Abstract

The deformation modulus of a rock mass is one of the crucial parameters used in the design of surface and underground rock engineering structures. Due to the problems in determining the deformability of jointed rock masses at the laboratory scale, various in-situ test methods have been developed. Although these methods are currently the best techniques, they are expensive and time-consuming, and present operational problems. To overcome this difficulty, in this paper, based on the basic concepts of a rock engineering systems (RES) approach, a new model for the prediction of the deformation modulus of a rock mass is presented. The newly proposed approach involves seven effective parameters (depth, rock quality designation, uniaxial compressive strength, the discontinuity density, the condition of discontinuities, the groundwater condition, and an adjustment for the orientation of discontinuities) pertinent to the deformation modulus of a rock mass, yet keeping simplicity as well. The performance of the RES model is compared with multiple regression models. The estimation abilities offered using RES and multiple regression models were presented by using field data obtained from road and railway construction sites in Korea. The results achieved indicate that the RES-based model predictor with the least mean square error and a higher coefficient of determination (R 2) performs better than the multiple regression models.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The deformation modulus of a rock mass is an important parameter for the design and successful execution of rock engineering structures, because the modulus of deformation is the best representative parameter of the pre-failure mechanical behavior of the rock mass (Fattahi 2016; Gholamnejad et al. 2013). There are several approaches to determine the deformation modulus of rock mass directly, by in-situ tests; plate loading test (PLT), like a pressure meter (Chun et al. 2009), plate jacking, cable jack, flat jack, radial jacking and geophysical methods. Although in-situ techniques are the best methods to determine the deformability modulus of rock masses, they are expensive, time-consuming and can only be performed when the exploration spaces are excavated (Gholamnejad et al. 2013). In recent years, the number of empirical approaches used for estimating the deformation modulus of rock masses has increased. The first empirical equation, which considers only rock mass rating (RMR) as an input parameter, was proposed by Bieniawski (1973). The main limitation of Bieniawski’s approach is that it has to be used for rock masses with RMR >50. Serafim and Pereira (1983) proposed an equation for rock masses with RMR <50 to overcome the limitation of Bieniawski’s equation. Hoek and Brown (1997) proposed an empirical equation based on the geology strength index (GSI) and uniaxial compressive strength (UCS) of intact rock. Mitri et al. (1995) and Nicholson and Bieniawski (1990) used two empirical equations to estimate the deformation modulus of a rock mass by reducing the elasticity modulus of the intact rock (E i ) based on the RMR value. Barton (2002) obtained a formula including tunneling quality index (Q) system and UCS. Gokceoglu et al. (2003) introduced an empirical equation based on UCS, rock quality designation (RQD) and weathering degree (WD) of rock. Kayabasi et al. (2003) presented the relation based on WD, E i and RQD. Zhang and Einstein (2004) presented an empirical equation based on E i and RQD. Palmström and Singh (2001) proposed relations based on the rock mass index (RMI) classification system. Hoek and Diederichs (2006) proposed formulas based on GSI and D (factor of disturbance). Sonmez et al. (2004) presented formulas based on Ei, GSI and D.

Also, some research works were carried out using computational intelligence methods to predict rock mass deformation modulus. For example, Sonmez et al. (2006) used artificial neural networks (ANN) for estimation of rock modulus. Majdi and Beiki (2010) used hybrid ANN and genetic algorithms for predicting the deformation modulus of rock masses. Gokceoglu et al. (2004) presented an adaptive network-based fuzzy inference system (ANFIS) model for prediction of deformation modulus of jointed rock masses.

