Abstract

This paper examines and assesses predictive methods for the saturated hydraulic conductivity of soils. The soil definition is that of engineering. It is not that of soil science and agriculture, which corresponds to “top soil” in engineering. Most predictive methods were calibrated using laboratory permeability tests performed on either disturbed or intact specimens for which the test conditions were either measured or supposed to be known. The quality of predictive equations depends highly on the test quality. Without examining all the quality issues, the paper explains the 14 most important mistakes for tests in rigid-wall or flexible-wall permeameters. Then, it briefly presents 45 predictive methods, and in detail, those with some potential, such as the Kozeny-Carman equation. Afterwards, the data of hundreds of excellent quality tests, with none of the 14 mistakes, are used to assess the predictive methods with a potential. The relative performance of those methods is evaluated and presented in graphs. Three methods are found to work fairly well for non-plastic soils, two for plastic soils without fissures, and one for compacted plastic soils used for liners and covers. The paper discusses the effects of temperature and intrinsic anisotropy within the specimen, but not larger scale anisotropy within aquifers and aquitards.

Résumé

Cet article examine et évalue les méthodes de prédiction de la conductivité hydraulique saturée des sols. La définition du sol est celle du génie. Ce n’est pas celle de science du sol et agriculture qui correspond au sol de surface en génie. La plupart des méthodes prédictives ont été calibrées avec des essais de perméabilité de laboratoire, réalisés sur des échantillons remaniés ou intacts, pour lesquels les conditions d’essai étaient soit mesurées soit supposées être connues. La qualité des équations prédictives dépend fortement de la qualité des essais. Sans examiner tous les aspects de qualité, l’article explique les 14 erreurs les plus importantes pour les essais en perméamètre à paroi rigide ou à paroi souple. Après, il présente brièvement 45 méthodes prédictives, et en détail celles avec potentiel comme l’équation de Kozeny-Carman. Ensuite, les données de centaines d’essais d’excellente qualité, sans aucune des 14 erreurs, sont utilisées pour évaluer les méthodes prédictives avec potentiel. La performance relative de ces méthodes est évaluée et présentée en graphes. On trouve que trois méthodes fonctionnent bien pour les sols non plastiques, deux pour les sols plastiques sans fissures, et une pour les sols plastiques compactés utilisés en tapis et couvertures. L’article discute les effets de la température et de l’anisotropie intrinsèque du spécimen, mais pas de l’anisotropie à plus grande échelle dans les aquifères et aquitards.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Groundwater seepage conditions are key parameters for drinking water supply, management of water resources, water contamination and engineered facilities for waste storage. Seepage is linked directly to hydraulic conductivity K through Darcy’s law (Darcy 1856). The K value of soils can be either measured or predicted. Most natural soils have spatially variable hydraulic properties. This implies that many K data are needed to adequately characterize the field K value. Most projects do not have the budget to perform many field and laboratory permeability tests, which are time consuming and more costly than predictions. This is why simple methods are used to predict either the saturated hydraulic conductivity K sat or the full function K(S r) at any degree of saturation S r. Predictive methods use simple properties such as porosity, grain size distribution curve (GSDC), and consistency limits, which are routinely and economically determined for all projects.

In soil science, predictive methods consider the soil texture, its bulk density, clay content and organic matter content (e.g., Kunze et al. 1968; Gupta and Larson 1979; Puckett et al. 1985; Haverkamp and Parlange 1986; Wosten and van Genuchten 1988; Vereecken et al. 1990; Jabro 1992; Rawls et al. 1993; Leij et al. 1997; Schaap et al. 1998, 2001; Cronican and Gribb 2004; Nakano and Miyazaki 2005; Costa 2006; Ghanbarian-Alavijeh et al. 2010). In this paper, the soil definition is that used for engineering or construction materials. It is not that used in soil science and agriculture, which corresponds to “top soil” in engineering. Therefore, the soils examined hereafter contain little or no organic matter and they have a single porosity (no fissures or secondary porosity that may be due to weathering effects or biological intrusions).

In theory, K sat depends on the pore sizes, and on how the pores are distributed and interconnected. Although a detailed description of the continuous complex void space is needed in theory to study seepage, this description is a scientific challenge (e.g., Windisch and Soulié 1970; Garcia-Bengochea et al. 1979; McKinlay and Safiullah 1980; Garcia-Bengochea and Lovell 1981; Delage and Lefebvre 1984; Juang and Holtz 1986; Lapierre et al. 1990; Delage et al. 1996; Horgan 1998; Tanaka et al. 2003; Nelson 2005; Barrande et al. 2007; Donohue and Wensrich 2008; Matyka et al. 2008; Li and Zhang 2009; Minagawa et al. 2009; Pisani 2011). This explains why most methods predicting K sat use the GSDC, which is information on the solids, instead of information on the pore space such as the pore size distribution curve or PSDC. Simplified descriptions of the pore space, such as bundles of straight tubes, have been used to predict K sat. However, most predictive methods for K sat use easy-to-measure parameters such as the soil porosity n (or the void ratio e) and the grain size distribution curve (GSDC), whereas a measured or estimated water retention curve (WRC) coupled with the previously estimated K sat are used by predictive methods for unsaturated K (e.g., Marshall 1958, 1962; Millington and Quirk 1959, 1961; Green and Corey 1960; Brooks and Corey 1964; Houpeurt 1974; Mualem 1976; van Genuchten 1980; Vogel and Roth 1988; Durner 1994; Leong and Rahardjo 1997; Poulsen et al. 1998; Arya et al. 1999; Fredlund et al. 1994, 2002; Moldrup et al. 2001; Hwang and Powers 2003; Chapuis et al. 2007).

Most predictive methods have been calibrated using laboratory permeability tests performed on either disturbed or intact soil specimens, for which the test conditions (GSDC, n and S r values) were either measured or supposed to be known. From a quality control point of view (e.g., Chapuis 1995), the complete chain of procedures must be analyzed to assess the quality of any laboratory permeability test before assessing a predictive method. Here, the major steps to consider and analyze are:

-

Selecting samples and specimens to be tested,

-

Preparing homogeneous specimens for laboratory tests,

-

Selecting appropriate testing methods for grain size distribution and permeability test,

-

Correctly performing the tests and,

-

Correctly interpreting the test data.

This paper does not examine all the quality issues related to laboratory permeability tests. However, it documents the frequent mistakes for tests in rigid-wall or flexible-wall permeameters. This will be used subsequently to assess the performance of predictive methods.

The paper then presents the characteristics of predictive methods, and whether they can be viewed as reliable. Afterwards, data from excellent quality tests, performed on remoulded (homogenized) or intact soil specimens, which have been fully saturated using de-aired water and either a vacuum or back-pressure technique, and which are not prone to internal erosion, are used to assess the better performing predictive methods.

Laboratory tests

The K sat data for laboratory permeability tests are examined versus the GSDC data, the void ratio e and the specific surface S S of tested specimens. In the laboratory, all conditions such as geometry, hydraulic heads and gradients, degree of saturation, can be, but are not always, controlled. Tests on non-plastic soils such as gravel, sand and silt are performed using remoulded homogenized specimens that have lost their in situ internal structure. Laboratory tests on plastic soils, however, can be done with intact specimens, which have kept their in situ internal structure.

