. The cationization process parameters were optimized to achieve the higher degree and uniform level of cationization in the cotton garments. The produced cationized cotton garments were dyed with Navy Blue and Green dye for a darker shade of 10% without the addition of salt. The colour strength of the produced cationized cotton dyed garment was compared with that of the conventionally dyed cotton garments. The results obtained are discussed in the following sections.

Materials and methods

Materials

100% Cotton-scoured, bleached and ready for dyeing plain weave woven garments with a cover factor of 180 g/m2 with ends per inch (EPI) and picks per inch (PPI) of 88 and 100 were used for this study. The cationic agent CHPTAC used in this study was procured from a local chemical supplier in Tiruppur. Hot brand reactive dyes namely Navy Blue and Green dyes were used for the study, and the dyeing recipe is given in Table 1. Other chemicals such as sodium chloride (NaCl), sodium carbonate (Na2CO3), sodium hydroxide (NaOH) were procured from Fisher Scientific Chemicals Ltd., Chennai, India.

Cationization of cotton garments

5 kg ready for dyeing cotton garment was loaded into the garment dyeing machine at 1:20 material to liquor ratio. The garment was first subjected to warm wash at 50 °C for removing any residue finishes in the fabric. The cationization process was started by the addition of 24 g/L sodium hydroxide to the wetted fabric at 40 °C. The machine was operated for 10 min followed by the addition of cationic agent (80 g/L CHPTAC) in the same bath, and the machine was run for 15 min. The temperature of the bath was raised to 80 °C, and it was held for 30 min. Then the bath was drained out and the cationized cotton garments were subjected to the after-treatment process such as hot wash, neutralization at 70 °C followed by the cold wash to remove the physically adsorbed cationic agent in the garments. The pH of the cationized garment was maintained at 6.5, and the dyeing process was started in the same bath.

Characterization of cationized cotton garment

FTIR was used to assess the presence of functional groups of the cationic agent on the cotton garment after the cationization process. The measurements were taken using a Nicolet-460 FTIR machine under standard operating conditions. The samples were loaded in the pellet form, and the pellets were made by mixing fibrous tuft with the potassium bromide (KBr).

X-ray diffraction (XRD) patterns of normal and cationized cotton were measured using X-ray powder diffractometer system by monitoring the diffraction angle from 10° to 70° (2θ) using monochromatized Cu K α (λ = 1.54051 Å) radiation. The crystalline index (CI) of each sample was calculated by following Eq. (1), according to methods described by Segal et al. (1959).

where I 200 is the maximum intensity of the (200) lattice diffraction peak, and I am is the intensity scattered by the amorphous fraction of the sample.

The effect of cationization treatment on morphological characteristics of the cotton fabrics was studied with a high-resolution FESEM analyser. The samples were sputter coated with a thin layer of gold for better electric conductivity. The FESEM was taken with a working distance of 9 mm with a magnification of 2.5 kX at an acceleration voltage of 20 kV.

Dyeing of cotton garments

The modified cotton garments were dyed separately as per dye recipe mentioned in Table 1 for Navy Blue—10% shade and Green—10% shade in exhaust garment dyeing machine with the liquor ratio of 1:20. The cationized cotton garments were run with the respective dye solution at 60 °C for 20 min without the addition of salt; then the recommended amount of alkali (Na2CO3) was added into the bath. The dyeing temperature was gradually raised to 80 °C for fixation of reactive dyes into the cationized cotton fabric and run for 40 min. At the end of the dyeing process, the garments were subjected to the after-treatment process to remove unfixed dyes from the garments by carrying out cold wash, neutralization, hot wash and soaping process. After dyeing process, the garments were introduced into a solution containing 0.5 g/L of silica for finishing at room temperature for 10 min and then the garments were subjected to hydro-extraction and tumble dried at 60 °C for 20 min. Similarly the cotton garments were dyed using conventional method of dyeing with the recommended addition of salt and alkali.