The empirical and computational intelligence methods that are based upon the survey data from various in-situ test methods, in a certain range of rock types, cannot be generalized for various ground conditions. Furthermore, all of above models do not simultaneously consider all the pertinent parameters in the modeling. Under such limitations or constraints, the estimation of the rock mass deformation modulus needs new innovative methods such as the rock engineering systems (RES)-based model, capable of accounting for unlimited parameters in the model. The RES concept has been applied to a number of rock engineering fields, for example, evaluation of the stability of underground excavations (Ping and Hudson 1993), hazard and risk assessment of rockfall (Cancelli and Crosta 1993), evaluation and classification of the spontaneous coal combustion potential (Saffari et al. 2013), development of an assessment system for the blast ability of rock masses (Lu and Latham 1994a), prediction of backbreak in bench blasting (Faramarzi et al. 2013a), rock mass characterization for indicating natural slope instability (Mazzoccola and Hudson 1996), prediction of flyrock distance in surface blasting (Faramarzi et al. 2014), prediction of out-of-seam dilution in longwall mining (Bahri Najafi et al. 2014), assessing geotechnical hazards for tunnel boring machine (TBM) tunneling (Benardos and Kaliampakos 2004), prediction of rock fragmentation by blasting (Faramarzi et al. 2013b), prediction of the advance rate in rock TBM tunneling (Moradi and Farsangi 2014) and quantitative hazard assessment for tunnel collapses (Shin et al. 2009). It has also been widely used for different engineering problems such as forest ecosystems (Avila and Moberg 1999; Velasco et al. 2006), environmental studies on the disposal of spent fuel (Skagius et al. 1997), radioactive waste management (Agüero et al. 2008; van Dorp et al. 1998), river catchment pollution (Matthews and Lloyd 1998), risk of reservoir pollution (Condor and Asghari 2009) and traffic-induced air pollution (Mavroulidou et al. 2004).

In this paper, the RES-based model, capable of accounting for many parameters in the model, was used to estimate the rock mass deformation modulus. To validate the performance of the model proposed, it is applied to field data from road and railway construction sites in Korea. Furthermore, the results obtained are compared with multiple regression models, which are carried out for the same data.

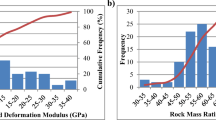

Properties of the database

To establish an RES-based method for prediction of rock mass deformation modulus, providing a dataset which includes a wide geographic distribution is the most important requirement. To achieve this, datasets given in a previous paper are borrowed (Chun et al. 2009). The collected datasets used to construct the database are from road and railway construction sites in Korea. A total of 60 datasets were collected. Each dataset contains the parameters of the RMR system (Bienniawski 1989) [rock quality designation (RQD), the discontinuity density (D d), the condition of discontinuities (D c), the groundwater condition (DW), an adjustment for the orientation of discontinuities (D o)], the measured uniaxial compressive strength (UCS; MPa), the measured deformation modulus (E m; GPa) and the depth (m) of the measurement (Table 1). The E m values were measured using pressure meter tests in most cases and performed at eight field sites which included six rock types such as granite, gneiss, andesite, tuff, sandstone and shale. The primary advantage of the pressure meter test is a relatively low cost compared to other types of tests (Chun et al. 2009). All data were randomly divided into two subsets: 80% of the total data (60 data points) was allotted to training data of RES model construction and 20% of the total data (12 data points) was allocated for test data used to assess the reliability of the developed RES model. For comparisons between RES and regression models, the same training and testing datasets were then used in regression models. the partial datasets used in this study are presented in Table 1. Also, the histograms and statistical evaluations of the data used in this research are shown in Fig. 1.

Statistical modeling

In reviewing the literatures published (Barton 2002; Bieniawski 1973; Gokceoglu et al. 2003; Hoek and Brown 1997; Hoek and Diederichs 2006; Kayabasi et al. 2003; Lagina Serafim and Pereira 1983; Mitri et al. 1995; Nicholson and Bieniawski 1990; Palmström and Singh 2001; Sonmez et al. 2004; Zhang and Einstein 2004), it is clear that many parameters can influence the deformation modulus. However, the most important parameters (D d, RQD, D c, GW, D o, UCS, D), which are easily obtainable, are shown in Table 2.

At the first stage of analysis, the significance of parameters in the modeling was investigated based upon correlations between the individual independent variables and the actual measured rock mass deformation modulus. Coefficient of determination (R 2) was used as an indicator of correlation strength. R 2 values for independent variables versus rock mass deformation modulus are presented in Table 3. It can be concluded that RQD, D d, D c, UCS and D have negligible effects on rock mass deformation modulus and should be excluded in the regression modeling. Therefore, for further statistical analysis and development of a prediction model, five independent variables were selected (RQD, D d, D c, UCS and D).

