Abstract

The rock mass deformation modulus is an important parameter for analysis of the mechanical behaviour rock structures. Due to high cost, time consuming activity and difficulties in interpretation of in-situ measurements, a number of empirical methods have been developed to estimate the deformation modulus on the basis of classification systems. However, due to a large number of empirical equations, the practical rock engineers have encountered the question which empirical relationship provides the most reliable estimation of the deformation modulus. This paper combines a review of empirical equations and statistical analyses based on the case studies from Iranian geography. Results of ninety-nine plate jacking tests from three dams and hydropower projects were used to evaluate the predictive performance of these empirical methods. Statistical analyses show that the Hoek and Diederichs (Int J Rock Mech Min Sci 43:203–215, 2006) and Ajalloeian and Mohammadi (Bull Eng Geol Environ 73:541–550, 2014) relationships provide the most precise and accurate estimation of the deformation modulus based on the in-situ measurements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Deformability is known as one of the most important characteristics that controls the mechanical behaviour of rock masses. It is characterised by a modulus which describes the relation between the applied load and the resulting deformation. As the behaviour of rock mass is not elastic, the term deformation modulus is commonly used, which is defined as the ratio of stress to corresponding strain including elastic and inelastic behaviour (Ulusay and Hudson 2007).

Due to the discontinuous nature of the rock mass, the deformability measured in laboratory experiments on small rock samples cannot be representative of the whole rock mass from which samples are taken. Therefore, the measured modulus in these laboratory experiments is expected to be significantly higher (Bieniawski 1978a; Isik et al. 2008a).

Several in-situ methods have been developed for measurement of the deformation modulus, such as plate bearing, plate jacking, Goodman jack, flat jack, pressuremeter and dilatometer tests. There are several sources of inaccuracy in these approaches and different methods usually do not provide the same deformation modulus (Palmström and Singh 2001; Panthee et al. 2016).

The plate bearing test is one of the most common in-situ tests for measurement of the deformation modulus. The plate bearing test involves applying a load to the rock surface and measuring the resulting deformations at the surface. The calculated deformation modulus based on the surface measurements generally gives much lower values due to the damage of rock near the surface, deflection of the loading plate and closure of the gap between plate and the rock mass (Hoek and Diederichs 2006; Palmström and Singh 2001; Sharma et al. 1989).

In the dilatometer test, as the volume of the tested area is too small and tensile stresses are involved in the borehole, the calculated deformation modulus is usually 2-3 times lower (Bieniawski 1978b; Rocha 1974). Goodman jack is another borehole test where the measured deformation modulus value needs to be corrected due to contact angle between the loading platen and the borehole surface as well as the deformation of loading plates in the test (Bieniawski 1978a; Palmström and Singh 2001). Therefore, depending on the chosen correction factor, different results can be obtained. The pressuremeter test is based on the expansion of infinitely long cylindrical cavity theory. As the effected volume during borehole expansion tests may not be representative of the whole rock mass and also the presence of disturbed annulus around the borehole can result in underestimation of the deformation modulus (Isik et al. 2008b; Wittke 1990). Hoek and Diederichs (2006) stated that the in-situ down-hole jacks and borehole pressuremeter tests are the least reliable methods due to difficulty in interpretation of results particularly in hard and jointed rock masses where the stressed rock volume is too small.

It is believed that the flat jack test provides less reliable results due to the small volume of rock tested near the surface as well as difficulties in interpretation of results due to a wide scatter even in a very uniform rock mass (Bieniawski 1978a; Bieniawski 1979).

In the plate jacking test, the rock deformation is measured by extensometers placed in the drill holes. These extensometers are less sensitive to variation of pressure distribution at the surface of the loading area and also measurements of deformation at different depths provide a check against gross errors of the measurements. In this method, it is possible to assess the behaviour of rock at different depths. Therefore, the plate jacking test generally gives the best results (Benson et al. 1970; Palmström 2001; Ribacchi 1988).

