Abstract

The grain size distribution of soils is known to be an important parameter in providing initial understanding for the physical and mechanical behavior of soils in many engineering geology applications. Therefore, the literature contains many grain size-based approaches, indices, or empirical models to describe soil for classification purposes or predict soil behavior under static and/or dynamic loading conditions. Because of the absence at present of a convenient single parameter that defines an entire grain size distribution curve, mean, median, standard deviation, the coefficients of uniformity and curvature, fines content, effective particle size etc., are currently used to describe the general slope and shape of the grain size distribution curve in engineering geological studies. In order to overcome with this limitation, comprehensive research has been performed in which an appropriate new parameter to represent grain size distribution curves is defined. Accordingly “grain size index (I GS)” is then used in a soil classification system and empirical models to predict physical and mechanical properties of soils. Statistical analyses were performed to prove its validity and to test its applicability for prediction of soil physical and mechanical properties. In addition to the availability of the I GS for soil classification and preliminary assessment of liquefaction properties of soil, it can also be used to estimate the swelling characteristics of expansive soils.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Grain size is a key parameter that controls the physical and mechanical behavior of soils. The Unified Soil Classification System (USCS), British Soil Classification System, and American Association of State Highway and Transportation Officials (AASHTO) systems are commonly used to describe grain size and texture of a soil for engineering geology purposes. Grain size distribution is of value in providing an initial understanding of the physical and mechanical behavior of soil, including for example, swelling and liquefaction potential, consolidation properties, and strength. There is also the potential for the soil–water characteristic curve (SWCC), which is of fundamental importance in unsaturated soil mechanics and is relatively time consuming and expensive to determine in field and laboratory tests, to be predicted from grain size distribution data (Satyanaga et al. 2013). Thus, Casagli et al. (2003) state that the acquisition of grain size data is extremely important for the correct interpretation of the evolution of landslide dams given that grain size influences the overall strength of the landslide material and its resistance to erosional processes, and ultimately, to overtopping or piping failures (Casagli and Ermini 1999) and the hydrograph applicable after dam failure (Pilotti and Bacchi 1996). According to Kalyoncu Erguler et al. (2014), grain size distribution is also an important parameter in the assessment of acid mine drainage hazards.

In fact, there are many engineering applications for which the grain size of soils is important; the following are main examples: (1) soil classification, particularly coarse-grained soils, (2) description of soil texture, (3) drainage filter design and selection, (4) selection of fill for engineering structures, (5) prediction the hydraulic conductivity of soils from effective grain size (D10) using Hazen’s Equation and the soil–water characteristic curve.

The engineering behavior of soils is a function of two main controlling factors, namely grain size distribution and mineralogical composition. The full grain size distribution of a soil can be determined by sieving and sedimentation methods, the full details of which are given in ASTM D422-63 (2007), British Standard 1377-2 (1990), and other standards. The distribution of sizes is usually presented as a curve on a semi-logarithmic plot, such as that in Fig. 1. Some statistical parameters such as mean, median, and standard deviation are used for representing grain size curves. Craig (2004) suggested using the coefficient of uniformity (CU) and the coefficient of curvature (CC) for describing the general slope and shape of the grain size distribution curve for engineering geology applications. In order to understand fully and/or predict engineering behavior of soils from grain size distribution curves by correlating mechanical parameters of soils (e.g., swelling pressure, swelling magnitude, and liquefaction properties) and grain size; these curves would ideally be represented by a single parameter. However, using the above mentioned statistical parameters, such as CU and CC is not sufficient for this to be done. Therefore, the basic objectives of this research are:

-

Review effect of grain size distribution on the behavior of soils.

-

Review existing methods of representing grain size distribution.

-

Derive new parameter for expressing grain size distribution.

-

Validation and evaluation of proposed index.

-

Demonstrate use of index for evaluation of swelling and liquefaction potential.