Multiple linear regression analysis

A multiple linear regression analysis was carried out between RQD, D d, D c, UCS and D as independent variables and rock mass deformation modulus as a dependent variable, using the commercial software packages for standard statistical analysis (SPSS). Based on the statistical analysis, the predictive model is as follows:

A multicollinearity analysis was carried out to check whether two or more independent variables are highly correlated. In the case of multicollinearity occurring, redundancy of the independent variables could be expected, which can lead to erroneous results. One of the most common tools for finding the degree of multicollinearity is the variance inflation factor (VIF). It has a range of 1 to infinity. Generally, if the calculated VIF is greater than 10, there may be a problem with multicollinearity (Jammalamadaka 2003). The VIF values of the independent variables in Eq. (1) were calculated, as shown in Table 4.

Also, the regression statistics, analysis of variance (ANOVA), for Eq. (1) are shown in Table 5. The model statistic value F and significance (Sig.) are used to provide enough evidence to reject the hypothesis of ‘‘no effect’’. From Table 5, an F of 32.238 and a Sig. of 0.000 (less than 0.05) were obtained, which show that the null hypothesis can be rejected.

Multiple non-linear regression analysis

Power, logarithmic, polynomial and exponential models with the same independent variables and rock mass deformation modulus as a dependent variable and also the same sets of data were used to carry out non-linear regression modeling. The mathematical equation obtained for the power model with R 2 = 0.8878 is

For logarithmic regression modeling, R 2 = 0.6397 is obtained and the relation is

Furthermore, for the polynomial model relation with R 2 = 0.8824 is

Finally, the exponential relation for regression modeling with R 2 = 0.8878 is

Rock engineering systems (RES)

The RES was introduced by Hudson (1992). It is a method which has the capability of simultaneous analysis of relations among effective parameters of a rock mass, site or structure, and discusses their interactions. For rock mechanics modeling and rock engineering design for a specific project, it is needed to be able to identify the relevant physical variables and the linking mechanisms, and then consider their combined operation. It is important to ensure that all the relevant factors and their interactions will be taken into account (Hudson 1992).

In the RES application, the interaction matrix device is the basic analytical tool and presentational technique for characterizing the important parameters and the interaction mechanisms in an RES. In the interaction matrix for a given RES, all parameters influencing the system are arranged along the leading diagonal of the matrix, called the diagonal terms. The influence of each individual factor on any other factors is accounted for at the corresponding off-diagonal position, named the off-diagonal terms. The off-diagonal terms are assigned numerical values which describe the influence degree of one factor on the other factors. Assigning these values is called coding the matrix.

Several coding methods have been developed for this purpose, such as the 0–1 binary method, the expert semi-quantitative (ESQ) method (Hudson 1992), the explicit method, continuous quantitative coding (CQC; Lu and Latham 1994b) and the probabilistic expert semi-quantitative (PESQ) method were proposed for numerically coding the interaction matrix. The most common coding method is the “expert semi-quantitative” (ESQ) method. ESQ coding has been used in nearly all previous works cited above. In this method, one unique code is deterministically assigned to each interaction, thereby expressing the effect of a parameter on another in the matrix. Typically, coding values vary between 0 and 4, with 0 indicating no interaction and 4 indicating the hyper level of interaction or “critical interaction” (Table 6). The general concept of the influences in a system is described by the interaction matrix, which is shown in Fig. 2. Here, the influence of ‘‘A’’ on ‘‘B’’ is not the same as that of ‘‘B’’ on ‘‘A’’, which means the matrix is asymmetric. Thus, it is important to put the parameter interactions in clockwise direction in the matrix.

)modified after Hudson 1992)

Illustration of the interaction matrix: a interaction matrix of two factors, b general illustration of the coding of interaction matrix and the set-up of the cause and effect coordinates

In the interaction matrix, the sum of a row is called the ‘‘cause’’ value and the sum of a column is the ‘‘effect’’ value, denoted as coordinates (C,E, respectively) for a particular parameter. The coordinate values for each parameter can be plotted in cause and effect space, forming the so-called C–E plot. The interactive intensity value of each parameter is denoted as the sum of the C and E values (C + E) and it can be used as an indicator of parameters’ significance in the system. That is, the weight for parameter i, indicated by a i , is given by its ‘‘parameter interaction intensity’’ (C i + E i ) divided by the (total) sum of interaction intensities of all parameters in the system (Hudson 1992).

An RES-based model to predict rock mass deformation modulus

The principles of RES were used in the vulnerability index (VI) methodology concept, first introduced by Benardos and Kaliampakos (2004), to identify the vulnerable areas that may pose a threat to the TBM tunneling operation. As there is an obvious relation between advance rate and the associated risk encountered, this concept was also used to predict the advance rate in TBM tunneling.