In spite of high costs and operational difficulties in undertaking in-situ tests, there are several sources of uncertainties in these tests caused by blast damage, testing method and test procedure, which may result in high variability of results even in well understood methods (Aksoy et al. 2012; Bertuzzi 2017; Bieniawski 1978a; Palmström and Singh 2001). For example, the deformation modulus in a drill-and-blast audit can typically be a third of the one carefully excavated (Palmström and Singh 2001). Due to high variability of results, a large number of in-situ tests are required to evaluate the rock mass deformability by a mean value. Therefore, a good characterisation of the rock mass may provide a comparable or even better estimation of the deformation modulus using rock mass classification systems. Empirical relationships have been proposed to estimate the rock mass deformation modulus using classification systems such as the rock mass rating (RMR), the rock quality designation (RQD), the tunnelling quality index (Q) and geological strength index (GSI). However, selection of an appropriate equation among the large number of empirical relationships has been made as a challenge for practical rock engineers.

This paper aims to investigate the reliability of empirical equations in estimation of the deformation modulus. The manuscript combines a review of empirical methods and statistical analyses for evaluating the predictive performance of these methods. A comprehensive review of empirical approaches in estimation of the deformation modulus is provided in the Section “Review of empirical approaches”. Results of 99 plate jacking tests undertaken at three dam and hydropower project sites in Iran are then statistically analysed, and the predictive performance of empirical methods are evaluated.

Review of empirical approaches

As noted in a previous section, a large number of empirical equations are available for estimation of the deformation modulus. A review of empirical relationships is presented in Table 1. These empirical equations are classified based on their input rock mass classification system in Table 2. Although these equations are simple and cost-effective, some uncertainties exist in the reliability of relationships which depends on the number and quality of employed data. Input parameters of these equations should be determined in a quantitative approach and a large database of reliable in-situ measurements are required for comparison between the measured and predicted values.

Some effort has been undertaken in recent years to develop new empirical models for predicting a deformation modulus using neural networks, neuro-fuzzy modelling, Bayesian models and support vector regression (Alemdag et al. 2016; Fattahi 2016; Feng and Jimenez 2015; Gokceoglu et al. 2004; Nejati et al. 2014; Radovanović et al. 2017; Rezaei et al. 2015). However, these models suffer from the lack of physical logic in relating the modulus to input parameters in an analytical form and also do not use a parametric approach, unlike the statistical methods (Nejati et al. 2014).

As shown in Table 2, more than forty empirical equations have been developed by researchers for estimation of the deformation modulus in the last 50 years, and the number of these equations has been increased considerably in recent years. However, practical rock engineers have encountered the question which equation(s) should be used for estimation of the deformation modulus, and which one provides the most reliable result. In the following section, the reliability of empirical equations are evaluated based on the in-situ measurements in Iran. The relationships noted in Table 2 with input parameters that can be acquired easily and widely mentioned in the literature are used for the analysis.

Methodology

As noted in the Section “Introduction”, previous studies have shown that the plate jacking test provides the most reliable approach for in-situ measurement of the deformation modulus. To investigate the ability of empirical methods in estimation of deformation modulus, 99 plate jacking tests data from three dam and hydroelectric project sites in Iran were provided.

The Bakhtiary dam and hydropower project are located downstream of the Bakhtiary river in Lorestan province, in the southwest of Iran in the Zagros Mountains. It includes a 325 m tall double-curvature concrete arch dam and a hydropower plant as an underground powerhouse complex with a total capacity of 1500 MW. The dam site is located in the marly and siliceous limestone beds of the Middle Cretaceous Sarvak formation in the north-western part of the folded Zagros. Laboratory experiments undertaken on intact core samples indicate that the saturated uniaxial compressive strength is 109 ± 29 MPa and the tangential elastic modulus is 69 ± 10 GPa.

The Karun III dam site is located on the Karun river in the western Zagros mountain range, in the north-east of the Khuzestan province, southwest of Iran. The Karun III dam is a 205 m high, double-curvature concrete arch dam and the underground power plant includes 8 × 285 Francis-type turbines. The dominant geological features in this region are Asmari and Pabdeh formations which consist of folded Oligocene and Miocene-age sedimentary rocks. The sediments are underlain by limestone and argillaceous sediments in this region and the project structure was founded on limestone and marly limestone.

Karun I dam and hydropower project is located 120 km downstream of the Karun III dam. The dam is a 200 high double-curvature concrete arch dam and the dam site houses two power stations with a combined generating capacity of 2000 MW. The underground power house No. 2 is located in the Asmari formation which is comprised of thick beds of limestone with the average uniaxial compressive strength of 100 MPa.