The definition of intact samples and specimens is part of sampling quality issues (ISSMFE 1981; Baldwin and Gosling 2009). Usually, five sample classes are defined by considering the relationships between sampling tools and methods, quality of sample and quality of laboratory tests, which have been the topic of many research projects that began before 1940 (e.g., Hvorslev 1940, 1949; Mazier 1974). The preceding references were used to prepare Table 1, which presents the sampling methods, the five quality classes and which properties can be determined with confidence for each class.

Top quality samples (class 1) are those in which no, or only slight, disturbance of the in situ soil structure (no change in water content w, void ratio e, and chemical composition) has occurred. Obtaining class 1 samples is only possible for plastic soils without secondary porosity: it requires a non-destructive technique drilling method and a thin wall piston sampler of 73 mm minimum inside diameter (e.g., La Rochelle et al. 1981; Lefebvre and Poulin 1979; Tanaka 2000). Only a portion of each class 1 sample provides specially cut class 1 specimens for laboratory tests to determine K and different mechanical properties.

In boreholes, obtaining high-quality (class 2) non-plastic samples (e.g., sand and gravel) requires a non-destructive technique drilling method and special techniques such as slow freezing (e.g., Hvorslev 1949; Singh et al. 1982; Konrad and Pouliot 1997; Vaid and Sivathalayan 2000). Class 2 or 3 samples of sand and silts can be recovered with a non-destructive technique drilling method and a thin-walled special sampler (e.g., Bishop 1948) or a thin-walled piston sampler (e.g., L’Écuyer et al. 1993). The hollow stem auger, rotary, percussion, cable tool and sonic drilling methods sometimes provide class 3, but more often class 4, samples of silt, sand and gravel (Baldwin and Gosling 2009). These drilling methods have a strong influence on the quality of recovered samples, and also on the quality of installation of monitoring wells (Chapuis and Sabourin 1989).

Since the internal structure of specimens tested for hydraulic conductivity in the laboratory may not represent the in situ conditions, special precautions must be taken to assess the in situ K sat values, as discussed at the end of this paper.

The next sections, on laboratory tests, present the most common errors for each type of permeameter (ASTM 2011a, 2011b, 2011c), which must be explained in detail before assessing the reliability and performance of the numerous predictive methods for K sat.

Rigid- and flexible-wall permeameters, common mistakes

Mistake No.1: a cylindrical soil core is inserted directly into a rigid-wall permeameter: to do this, the soil core diameter must be smaller than the permeameter internal diameter. Thus, there is some void space between the core and the rigid wall. Therefore, some preferential leakage occurs along the wall (Tokunaga 1988). With soil specimens having some plasticity, the wall leakage rate may be much higher than the percolation rate through the specimen. Mistake No.1 is easy to avoid knowing that the only way to test correctly a soil core is using a flexible wall permeameter, in which the lateral membrane prevents side leakage.

Mistake No.2: a remoulded specimen is compacted in the permeameter but some lateral leakage occurs between the specimen and the rigid wall. Various reasons may lead to lateral leakage or preferential leakage through the specimen. A first reason may be the presence of particles which are too large. According to ASTM (2011a) the inner diameter of the permeameter must be at least 8 or 10 times the maximum particle size of the tested specimen. This requirement helps to avoid poor packing conditions, with large voids along the wall, thus preferential lateral leakage. A second reason is segregation of solids within the tested specimen, either during compaction or seepage (internal erosion), resulting in preferential seepage through large pores, and also along the wall: segregation and internal erosion are examined below in more detail (see mistake No.8). Preferential seepage may be visualized by using dyed water (Govindaraju et al. 1995). A non-reactive tracer test through the specimen provides the values of effective porosity n e and longitudinal dispersivity α L. The n e value of a good specimen is close to its n value, whereas the n e value of a poor specimen with preferential leakage is much lower than its n value. Respecting criteria for the ratio of maximum particle size to permeameter inner diameter, and running a non-reactive test, are good methods to avoid or detect mistake No.2.

Mistake No.3: the tested specimen is not fully saturated: ignoring this situation leads to confusing K(S r) with K sat (fully saturated). The role of S r and its influence on K(S r) has been known for a long time (e.g., Hassler et al. 1936; Wyckoff and Botset 1936; Wyllie and Gardner 1958a, b; Bear 1972; Houpeurt 1974). The role of trapped gas during permeability tests was studied by Christiansen (1944), Pillsbury and Appleman (1950), Chapuis et al. (1989a), Chapuis (2004a) and Chapuis and Aubertin (2010), among others. Most gas bubbles in the pore space of tested specimens are too small to be visible. Usually they adhere to the solids but may become mobile. They may either grow or shrink by diffusion depending upon temperature and pressure variations, and whether the surrounding water is over-saturated or under-saturated with gas. These micro gas bubbles have a stability that depends on water velocity (direction and amplitude); they may act as micro valves in the pore channels and can explain the hysteresis of the K versus S r relationship (Chapuis et al. 1989a).

It may be thought that letting water seep upward in the specimen minimizes gas entrapment and provides full saturation. This is wrong: this method cannot give full saturation. It gives a S r value in the 80–85% range for sand, and as low as 65% for silty sand (Chapuis et al. 1989a). In a rigid-wall permeameter the specimen saturation may be increased up to 100% by using either an initially dry specimen, applying first a high vacuum and then using de-aired water (D2434, ASTM 2011a), or using an initially wet specimen and applying a back pressure (ASTM 2011b; Lowe and Johnson 1960; Black and Lee 1973; Camapum de Carvalho et al. 1986).

The value of S r may be directly verified after the test, by weighing the tested specimen, only if it retains all its water by capillarity. However, if the specimen does not retain all its water, the standards do not provide a method to determine the S r value at any time. However, there is such a method (Chapuis et al. 1989a). Equations were provided to relate the accuracy of this mass-and-volume method to the uncertainties in the different measured parameters. Simple procedures have been proposed to check that the permeameter is not only watertight but also airtight (which is crucial for saturation under vacuum), and whether the specimen is fully saturated (Chapuis et al. 1989a). This mass-and-volume method can provide the S r value at any time during a permeability test. It was used to establish that the usual test termination criterion based on equality of inflow and outflow volumes may be misleading (Chapuis 2004a). Without knowing the method to obtain the S r value at any time, the test may give some K(S r) value for an unknown S r with the risk of confusing this result with K(S r = 100 %). Examples of sand specimens were provided where the inflow and outflow volumes were equal within 1 % whereas S r increased from 80 to 100 % and K(S r) increased by a factor of 4.

Equations for gas transfer between water and tiny gas bubbles were also established and verified for non-plastic soil specimens permeated with either de-aired water or water over-saturated with air (Chapuis 2004a).

Mistake No.3, assuming that the specimen is fully saturated and then confusing K(S r) with K sat, seems common in documents relative to aquifer soils tested in rigid-wall permeameters.

Mistake No.4: parasitic head losses in pipes, valves, and porous stones, are ignored when calculating the K value. This mistake can be avoided by using lateral manometers or piezometers, as required by ASTM (2011a), which measure the hydraulic head loss only within the tested specimen. Unfortunately, not all commercial equipment has lateral piezometers. Mistake No.4 is common when testing aquifer soils in rigid-wall permeameters, leading to errors up to one order of magnitude. Note that there are no lateral manometers in flexible-wall permeameters: using them to test sand and gravel may lead to errors in K values of up to two or three orders of magnitude.