In this research, a similar methodology, inspired by previous works carried out (Faramarzi et al. 2013a, b; Benardos and Kaliampakos 2004) is adopted to define a model and predict the rock mass deformation modulus. In defining the new model, three main steps must be taken into account. The first steps are to identify the parameters that are responsible for the occurrence of risk, analyze their behavior and evaluate their significance (weight) in the overall risk conditions. In this step, the RES principles can be used to assess the weighting of the parameters involved.

In the second step, the VI can be determined (Benardos and Kaliampakos 2004):

where a i is the weighting of the ith parameter, Q i is the value (rating) of the ith parameter, and Q max is the maximum value assigned for ith parameter (normalization factor).

Based upon the estimated VI and the classification of the VI, which is divided into three main categories with different severity of the normalized scale of 0–100 (Table 7; Benardos and Kaliampakos 2004). In category I, small-scale problems are expected that cannot significantly affect the results. In category II, which must be taken into account. In category III, which might cause several difficulties during the loading and unloading must be considered.

In the third step, a relation between rock mass deformation modulus and VI can be determined. Based upon this new relation, the rock mass deformation modulus for every in-situ test can be obtained having VI.

The most important parameters in the RES-based model

Parameters in Table 8 as well as three descriptive parameters, discontinuity condition, rock properties and groundwater condition, were used to define the RES-based model.

Interaction matrix and rating of parameters

Interaction matrix

The seven principal parameters affecting on the rock mass deformation modulus are located along the leading diagonal of the matrix and the effects of each individual parameter on any other parameter (interactions) are placed on the off-diagonal cells. The assigning of values to off-diagonal cells and coding the matrix were carried out using the ESQ coding method as proposed by Hudson (1992). Based upon the views of three experts, working in the field of rock engineering for many years, the interaction matrix for the parameters affecting the rock mass deformation modulus is established as presented in Table 9. As it can be seen in Tables 3 and 9, the views of three experts (Table 9) have good compliance with individual relations in Table 3.

Table 10 gives cause (C), effect (E), interactive intensity (C + E), dominance (C–E) and weight of each parameter (a i ). As it can be seen in Table 10, burden has the highest weight in the system, and highly controls other elements. The E–C histogram and C + E for each parameter are illustrated in Figs. 3 and 4, respectively. The points below the C = E line are called dominant and the points above the C = E line are called subordinate.

Rating of parameters

The rating of the parameter’s values was carried out based upon their effect on the rock mass deformation modulus. In total, five classes of rating, from 0 to 4, were considered, where 0 denotes the worst case (most unfavorable condition) and 4 the best (most favorable condition). The rating of each parameter is presented in Table 11. The ranges of parameters in Table 11 were proposed based on the judgments of three experienced experts in the field of rock engineering.

Risk analysis and rock mass deformation modulus prediction

A dataset that includes 60 data points was employed in the current study, while 48 data points (80%) were applied to determine the associated VI for each data point using Eq. (7) and the remaining data points (12 data points) were utilized for assessing the degree of accuracy and robustness.

To make the methodology more understandable, an example of determining VI for data point no. 1 is shown in Table 12. Variations in the VI for the 48 data points are shown in Fig. 5. As it can be seen, the mean of VI is close to 40, showing that the level of risk is in the second category (medium–high).

Based on the calculated VI and measured rock mass deformation modulus for 48 data points, a logarithmic regression analysis was carried out [Fig. 6 and Eq. (8)] with a coefficient of determination (R 2) of 0.81 being obtained. This relation can be used as a predictive model to predict the rock mass deformation modulus based on VI.

Evaluation of models performance

12 data points (out of 60 data points) were used and the results obtained are shown in Table 13. Also, for 12 data points, a comparison was made between the predicted and the measured rock mass deformation modulus for different models as shown in Fig. 7.

To verify the performance of the models, two statistical criteria viz. mean squared error (MSE) and squared correlation coefficient (R 2) were chosen to be the measures of accuracy. Let t k be the actual value and \( \hat{t}_{k} \) be the predicted value of the kth observation and n be the number of observations; then, MSE and R 2 could be defined, respectively, as follows:

The results of performance analysis of different models are shown in Table 14.

As it can be seen from the performance indices (Table 14), the RES-based model with R 2 = 0.9245 and MSE = 0.0175 shows the best agreement with the measured rock mass deformation modulus and works better in comparison with other models.