Evaluation of colour strength and dyeing levelness

The colour strength of the dyed garment was expressed as K/S value which is obtained from the Kubelka–Munk Eq. (2). The colour strength was measured at the minimum reflectance of the dyed fabric using a UV–Visible spectrophotometer, and the value for Navy Blue dye was 580 nm and for Green dye was 680 nm. The other dyeing parameters such as relative colour strength (RCS) percentage, colour co-ordination values CIE Lab values (L*, a* and b*), hue angle (h°) and chroma values (C*) were measured using a following Eqs. (3)–(8).

where L*—lighter/darker; a*—redder/greener; and b*—yellower/bluer tone of the fabric. The hue angle (h°) denotes tone of the colour, and chroma (C*) values denote the saturation of colour in terms of dullness to brightness.

The levelness of the dyed garments was measured using relative unlevelness index (RUI) for which the colour of the garment was measured at eight different places and the RUI value was measured using Eqs. (9) and (10). The lower value indicates the better levelness in the dyed garments.

where S λ —Standard deviation of reflectance values measured at specific wavelengths, n—number of spots measured at each wavelength, R i —reflectance value of the ith measurement for each wavelength, \(\bar{R}\)—mean of the reflectance value of n measurements for each wavelength, V λ —photopic relative luminous efficiency function. The visual appearance of levelness and the grading of RUI values for dyed fabrics were calculated as per the standard (Chong 1992).

Assessment of fastness properties

All the dyed cotton garments were tested for fastness properties such as washing, rubbing and perspiration according to ISO 105-C06-C2S, ISO 105 X 12 and ISO 105 EO4 standards. The colour change was rated according to the appropriate grey scale value. Colour fastness to light was tested according to ISO 105 B02, and the degree of fading was assessed by the Society of Dyers and Colourist blue wool scales.

Result and discussion

The cationization process was carried out in two steps; in the first step, the cationic agent CHPTAC was converted into 2,3-epoxypropyl trimethylammonium chloride (EPTAC) in an alkaline medium. In the second step, the formed EPTAC was ring-opened in an alkaline medium to react with the primary hydroxyl group of the cotton by “etherification reaction” to produce cationized cotton garment. The cationized cotton garments strongly attract the anionic reactive dyes without the addition of salt.

The reaction of cationic agent with cotton garment was carried out in situ by the reaction of quaternary ammonium compound with alkali at 80 °C for 70 min. Based on the previous trials (Arivithamani and Dev 2016, 2017a, b), the optimized conditions for achieving a higher degree of cationization in the cotton garments by exhaust method were fixed as 1:2 molar ratio of cationic agent to alkali. The process cycle for cationization of cotton is given in Fig. 1.

Characterization of cationized cotton

FTIR study of the cationized cotton garment

The IR spectrum of the cotton garment and cationized cotton garment is presented in Fig. 2. The cotton garment showed a characteristic cellulosic peak at 945–1200 cm−1, strong absorption peak for –OH stretching at 3100–3686 cm−1, C–H stretching at 2771–3000 cm−1, C–H rocking vibration at 1386 cm−1 and C–O stretching vibration at 1120 cm−1 (Khalil-Abad et al. 2009). Compared with cotton garment, cationized cotton garment showed narrow hydrogen bonded O–H stretching peak at 3100–3686 cm−1 and aliphatic C–H stretching at 2917 cm−1, C–N stretching vibration at 1200 cm−1 (Zhang et al. 2015). A sharp peak at 1494–1510 cm−1 corresponds to the presence of quaternary ammonium (3R–N+–) groups (Zhang et al. 2007). The peaks confirm the fixation of the CHPTAC on the cotton garments.

X-ray diffraction analysis for cotton and cationized cotton fabric

X-ray diffraction analysis was carried out to study the effect of cationization on crystal structural changes. From the results shown in Fig. 3, it can be seen that typical diffraction peaks of cotton existed at 2θ of 14.8°, 16.4°, 22.9°, and 33.8° for both cotton and cationized cotton fabric (Fig. 3). It corresponds typically to cellulose I crystalline form (Klemm et al. 2005). The crystallinity of cotton was found to be 66%, whereas for cationized cotton fabric it was slightly reduced to 63%. The XRD spectra result reveals that the cationization process has not altered the crystallinity and crystal form in cotton.