Mistake No.5: the K value is derived indirectly from a time-settlement curve using consolidation theory (Terzaghi 1922a; Taylor 1948), which makes simplifying assumptions. Tavenas et al. (1983a) recommended abandoning these indirect methods because they give poor estimates of the K value. A set of such poor estimates of the K values appears in Fig. 1 for a Champlain Sea clay specimen (authors’ files). Further developments in testing techniques, better understanding of phenomena and improved accuracy (e.g., Tavenas et al. 1983a; Daniel et al. 1984; Daniel 1994; Haug et al. 1994; Hossain 1995; Delage et al. 2000) as well as duration considerations for clays such as bentonite (e.g., Chapuis 1990a) have helped to obtain better K values that are equal (or almost equal) to those obtained using flexible-wall permeameters (triaxial cells) with a high backpressure and enough time to ensure full saturation and complete consolidation or swelling of the specimen, especially for soil-bentonite mixes (Chapuis 1990a). With œdometer cells, correct K values are obtained when a variable head test is done after completion of a consolidation step, and when the specimen height is kept constant to avoid interferences between consolidation and seepage (Tavenas et al. 1983a). The difference in hydraulic head for the variable-head test must be small to avoid seepage-induced consolidation (Pane et al. 1983).

For this variable head test, the piezometric level (PL) inside the soil specimen is usually assumed to be equal to that of the water bowl, which is not true if the excess pore pressure within the previously loaded specimen is not fully dissipated. As a result, the graph of the logarithm of the applied difference in total head, ln(Δh), versus time t is not straight but curved. In all cases, however, the velocity graph method provides the true PL for the test (whether the excess pore pressure within the specimen is fully dissipated or not) and straighten the data graph (e.g., Chapuis et al. 1981; Chapuis 1998a, 1999, 2001, 2007, 2010; Chapuis and Chenaf 2002, 2003). When monitoring systems provide huge amounts of data for water levels versus time, special analysis techniques can be used (Chapuis 2009).

Direct permeability tests are needed to get the correct variation of K with void ratio e and effective stresses, but this lengthens the total test duration, as compared to simply using the simplified and inexact consolidation theory for the settlement curve (indirect tests). A modified œdometer cell and procedure may be used (Morin 1991) to shorten the total test duration. In addition, the constant rate of strain test and the controlled gradient test are known to provide poor results as compared to direct falling head tests in rigid- and flexible-wall permeameters (Tavenas et al. 1983a). Mistake No.5 is still common although it has been known for a long time, and it is easy to avoid.

Mistake No.6: The K value is obtained after a compaction which is too intense. In the rigid-wall permeameter standard for sand and gravel (ASTM 2011a) the compaction procedure is not that of the Proctor tests, which can break or damage grains, and thus create some mobile fines. The sliding compaction tampers have weights of 4.5 and 9 kg in the Proctor tests but only 100 g to 1 kg in permeability tests (ASTM 2011a). Heavy compaction can break solid angles, thus creating fine particles that can migrate (internal erosion is discussed in detail as mistake No.8) due to vibration or seepage (Chapuis et al. 1996; Cyr and Chiasson 1999). Modification of the GSDC by compaction is frequent with crushed stone and mine tailings. Mistake No.6 is easy to avoid.

Mistake No.7: certain requirements of ASTM or other standards are not respected. At least 40 or 50 items must be respected, for equipment pieces and procedures. For example, in D2434, saturation is done with upward seepage of de-aired water after applying a vacuum, but the permeability test involves downward seepage; oversize particles must be removed; there are rules to select the size of the permeameter, etc. In addition, it should be remembered that standards represent an attempt to reflect the best recent knowledge but with some time lag. Mistake No.7 can be made with rigid- and flexible-wall permeameters.

Mistake No.8: the specimen is prone to internal erosion, which means migration of fine particles in the pore space between coarser particles: “suffossion” is the correct word as explained in Chapuis et al. (1992). The GSDC can be used to evaluate a priori the risk of particle migration (see criteria in “Grain size distribution curve”). Internal erosion may occur with man-made soil mixes used for embankment or zoned dams (Chapuis and Tournier 2006), and soil-bentonite mixtures used for liners and covers (Chapuis 1990a, b, 2002; Sällfors and Öberg-Högsta 2002; Kaoser et al. 2006). Internal erosion may be confirmed, and its amplitude may be assessed, after the permeability test, by performing grain size analyses on the lower, central and upper thirds of the tested specimen. This technique was used to study internal erosion in soil-bentonite mixtures (Chapuis 1990a, 2002; Chapuis et al. 1992) and internal erosion in crushed stone (Chapuis et al. 1996; Cyr and Chiasson 1999), but it is not used in all testing programs (e.g., Randolph et al. 1996). Mistake No.8 is easy to avoid. It can be made with both rigid- and flexible-wall permeameters.

Mistake No.9: measuring only one of the flow rates (inflow or outflow). This may lead to a serious error on the K value, especially with fine-grained soils in which several phenomena such as saturation, consolidation, swelling, creep and permeability occur all together. Mistake No.9 is easy to avoid. It can be made with both rigid- and flexible-wall permeameters.

Mistake No.10: according too much confidence to equality of inflow and outflow rates and using this equality as a termination criterion for the test. For example, Chapuis (2004a) presented the case of sand and silt specimens tested in rigid-wall permeameters. During the tests, the difference between inflow and outflow rates never exceeded 1 %: this could have been used as a “proof” that equilibrium and steady-state was achieved, and that the permeability test could be stopped, since, for example, standard D5856 (ASTM 2011b) requires an equality within ±5 % or better. However, such a proof is erroneous. The measured initial S r values were in the 80–85 % range for sand, and as low as 70 % for silty sand, using an accurate technique of mass and volume measurements (Chapuis et al. 1989a). Thus, the measured K value was not that of K sat. Slow circulation of de-aired water through the specimens steadily increased the S r value by slow dissolution of micro (invisible) bubbles adhering to solids. However, the pore volume had to be replaced 60–100 times before reaching S r = 100 % (which took several days or weeks) and then measuring a K sat value that could be 5 times higher than the initial K value. During all the slow gas removal by dissolution, the inflow and outflow volumes were equal to within about 0.2 %, and the K value was steady for four consecutive measurements every 60 min: however, this was neither a proof that the test was completed nor a proof that the specimen was fully saturated. Full saturation can take a very long time in rigid- and flexible-wall permeameters.

Mistake No.10 seems frequent when the technique of controlled rate of flow is used. It can mislead the user in concluding that the test is steady and can be stopped after a short time, especially since the standard (ASTM 2011b) requires checking only if the ratio of inflow to outflow rates is between 0.75 and 1.25 for this type of test. Some consider that the controlled rate of flow test (or flow pump technique test) should be preferred because it takes much less time to perform than variable-head or constant-head tests (e.g., Bolton 2000; Berilgen et al. 2006; Malinowska et al. 2011). This preference results from an illusion, scientifically unjustified. It has been argued that the advantage can be proven using the ground water conservation equation written with the specific storativity S s. However, the equation with S s is a simplified equation, valid only for aquifer materials (short duration tests), and resulting from several simplifying assumptions (full saturation, linear elasticity, immediate strains, etc.). In the case of low-permeability soils (aquitards, long-duration tests), which must be proven to be saturated, the basic and complete equation of Richards (1931) should be used because the simplified equation with S s is unrealistic and cannot predict the end of a test. In Richards’ equation, the seepage phenomena and solid mechanics phenomena are linked through the θ (volumetric water content) term, to account, for example, for partial saturation, time delayed strains, etc., which greatly complicates the mathematical problem. However, since constant head, variable head, and controlled rate of flow tests are governed by the same complex conservation equation, and differ only by boundary conditions, they need similar durations to eliminate all phenomena that affect the seepage process (change in saturation, stress-induced consolidation, seepage-induced consolidation, creep, etc.).