Conclusions

In this paper, a new approach, namely an RES-based model, is proposed for predicting the rock mass deformation modulus. The RES-based model is an expert-based model, which can deal with the inherent uncertainties in the geological systems. Also, it has the advantage of considering unlimited input parameters, which may effect the system. Moreover, it has the merit of considering descriptive input parameters which are not applicable in statistical modeling.

It is concluded that the RES-based model with performance indices R 2 = 0.9245 and MSE = 0.0175 performs better than linear, polynomial, power, logarithmic and exponential models. This study shows that the RES-based model can be used as a powerful tool for modeling of some problems involved in rock engineering.

References

Agüero A, Pinedo P, Simón I, Cancio D, Moraleda M, Trueba C, Pérez-Sánchez D (2008) Application of the Spanish methodological approach for biosphere assessment to a generic high-level waste disposal site. Sci Total Environ 403:34–58

Avila R, Moberg L (1999) A systematic approach to the migration of 137Cs in forest ecosystems using interaction matrices. J Environ Radioactiv 45:271–282

Bahri Najafi A, Saeedi GR, Ebrahimi Farsangi MA (2014) Risk analysis and prediction of out-of-seam dilution in longwall mining. Int J Rock Mech Min Sci 70:115–122

Barton N (2002) Some new Q value correlations to assist in site characterization and tunnel design. Int J Rock Mech Min Sci 39:185–216

Benardos A, Kaliampakos D (2004) A methodology for assessing geotechnical hazards for TBM tunnelling—illustrated by the Athens Metro, Greece. Int J Rock Mech Min Sci 41:987–999

Bieniawski Z (1973) Engineering classification of rock masses. Trans S Afr Inst Civ Eng 15:335–344

Bienniawski Z (1989) Engineering rock mass classification. Wiley, New York

Cancelli A, Crosta G (1993) Hazard and risk assessment in rockfall prone areas Risk and reliability in ground engineering. Thomas Telford, London, pp 177–190

Chun B-S, Ryu WR, Sagong M, Do J-N (2009) Indirect estimation of the rock deformation modulus based on polynomial and multiple regression analyses of the RMR system. Int J Rock Mech Min Sci 46:649–658

Condor J, Asghari K (2009) An alternative theoretical methodology for monitoring the risks of CO2 leakage from wellbores. Energy Proc 1:2599–2605

Faramarzi F, Farsangi ME, Mansouri H (2013a) An RES-based model for risk assessment and prediction of backbreak in bench blasting. Rock Mech Rock Eng 46:877–887

Faramarzi F, Mansouri H, Ebrahimi Farsangi M (2013b) A rock engineering systems based model to predict rock fragmentation by blasting. Int J Rock Mech Min Sci 60:82–94

Faramarzi F, Mansouri H, Farsangi MAE (2014) Development of rock engineering systems-based models for flyrock risk analysis and prediction of flyrock distance in surface blasting. Rock Mech Rock Eng 47:1291–1306

Fattahi H (2016) Application of improved support vector regression model for prediction of deformation modulus of a rock mass. Eng Comput 32:567–580

Gholamnejad J, Bahaaddini H, Rastegar M (2013) Prediction of the deformation modulus of rock masses using artificial neural networks and regression methods. J Min Environ 4:35–43

Gokceoglu C, Sonmez H, Kayabasi A (2003) Predicting the deformation moduli of rock masses. Int J Rock Mech Min Sci 40:701–710

Gokceoglu C, Yesilnacar E, Sonmez H, Kayabasi A (2004) A neuro-fuzzy model for modulus of deformation of jointed rock masses. Comput Geotech 31:375–383

Hoek E, Brown E (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34:1165–1186

Hoek E, Diederichs M (2006) Empirical estimation of rock mass modulus. Int J Rock Mech Min Sci 43:203–215

Hudson JA (1992) Rock engineering systems: theory and practice. Horwood, Chichester

Jammalamadaka SR (2003) Introduction to linear regression analysis. Am Stat 57:67–87. doi:10.1198/tas.2003.s211

Kayabasi A, Gokceoglu C, Ercanoglu M (2003) Estimating the deformation modulus of rock masses: a comparative study. Int J Rock Mech Min Sci 40:55–63

Lagina Serafim J, Pereira J (1983) Considerations on the geomechanical classification of Beniawski. In: International symposium on engineering geology and underground construction, pp II, 33-II, 42