The work described below includes a review of relevant literature together with experimental work to prove the applicability of the proposed parameter “grain size index (I GS)”. This is applied to the assessment of soil characterization according to the Unified Soil Classification System (USCS), as well as the swelling and liquefaction properties of soils.

Previous studies and data collection

Figure 1 shows grading curves for many soils from around the world that were examined in this study and used to evaluate boundary conditions. While highly organic soils and peat can generally be identified visually, the other major divisions in the USCS are determined according to grain size percentage. Priority was particularly given to previous studies involving coarse-grained (GW, GP, GM, GC, SW, SP, SM, SC) and fine-grained (CH, CL, MH, ML) soils. To provide a further understanding of the data from previous studies, more information about these soils is summarized in Table 1.

Soil sampling and testing

The data in Fig. 1 were supplemented with data, presented in Table 2, for disturbed and undisturbed samples from different locations in the Ankara, Turkey residential area. The latter samples of Ankara Clay were extracted from a depth of about 1 m to avoid the presence of grass roots and short-term fluctuations in water content. The shallow depth of foundations of lightweight engineering structures was another reason for choosing this sampling depth. The samples were subjected to the tests described below.

Mineralogical and physical properties of samples

X-ray diffraction (XRD) analyses revealed that the samples consisted of clay minerals, quartz, feldspar, and calcite as shown in Fig. 2a. Further analyses of the separated clay sized fraction revealed the presence of kaolinite, illite, and the swelling clay mineral, smectite (Fig. 2b). In addition to mineralogical characterization, natural water content, unit weight, dry density and specific gravity, Atterberg limits, mechanical sieving, and hydrometer analysis were performed, where the results are given in Table 2.

Swelling tests

Compared with coarse-grained soils, there is a potential for fine-grained soils to contain more clay minerals. It is well know that grain size of a soil is a key indicator for predicting its swelling characteristics. To see the relationship between particle size and swelling parameters of soils, swelling tests were carried out on the Ankara samples. The foundations of many lightweight structures in this area are constructed within the active zone in which the water content is likely fluctuate in response to climatic events and engineering structures are usually subjected to several swelling/shrinkage cycles each year. In addition, it is well known that soil swelling diminishes with increasing water content (Day 1998). The active zone of Ankara clay is between 1 and 2 m thick and the water content of the samples ranged between 14 and 44 %, with a mean of 28 % at the time of sampling. Such high level of water content suggests that some samples would have undergone considerable swelling before being sampled.

Chen (1988) reported that damage to structures is liable to be more severe for swelling of desiccated clays. Similarly, Day (1998) performed swelling tests on dry clay samples collected from California to simulate field conditions and suggested that a substantial increase in the swell pressure occurred as the initial water content of the clay specimens decreased. To consider previous findings about the importance of water content on swelling potential of soils, and to achieve extreme conditions, swelling percentage, and pressure tests were carried out on dry samples in accordance with the test procedure suggested by the ASTM D4546-90 (1996). The measured swelling percentage and pressure values are summarized in Table 2.

A new approach for defining grain size distribution of soils

Boundary conditions for grain size distribution of soils

Engineers have found it convenient to use a logarithmic scale for particle size because the ratio of particle sizes from the largest to the smallest in a soil can be greater than 104 (Budhu 2000). As Fig. 1 shows, the practical upper size limit for soils in engineering geological applications is 75 mm. This is the case in classifications such as USCS, AASHTO, and ASTM, in which it is the boundary between gravel and cobbles. Figure 1 indicates that nearly all grain size distribution curves lie between 0.001 mm and 75 mm; therefore, the lower and upper boundary conditions were respectively defined as this range.