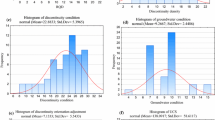

The histograms of in-situ measurements at project sites are illustrated in Fig. 1. The measured deformation modulus was in the range of 1 to 54 GPa and RMR values varied from 32 to 77. The RMR value for each plate jacking was measured, and the relationships between the RMR and the measured deformation modulus, as well as RMR and normalised deformation modulus (Erm/Ei) are shown in Fig. 2, which show sigmoid shapes in both graphs. To investigate the ability of empirical methods in estimation of the deformation modulus, forty-one relationships were chosen. These equations were selected based on their input parameters, which are well-defined and can be acquired easily without any special difficulty for their estimation (Clerici 1993). For cases where Q, RMi or GSI values were not available in the filed measurements or there was a need for conversion between classification systems, these parameters were determined using the following well-known equations;

Five statistical approaches were employed to evaluate the predictive performance of these empirical methods. Root mean square error (RMSE) measures the departure of estimated values from the measured values and shows both bias and precision where low RMSE value indicates high predictive ability. RMSE is calculated as follows:

where N is the number of data points, Ai meas and Ai pred are the measured and predicted deformation modulus, respectively. The variance accounted for (VAF) is the other statistical method which is used to measure preciseness of the prediction method, and the one with high VAF denotes high predictive performance for a given dataset. VAF is calculated as follows:

The mean absolute percentage error (MAPE) is a measure of prediction accuracy of a forecasting method and usually expresses the accuracy as a percentage as:

Low MAPE value shows high predictive performance. The coefficient of determination (R2) is a measure of how well the prediction regression equation approximates the measured data points where R2 of 100% indicates that the prediction regression line perfectly fits the measured data.

where \( {\overline{A}}_{pred} \) and \( {\overline{A}}_{meas} \) are the mean of predicted and measured deformation modulus values, respectively.

The F-test is a statistical analysis, which is used to compare the variances of two data sets, and the F-statistic can be used to evaluate the quality of regressions. The high F-statistic indicates that the error is low relative to the predicted value, and the equation with higher F-statistic has better predictive performance for a given dataset. The F-statistic is calculated as follows:

As the measured rock mass modulus values varies considerably in this study and the F-statistic is strongly influenced by the error of largest values, logarithmic transformation was applied on the input data to address this variation (Kallu et al. 2015).

Results and discussion

The predictive performance of empirical methods was evaluated using five statistical analyses of RMSE, VAF, MAPE, R2 and F-statistic, and the results are presented in Table 3. Based on each analysis, the calculated statistical values were sorted, and the results are presented in Figs. 3, 4, 5, 6 and 7 (to provide better comparisons in these figures, thirty empirical equations with higher predictive performance are shown). The number of data in statistical analyses for equations of Coon and Merritt (1970), Bieniawski (1978a, b), Grimstad and Barton (1993) and Palmström (2001) were lower than other equations due to limitation of the range of applicability of these equations, as noted in Table 1. In these equations, Mitri et al. (1994) equation tends to overestimate the deformation modulus while Isik et al. (2008a, b) equations underestimate the deformation modulus in most cases.

Comparison of the results show that different empirical equations show the highest predictive performance based on each statistical analysis. However, empirical approaches of Hoek and Diederichs (2006), Ajalloeian and Mohammadi (2014), Alemdag et al. (2015), Kavur et al. (2015) and Gokceoglu et al. (2003) in most of the analyses show high estimation accuracy compared to the others. Therefore, these equations were chosen for detailed analyses.

The prediction error (PE) is a measure of prediction accuracy for each data point and is usually expressed as a percentage as:

The negative value of PE shows underestimation while its positive value shows overestimation of the deformation modulus. The graph of prediction error for measured data points is depicted in Fig. 8. Comparison of the PE of the selected empirical approaches show that the Ajalloeian and Mohammadi (2014) and Hoek and Diederichs (2006) equations provide the lowest error in estimation of the deformation modulus while the Kavur et al. (2015) equation tends to overestimate and Gokceoglu et al. (2003) and Alemdag et al. (2015) equations tend to underestimate the deformation modulus.

The PE cumulative frequency graph of the selected empirical approaches is shown in Fig. 9. The steep curve of PE cumulative frequency, which is located close to the vertical axis, can be a good representative of prediction precision and accuracy. The Ajalloeian and Mohammadi (2014) and Hoek and Diederichs (2006) equations are the closest curves to the vertical axis. The Ajalloeian and Mohammadi (2014) equation provides the most precise estimation of the deformation modulus (due to steepness of the curve compared to the Hoek and Diederichs (2006) equation). The vertical axis intercept of the PE cumulative frequency curve can be a measure of the empirical equation trueness. The Ajalloeian and Mohammadi (2014) equation underestimates the deformation modulus in 78% of the data points while the Hoek and Diederichs (2006) equation shows underestimation in 44% of the data points.

The graph of estimated deformation modulus versus the measured one for the selected empirical equations is illustrated in Fig. 10. This graph shows that equation of Kavur et al. (2015) overestimates the deformation modulus while Alemdag et al. (2015) and Gokceoglu et al. (2003) equations underestimate the deformation modulus. Empirical relationships of Hoek and Diederichs (2006), Ajalloeian and Mohammadi (2014) slightly underestimate the deformation modulus based on this graph, but they are on the safe side from practical design considerations.

Conclusions

In this study, the predictive performance of empirical methods in estimation of the deformation modulus was evaluated. There were 99 data of plate jacking tests from three dam and hydropower project sites in Iran provided, and the reliability of empirical equations was evaluated using different statistical analyses. Results of this study clearly show that empirical equations of Hoek and Diederichs (2006) and Ajalloeian and Mohammadi (2014) provide the most precise and accurate estimation of the deformation modulus.

One of the main sources of inaccuracy in empirical estimation of the deformation modulus is related to employed data for developing the empirical equations. Several approaches have been proposed for measurement of the deformation modulus where in some of them there is a need for a correction factor due to small volume of the stressed rock mass and disturbance of the rock near the loading place. The difficulty in interpretation of the experiment results especially in anisotropic rock masses can lead to misleading estimation of the deformation modulus. The other source of inaccuracy in empirical equations is related to the limited number of measurement data in a narrow range of rock mass classification systems which results in uncertainty beyond the range for which these equations have been derived. The Hoek and Diederichs (2006) equation, which is developed based on around 500 data in a wide range of rock characteristics, provides the most reliable estimation of the rock mass modulus based on the results of this study. However, development of new equations based on a wide range of data set in well-characterised rock masses are recommended for future studies to increase the accuracy and precision of the deformation modulus estimation for practical purposes. New improvements in numerical modelling, especially in discrete element modelling, can also be employed to enhance our understanding regarding the effect of rock mass characteristics on the deformation modulus.

References

Ajalloeian R, Mohammadi M (2014) Estimation of limestone rock mass deformation modulus using empirical equations. Bull Eng Geol Environ 73:541–550. https://doi.org/10.1007/s10064-013-0530-3

Aksoy CO, Geniş M, Uyar Aldaş G, Özacar V, Özer SC, Yılmaz Ö (2012) A comparative study of the determination of rock mass deformation modulus by using different empirical approaches. Eng Geol 131-132:19–28. https://doi.org/10.1016/j.enggeo.2012.01.009

Alemdag S, Gurocak Z, Cevik A, Cabalar AF, Gokceoglu C (2016) Modeling deformation modulus of a stratified sedimentary rock mass using neural network, fuzzy inference and genetic programming. Eng Geol 203:70–82. https://doi.org/10.1016/j.enggeo.2015.12.002

Alemdag S, Gurocak Z, Gokceoglu C (2015) A simple regression based approach to estimate deformation modulus of rock masses. J Afr Earth Sci 110:75–80. https://doi.org/10.1016/j.jafrearsci.2015.06.011

Arora VK (1987) Strength and deformational behaviour of jointed rocks. Indian Institute of Technology, Delhi, India

Aydan O (1989) The stabilisation of rock engineering structures by rockbolts. In: Nagoya university. Nagoya, Japan

Aydan Ö, Ulusay R, Kawamoto T (1997) Assessment of rock mass strength for underground excavations. Int J Rock Mech Min Sci 34:18.e11–18.e17. https://doi.org/10.1016/S1365-1609(97)00273-6

Barton N Application of Q-system and index tests to estimate shear strength and deformability of rockmasses. In: International symposium on engineering geology and underground construction, Lisbon, Portugal, 1983. pp 51-70

Barton N The influence of joint properties in modelling jointed rock masses In: 8th ISRM Congress, Tokyo, Japan, 25-29 September, 1995. pp 1023-1032

Barton N Estimating rock mass deformation modulus for excavation disturbed zone studies. In: International Conference on Deep Geological Disposal of Radioactive Waste, Winnipeg, Minitoba Canada, 1996. pp 1-12

Beiki M, Bashari A, Majdi A (2010) Genetic programming approach for estimating the deformation modulus of rock mass using sensitivity analysis by neural network. Int J Rock Mech Min Sci 47:1091–1103. https://doi.org/10.1016/j.ijrmms.2010.07.007

Benson RP, Murphy DK, McCreath DR (1970) Modulus testing of rock at the Churchill falls underground powerhouse, Labrador. In: Determination of the in-situ modulus deformation of rock, ASTM STP 477. pp 89 - 116

Bertuzzi R (2017) Back-analysing rock mass modulus from monitoring data of two tunnels in Sydney, Australia. J Rock Mech Geotech Eng 9:877–891. https://doi.org/10.1016/j.jrmge.2017.05.005

Bieniawski ZT (1978a) Determining rock mass deformability: experience from case histories. Int J Rock Mech Min Sci Geomech Abstr 15:237–247. https://doi.org/10.1016/0148-9062(78)90956-7

Bieniawski ZT (1978b) Determining rock mass deformability: experience from case histories. Int J Rock Mech Min Sci Geomech Abstr 15:237–247

Bieniawski ZT A comparison of rock deformability measurements by Petite sismique, the Goodman jack and hlat jacks. In: Rapid Excavation and Tunneling Conference (RETC), Atlanta, 1979. SME

Brown ET (1970) Strength of models of rock with intermittent joints. J Soil Mech Found Div 96:1935–1949

Chun B-S, Lee Y-J, Seo D-D, Lim B-S (2006) Correlation deformation modulus by PMT with RMR and rock mass condition. Tunn Undergr Space Technol 21:231–232. https://doi.org/10.1016/j.tust.2005.12.011

Chun B-S, Ryu WR, Sagong M, Do J-N (2009) Indirect estimation of the rock deformation modulus based on polynomial and multiple regression analyses of the RMR system. Int J Rock Mech Min Sci 46:649–658. https://doi.org/10.1016/j.ijrmms.2008.10.001

Clerici A Indirect determination of rock masses - case histories. In: ISRM International Symposium - EUROCK 93, Lisbon, Portugal, 1993. pp 509-517

Coon RF, Merritt AH (1970) Predicting in situ modulus of deformation using rock quality indices. ASTM STP477

Diederichs MS, Kaiser PK (1999) Stability of large excavations in laminated hard rock masses: the voussoir analogue revisited. Int J Rock Mech Min Sci 36:97–117. https://doi.org/10.1016/S0148-9062(98)00180-6

Ebisu S, Aydan O, Komura S, Kawamoto T Comparative study on various rock mass characterization methods for surface structures. In: Rock characterization: ISRM symposium, Eurock 92, Chester, UK, 1992. pp 203-208

Einstein HH, Hirschfeld RC (1973) Model studies on mechanics of jointed rock. J Soil Mech Found Div 99:229–248

Fattahi H (2016) Application of improved support vector regression model for prediction of deformation modulus of a rock mass. Eng Comput 32:567–580. https://doi.org/10.1007/s00366-016-0433-6

Feng X, Jimenez R (2015) Estimation of deformation modulus of rock masses based on Bayesian model selection and Bayesian updating approach. Eng Geol 199:19–27. https://doi.org/10.1016/j.enggeo.2015.10.002

Galera JM, Álvarez M, Bieniawski ZT Evaluation of the deformation modulus of rock masses using RMR: comparison with dilatometer tests. In: ISRM 2007, Underground Works under Special Conditions, Lisbon, 2007. pp 71-77

Gardner WS Design of drilled piers in the Atlantic Piedmont. In: Smith RE (ed) Foundations and Excavations in Decomposed Rock of the Piedmont Province, New York, 1987. ASCE, pp 62-86

Gokceoglu C, Sonmez H, Kayabasi A (2003) Predicting the deformation moduli of rock masses. Int J Rock Mech Min Sci 40:701–710. https://doi.org/10.1016/S1365-1609(03)00062-5

Gokceoglu C, Yesilnacar E, Sonmez H, Kayabasi A (2004) A neuro-fuzzy model for modulus of deformation of jointed rock masses. Comput Geotech 31:375–383. https://doi.org/10.1016/j.compgeo.2004.05.001

Grimstad E, Barton (1993) N Updating the Q-system for NMT. In: Proceedings of the International Symposium on Sprayed Concrete-Modern use of wet mix sprayed concrete for underground support, Fagernes, Oslo. Norwegian Concrete Association, pp 46-66

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34:1165–1186. https://doi.org/10.1016/S1365-1609(97)80069-X

Hoek E, Carranza-Torres C, Corkum B Hoek-Brown failure criterion - 2002 Edition. In: Proceedings of the 5th North American Rock Mechanics Symposium and 17th Tunnelling Association of Canada Conference (NARMS-TAC 2002), University of Toronto, 2002. pp 267-271

Hoek E, Diederichs MS (2006) Empirical estimation of rock mass modulus. Int J Rock Mech Min Sci 43:203–215

Isik NS, Doyuran V, Ulusay R (2008a) Assessment of deformation modulus of weak rock masses from pressuremeter tests and seismic surveys. Bull Eng Geol Environ 67:293–304. https://doi.org/10.1007/s10064-008-0163-0

Isik NS, Ulusay R, Doyuran V (2008b) Deformation modulus of heavily jointed–sheared and blocky greywackes by pressuremeter tests: numerical, experimental and empirical assessments. Eng Geol 101:269–282. https://doi.org/10.1016/j.enggeo.2008.06.004

Kallu RR, Keffeler ER, Watters RJ, Agharazi A (2015) Development of a multivariate empirical model for predicting weak rock mass modulus. Int J Min Sci Technol 25:545–552. https://doi.org/10.1016/j.ijmst.2015.05.005

Kang S-S, Kim H-Y, Jang B-A (2013) Correlation of in situ modulus of deformation with degree of weathering, RMR and Q-system. Environ Earth Sci 69:2671–2678. https://doi.org/10.1007/s12665-012-2088-y

Kavur B, Štambuk Cvitanović N, Hrženjak P (2015) Comparison between plate jacking and large flat jack test results of rock mass deformation modulus. Int J Rock Mech Min Sci 73:102–114. https://doi.org/10.1016/j.ijrmms.2014.09.022

Kayabasi A, Gokceoglu C, Ercanoglu M (2003) Estimating the deformation modulus of rock masses: a comparative study. Int J Rock Mech Min Sci 40:55–63. https://doi.org/10.1016/S1365-1609(02)00112-0

Khabbazi A, Ghafoori M, Lashkaripour GR, Cheshomi A (2013) Estimation of the rock mass deformation modulus using a rock classification system. Geomech Geoeng 8:46–52. https://doi.org/10.1080/17486025.2012.695089

Martins FF, Miranda TFS (2012) Estimation of the rock deformation Modulus and RMR based on data mining techniques. Geotech Geol Eng 30:787–801. https://doi.org/10.1007/s10706-012-9498-1

Mehrotra VK (1992) Estimation of engineering parameters of rock mass. University of Roorkee

Mitri H, Edrissi R, Henning J Finite element modeling of cable bolted stopes in hard rock ground mines. In: SME annual meeting, New Mexico, Albuquerque, 1994. pp 94-116

Mohammadi H, Rahmannejad R (2010) The estimation of rock mass deformation modulus using regression and artificial neural networks analysis. Arab J Sci Eng 35:205–217

Nejati HR, Ghazvinian A, Moosavi SA, Sarfarazi V (2014) On the use of the RMR system for estimation of rock mass deformation modulus. Bull Eng Geol Environ 73:531–540. https://doi.org/10.1007/s10064-013-0522-3

Nicholson GA, Bieniawski ZT (1990) A nonlinear deformation modulus based on rock mass classification. Int J Min Geol Eng 8:181–202. https://doi.org/10.1007/bf01554041

Palmström A (1995) RMi - a rock mass characterization system for rock engineering purposes. Oslo University

Palmström A (2001) Measurement and characterization of rock mass jointing. In: Sharma VM, Saxena KR (eds) In-situ characterization of rocks. A. A. Balkema

Palmström A, Singh R (2001) The deformation modulus of rock masses- comparisons between in situ tests and indirect estimates. Tunn Undergr Space Technol 16:115–131

Panthee S, Singh PK, Kainthola A, Das R, Singh TN (2016) Comparative study of the deformation modulus of rock mass. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-016-0974-3

Radovanović S, Ranković V, Anđelković V, Divac D, Milivojević N (2017) Development of new models for the estimation of deformation moduli in rock masses based on in situ measurements. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-017-1027-2

Ramamurthy T (2001) Shear strength response of some geological materials in triaxial compression. Int J Rock Mech Min Sci 38:683–697. https://doi.org/10.1016/S1365-1609(01)00035-1

Ramamurthy T (2004) A geo-engineering classification for rocks and rock masses. Int J Rock Mech Min Sci 41:89–101. https://doi.org/10.1016/S1365-1609(03)00078-9

Read SAL, Perrin ND, Richards LR Applicability of the Hoek-Brown failure criterion to New Zealand greywacke rocks. In: 9th ISRM Congress, 25-28 August, Paris, France, 1999. pp 655-660

Rezaei M, Asadizadeh M, Majdi A, Hossaini MF (2015) Prediction of representative deformation modulus of longwall panel roof rock strata using Mamdani fuzzy system. Int J Min Sci Technol 25:23–30. https://doi.org/10.1016/j.ijmst.2014.11.007

Ribacchi R (1988) Rock mass deformability; in situ tests, their interpretation and typical results in Italy. In: S S (ed) Second international symposium on field measurements in geomechanics, Kobe. Balkema, Rotterdam, pp 171–192

Rocha M Present possibilities of studying foundations of concrete dams. In: 3rd International Congress on Rock Mechanics, Denver, 1974. International Society for Rock Mechanics, pp 879-896

Roy N (1993) Engineering behaviour of rock masses through study of jointed models. Indian Institute of Technology, Delhi, India

Sanei M, Rahmati A, Faramarzi L, Goli S, Mehinrad A Estimation of rock mass deformation modulus in Bakhtiary dam project in Iran. In: 3rd ISRM SINOROCK Symposium, Rock Characterisation, Modelling and Engineering Design Methods, Shanghai, China, 2013. pp 161-164

Serafim JL, Pereira JP Consideration of the geomechanics classification of Bieniawski. In: International Symposium on Engineering Geology and Underground Constructions, 1983. pp 1133 - 1144

Sharma VM, Singh RB, Chaudhary RK Comparison of different techniques and interpretation of the deformation modulus of rock mass. In: Indian Geotechnical Conference (IGC), New Delhi1989. pp 439-443

Shen J, Karakus M, Xu C (2012) A comparative study for empirical equations in estimating deformation modulus of rock masses. Tunn Undergr Space Technol 32:245–250. https://doi.org/10.1016/j.tust.2012.07.004

Sonmez H, Gokceoglu C, Nefeslioglu HA, Kayabasi A (2006) Estimation of rock modulus: for intact rocks with an artificial neural network and for rock masses with a new empirical equation. Int J Rock Mech Min Sci 43:224–235. https://doi.org/10.1016/j.ijrmms.2005.06.007

Sonmez H, Gokceoglu C, Ulusay R (2004) Indirect determination of the modulus of deformation of rock masses based on the GSI system. Int J Rock Mech Min Sci 41:849–857. https://doi.org/10.1016/j.ijrmms.2003.01.006

Stephens RE, Banks DC Moduli for deformation studies of the foundation and abutments of the Portugues Dam - Puerto Rico. In: The 30th U.S. symposium on rock mechanics (USRMS), Morgantown, West Virginia, 1989. pp 31-38

Thorpe R, Watkins DJ, Ralph WE, Hsu R, Flexser S (1980) Strength and permeability tests on ultra-large Stripa granite core. University of California, Berkeley

Ulusay R, Hudson JA (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974-2006. International Society of Rock Mechanics. Compilation arranged by the ISRM Turkish National Group

Wittke W (1990) Rock mechanics (theory and applications with case histories). Springer-Verlag, Berlin

Yaji RK (1984) Shear strength and deformation response of jointed rocks. Indian Institute of Technology, Delhi, India

Zhang L, Einstein HH (2004) Using RQD to estimate the deformation modulus of rock masses. Int J Rock Mech Min Sci 41:337–341. https://doi.org/10.1016/S1365-1609(03)00100-X

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bahaaddini, M., Hosseinpour Moghadam, E. Evaluation of empirical approaches in estimating the deformation modulus of rock masses. Bull Eng Geol Environ 78, 3493–3507 (2019). https://doi.org/10.1007/s10064-018-1347-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-018-1347-x