Lu P, Latham J (1994a) A continuous quantitative coding approach to the interaction matrix in rock engineering systems based on grey systems approaches. In: Proceedings of 7th international congress of the IAEG, Lisbon, Portugal, pp 4761–4770

Lu P, Latham JP (1994b) A continuous quantitative coding approach to the interaction matrix in rock engineering systems based on grey systems approaches. In: Proceedinsg of the 7th international congress of IAEG. Balkema, Rotterdam, pp 4761–4770

Majdi A, Beiki M (2010) Evolving neural network using a genetic algorithm for predicting the deformation modulus of rock masses. Int J Rock Mech Min Sci 47:246–253

Matthews M, Lloyd B (1998) The river test catchment surveillance project South Water Utilities Final Research Report, Department of Civil Engineering, University of Surrey, UK

Mavroulidou M, Hughes SJ, Hellawell EE (2004) A qualitative tool combining an interaction matrix and a GIS to map vulnerability to traffic induced air pollution. J Environ Manag 70:283–289

Mazzoccola D, Hudson J (1996) A comprehensive method of rock mass characterization for indicating natural slope instability. Q J Eng Geol 29:37–56

Mitri H, Edrissi R, Henning J (1995) Finite-element modeling of cable-bolted stopes in hard-rock underground mines. Trans-Soc Min Metall Explor Inc 298:1897–1902

Moradi MR, Farsangi MAE (2014) Application of the risk matrix method for geotechnical risk analysis and prediction of the advance rate in rock TBM tunneling. Rock Mech Rock Eng 47:1951–1960

Nicholson G, Bieniawski Z (1990) A nonlinear deformation modulus based on rock mass classification. Int J Min Geol Eng 8:181–202

Palmström A, Singh R (2001) The deformation modulus of rock masses—comparisons between in situ tests and indirect estimates. Tunn Undergr Sp Tech 16:115–131

Ping L, Hudson J (1993) A fuzzy evaluation approach to the stability of underground excavations. In: ISRM international symposium-EUROCK 93. International Society for Rock Mechanics

Saffari A, Ataei M, Ghanbari K (2013) Applying rock engineering systems (RES) approach to evaluate and classify the coal spontaneous combustion potential in Eastern Alborz coal mines. Int J Min Geo Eng 47:115–127

Serafim JL, Pereira JP (1983) Considerations of the geomechanics classification of Bieniawski. In: International symposium on engineering geology and underground construction, pp 1133–1144

Shin H-S, Kwon Y-C, Jung Y-S, Bae G-J, Kim Y-G (2009) Methodology for quantitative hazard assessment for tunnel collapses based on case histories in Korea. Int J Rock Mech Min Sci 46:1072–1087

Skagius K, Wiborgh M, Ström A, Morén L (1997) Performance assessment of the geosphere barrier of a deep geological repository for spent fuel: the use of interaction matrices for identification, structuring and ranking of features, events and processes. Nucl Eng Des 176:155–162

Sonmez H, Ulusay R, Gokceoglu C (2004) Indirect determination of the modulus of deformation of rock masses based on the GSI system. Int J Rock Mech Min Sci 41:849–857

Sonmez H, Gokceoglu C, Nefeslioglu H, Kayabasi A (2006) Estimation of rock modulus: for intact rocks with an artificial neural network and for rock masses with a new empirical equation. Int J Rock Mech Min Sci 43:224–235

van Dorp F, Egan M, Kessler JH, Nilsson S, Pinedo P, Smith G, Torres C (1998) Biosphere modelling for the assessment of radioactive waste repositories; the development of a common basis by the BIOMOVS II reference biospheres working group. J Environ Radioactiv 42:225–236

Velasco H, Ayub J, Belli M, Sansone U (2006) Interaction matrices as a first step toward a general model of radionuclide cycling: application to the 137 Cs behavior in a grassland ecosystem. J Radioanal Nucl Ch 268:503–509

Zhang L, Einstein H (2004) Using RQD to estimate the deformation modulus of rock masses. Int J Rock Mech Min Sci 41:337–341

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fattahi, H., Moradi, A. A new approach for estimation of the rock mass deformation modulus: a rock engineering systems-based model. Bull Eng Geol Environ 77, 363–374 (2018). https://doi.org/10.1007/s10064-016-1000-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-016-1000-5