When comparing the predictive methods, it will appear that using the flow pump technique leads to inaccurate data and thus leads to inaccurate predictive methods for K (see “Comparing the performances” in “Predicting methods for plastic soils”). It may also lead to an incorrect correlation between K and the hydraulic gradient, if the time-dependent seepage-induced consolidation (and thus, change in porosity) is not taken into account.

Mistake No.10 can be avoided by verifying strict equality of inflow and outflow rates without drawing unjustified conclusions from it, and also using other checks (control of S r by the mass-and-volume method of Chapuis et al. 1989a) and criteria when performing long duration tests. Mistake No.10 can be made with both rigid- and flexible-wall permeameters.

Mistake No.11: not taking into account possible scale effects for natural clays. The clay specimens tested in œdometers test a vertical flow path of about 2.0 or 2.5 cm, whereas the specimens tested in triaxial cells test a vertical flow path of 15–30 cm. Scale effects do exist for natural clay without fissures but are usually small, whereas they may be high for compacted clays (Benson and Boutwell 2000; Chapuis 2002; Chapuis et al. 2006). For duplicating field K values of recent Champlain Sea clays and much older clays, it is recommended to use either triaxial tests with specimens at least 7 cm in diameter and 10 cm in height, or field tests in monitoring wells (Cazaux and Didier 2002; Benabdallah and Chapuis 2007).

Mistake No.12: parasitic head losses in pipes, valves and porous stones are not considered in flexible-wall permeameters (triaxial cells), which usually are not equipped with lateral manometers. These head losses may be important, thus yielding an incorrect K value, especially for aquifer soils. Triaxial cells are designed for impervious soils, not for aquifer soils. Any user of triaxial cells can make the following simple control test. The soil specimen is replaced with a straight tube section, with an almost infinite hydraulic conductivity. The permeability test, with such a hollow cylinder, gives a K value that corresponds to the hydraulic head losses in the pipes, valves, and porous stones. Typically, this K value is in the 10−4–10−6 m/s range, which means that for correctly testing a soil specimen in a triaxial cell, the K value of the specimen must be lower than 10−6 m/s. The ASTM standard (ASTM 2011c) requires lower than 10−5 m/s, and that the K value of the porous stones must be significantly greater than that of the specimen to be tested. This verification was not performed for several papers (e.g., Hatanaka et al. 1997, 2001; Bandini and Shathiskumar 2009), for which the reported K values seem abnormally low. Mistake No.12 is easy to avoid by running prior verification tests with hollow cylinders.

Mistake No.13: clogging of porous stones is frequent when testing mixes of fine and coarse soils, for example sand-bentonite mixes (Chapuis 1990a, 2002) or mixes of sand and small amounts of silt, which can migrate through the void space of the sand, and then reach the porous stone against which fine particles accumulate whilst some of these fine particles penetrate and clog the porous stone. Experiments can be done with filter paper between the porous stones and the specimen. The filter paper then protects the stones from clogging: bentonite or other fine particles cannot reach the valves and the burettes. This may be important if the stones (e.g., stainless steel), or the set “stones + filter paper”, must be tested alone (no specimen in the cell) to prove null interference with chemical processes, before each test with a soil specimen. In one case, a K value of 10−8 m/s was found for a sand and gravel specimen, tested in a triaxial cell. It was proven later that the true K value was in the 10−4 m/s range, and that the porous stones of the triaxial cell were heavly clogged with clay particles (testing clay had been the common use of the cell). The simple control test, presented in mistake No. 12, testing a hollow cylinder, should be done as a routine test, with a set of new stones, and also with old stones. The difference in the K values for sets of new and old stones, gives an indication of how much the old stones are clogged. Mistake No.13 is easy to avoid with the prior verification test.

Mistake No.14: testing heterogeneous soil specimens cannot yield a good correlation between some average vertical K ave value and some average void ratio e ave. This happens with specimens containing several intact layers (each layer thickness may vary, and each layer void ratio may vary) as tested by Hatanaka et al. (1997, 2001). This happens also when testing artificial (man-made) mixes of several layers, or a specimen that contains a heavily remoulded portion and a slightly remoulded portion. To obtain good correlations between K and e, the specimens must be homogenous in GSDC and e.

Grain size distribution curve (GSDC)

The GSDC may be established using different standards (e.g., ASTM 2011d). It is usually plotted as the percentage p of solid mass smaller than size d (mm), as determined by sieving and hydrometer test, against the decimal logarithm of d, log(d), thus yielding a curve p(d). The GSDC is then a cumulative distribution function, defined as the integral of the probability density distribution of grain sizes (histogram); the density distribution is rarely plotted and used in engineering.

The GSDC is used to define any grain size d x as the size such that x % of the solid mass is made of grains finer than d x. The size d 10 is called the effective size. The uniformity coefficient C U is defined as the ratio d 60/d 10.

Laboratory permeability tests must take into account the risks of segregation and suffossion (internal erosion), which means that either existing or newly created fine particles migrate within the void space of the tested specimen. First, let us explain the origin of the word “suffossion”, an old English and French word, derived from Latin (Chapuis 1992). Three words have been used to describe the migration of fine soil particles within the soil pore space: “suffusion”, “suffosion” and “suffossion”. The English version of the textbook by Kovács (1981) used the word “suffusion” to describe such motion of fine grains in the pore space of a soil. However, “suffusion”, mainly used in medicine, basically refers to a permeating process, often a fluid movement towards a surface or over a surface. Thus, using it for internal erosion, a movement of solids, would be incorrect, either in English or in French. The second word, “suffosion”, appeared in the translation of Russian papers, where it was also used to describe internal erosion. It was also used by Kenney and Lau (1985) who referred to Lubochkov (1965, 1969). But this word is not found in English and French dictionaries. The correct word is “suffossion” with two each of the letters f and s, which comes from the Latin “suffossio, onis”, and can be found for example in Volume 10 of the Oxford English Dictionary (Oxford University 1970). This is the correct word that is used in this paper.

Three criteria are used to verify the risk of suffossion of non-cohesive soils, those of Kezdi (1969), Sherard (1979) and Kenney and Lau (1985, 1986), based on the work of Lubochkov (1965, 1969). Usually, they involved cumbersome calculations. The GSDC is split at a value of d, the GSDC of the coarse and fine fractions thus defined are calculated, and the filter criteria between the fine and coarse fractions are verified. The procedure is cumbersome because it must be repeated several times at several splitting values of d. Using the grain-size curve coordinates, simple equations were established for each criterion (Chapuis 1992; Chapuis and Tournier 2006). As a result, the three criteria can be simply verified by graphical superimposition as in the example of Fig. 2.

In Fig. 2, the soil curve to be checked (bold, hollow circles) is drawn with the three criteria of Sherard (dash bold line of slope 21.5% per cycle), Kezdi (bold line of slope 24.9% per cycle), and Kenney and Lau (fine solid master curve). The three theoretical curves can easily be moved in a spreadsheet by using translation factors. The visual superposition indicates that the criteria of Sherard and Kezdi are not satisfied: the GSDC is flatter than the straight-line criteria at sizes smaller than about 0.08 mm). Similarly, the criterion of Kenney and Lau is not satisfied: the soil curve is flatter than the master curve at sizes smaller than about 0.08 mm.

Therefore, soils that are prone to internal erosion (suffossion) can be identified a priori, simply by checking their GSDC. According to several tests, the criterion of Sherard (1979) seems the most realistic, because examples were found for which the Sherard criterion predicted no erosion whereas the two other criteria predicted erosion, and no internal erosion was observed (Chapuis et al. 1996; Chapuis and Tournier 2006). The complex criterion of Sherard (1979) was shown to be equivalent to “the slope of the GSDC must never be lower than 21.5 % per log cycle” (Chapuis 1992).

The three criteria may be used as a screening tool for selecting specimens to be tested, and also assessing the quality of samples recovered in boreholes (Chapuis and Tournier 2008). However, at least three grain size analyses (upper, central and lower parts of the specimen) are needed after a laboratory permeability test to assess whether internal erosion did occur and how much, which may depend on the porosity and the type of stresses acting on the soil, two parameters that do not appear at present in the internal erosion criteria.

Range of porosity for a single specimen

The GSDC by itself does not indicate how dense the specimen is, either in the laboratory or in the field. Mass and volume measurements are needed. We only know a priori that the porosity n or void ratio e of this specimen is comprised between some minimum and maximum values. The range achieved by the porosity has been studied at length in civil engineering and powder technology (e.g., Yu and Standish 1987), because this is a key factor for many physical properties. A few textbooks, however, still suggest that each GSDC has a single porosity value, which is a mistake. For example, Vuković and Soro (1992) proposed to assess the soil specimen porosity n using Eq. 1.

This Eq. 1, which predicts a single porosity value for each soil sample, is physically meaningless.

In the laboratory, mass and volume techniques are available to accurately determine the values of n and e, as well as the value of the degree of saturation S r of the tested specimen at any time during a permeability test (Chapuis et al. 1989a). For a non-plastic soil sample, the maximum and minimum possible values of the void ratio, e max and e min, can be obtained experimentally using detailed laboratory procedures (ASTM 2011e, f). For a plastic soil sample, the void ratios at the liquid and plastic limits can be used as references to define a density index I D.

For sand and gravel samples, using the data of Youd (1973), Chapuis (2012) proposed to assess the values of e max and e min with best fit relationships as follows.

In Eqs. 2 and 3, RF is the roundness factor of the solid grains, which can be estimated using visual charts (Wadell 1933, 1935; Krumbein 1941; Rittenhouse 1943; Powers 1953; Krumbein and Sloss 1963). The in situ compactness and density index I D can be evaluated using in situ mechanical (geotechnical) tests, including the standard penetration test.

Specific surface

Many methods can be used to measure or assess the specific surface S S of soils (Lowell and Shields 1991), several of them requiring high-tech equipment: they are not commonly used in soil mechanics and hydrogeology. In the case of clays, each method measures different surface areas (Cerato 2001; Yukselen-Aksoy and Kaya 2006, 2010), because clay particles have external, internal and total surfaces, and their basal, edge and interlayer surfaces have different properties. Furthermore, several authors tested clays for which the consistency data fall well below the A-line in the clay classification diagram, meaning clays containing organic matter, which increases the S S value. The contribution of organic matter to S S is important but not well known. Such clays (top soils) are not considered in this paper.

Hereafter, make a distinction is made between non-plastic soils for which S S can be assessed using the GSDC, and plastic soils for which S s can be assessed using relationships with the consistency limits.

Specific surface of non-plastic soils

In soil mechanics and hydrogeology, the specific surface S S of a soil specimen is rarely measured and used. However, several predictive equations are available based on the GSDC, most of them simple, often based on local experience, a few of them subjective. An operator-independent method to estimate S S from the complete GSDC (i.e., including sieving and sedimentation) was proposed by Chapuis and Légaré (1992). This method was used to evaluate the capability of the Kozeny-Carman equation to predict the soil K sat value, using numerous high quality laboratory test data (Chapuis and Aubertin 2003). It proceeds as follows. If d is the diameter (in m) of a solid sphere or the side of a solid cube of solid density ρ s (kg/m3), the specific surface S S (in m2/kg) of a group of such spheres or cubes is given by:

Many theoretical developments start with Eq. 4 and obtain S S by introducing shape, roughness, or projection factors (e.g., Dallavale 1948; Orr and Dallavale 1959; Gregg and Sing 1967). In the case of non-plastic soils, Chapuis and Légaré (1992) have proposed to apply Eq. 4 simply as follows:

where (P No.D− P No.d) is the percentage of solid mass smaller than size D (P No.D), and larger than the next size d (P No.d). Table 2 shows how to use the complete GSDC of the soil specimen to calculate S S.

If d min is the smallest measured particle size of the GSDC, an equivalent size, d eq., must be defined for all particles smaller than d min: it corresponds to the mean size with respect to the specific surface (Chapuis and Légaré 1992) and is defined as.

For the example of Table 2 where d min equals 1.35 μm, d eq is 0.78 μm. This method (Eqs. 5, 6) was used here to estimate the non-plastic soil specific surface S S to be used in the Kozeny-Carman equation. There are other methods, for organic top soils, to estimate the specimen S S using the geometric mean and standard deviation of the particle size, which may be related to fractions of clay, silt and sand in the specimen (e.g., Sepaskhah et al. 2010), but these methods are outside the scope of this paper.

Specific surface of plastic soils

The methods for measuring the S S value of plastic soils involve adsorption of either a gas or a polar liquid. For example, the BET method (Brunauer et al. 1938) uses nitrogen and measures only the external surface of clays, whereas methods using polar liquids (methylene blue, EGME, CNB, PNP …) measure the total surface. Several studies have compared the various methods (Cerato 2001; Cerato and Lutenegger 2002; Santamarina et al. 2002; Yukselen-Aksoy and Kaya 2006, 2010; Arnepalli et al. 2008; Sivappulaiah et al. 2008).

Experimental correlations were found between the total S S and soil engineering properties, including consistency limits, for plastic soils with or without organic matter. For example, Cerato (2001, his Table 2.5) listed 12 correlations between the liquid limit w L and S S as proposed by different authors before 2001 (e.g., De Bruyn et al. 1957; Farrar and Coleman 1967; Locat et al. 1984; Sridharan et al. 1986, 1988; Muhunthan 1991). More data were published after 2001 (e.g., Mbonimpa et al. 2002; Chapuis and Aubertin 2003; Arnepalli et al. 2008; Dolinar and Trauner 2004; Dolinar et al. 2007; Dolinar 2009), including more correlations. It seems that w L can be used to predict S s; however a calibration is needed using soils having regionally similar origin and characteristics, or clays having similar mineralogy. In general, the correlation between w L and S S is weak as shown in Fig. 3, where the data of Chapuis and Aubertin (2003) include those of De Bruyn et al. (1957), Farrar and Coleman (1967), Locat et al. (1984), Sridharan et al. (1986, 1988).

In practice, unless a local correlation between w L and S S is available, K sat(e) is usually predicted using a semi-log law or a power law after the laboratory measurement of one K sat(e 0) value for a first void ratio e 0 or a set of K sat(e i) for several void ratios e i,. This will be presented in “Comparing the performances” in “Predicting methods for plastic soils”.

Predictive methods: historical background

The saturated hydraulic conductivity K sat can be predicted using several methods, such as empirical relationships, capillary models, statistical models and hydraulic radius theories (Scheidegger 1974; Bear 1972; Houpeurt 1974). The best models include at least three parameters to account for relationships between flow rate and porous space, such as fluid properties, void space and solid grain surface characteristics.

According to the preceding discussion of predictive methods and laboratory permeability tests, a reliable predictive method should take into account: (1) the porosity n or the void ratio e; (2) some characteristic grain size or the specific surface of the solid grains; (3) only tests which were performed on fully saturated specimens; (4) only tests in which parasitic head losses were excluded by using lateral manometers, or proven to be negligible (most tests on cohesive soils tested in œdometers or triaxial cells); and (5) only tests on specimens that are not prone to internal erosion.

Since Seelheim (1880) wrote that K sat should be related to the squared value of some pore diameter, many predictive equations for K sat have been proposed. Table 3 lists 45 predictive methods with their characteristics: type of soil for which they were proposed, use of either some grain size (d 5, d 10, d 17 or d 50) or specific surface S S, condition on the coefficient of uniformity C U for non-plastic soils, use of porosity n or void ratio e, and which checks were done on the tests (direct measurement of the degree of saturation S r, use or not of lateral manometers, verification of internal erosion). The predictive methods of Table 3 were proposed by Seelheim (1880), Hazen (1892), Slichter (1898), Terzaghi (1925), Mavis and Wilsey (1937), Tickell and Hiatt (1938), Krumbein and Monk (1942), Craeger et al. (1947) for the USBR formula, Taylor (1948), Loudon (1952), Kozeny (1953), Wyllie and Gardner (1958a, b) for the generalized Kozeny-Carman equation, Harleman (1963), Beyer (1964), Masch and Denny (1966), Nishida and Nakagawa (1969), Wiebenga et al. (1970), Mesri and Olson (1971), Beard and Weyl (1973), Navfac DM7 (1974), Samarasinghe et al. (1982), Carrier and Beckman (1984), Summers and Weber (1984), Kenney et al. (1984), Shahabi et al. (1984), Vienken and Dietrich (2011) for the method of Kaubisch and Fischer (1985), Driscoll (1986) for the charts of Prugh (Moretrench American Corporation), Shepherd (1989) and discussion by Davis (1989), Uma et al. (1989), Nagaraj et al. (1991), Vukovic and Soro (1992) for the Sauerbrei formula, Alyamani and Sen (1993), Sperry and Pierce (1995), Boadu (2000), Sivappulaiah et al. (2000), Mbonimpa et al. (2002), Chapuis and Aubertin (2003), Chapuis (2004b), Berilgen et al. (2006), Chapuis et al. (2006), Ross et al. (2007), Mesri and Aljouni (2007), Dolinar (2009), Sezer et al. (2009), and Arya et al. (2010).

Comments on predictive methods

Table 3 presents a clear picture of 45 predictive methods and their characteristics and/or limitations. Considering what is presently known on how to correctly perform laboratory permeability tests and how to build a complete predictive method, several comments can be made on Table 3.

Surprisingly, several predictive methods proposed before 2000 consider neither the porosity n nor the void ratio e, which means that for a given soil, these methods predict the same K sat value for dense, medium or loose packing state. This first surprise may be related to the wrong belief that each soil has its own and unique porosity, whereas each soil has a range of values for its porosity. After 2000, all predictive methods listed in Table 3 do consider either n or e.

Until recently, very few predictive methods for non-plastic soils used rigid-wall permeability test data for which the real degree of saturation was determined. Hence, many predictive methods used test data for which S r = 100 % was assumed incorrectly, but was not checked using either direct or indirect techniques. Most undisturbed plastic soil cores, however, when tested in œdometers or triaxial cells, were fully saturated.

Many predictive methods for non-plastic soils were calibrated using laboratory tests for which lateral manometers were not used, leading to poor tests with unknown parasitic head losses. In the case of œdometers and triaxial cells, lateral manometers usually are not installed and used (the mention “n/a” in Table 3 means not applicable).

Further, many most predictive methods were calibrated using laboratory permeability test data without checking, before the test, the GSDC for potential internal erosion and without measuring, after the test, how much erosion did occur during the test.

For non-plastic soils most predictive methods use the effective grain size d 10, with a few exceptions that use d 5, d 17, d 20, d 34, or d 50 (Table 3). In several experimental studies of the GSDC influence on K (at some S r value, because these studies could not confirm that S r = 100%), the correlations between K and d 10 were better than those between K and d 17, d 20 or d 50. For example, Moraes (1971) found that using d 50 gave about 3 times more scatter than using d 10. As a result, the effective diameter d 10 seems to adequately represent the influence of the smallest particles on the pore sizes and water seepage.

Methods presented in detail

Considering the previous comments, and the detailed list of 14 mistakes (usually, only a few of them can be detected in publications), not all methods listed in Table 3 will be presented hereafter. Only those methods that are deemed to be the most reliable are presented in the two next sections, “Predictive methods for non-plastic soils”, and “Predictive methods for plastic soils”.

The predictive methods for non-plastic soils which are deemed to be the most reliable and whose performances will be compared are: Hazen (1892) coupled with Taylor (1948) to encompass any void ratio, Terzaghi (1925), Navfac DM7 (1974), Shahabi et al. (1984), Mbonimpa et al. (2002), Kozeny-Carman when the specific surface is known with enough accuracy (Chapuis and Aubertin 2003, 2004), and Chapuis (2004b). The “Predictive methods for non-plastic soils” briefly presents these methods, and then assesses their predictions using a data set for high quality laboratory tests.

The following predictive methods for intact or remoulded plastic soils (without fissures or secondary porosity) have been selected, and their performances are assessed in “Predictive methods for plastic soils”: Kozeny-Carman, and equations of Nishida and Nakagawa (1969), Samarasinghe et al. (1982), Carrier and Beckman (1984), Nagaraj et al. (1991), Sivappulaiah et al. (2000), Mbonimpa et al. (2002), Berilgen et al. (2006) and Dolinar (2009), which can be used to provide either an estimate of the full K sat(e) relationship or an initial value K 0(e 0) to be used in semi-log and power law semi-predictive equations. Finally, for compacted plastic soils (used as liners and covers, with or without fissures), the equations of Chapuis et al. (2006) can be used.

Comparing their performances is essential, since a given equation may work well (give a good fit) for the few tests it was derived for, those tests being biased by the same mistakes. However, it will not work for other tests, which include different mistakes or none. Working well, for a predictive equation, may simply mean that there is some consistency in its data and their errors, but working well for a few tests does not mean that the predictive method is reliable.

Predictive methods for non-plastic soils

Seven predictive methods were retained as having potential, and are presented here.

Hazen (1892) coupled with Taylor (1948)

Hazen’s equation applies to loose uniform sand with a uniformity coefficient C U ≤ 5 and a grain size d 10 between 0.1 and 3 mm. First, one must verify whether or not the four conditions—(1) sand, (2) “loose” meaning that the void ratio e is close to e max, its maximum value, (3) “C U ≤ 5” and (4) “0.1 ≤ d 10 ≤ 3 mm”—are satisfied. If the four conditions are not satisfied, Hazen’s equation loses accuracy. Most textbooks refer to (Hazen 1911) and present Eq. 7 where d 10 is expressed in mm:

This Eq. 7 is not the true Hazen’s equation, which is (Hazen 1892):

in which the water temperature T is in degrees Celsius. The common equation in textbooks corresponds to T = 5.5 °C. In laboratory tests, the reference temperature is presently 20 °C, and thus

For field conditions, for example at 10 °C, one should use

As discussed above, Hazen’s equation predicts the K value for loose uniform sand (e ≈ e max). Various equations are also available to define K as a function of void ratio e, i.e. K = K(e). Taylor (1948) proposed an equation similar to that known as Kozeny-Carman, expressed as

In Eq. 11, the coefficient A (same units as K sat) has a specific value for each soil. The A value can be obtained from a first set of experimental values (e, K sat). Here, for a prediction, one can use Hazen’s equation to predict K sat (e max) and then Taylor’s equation to predict K sat (e) for any e value. One way to proceed is to write:

The A value is extracted from Eq. 12, and then used in Eq. 11. A second way to proceed is to use the ratio of two K values directly to eliminate the coefficient A:

Terzaghi (1925)

Terzaghi (1925) proposed, for sand, that

where the constant C 0 equals 8 for smooth rounded grains and 4.6 for irregularly shaped grains, and μ 10 and μ Τ are the water viscosities at 10 °C and T (°C) respectively. Laboratory tests are usually performed close to T = 20 °C, for which the ratio of viscosities is 1.30.

Kozeny-Carman, specific surface

Following independent work by Kozeny (1927) and Carman (1937, 1938a, b, 1939, 1956), who never published together, and were interested in permeability testing of industrial powders to determine their specific surface, the so-called Kozeny-Carman equation for hydraulic conductivity (e.g., Wyllie and Gardner 1958a, b) can be presented under several forms, for example

where C is a constant which depends on the porous space geometry, g the gravitational constant (m/s2), μ w the dynamic viscosity of water (Pa·s), ρ w the density of water (kg/m3), ρ s the density of solids (kg/m3), G s the specific gravity of solids (G s = ρ s/ρ w), S S the specific surface (surface of solids in m2/mass of solids in kg) and, e the void ratio. Equation 15 predicts that, for a given soil specimen, there should be a proportionality between its K sat values and its values of e 3/(1 + e). It can also be used to predict the intrinsic permeability, k (unit m2), knowing that:

According to soil mechanics textbooks (e.g., Taylor 1948; Lambe and Whitman 1969), the Kozeny-Carman equation would be roughly valid for sands, but not for clays. Some hydrogeology textbooks share the same opinion, although they generally use an equation without the specific surface S S but with an equivalent (usually not defined) diameter d eff for the soil, the two forms being equivalent (Barr 2001; Trani and Indraratna 2010).

In practice, Eq. 15 is not easy to use, the difficulty being to determine either the specific surface S S or the equivalent diameter d eff. The S S value can be either measured or estimated. Several methods are available for measuring the specific surface (e.g., Dallavale 1948; Lowell and Shields 1991) but they are not commonly used in soil mechanics and hydrogeology. In addition, such methods seem accurate only for granular soils with few non-plastic fine particles. These practical difficulties may explain why the Kozeny-Carman predictive equation has not been commonly used, until recently (e.g., Chapuis and Aubertin 2003, 2004; Carrier 2003; Hansen 2004; Aubertin et al. 2005; Côté et al. 2011; Esselburn et al. 2011).

Chapuis and Aubertin (2003) examined, in detail, the capacity of Eq. 15 and concluded that it may be used for any soil, either plastic or non-plastic, under the form

In Eq. 17, K sat is in m/s, S S is in m2/kg, and G s is dimensionless. Usually, Eq. 17 predicts a K sat value between one-third and three times the K sat value obtained with a high quality laboratory test and a fully saturated specimen.

For non-plastic soils, using the Kozeny-Carman equation requires knowing S S and thus having a complete GSDC (sieving and sedimentation). Often sedimentation is not done for non-plastic soils. This is why other predictive methods, relying on readily determined parameters, have been developed for non-plastic soils.

Navfac DM7 (1974)

The chart of Navfac DM7 (1974) provides K sat as a function of e and d 10, under five conditions: (1) sand or a mix of sand and gravel, (2) 2 ≤ C U ≤ 12, (3) d 10/d 5 ≤ 1.4, (4) 0.1 ≤ d 10 (mm) ≤ 2 mm, and (5) 0.3 ≤ e ≤ 0.7. This chart can be summarized by the formula (Chapuis et al. 1989b):

Programming this power-of-power equation is prone to errors. It is thus recommended to check the program predictions against the values shown in the chart. If the five conditions are not satisfied, the predicted K sat value will lose accuracy.

Shahabi et al. (1984)

Shahabi et al. (1984) took a single sand sample in the field, and separated its fractions by sieving. These fractions were mixed in various proportions to obtain four groups of five new samples each, each group having a single d 10 value and several C U values. The data of constant-head permeability tests performed in rigid-wall permeameters gave them the following correlation

This equation was used for a few sand specimens verifying four conditions: (1) sand, (2) 1.2 ≤ C U ≤ 8, (3) 0.15 ≤ d 10 (mm) ≤ 0.59 mm, and (4) 0.38 ≤ e ≤ 0.73.

Mbonimpa et al. (2002)

For non-plastic soils, Mbonimpa et al. (2002) proposed

A warning must be made for Eq. 20: d 10 here is in cm. The parameters of Eq. 20 take the following values: C G = 0.1, γ w = 9.8 kN/m3, μ w ≈ 10−3 Pa·s, and x = 2. The predictions of Eq. 20 for non-plastic soils were found to be usually within half an order of magnitude, for natural soils, crushed materials such as mine tailings, and low plasticity silts.

Chapuis (2004b)

This equation was obtained as a best-fit equation, correlating the values of (d 10)2 e 3/(1 + e) to the measured K sat values for homogenized specimens, high quality laboratory tests, and fully saturated specimens (Chapuis 2004b). It may be used for any natural non-plastic soil, including silty soils. For crushed materials, its accuracy may be poor, and specific predictive methods may be required (Aubertin et al. 1996). The predictive equation links K sat to d 10 and e as follows:

Good predictions (usually between half and twice the measured values) were obtained for natural soils in the following ranges, 0.003 ≤ d 10 (mm) ≤ 3 mm and 0.3 ≤ e ≤ 1 (Chapuis 2004b), which means that three conditions must be met for this method (natural, d 10 and e). Current data appear in Fig. 4.

With crushed materials, such as crushed stone and mine tailings, the predictions of Eq. 21 are usually poor (Chapuis 2004b) as shown with a few data in Fig. 5. At least three factors can explain the poor correlation. First, crushed materials have angular, sometimes acicular, particles, which increases the tortuosity effect as compared with natural rounded or sub-rounded particles. Second, as a result, the void space geometry of crushed materials is unlike that of natural soils. Third, several phenomena may take place during testing of crushed materials (Bussière 2007), such as creation of new fines (DeJong and Christoph 2009) and migration of these fines during testing (Chapuis et al. 1996), which are not easy to consider in predictive equations.

Poor predictions are obtained using Eq. 20 for crushed materials

Comparing the performances

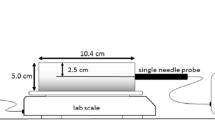

To conclude “Predictive methods for non-plastic soils”, the selected predictive methods for non-plastic soils are compared for a set of high quality fully saturated laboratory tests (Fig. 6). This set has more data than the set of Chapuis (2004b), and is used here to assess more methods. The tests were performed on homogenous non-plastic soil specimens, which were 100% saturated using de-aired water and either a vacuum or back-pressure technique, and which were not prone to internal erosion. Aquifer soils were tested in rigid-wall permeameters equipped with lateral manometers. Aquitard non-plastic soils were tested in flexible-wall permeameters (triaxial cells).

The comparison is presented as y = the percentage of cases smaller than x, where x = log (measured K sat/predicted K sat). The methods of Hazen (1892) combined with Taylor (1948), Terzaghi (1925), and Shahabi et al. (1984) provide usually fair predictions. The equation of Chapuis (2004b) was designed to have a mean of zero with the smallest dispersion: this property is still verified here with more data than in 2004.

As explained in Chapuis (2004b), other predictive equations for non-plastic soils (mostly sand and gravel, most of them less complete than the seven retained here) have a much lower predictive capacity than those retained in this section (“Predictive methods for non-plastic soils”).

Predictive methods for plastic soils

Natural soils without fissures

As already shown, the Kozeny-Carman equation can be used for the predictions, and there are several methods to measure or estimate the S S value of plastic soils. For example, following Muhunthan (1991) who stated that there should be a correlation between 1/S S, and 1/w L, Chapuis and Aubertin (2003) used many data for plastic soils (De Bruyn et al. 1957; Farrar and Coleman 1967; Locat et al. 1984; Sridharan et al. 1986, 1988; Muhunthan 1991). They found a linear correlation (R 2 = 0.83) between 1/S S (where S S is in m2/g) and 1/w L, (where the liquid limit w L is in percentage), which is valid for w L < 110 %:

Usually, the Kozeny-Carman equation (Eq. 17) predicts a K sat value between one-third and three times the K sat value obtained with a high quality laboratory test and a fully saturated specimen. The predicted versus measured K sat values appear in Fig. 7 for fine-grained soils (either plastic or not) for which the specific surface is known (Chapuis and Aubertin 2003).

Mbonimpa et al. (2002) proposed a power law relationship between w L and S s, which provides similar S S estimates for w L < 110%. Equation 22 predicts an S S value usually within ±25 % of the measured value when 1/w L > 0.0167 (w L < 60 %). The predictions of Eq. 22 are poorer for clays with w L > 60 %, especially those with some bentonite, and organic clays.

Independent of the Kozeny-Carman equation, several experimental relationships were proposed and are presented here in chronological order. Having obtained K sat values by analysing consolidation settlement data, Nishida and Nakagawa (1969) proposed

In Eq. 23, K sat is in cm/s, and I P is in percentage. Dassargues et al. (1991) used this type of correlation between K sat and e, but with specific coefficients for their clays.

Determining the K sat value of normally consolidated remoulded clays using Terzaghi’s consolidation theory, Samarasinghe et al. (1982) proposed

In Eq. 25, K sat is in m/s, x is about 5 (or in a range of 3.97–6.39, according to Sridharan and Nagaraj 2005), and C (m/s) can be assessed by

Nagaraj et al. (1991) observed that all clays have almost the same K sat value at their limit liquid w L. For normally consolidated clay, the test starting with a clay slurry at w = w L, Nagaraj et al. (1993) proposed

Whereas Nagaraj et al. (1994) proposed

and Prakash and Sridharan (2002) proposed

In Eqs. 26–28, K sat is in cm/s, and e L is the void ratio at the liquid limit. Equations 26–28 imply that, at the liquid limit (e/e L = 1), the K sat value takes a constant value whatever the clay.

Performing œdometer tests with sand-bentonite mixtures (w L > 50 %), and determining the K sat value using Terzaghi’s consolidation theory, Sivappulaiah et al. (2000) proposed four relationships where K sat is in m/s, the best correlation being obtained with Eq. 30:

For plastic soils, Mbonimpa et al. (2002) proposed

The parameters to be used in Eq. 33 are: K sat in cm/s, C P = 5.6 g2/m4, γ w ≈ 9.8 kN/m3, μ w ≈ 10−3 Pa·s, χ = 1.5, ρ s in kg/m3, w L in %, whereas the parameter x is defined by

The predicted values for plastic soils using Eqs. 33–34 were usually within half an order of magnitude of the measured values (Mbonimpa et al. 2002).

Sridharan and Nagaraj (2005) found that Eq. 24 provided a poor correlation for their tests, and proposed to link C (m/s) and x to the shrinkage index I S by

With the C and x values experimentally obtained for each specimen tested at different void ratios, they found that Eq. 24 predicted K sat values usually between half and twice the measured values. However, this is not really a prediction, since the parameters were fitted first to experimental data.

Stating that “The portion of clay minerals p in soils can be obtained from a particle size analysis”, Dolinar (2009) proposed three equations correlating S S to p and w L, w P and I P,

Dolinar (2009) then proposed the following equation to predict K sat

The capacities of all predictive equations for K sat will be assessed after presenting the equations of the next sub-section for “Dredged sediments, without fissures”.

Dredged sediments, without fissures

The disposal of waste slurries from mining operations and dredging activities presents challenging problems. These materials, when made of plastic fines, with little or large organic content, have very high void ratios, which vary greatly during consolidation. As a result, it may be difficult to estimate the final volumes of such materials in disposal facilities, and how many years they will take to consolidate. The correctness of estimates depends on the accuracy of relationships between effective stresses, void ratio and hydraulic conductivity. For preliminary designs, correlations based on geotechnical index properties are useful. Equations for dredged sediments were proposed for a much larger range of void ratio e and variation of e during consolidation than the previous equations in “Natural soils without fissures”.

The permeability change of slurry made of plastic soil during a 1D consolidation was described with a power law similar to that of Mesri and Olson (1971), with two fitting factors, C (m/s) and D (non-dimensional), such as

For remoulded clays, a general permeability equation was proposed by Carrier and Beckman (1984) and Carrier (1986) under the form

in which K sat is in m/s, e is the void ratio, w P is the plastic limit (in percent) and I P is the plasticity index (in percent). Equation 42 should be used with caution because it may predict a negative K sat value.

For fine-grained dredged materials, Morris (2003) proposed

In Eq. 42, K sat is in m/s, and e L is the void ratio at the plastic limit, w L. However, the K sat(1 + e) data of Morris (2003) were scattered over about two orders of magnitude at e = 2, and about four at e = 4. For mine tailings, which usually contain angular and brittle particles (the GSDC is changed, becomes finer, during settlement), Morris et al. (2000) proposed another specific equation. The predictions for dredged sludge were examined by Stepkowska et al. (1995).

Using the data of a few permeability tests (constant flow rate method, 1 h duration), Berilgen et al. (2006) correlated the parameters C and D of Eq. 41 with the plasticity index I P and the liquidity index I L

Comparing the performances

The predictive capacity of equations presented in Sects. “Natural soils without fissures” and “Dredged sediments, without fissures” (Nishida and Nakagawa 1969; Samarasinghe et al. 1982; Carrier and Beckman 1984; Nagaraj et al. 1991; Sivappulaiah et al. 2000; Mbonimpa et al. 2002; Berilgen et al. 2006; Dolinar 2009) is assessed here using a large number of high quality laboratory tests. The data bank includes data of Tavenas et al. (1983b); Sridharan and Nagaraj (2005); Al-Tabbaa and Wood (1987); Babu et al. (1993); Lapierre et al. (1990); