Abstract

Dehairing is one of the important operations in leather processing where hair is removed by using suitable chemicals. Conventional dehairing is based on application of huge amount of chemicals such as lime and sodium sulfide that generate lot of pollution problem. Enzyme assisted dehairing is the eco-friendly option that reduces nearly 40% of BOD and 50% of COD in leather processing. For this; an alkaline protease producing strains namely Bacillus subtilis was isolated from fresh goat skins and the enzyme was extracted. The enzyme was applied on flesh side goat skins at different concentration (1–4% with 10% water) and dehairing was carried out. The complete dehairing was achieved at 2% enzyme for duration of 16 h. The pollution loads such as BOD, COD, TSS, and TDS were reduced at the level of 62.8, 79.0, 88.2, and 82.5% in comparison with the control sample. The enzymatic dehaired leather was analyzed by scanning electron microscopic (SEM) studies. The SEM analyses revealed similar fiber orientation and compactness compared with control sample. The color measurements of the enzyme dehaired leather showed better color properties than control sample.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biotechnology is harnessing the power of the living organisms to improve biological and chemical processes thereby making them more effective, quicker, safer, and more environmentally acceptable. Industrial biotechnology can provide an unlimited and pure source of enzymes as an alternative to the harmful industrial chemicals. Leather industry makes use of enzymes like protease, lipase that softens fibers; improve quality, and present alternatives to chemical method (Dayanandan et al. 2003). Enzymology is one of the avenues of biotechnology, which can provide an unlimited and pure source of enzymes as an alternate to the hazardous chemicals traditionally used in leather industries. Large quantities of enzymes are often needed for industrial use. Hence the microorganisms are multiplied through fermentation, which provides large quantities of enzymes (Kanagaraj 2009; Annapurna Raju et al. 1996).

Global concerns about the environmental impact of leather industry have led tanners to try to reduce the elements of toxicity in their effluents. Dehairing procedures are known for uncleanness and contribute to 60–70% of the total pollution load in leather processing. The conventional dehairing process with sodium sulfide and lime contributes a significant amount of BOD, COD, sulfide, and solid wastes. Extensive use of sodium sulfide bears unfavorable consequences on environment and the efficacy of effluent treatment plants. Consequently it will be worthwhile to look for alternative dehairing process, to replace the lime and sodium sulfide completely and diminish the ecotoxicological parameters (Oppong et al. 2006).

Several researchers have reported that the protease enzyme obtained from Thermoactinomyces sp. RM4, from soil sample showed optimum activity at pH 10 and temperature 80°C and retains 45% of its activity at 90°C in 3 h. This enzyme showed good dehairing of hide with short incubation time, intact hair recovery and clean pelt. The complete dehairing was achieved in 24 h of treatment of enzyme (Arunachalam and Saritha 2009; Verma et al. 2011; Dettmer et al. 2011).

The alkaline protease produced by Bacillus circulans showed optimum pH of 11 and temperature at 35°C. The molecular weight of the purified enzyme was estimated to be 39.5 kDa on SDS-PAGE. By using the enzyme, the complete dehairing was achieved in 12 h duration time. The other advantage was that it could open up the collagen fiber structure without hydrolyzing fiber protein (Subba rao et al. 2009).

Enzymatic unhairing using protease and related kinetics was studied. The studies were useful in providing information about total protein released in enzyme bath during unhairing. A good linearity between released total protein and square root of time was obtained at the initial stage. The good linearity suggests that enzymatic unhairing by protease was a diffusion controlled process at the initial stage. The results showed that released total protein further confirms that it is a hydrolysis of core protein by protease that leads to the degradation of proteoglycans and release of protein and saccharides (Jians et al. 2010; Song et al. 2011; Wang et al. 2009).

Several commercial enzyme formulations were chosen in combination with hydrosulfide and peroxides for better results. Results show that activity of enzyme is stabilized by the addition of hydrosulfide through activity measurements; peroxide has some activation effect on protease. Hair removal is found to be complete using scanning electron microscopic (SEM) analysis. Those two processes enjoy a significant reduction in BOD, COD, TDS, and TSS. The qualities of leathers were comparable to that of conventional ones. These cleaner process technologies were chosen to mitigate the problems of traditional unhairing methods (Wei et al. 2010).