Surface morphology analysis of the cationized cotton garment

Figures 4 and 5 give the FESEM images and EDX (Energy-Dispersive analysis of X-rays) results for cotton and cationized cotton garments. The fibres in the cotton garment have convoluted morphology, which is the characteristic feature of cellulosic materials. The fibres in the cationized cotton garments show rounded rod-like morphology due to the addition of alkali during cationization process. This confirms the fixation of CHPTAC on the cotton garments. The EDX result shows the presence of carbon and oxygen content in the cotton garment; on the other hand the cationized cotton garment showed nitrogen content in addition to the carbon and oxygen content, thereby confirming fixation of CHPTAC in the cationized cotton garment (Fig. 5).

Dyeing of cotton and cationized cotton garment

All the garments (cotton and cationized cotton) were dyed based upon the temperature raise method suggested by the dye manufacturer, and the dyeing cycle for conventional and salt-free dyeing process is given in Fig. 6. The process cycle was divided into three sections, namely cationization, dyeing and after-treatment process, while comparing the conventional and salt-free dyeing process, the salt-free dyeing process should have taken a long time since this process contains additional cationization process. But Fig. 6 shows that conventional dyeing process takes 517 min (8 h, 37 min) and on the other hand salt-free dyeing process takes 502 min (8 h, 22 min) to complete the process. It can be inferred from Fig. 6 that both the conventional and salt-free dyeing consumes almost equal processing time, even though the salt-free dyeing process consists of additional cationization process. The reason behind is that the salt-free dyeing process eliminates the salt dosage time of 20 min, salt migration time of 20 min and also the number of washing cycles is decreased. This is due to better dye utilization in the case of cationized cotton dyed garment during salt-free dyeing process.

Evaluation of dyeing parameters and levelness

The cationized cotton garments were dyed without the addition of salt, and cotton garments were dyed with the recommended dosage of salt (Navy Blue—40 g/L and Green—60 g/L of NaCl) and the dyeing mechanism is given in Figs. 7 and 8. The reflectance curves for all dyed garments are given in Fig. 9. From the figure, it can be seen that the cationized cotton dyed garments have lower reflectance values than the conventionally dyed cotton garments. It reveals that the colour strength of the cationized cotton dyed garments is higher than the conventional dyed cotton garments. At the same time, the curves follow a similar trend to that of the conventionally dyed cotton garments and it suggests that the tone of the fabric is not altered due to the cationization treatment. Table 2 gives the colour strength and dyeing levelness (RUI) values of the cationized cotton dyed garment with two different reactive dyes. The cationized cotton dyed with Navy Blue showed colour strength of 24.26 which is almost twice the colour strength of the conventionally dyed cotton garment which had the colour strength of 10.31. Similarly for Green dye, cationized cotton dyed garments showed five times higher colour strength (25.46) than the conventionally dyed cotton garment with the colour strength (5.06). The colour coordinate values (L*, a*, b*, h°) for both the dyes were assessed in which the cationized cotton dyed garments showed decreased lightness values (L* = 16.3 for Navy Blue and 19.4 for Green) compared to the conventionally dyed cotton garments (L* = 28.9 for Navy Blue and 44.3 for Green). It reveals that the cationized cotton dyed garments have a higher depth of shade compared to the conventionally dyed cotton garment. The a* and b* values did not significantly altered for Navy Blue and Green dyed garments, and it suggests that the tone of the fabric is not altered.

The dyeing mechanism of reactive dye in a cationized cotton garment is illustrated in Fig. 8. It was found that most of the reactive dyes were easily absorbed and diffused into the cationized cotton garment due to the presence of cationic sites which attract the oppositely charged anionic reactive dyes in the exhaust dyeing process. This would greatly increase the concentration of reactive dyes inside the cationized cotton garment which in turn enhances dye-fibre fixation in the cationized cotton garment during the subsequent addition of alkali (Na2CO3) in the dyeing process. The cationic sites of the cationized cotton garment could also temporarily restrict the movement of dye anions resulting in the decreased hydrolysis of reactive dyes and increased utilization of reactive dyes by the cationized cotton garments. This ensures the dyeing levelness of the cationized cotton. The dyeing levelness of the dyed garments expressed in terms of the relative unlevelness index is given in Table 2. Cationized cotton dyed garments with Green dye showed the excellent levelness value, whereas all other garments showed good levelness value.

Thus, the dyeability of cationized cotton dyed garments with the two different reactive dyes (Navy Blue—10% and Green—10%) with combination shades (three-dye) was examined in the absence of salt and the results reveals that the cationized cotton dyed garments showed increased colour strength for the two different reactive dyes even with the darker shades (10%). The tone of the fabrics was also not changed. Figure 10 shows images of dyed garments with two different reactive dyes. The colour of the cationized cotton dyed garments was markedly deeper than the conventionally dyed cotton garments. The cationized cotton substrate would be a suitable starting material for eco-friendly dyeing process for reducing the pollution load in terms of salinity and colour discharge from the textile dyeing industries. The fastness ratings of conventional and salt-free dyed garments were good to excellent for washing, rubbing, perspiration and light, and the values are given in Table S1 in the supplementary material.

Conclusions

Garment dyeing at present is carried out using exhaust dyeing machines. The application of cationic agent (CHPTAC) by exhaust method using existing garment dyeing machinery is first reported in this work. FTIR studies carried out confirm the presence of quaternary ammonium group on the cationized fabrics, and XRD studies revealed that the crystallinity of cotton is not affected due to the cationization process. Commercially used dyes and its recipes were selected to validate the cationization process. The dyes selected for the study was Navy Blue and Green dyes, and the garments were dyed for 10% shade. Significant improvement in colour strength is observed for both the dyes on using cationized garments compared to control garments. The dyeing levelness and fastness properties were good. The tone of the dyed garments was not altered while using cationized garment for dyeing. The study has shown a way to eliminate the usage of salt in garment dyeing using reactive dyes and can be easily adopted by the industries using existing garment dyeing machinery. Moreover, impediments in treating a saline coloured effluent for garment dyers have been successfully overcome by the new route suggested in the paper.

References

Aktek T, Millat AKMM (2017) Salt free dyeing of cotton fiber—a critical review. Int J Text Sci 6:21–33

Allègre C, Moulin P, Maisseu M, Charbit F (2006) Treatment and reuse of reactive dyeing effluents. J Memb Sci 269:15–34. doi:10.1016/j.memsci.2005.06.014

Arivithamani N, Dev VRG (2016) Salt-free reactive dyeing of cotton hosiery fabrics by exhaust application of cationic agent. Carbohydr Polym 152:1–11. doi:10.1016/j.carbpol.2016.06.087

Arivithamani N, Dev VRG (2017a) Sustainable bulk scale cationization of cotton hosiery fabrics for salt-free dyeing process. J Clean Prod 149:1188–1199. doi:10.1016/j.jclepro.2017.02.162

Arivithamani N, Dev VRG (2017b) Industrial scale salt-free reactive dyeing of cationized cotton fabric with different dye chemistry. Carbohydr Polym 174:137–145. doi:10.1016/j.carbpol.2017.06.045

Arivithamani N, Mary SA, Kumar MS, Dev VRG (2014) Keratin hydrolysate as an exhausting agent in textile reactive dyeing process. Clean Technol Environ Policy 16:1207–1215. doi:10.1007/s10098-014-0718-7

Chattopadhyay DP, Chavan RB, Sharma JK (2007) Salt-free reactive dyeing of cotton. Int J Cloth Sci Technol 19:99–108. doi:10.1108/09556220710725702

Chen L, Wang B, Ruan X et al (2015) Hydrolysis-free and fully recyclable reactive dyeing of cotton in green, non-nucleophilic solvents for a sustainable textile industry. J Clean Prod 107:550–556. doi:10.1016/j.jclepro.2015.05.144

Chong CL, Li SQ, Yeung KW (1992) An objective method for the assessment of levelness of dyed materials. J Soc Dye Colour 108:528–530

Choudhury AKR (2014) Coloration of cationized cellulosic fibers—a review. AATCC J Res 1:11–19

Farha SAA, Gamal AM, Sallam HB et al (2010) Sodium edate and sodium citrate as an exhausting and fixing agents for dyeing cotton fabric with reactive dyes and reuse of dyeing effluent. J Am Sci 6:109–127

Hauser PJ, Tabba AH (2001) Improving the environmental and economic aspects of cotton dyeing using a cationised cotton+. Color Technol 117:282–288. doi:10.1111/j.1478-4408.2001.tb00076.x

Khalil-Abad MS, Yazdanshenas ME, Nateghi MR (2009) Effect of cationization on adsorption of silver nanoparticles on cotton surfaces and its antibacterial activity. Cellulose 16:1147–1157. doi:10.1007/s10570-009-9351-8

Khatri A, Hussain M, Mohsin M, White M (2015) A review on developments in dyeing cotton fabrics with reactive dyes for reducing effluent pollution. J Clean Prod 87:50–57. doi:10.1016/j.jclepro.2014.09.017

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Lewis DM, Mcllroy KA (1997) The chemical modification of cellulosic fibres to enhance dyeability. Rev Prog Color 27:5–17. doi:10.1111/j.1478-4408.1997.tb03770.x

Lim S-H, Hudson SH (2004) Application of a fibre-reactive chitosan derivative to cotton fabric as a zero-salt dyeing auxiliary. Color Technol 120:108–113. doi:10.1111/j.1478-4408.2004.tb00215.x

Ma W, Wang T, Li H, Zhang S (2015) Cotton fabric modification through ceric (IV) ion-initiated graft copolymerisation of 2-methacryloyloxyethyltrimethyl ammonium chloride to enhance the fixation of reactive dyes. Cellulose 22:4035–4047. doi:10.1007/s10570-015-0713-0

Montazer M, Malek RMA, Rahimi A (2007) Salt free reactive dyeing of cationized cotton. Fibers Polym 8:608–612. doi:10.1007/BF02875997

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Shore J (1995) Cellulosics dyeing. Society of Dyers and Colourists, Manchester

Suesat J (2008) The influence of NaCl concentration on the build-up properties and aggregation of reactive dyes. Kasetsart J Nat Sci 42:558–568

Taylor JA (2000) Recent developments in reactive dyes. Rev Prog Color 30:93–106

Varadarajan G, Venkatachalam P (2015) Sustainable textile dyeing processes. Environ Chem Lett 14:113–122. doi:10.1007/s10311-015-0533-3

Wang H, Lewis DM (2002) Chemical modification of cotton to improve fibre dyeability. Color Technol 118:159–168

Wang X, Liu Y (2014) A comparative study of the salt-free reactive dyeing property of treated cotton fabric with a chicken-feather protein derivative agent and a linking cationic agent materials and instruments. J Fiber Bioeng Inform 3:363–375. doi:10.3993/jfbi09201406

Wang L, Ma W, Zhang S et al (2009) Preparation of cationic cotton with two-bath pad-bake process and its application in salt-free dyeing. Carbohydr Polym 78:602–608. doi:10.1016/j.carbpol.2009.05.022

Zhang M, Ju BZ, Zhang SF et al (2007) Synthesis of cationic hydrolyzed starch with high DS by dry process and use in salt-free dyeing. Carbohydr Polym 69:123–129. doi:10.1016/j.carbpol.2006.09.011

Zhang F, Panga Z, Donga C, Liu Z (2015) Preparing cationic cotton linter cellulose with high substitution degree by ultrasonic treatment. Carbohydr Polym 132:214–220. doi:10.1016/j.carbpol.2015.06.055

Acknowledgements

The authors would like to express sincere gratitude to Mr. G. Ramesh Kanna, Managing director Motherland Garments Pvt. Ltd., SIDCO Industrial Estate, Chennai, India, for permitting us to carry out this study in his industry and special thanks to University Grants Commission (UGC) for financial support (Grant number F1-17.1/2012-13/RGNF-2012-13-SC-TAM-31034).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Arivithamani, N., Dev, V.R.G. Cationization of cotton for industrial scale salt-free reactive dyeing of garments. Clean Techn Environ Policy 19, 2317–2326 (2017). https://doi.org/10.1007/s10098-017-1425-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-017-1425-y