Grain size index (I GS)

Although the CU and CC are successfully applied for classifying of soil, particularly for separation well-graded soils (GW and SW) from poorly graded soils (GP and SP), they cannot be directly used for understanding the effect of grain size on such mechanical parameters such as swelling pressure, swelling magnitude, hydraulic conductivity, and consolidation properties. Erguler and Shakoor (2009) proposed a “disintegration ratio” to define particle size distribution curves after wetting–drying cycles and to find the relationships between disintegration rate of clay-bearing rocks and their physical properties. A similar approach has been adopted here to represent grain size distribution curves with a single parameter designated as the grain size index, (I GS). It is defined as:

where A C is the area under the grain size distribution curve and A T is the total area encompassing boundary conditions between 0.001 and 75 mm, as explained above.

Figure 3 shows the procedure for determining I GS from grain size distribution curves for selected different soils in which rectangle “abcd” represents the total area based on the (0.001 and 75 mm) boundary conditions. The areas under the grain size distribution curves are variable, depending on percentages of clay, silt, sand, and gravel sizes. In order to demonstrate the deviation of the grain size index (I GS) for different grain size distribution curves and compare this new parameter with other parameters such as Cu and Cc for its validation, some hypothetical curves and typical curves shown in Fig. 1 are considered in Fig. 4. The clay content, D10, D30, and D60 used for the determinations of coefficients Cu and Cc and I GS values relating to these curves are presented in Table 3, where for curves 4 and 5, it was not possible to determine the D values and thus their coefficient of uniformity and curvature of could not be defined. In addition, the Cu and Cc values for the remaining curves (1, 2, and 3) are approximately the same. Nearly all grain size distribution curves reviewed in Fig. 1 and many curves in previous studies, have rather high fines content so Cu values could not be determined. However, as shown in Fig. 4, I GS changes depending on the location of each curve, and it increases with increasing fines content, thus demonstrating that I GS takes account of the slope, shape, and position the grain size distribution curve.

It has to be stressed that the value of the grain size index (I GS) value is not unique. Thus, a uniformly graded coarse soil could have the same index as a well graded fine one. However, although the grain size distribution is very useful tool for understanding physical and mechanical behavior of soils, in many cases, there is no need to carry out sieving and hydrometer analysis on uniformly-graded coarse soil to predict its swelling potential or on a well-graded fine one to determine its liquefaction potential. It can be easily concluded that swelling behavior is generally observed in well-graded and fine grained soils composed also of swelling type clay minerals, whereas liquefaction is more likely in saturated uniformly-graded silty sands and fine-grained sands. As in Fig. 1 shows, nearly all Ankara Clay samples were well-graded mixtures of clay, silt and sand with some gravel. The limitations of the I GS parameter can be overcome by also quoting Coefficient of uniformity (Cu = D60/D10) with values of 4 and 6 defining the divisions between respectively well- and uniformly graded gravel and sand. Based on all grain size distribution curves in Fig. 1, Cu ≤ 6 identifies soils liable to undergo liquefaction. Likewise, the I GS value for well-graded soil in which Cu > 6 would define a soil that is likely to undergo swelling.

Some examples of the application of I GS

Grain size index (I GS) as an input parameter for unified soil classification system (USCS)

Basically, the percentage of grains finer or coarser than 0.075 mm (No. 200 sieve), CU and CC, liquid limit and plastic limit are required for the classification of a soil using the Unified Soil Classification System (USCS). Although the higher the value of the coefficient of uniformity, the larger the range of particle sizes in the soil, soils having the same degree of uniformity are represented by curves of the same shape regardless of their positions on the particle size distribution plot (Craig 2004). Therefore, as illustrated in Fig. 4, grain size index (I GS) in conjunction with soil description would differentiate between these soils. For this purpose, the curves representing upper and lower boundaries well-graded gravel (GW), poorly graded gravel (GP), and sands [well-graded sand (SW) and poorly graded sand (SP)] are illustrated in Fig. 5. It is recommended that I GS is used directly for Unified Soil Classification purposes, where the I GS values for well-graded soils (GW and SW) ranges between 0.14 and 0.42, as in Fig. 5. Listed below are I GS values for poorly and well-graded sands and gravels:

Poorly graded gravel (GP): I GS = 0.00–0.14;

Well-graded gravel (GW): I GS = 0.14–0.28;

Well-graded sand (SW): I GS = 0.27–0.42; and

Poorly graded sand (SP): I GS = 0.42–0.59.