The pollution control board in India is strictly following the discharge norms for bio-chemical oxygen demand (BOD) and chemical oxygen demand (COD) as 40 and 200 ppm for treated effluent. Maintenance of this norm is very difficult without cleaner leather processing such as enzymatic unhairing. The aim of this study is to remove the hair with no destruction of the collagen network, which is the building network for the leather. The Bacillus subtilis commonly produces a large variety of extra-cellular enzymes of proteases that offers significant industrial importance. The purified enzyme proved to be a potential dehairing agent, which completely dehairs the goat skin and helps for obtaining cleaner leather.

Materials and methods

Fresh goat skins, nutrient broth medium, nutrient agar medium, skimmed milk agar medium, simmon’s citrate agar medium, 2% sodium carbonate, 0.1 N sodium hydroxide, 0.5% copper sulphate, 1% sodium potassium tartrate, folin’s phenol reagent, standard bovine serum albumin (BSA). 2% casein, citrate–phosphate buffer (pH 7.0), 0.1 M citric acid, 0.2 M dibasic sodium phosphate, 10% TCA, Folin–Ciocalteau reagent (FCR), tyrosine (all microbial media and chemicals were purchased from Hi-media and Sigma Aldrich chemicals, Mumbai, India).

Isolation of organism

The fresh goat skins were taken for this study, which were purchased from commercial market in Chennai after immediate flaying house operation. The skins were unhaired by using scissors. 50 g of skin samples (four nos) from each skin were taken. These skins were cut into small pieces and soaked well in the sterile water in four different beakers. After soaking the skins; the skin samples were suspended in four different conical flasks containing 100 ml nutrient broth. Then all conical flasks were incubated for 24 h at 37°C; the broth was then serially diluted. This method was followed to isolate and enumerate different types of bacteria that are obtained from the skin samples (Kayalvizhi et al. 2008). Serial dilution was repeatedly performed from 10−1 to 10−9 dilution. Suspensions of volumes 0.1 ml from 10−4 to 10−8 were streak on to the nutrient agar plates using inoculating loop. They were then incubated at 37°C for 24–48 h. Individual colonies were isolated from the plates and sub cultured on nutrient agar plates which were in turn taken for enzyme production. The organism was systematically checked for the presence of proteolytic activity and collagenolytic activity by using skim milk agar and gelatin agar medium. The organism that showed protease activity was taken for enzyme production and further tested for the dehairing of goat skin.

Identification of micro organisms

The various staining techniques, such as, grams staining, spore staining and motility test, and biochemical tests, such as, indole production test, methyl red test, vogues–proskauer test, citrate utilization test, urease test, triple sugar iron agar test, mannitol motility test, catalase test, and oxidase test were carried out for the identification of morphological, physiological, and biochemical characterization of isolated microorganism (Gehring 2002). For further conformation it was sent to IMTECH, Chandigarh, India and was identified as Bacillus subtilis.

Selective screening for collagenase activity on gelatin agar plates

Glucose and gelatin agar powder were added to autoclaved medium containing agar, tryptone, and yeast agar. This medium was poured into petri plates and inoculums were added to these media after solidification. Then the plates were incubated at 37°C and no colonies were formed on selective media. The strains that did not show any clear zone in petri plates were identified.

Selective screening for protease activity on skimmed milk agar plates

Glucose and skimmed milk agar powder were added to autoclaved medium containing agar, tryptone, and yeast extract. This medium was poured into petri plates and inoculums were added to these media after solidification. Then the plates were incubated at 37°C and the strains that show clear zone were identified.

Production of enzyme

Nutrient broth was used for studies related to production of proteolytic enzyme. A quantity of 250 ml of this broth was dispensed in 500 ml of Erlen Meyer flask and sterilized in 121°C at 1 atm for 15 min in autoclave and inoculated with the desired cultures. It was then incubated at 37°C for 24–48 h. Then the broth was centrifuged at 12,000 rpm for 20 min at 4°C and the supernatant was taken for the experiment. The supernatant containing the crude enzyme was assayed for its activity. The protein content present was estimated by Lowry’s method using bovine serum albumin (BSA) as standard.

Purification of enzyme

The ammonium sulphate precipitation method was used for protein precipitation, because it was highly soluble in water and had no deleterious effect. This process was carried out at 0–10°C to minimize the supernatant denaturation and was fractioned by adding 30% ammonium sulphate (Hi-pure fine chem, Industry) and incubated overnight for at 4°C (Qiang He et al. 2006). The precipitated biomass was separated and dried; after that protein was estimated by Lowry’s method. Further the dried biomass was used for application process.

Enzyme assay

The enzyme activity in the crude enzyme powder was determined by a modified method of Anson (Anson 1938). Using 1% w/v casein containing 2 Mm CaCl2 in 0.02 M Borate buffer, pH 8.0, and incubating the reaction mixture at 45°C for 30 min. One unit of enzyme activity is defined as the amount of enzyme required to liberate 1 μg of tyrosine under standard assay conditions. The data represent the mean of three sets of experiments performed in duplicate.

Dehairing studies

Dehairing study was carried out at commercial level (400 kg) at one of the tannery in Pernambut sector. Paste method of dehairing was followed for both experiments and control sample. Protease at different levels (1, 2, and 4% for Experiment 1, 2, 3) were dissolved in the water (10%) and made into paste. The paste was applied on the flesh side of the skin then folded and left for 12–24 h. After this duration, dehairing was done manually and carefully with a blunt knife. Similarly to compare the efficacy of dehairing of the experimental samples; conventional dehairing was also carried out using water 10%, sodium sulfide 2%, and lime 10% (weight is based on wet salted skin weight basis). The control experiment was also carried out in a similar (basis taken carefully before starting process) way as described above and dehaired with the same duration. The scale of dehairing was observed as follows: (a) difficult dehairing, (b) slight dehairing, (c) moderate dehairing, (d) complete dehairing. The dehaired skins were processed to crust leather and the leather properties were observed at each step. The pollution load generated in dehairing process, the functional groups observed in the spent liquor of the dehaired sample was carried out before the skin was processed into the leather (Punitha et al. 2008). The skin was then tanned and dyed and made into crust leather. Then the leathers were assessed for color measurement properties, SEM properties, and physical testing properties.

Pollution load generated in dehairing process

The spent liquor from control and experimental sample after dehairing process were collected from various stages and analyzed for the pollution loads such as bio chemical oxygen demand (BOD), chemical oxygen demand (COD), total dissolved solids (TDS), and total suspended solids (TSS) using the standard method (Eaton et al. 1995; Thangam et al. 2001). The results are expressed in parts per million (ppm) of the sample.

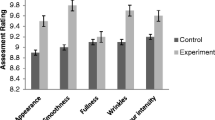

Color measurement studies

It is obvious that the crust leather obtained from the dehairing experiments by treating with enzyme may vary fiber splitting property and therefore it is important to study the color values of the dyed crust leathers, which had been dehaired using protease in the experiment. All color measurements were carried out using Gretag Macbeth Spectrolino spectrophotometer with the measurement geometry of 45°/0° and L, a, b, c, H, and ΔE were obtained using standard procedure.

Physical testing

Samples for various physical tests from experimental and control crust leathers were obtained as per IULTCS standard method. Specimens were conditioned at 80 ± 4°C and 65 ± 2% RH. Over a period of 48 h, physical properties such as tensile strength, % elongation at break, tear strength, and grain crack were examined for both experimental and control sample.

SEM studies

The samples, after making the crust leather, were subjected to SEM studies to assess the effect of fiber splitting in the experimental sample for the presence of hair in the grain surface and fiber orientation in the cross section of leather. A JOEL JSM 5300 scanning electron microscope was used to study cross section of the leather.

Results and discussion

Enzyme is a kind of biocatalyst which can react with components of skin such as collagen protein, keratin, glycoprotein and fat, etc., and is helpful in removing unwanted components of leather during leather processing. Several researchers have tried and rationalized enzymatic dehairing as an alternative to sulfide dehairing. Even then, tanners are hesitant to use the enzyme because the quality and activity of proteases used in traditional process are so unstable that it can lead to inefficient dehairing. Therefore, application of enzymes in dehairing is limited to some extent. Taking into account of limitations of conventional dehairing, enzymatic dehairing process with or without sulfide plays a major role that needs much attention.

Dehairing of skin is removal of hair by using enzyme, where the root of the hair is attacked by a selective proteolytic action. The mechanism of enzymatic dehairing is based on the capacity to break the number of peptide bonds that surrounds the basement membrane of the hair bulb that constitutes mainly proteoglycans such as glycosaminoglycans and dermatan sulphate, thereby, removing hair very safely. The primary objective of the experiment is to isolate and utilize the enzyme for dehairing of skin to reduce pollution problem that are arising out of using lime and sodium sulfide in the conventional dehairing of leather in leather processing.

Biochemical tests

The bacterial sp. isolated from fresh goat skins were cultured by nutrient agar medium and the cultures were examined for various biochemical tests for the suitability of using for further operation.

The cultures were tested for various biochemical tests and the results are shown in Table 1 and Fig. 1. The identified cultures were of Bacillus subtilis and they were selected for further study. The present culture showed positive result with the Indole test. Hence it is confirmed that the culture is Bacillus in nature (Fig. 1). It is seen from the Fig. 1 that the sample produces pink color and this due to hydrolysis of tryptophan by tryptophanase enzyme and subsequent release of indole, pyruvic acid, and ammonia that produces pink color in the medium used.

Screening of protease producing bacteria

The four obtained cultures were further screened for protease activity. For this; the cultures were treated in the skimmed milk agar medium and observed for clear zone in the plate and the results are shown in Fig. 2. It is shown from the Fig. 2 that there is a clear zone in the plate and this is due to the hydrolysis of protein of milk by protease. It is evident that the enzyme produced by species is of protease in nature. Among four, two were found to be the best protease producers. The culture that gave the maximum zone of proteolysis was taken for enzyme production.

The identified culture was further tested for collagenolytic activity by using gelatin agar medium and is presented in the Fig. 3. It is seen from the figure that there is no clear zone formation in the gelatin agar plate and this may be due to the fact that the present culture does not produce any collagenases and therefore the culture can be very well used for the dehairing study.

Purification of enzyme

The enzyme that can dehair the skin belongs to the category of protease. Bacillus subtilis also produces protease enzyme and hence the enzyme is of greater significance in the present approach. The protease enzyme obtained from Bacillus subtilis was partially purified and used for dehairing of skin in leather processing operation (Fig. 4). The crude enzyme was purified by using ammonium sulphate and ice cold ethanol.

Enzyme activity

The activity of the enzyme was found out at the different parameters of pH, duration and temperature. The results of the activity of the enzyme are presented in Table 2. The activity of the protease is very high at pH of 9. It was 1.42 (U/ml). The activity shows decreased trend on either side of the optimum pH. Similarly the activity is high at 37°C and the activity was 1.46 (U/ml). The optimum duration is 36 h for the enzyme activity. However, the enzyme showed better activity in the purification step. The activity of the enzyme was increased to three fold after purification step. It has been found that Bacillus subtilis are producers of large variety of extra-cellular enzymes of proteases. The purified enzyme proved to be a potential dehairing agent in leather processing.

Application of the protease enzyme on fresh goat skins for dehairing studies

Tables 3 and 4 show dehairing efficacy of various dehairing experiments. The dehairing effect was observed at different duration from 12 to 24 h. It is seen from the tables that experiment 3 (carried out with protease 4% + water 10%) shows complete dehairing at the end of 12 h as compared with other two experiments (1 and 2). The experiment 2 shows complete dehairing at the end of 16 h. The reason behind complete dehairing of the skin in the experiment 3 was due to the use of optimum quantity of protease that expedited the dehairing activity. The experiment 1 shows moderate dehairing and this may be due to the fact that the enzyme concentration was not sufficient to dehair completely. The Fig. 5 shows dehaired skin sample and Fig. 6 shows control sample of skin before dehairing. The conventionally dehaired sample carried out with the help of lime 10% and sodium sulphide 2% showed complete dehairing. The major differences observed in the control sample are black coloration and better swelling and plumping as compared to the experimental sample. This may be due to the fact more amounts of lime and sulphide used in the control sample. Several workers have carried out enzymatic dehairing by using protease. It has been concluded that the skin hydrolyzed by facultative anaerobic microbes such as Bacillus species and Pseudomonas species are capable of dehairing the skins at both aerobic and anaerobic conditions, but the hydrolysis of skin collagen was found less when the organisms were grown anaerobically studied on jawasee protease, microbial protease, and on lime for dehairing system.

Alkaline protease isolated from a new strain Alcaligenes faecalis was evaluated for its unhairing potential in leather processing. The enzyme is relatively stable in the pH range of 8–11 and at temperature up to 30°C for 24 h. Unhairing action was found to be best at pH 9 and at the temperature of 30–37°C with 0.5% w/w enzyme concentration. Microscopic studies of the unhaired skins and the physical properties of the enzyme-treated finished leathers were well comparable with leather processed by conventional methods. These results indicate that the protease produced by A. faecalis is suitable for unhairing and can be exploited as an eco-friendly unhairing agent for leather processing.

It has been found that proteases were capable of causing depilation of skins. If, however, the skin is pre-treated with strong alkali, a preparation that includes proteases with a narrower range of specificities may be sufficient to induce depilation. The model helped to disrupt the basal membrane at the dermal-epidermal junction through the degradation of its constituent molecular components by combination of proteases with alkali, resulting in the removal of both the epidermis and associated wool or hair (Brady et al. 2002).

It is evident from these results that complete dehairing was possible in 16 h duration by using 2% of enzyme in our experiments, where as, it requires 24 h in the case of protease produced by Alcaligenes faecalis (Thangam et al. 2001). The other difference was the strain and the strain was produced from tannery soil as compared to the strain produced from skin in our experiment. The dehairing work carried out by Brady et al. (2002) showed that skins pretreated with alkali produced better results. It has been found that complete dehairing was achieved for the above work at the duration of 12 h, whereas, this study had no such pretreatments and has been carried out with enzyme alone. The alkaline pretreatment helps to reduce the amount of enzyme and also the duration of dehairing. Compare to the above methods, this study is very economical and helps in reducing the chemical usage thereby reducing the environmental pollution.

Pollution load generated in dehairing experiments

Table 5 shows the pollution load generated in dehairing process. It is seen from the table that due to use of protease there is a reduction in pollution loads such as BOD, COD, TDS, and TSS in comparison with control sample. The control sample shows more amounts of pollution loads in dehairing experiment. It has been found from the experiment 3 that there is a reduction of BOD, COD, TDS, and TSS at the level of 62.8, 79, 88.2, and 82.5%, respectively. The experimental skin also shows complete dehairing along with 50% reduction in the suspended solids level.

This study carried out using enzyme for hide depilation without sulfur contaminant has been studied (Nashy et al. 2005). The process does not use sodium sulfide, involves recycling of lime liquor. It has performed successful unhairing of sheep skins and cattle hides with a neutral amylase containing metallic proteinase derived out of Streptomyces hygroscopicus to reduce the sulfide loads in the waste waters of conventional unhairing process. There was a tremendous reduction in pollution load in the dehairing process that was dehaired with enzyme. The skins dehaired with jawasee protease showed the reduction of BOD value in the effluent.

Color measurement study for the leather

The enzymatic dehairing in general, increases the fiber splitting of the collagen fibers. These ‘fibers splitting’ some time may influence the uptake of the chemicals. Hence, the color measurements of the crust leather were studied after dyeing with suitable dye. The experimental sample shows lighter in shade as indicated by ΔL value. It is seen from the Table 6 that the chrome treated experimental leather had more of greener component in comparison with that of control sample as shown by Δa value. Similarly Δb value for the experimental sample shows bluer shade. There is not much appreciable change noted in experimental sample. The hue difference of the experimental sample shows a decreasing trend towards the greenish bluer hue. The magnitude of the overall color difference ΔE CIE for the experimental sample is increasing and this is due to the increase in color uptake of the leather.

Physical testing for crust leather

Table 7 shows the physical strength properties of the crust upper leather. The leathers obtained from all the experiments show comparable tensile and tear strength values relative to control leather. The elongation at break for the experimental leathers made out of this study was comparable to the control sample. The ‘strength’ property is the evidence that the leather produced in the experiment does not show any alteration in leather property.

SEM studies

The Figs. 7a–d shows the SEM for the crust leather that has been dehaired with protease enzyme and control sample. The figure shows the grain surface of the crust leather and cross section view of the samples. It is seen from the figure that there was absence of short hair in the sample from SEM figures. It is also evident that there was comparable fiber orientation and compactness in both experimental and control samples. The angle of view of the experiment sample was similar to the control sample.

Conclusion

In this study, the protease enzyme is found to be capable of dehairing goat skins at commercial level. The enzyme helps to replace/reduce the sodium sulfide that is harmful and causes lot of pollution problem in terms of BOD and COD. Hence, the enzyme developed is not only advantageous in eliminating sulfide but also benevolent in attaining better leather qualities. The pollution loads such as BOD, COD, TSS, and TDS were reduced at the level of 62.8, 79.0, 88.2, and 82.5% in comparison with the control one. The color measurements of the experimental leather were better than the control sample because of more uptake of dye in the experimental sample than in the control sample. The physical strength properties of the experimental crust upper leathers were comparable to the control leather. The SEM studies showed the absence of short hair and comparable fiber orientation and compactness in both experimental and control samples.

References

Annapurna Raju A, Chandrababu NK, Samivelu N, Rose C, Muralidhara Rao N (1996) Eco-friendly enzymatic dehairing using extra-cellular proteases from a Bacillus species isolate. J Am Leath Chem Ass 91:115–118

Anson ML (1938) The estimation of pepsin, papain, and cathepsin with hemoglobin. J Gen Physiol 22:79–89

Arunachalam C, Saritha K (2009) Protease enzyme an eco-friendly alternative for leather industry. Ind J Sci Technol 2(12):29–32

Brady D, Duncan JR, Rusell AE (2002) Purification of extra-cellular protease produced by Proteus vulgaris. J Am Leath Chem Ass 78:153–156

Dayanandan A, Kanagaraj J, Sounderraj L, Govindaraju R, Suseela Rajkumar G (2003) Application of an alkaline protease in leather processing: an ecofriendly approach. J Clea Prod 11:533–536

Dettmer A, Ayub MAZ, Gutterres M (2011) Hide unhairing and characterization of commercial enzymes used in leather manufacture. Braz J Chem Eng 28(3):381–391

Eaton AD, Clesceri LS, Greenberg AE (1995) Standard Methods of the examination of water and waste water. The American Public Health Association (APHA), Washington

Gehring A (2002) Unhairing with proteolytic enzymes derived from Streptomyces griseus. J Am Leath Chem Ass 91:406–411

He Q, Yuo K, Sun DH, Shi B (2006) Biodegradability of wastewater from enzymatic soaking and unhairing processes in leather manufacture. J Am Leath Chem Ass 101:217–230

Jians S, Wenyi T, Wuyong C (2010) Studies on the application of ultrasound in leather enzymatic unhairing. Ultrason Sonochem 17(2):376–382

Kanagaraj J (2009) Cleaner leather processing by using enzymes: a review. Adv Biotech 4:13–18

Kayalvizhi K, Anthony T, Gunasekaran P (2008) Characterization of the predominant bacteria associated with sheep and goat skin. J Am Leath Chem Ass 103:182–187

Nashy EHA, Ismail SA, Ahmady AM, El-Fadaly H, El-Sayed NH (2005) Enzymatic bacterial dehairing of bovine hide by a locally isolated strain of Bacillus lichniformis. J Soc Leath Technol Chem 89:242–249

Oppong D, Stephen Bryant D, Rangarajan R, Steele S (2006) Application of molecular techniques to identify bacteria isolated from the leather industry. J Am Leath Chem Ass 101:140–145

Punitha V, Kannan P, Saravanabhaven S, Thanikaivelan P, Rao JR, Saravanan P, Nair B (2008) Enzymatic removal of melanin in enzyme based dehairing and fiber opening. J Am Leath Chem Ass 103(7):203–208

Song S, Tao W, Chen W (2011) Kinetics of enzymatic unhairing by protease in leather industry. J Clea Prod 119(4):325–331

Subba rao CH, Sathish T, Ravichandra P, Prakasam RS (2009) Characterization of thermo and detergent stable serine protease from isolated Bacillus circulans and evaluation of eco-friendly applications. Proc Biochem 44:262–268

Thangam EB, Nagarajan T, Rajkumar SG, Chandrababu NK (2001) Application of alkaline protease isolated from Alkaligens faecalis for enzymatic unhairing in tanneries. J Am Leath Chem Ass 96:127–132

Verma A, Pal HS, Singh R, Agarwal S (2011) Pottential of Alkaline protease isolated from Thermoactinomyces sp. RM4 as an alternative to conventional chemicals in leather industry dehairing process. Int Jr Agril Env Biotech 4(2):173–178

Wang R, Min C, Haiming C, Li Z (2009) Enzyme unhairing an eco-friendly biotechnological process. J Soc Leather Technol Chem 93:51–55

Wei X, Lifen H, Lei Z (2010) Cleaner dehairing technology for goatskins: effects of hydrosulfide and peroxide on enzyme unhairing. Adv Mat Res 113–114:1726–1731

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Senthilvelan, T., Kanagaraj, J. & Mandal, A.B. Application of enzymes for dehairing of skins: cleaner leather processing. Clean Techn Environ Policy 14, 889–897 (2012). https://doi.org/10.1007/s10098-012-0458-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-012-0458-5