Swelling properties of soils and the importance of grain size index (IGS) for its prediction

Standard ASTM D4546-90 (1996) specifies three different methods for determination of the one-dimensional swelling parameters of potentially expansive soils. However, due to the relatively time consuming and high cost of these methods, the literature contains a considerable number of empirical techniques for doing this based on simple index properties (e.g., Seed et al. 1962; Chen 1988; Al-Homoud and Al-Suleiman 1997; Erguler and Ulusay 2003; Yilma 2009; Puppala et al. 2014). Of these, the most commonly used ones are liquid limit, natural water content, clay content, plasticity index, dry unit weight, and activity. However, among these, clay content and Atterberg limits are determined on the fine-grained fraction and, therefore, do not take account of the effects of coarser particles that would tend to decrease the swelling potential.

In addition to simple and multiple regression models, some simple testing methods such as “free swell test (FS)” (Holtz and Gibbs 1956) and “modified free swell index test (MFSI)” (Sivapullaiah et al. 1987) have also been suggested for predicting swelling properties of expansive soils. However, as in these tests a known mass or volume of dry soil sample passing 0.42 mm is used, the effect of coarser particles that are liable to be dominated by non-swellable constituents are ignored in the swelling prediction.

Although all above mentioned properties of the soils can be correlated with swelling properties, the effect of grain size was not included in this assessment. However, the mechanisms governing the swelling behavior of soils depend on mineralogical composition, structure and grain size distribution so “grain size index (I GS)” should facilitate prediction of the swelling potential. Analysis of the data in Fig. 1 to determine the morphology of the distributions (normal, log normal, beta, exponential, largest extreme value, etc.) using Statgraphics® Centurion XVII (STSC 2014) revealed that the best fitting distributions for swelling pressure, swelling percent, and I GS values are respectively log-normal, gamma, and normal. As demonstrated in Fig. 6, grain size index is another important key parameter controlling swelling pressure and swelling magnitude. According to this figure and a simple regression model, a considerable amount of variability in the swelling pressure and swelling percentage (about 88 and 75 %, respectively) can be explained by incorporating grain size index into the model.

Application of grain size index (IGS) for preliminary assessment of liquefaction

Grain size distribution is also known as one of important factor controlling liquefaction susceptibility in cohesionless soils. A number of other parameters including relative density, depth to groundwater table and saturation degree, maximum ground acceleration, epicentral distance, effective stress, geological age, and seismic strain history are also important. Seed et al. (1976) investigated the settlement and liquefaction of sands under multi-directional shaking and stated that the behavior of these materials under cyclic loading conditions is a function of geological and seismic history and grain structure as well as its placement density. As known from previous investigations (e.g., Seed 1968), earthquake-induced liquefaction most commonly occurs in saturated silty sands and fine sands.

To identify the effect of grain size on assessment of liquefaction hazard, Lee and Fitton (1969) conducted cyclic triaxial tests and proposed the term of “liquefaction difficulty ratio”. This parameter, which is based on only mean grain size (D50), was proposed for preliminary assessment of liquefaction potential. According to Lee and Fitton (1969), uniformly graded soils, particularly fine sands having D50 ranging between 0.5 and 0.06 mm and with a coefficient of uniformity (Cu) <5, are more susceptible to liquefaction than well-graded materials. It is generally considered that liquefaction resistance increases with increased grain size due to improved drainage, and it increases for finer grained soils due to increased soil cohesion (Numata and Mori 2004). Lee and Fitton (1969) attempted to use mean grain size and coefficient of uniformity to define grain size distribution curves to derive relationships between liquefaction difficulty ratio and grain size distribution; however, I GS might be more useful. Shortly after this work, Tsuchida (1970) carried out an investigation to identify liquefiable soils in several previous Japanese earthquakes based on grain size distribution curves and proposed the grain size distribution boundaries shown in Fig. 7. These are now used in the Japan Port and Harbor Association (1999) Technical Standards for Port and Harbour Facilities and in the ATC-32 (1996), the earthquake-resistant design code for bridges in the USA (Numata and Mori 2004).

In order to understand the effect of grain size distribution curves on liquefaction potential of soils, and consequently assess the relationship between the grain size index proposed in this study and liquefaction behavior of soils, several grain size distribution curves of liquefied soils observed during different worldwide earthquakes are illustrated in Fig. 7. As seen in this figure, whereas most curves lie within the zones defined by Tsuchida (1970), a few curves relating to the Ormond earthquake (Christensen 1993) and tailings failures (Ishihara 1985) lie outside of this range. However, Christensen (1993) suggested that gravel particles from above the layer of liquefied sand were probably entrained in the ejected soil and were not themselves subject to liquefaction. In addition, as seen in Fig. 7, some soils comprised entirely of very coarse sand also liquefied during this earthquake. Although it is less likely that soils with a grain size distribution outside the proposed range would liquefy, in some exceptional cases it may occur (e.g. Seed 1968; Ishihara 1985). Furthermore, Ishihara (1985) modified and broadened Tsuchida’s range taking into account the low resistance of these deposits to liquefaction (Fig. 7). Based on extensive dynamic tests on silts, Walker and Steward (1989) also concluded that non-plastic and low plasticity silts, despite having grain size distribution curves outside of Tsuchida’s boundaries, have a potential for liquefaction similar to that of sands (GEB 2007). Despite these minor exceptions, as seen from Fig. 7, many grain size distribution curves of ejected materials resulting from earthquake liquefaction are within Tsuchida’s boundaries, particularly ranges proposed for most liquefiable soils. In addition, the grain size distribution curves in Fig. 7 are naturally uniformly graded. In terms of the boundaries for preliminary assessment of liquefaction of uniformly graded soils, the I GS values define a range between 0.74 and 0.34 for potentially liquefiable soil, and between 0.62 and 0.43 for the most liquefiable soil.

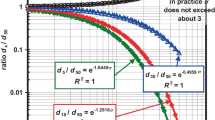

The semi-representative parameters that have been used for understanding or predicting liquefaction behavior are given in Table 4. Youd et al. (2001) proposed standardized SPT blow count [(N1)60], fine grain content of cohesionless soils and the observations of field performance of these materials during several destructive past earthquakes in the western United States, Alaska, South America, Japan, and China. Previous studies by Lee and Fitton1969); Tsuchida (1970); Christensen (1993); Youd et al. (2001); Numata and Mori (2004); and others have demonstrated the importance of grain size for prediction of soil behavior under dynamic loading. Liquefaction resistance of soil increases with increasing fines content due to decreasing permeability of soils so preventing drainage of excess pore water pressure generated by shaking. The correlation between grain size index (I GS) and fines content is given in Fig. 8 based on data given in Fig. 1. Although there is statistically strong correlation between these variables (Fig. 8) for fines contents between 49 and 97 %, the data are scattered. This is thought to result from a lack of data about soils with low and high fines contents at. Notwithstanding this poor correlation at high and low fines contents, the equivalent I GS values for Youd et al. (2001) fines content of 5, 15, and 35 % are respectively 0.34, 0.40, and 0.52. However, further investigation of soil behavior and strength under dynamic loading for soils possessing a wider range of the I GS values is required to underpin this prediction tool.

Conclusions

A single, continuous parameter that expresses the essential aspects of the grain size distribution curve of soils used in engineering applications is of long-standing great need. The proposed “grain size index (I GS)” provides a convenient means of making accurate predictions of the mechanical properties of engineering soils as well as being a useful adjunct to their classification. This study has included a preliminary evaluation of the applicability of the proposed parameter applied to the Unified Soil Classification System (USCS) and demonstrated its application in the assessment of swelling and liquefaction potential of soils.

The main conclusions are as follows:

-

1.

The proposed grain size index (I GS) is potentially an important additional single index parameter to be used for describing grain size distribution curves. It expresses both mean particle size and the spread of sizes, although not absolutely uniquely.

-

2.

The grain size index (I GS) is available for use as an input additional parameter for classification of soils, particularly for well-graded gravel (GW), poorly graded gravel (GP), well-graded sand (SW), and poorly graded sand (SP) soils.

-

3.

The statistically significant relationships between the I GS and swelling pressure and swelling amount of soils demonstrate the applicability of this parameter in these applications. The outputs of statistical analyses reveal that multiplicative models can be used to predict swelling pressure and amount of soils by using grain size index. Since Atterberg limits, “free swell (Holtz and Gibbs 1956)”, and “modified free swell index (Sivapullaiah et al. 1987)” are determined on the less than No. 40 sieve (0.425 mm) fraction, this parameter is expected to provide a more reliable indication of plasticity and swelling parameters.

-

4.

For uniformly graded soils, the ranges of I GS value for potentially liquefiable and most liquefiable soils (Tsuchida 1970) are 0.74–0.34 and 0.62–0.43, respectively. In addition, the equivalent I GS values for fines content of 5, 15, and 35 % were predicted as 0.34, 0.40, and 0.52, respectively. These values can be used in the empirical approach suggested by Youd et al. (2001) for determination of cyclic resistance ratio.

-

5.

I GS has the potential for facilitating abetter understanding of the grain size dependency of the liquefaction potential and cyclic resistance ratio (CRR) of soil deposits as well as its strength and behavior under dynamic loading conditions.

References

Abbasoglu C (1971) Ion exchange process affecting swelling and other properties of Ankara clay. MSc. Thesis, METU, Civil Engineering Department, p 78

Al-Homoud AS, Al-Suleiman TI (1997) Loss in serviceability of pavements due to expansive clay subgrades. Environ Eng Geosci III(1):277–294

Al-Mhaidib AI (2006) Swelling behavior of expansive shale: a case study from Saudi Arabia. In: Al-Rawas AA, Goosen MFA (eds) Expansive soils: recent advances in characterization and treatment. Taylor and Francis––AA Balkema Publishers, The Netherlands, pp 273–287

ASTM D4546-90 (1996) Standard test methods for one-dimensional swell or swell settlement potential of cohesive soils. ASTM International, West Conshohocken

ASTM D422-63 (2007) Standard test method for particle-size analysis of soils. ASTM International, West Conshohocken

ATC-32 (Applied Technical Council) (1996) Improved seismic design criteria for California bridges. Provisional recommendations. Department of Transportation, California, pp 89–92

Attom MF, Abu-Zreig MM, Obaidat MT (2006) Effect of remolding techniques on soil swelling and shear strength properties. In: Al-Rawas AA, Goosen MFA (eds) Expansive soils: recent advances in characterization and treatment. Taylor and Francis––AA Balkema Publishers, The Netherlands, pp 127–138

Bardet JP, Kapuskar M (1993) Liquefaction sand boils in San Francisco during 1989 Loma Prieta earthquake. J Geotech Eng 119(3):543–562

Baser O (2009) Stabilization of expansive soils using waste marble dust. MSc. Thesis, Department of Civil Engineering, Middle East Technical University, Ankara, pp 102

British Standard 1377-2 (1990) Methods of test for soils for civil engineering purposes, classification tests, British Standards Institution, London

Budhu M (2000) Soil mechanics and foundations. Wiley, USA

Calisan OF (1987) A study on volume change behavior of silt added METU Clay. MSc Thesis, Department of Civil Engineering, Middle East Technical University, Ankara

Casagli N, Ermini L (1999) Geomorphic analysis of landslide dams in the Northern Apennines. Trans Jpn Geomorphol Union 20(3):219–249

Casagli N, Ermini L, Rosati G (2003) Determining grain size distribution of the material composing landslide dams in the Northern Apennines: sampling and processing methods. Eng Geol 69:83–97

Cetiner SI (2004) Stabilization of expansive soils by çayirhan fly ash and desulphogypsum. M.S. Thesis, METU, Turkey, pp 107

Chen FH (1988) Foundations on expansive soils. Elsevier, New York

Christensen SA (1993) Ormond earthquake liquefaction reconnaissance report. Bull N Z Nat Soc Earthq Eng 26(3):312–328

Craig RF (2004) Soil mechanics. Taylor & Francis Group, New York

Day RW (1998) Swelling behavior of desiccated clay. Environ Eng Geosci IV(1): 124–129

Elgamal AW, Adalier K, Amer M (1993) Liquefaction during the October 12, 1992 Egyptian Dahshure earthquake.In: Proc of 3rd Int Conf on Case Histories in Geotechnical Engineering, St. Louis, Missouri, 1–4 June, paper no. 14.18

Erguler ZA, Shakoor A (2009) Relative contribution of various climatic processes in disintegration of clay-bearing rocks. Eng Geol 108:36–42

Erguler ZA, Ulusay R (2003) A simple test and predictive models for assessing swell potential of Ankara (Turkey). Eng Geol 67:331–352

Ertekin Y (1991) Measurement of lateral swell pressure with thin wall oedometer technique. MSc Thesis, Department of Civil Engineering, Middle East Technical University, Ankara

GEB (Geotechnical Engineering Bureau: NYS DOT) (2007) Liquefaction potential of cohesionless soils. DOT.NY.GOV, https://www.dot.ny.gov/divisions/engineering/technical-services/technical-services-repository/GDP-9b.pdf. Accessed 9 Dec 2013

Hashim R, Muntohar AS (2006) Swelling rate of expansive clay soils. In: Al-Rawas AA, Goosen MFA (eds) Expansive soils: recent advances in characterization and treatment, Taylor and Francis––AA Balkema Publishers, The Netherlands, pp 139–148

Hergül T (2012) An experimental study on the treatment of expansive soils by granular materials. PhD Thesis, Department of Civil Engineering, Middle East Technical University, Ankara, pp 322

Holtz WG, Gibbs H (1956) Engineering properties of expansive clays. Trans Am Soc Civ Eng 121:641–677

Holtz RD, Kovacs WD (1981) An introduction to geotechnical engineering. Prentice-hall, Eaglewood cliffs

Ishihara K (1985) Stability of natural deposits during earthquakes. In: Proc 11 Int Conf on Soil Mechanics and Foundation Engineering, San Francisco

Iskender C (1971) Permeability of Ankara clay subjected to various compaction efforts. MSc Thesis, Department of Civil Engineering, Middle East Technical University, Ankara

Japan Port and Harbor Association (1999) Technical standards for port and harbour facilities in Japan, pp 281–288 (in Japanese)

Kalyoncu Erguler G, Erguler ZA, Akcakoca H, Ucar A (2014) The effect of column dimensions and particle size on the results of kinetic column test used for acid mine drainage (AMD) prediction. Miner Eng 55:18–29

Lee KL, Fitton JA (1969) “Factors affecting the cyclic loading strength of soil,” Vibration effects of earthquakes on soils and foundations, ASTM STP 450, American Society for Testing and Materials

Numata A, Mori S (2004) Limits in the gradation curves of liquefiable soils. In: 13th World Conf on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August, paper no. 1190

PEER (Pacific Earthquake Engineering Research Center) (2013) Some observations of geotechnical aspects of the february 28, 2001, nisqually earthquake in Olympia, South Seattle, and Tacoma, Washington. Soil Liquefaction and Ground Failure. http://peer.berkeley.edu/publications/nisqually/geotech/ liquefaction/distribution/.Accessed 9 Dec 2013

Pilotti M, Bacchi B (1996) Analysis of the uncertainties in the identification of the outflow hydrograph following a landslide dam breach process. In: Luino L (ed) Proceedings of International Conference on Prevention of Hydrogeological Hazards: The Role of Scientific Research, “Alba’96”, vol. II. L’artisticadi Savigliano, Assisi, pp 535–544

Powrie W (2004) Soil mechanics: concepts and applications. Spon, London

Puppala AJ, Manosuthikij T, Chittoori BCS (2014) Swell and shrinkage strain prediction models for expansive clays. Eng Geol 168:1–8

Satyanaga A, Rahardjo H, Leong EC, Wang JY (2013) Water characteristic curve of soil with bimodal grain-size distribution. Comput Geotech 48:51–61

Seed HB (1968) The Fourth Terzaghi Lecture: landslides during earthquakes due to liquefaction. J Soil Mech Found Div ASCE 94(5): 1053–1122

Seed HB, Woodward RJ, Lundgren R (1962) Prediction of swelling potential for compacted clays. J Soil Mech Found Div ASCE 88(SM3):53–87

Seed HB, Arango I, Chan CK (1976) Evaluation of soil liquefaction potential for level ground during earthquakes––a summary report. Shannon and Wilson, Inc. Agbabian Associates. Washington, DC, p 113. (NUREG-0026-NRC-6)

Sivapullaiah PV, Sitharam TG, Rao KSS (1987) Modified free swell index for clays. Geotech Test J 10(2):80–85

STSC (2014). Statgraphics® Centurion XVII User Manual

Thevanayagam S, Martin GR (2002) Liquefaction in silty soils-screening and remediation issues. Soil Dyn Earthq Eng 22:1035–1042

Tilgen HP (2003) Relationship between suction and shear strength parameters of compacted METU campus clay. MSc Thesis, Department of Civil Engineering, Middle East Technical University, Ankara, pp 120

Tsuchida H (1970) Evaluation of liquefaction potential of sandy deposits and measures against liquefaction induced damage. In: Proc of the annual seminar of the Port and Harbour Research Institute, 1970 (3-1)-(3-33) (in Japanese)

Walker AJ, Steward HE (1989) Cyclic undrained behavior of nonplastic and low plasticity silts. Technical report NCEER-89-0035, National Center for Earthquake Engineering Research, SUNY, Buffalo

Wasti Y (1967) Effect of sand content on some properties of clays with special reference to compressibility. MSc Thesis, Department of Civil Engineering, Middle East Technical University, Ankara

Yazici V (2004) Stabilization of expansive clays using granulated blast furnace slag (GBFS), GBFS-lime combinations and GBFS cement. MSc Thesis, Department of Civil Engineering, Middle East Technical University, Ankara, p 100

Yesilbas G (2004) Stabilization of expansive soils using aggregate waste, rock powder and lime. MSc Thesis, Department of Civil Engineering, Middle East Technical University, Ankara, p 112

Yilma zI (2009) Swell potential and shear strength estimation of clays. Appl Clay Sci 46:376–384

Youd TL, Idriss IM et al (2001) Liquefaction resistance of soils: summary report from the 1996 NCEER and 1998 NCEER/NSF workshops on evaluation of liquefaction resistance of soil. J Geotech Geoenviron Eng 127:817–833

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Erguler, Z.A. A quantitative method of describing grain size distribution of soils and some examples for its applications. Bull Eng Geol Environ 75, 807–819 (2016). https://doi.org/10.1007/s10064-015-0790-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-015-0790-1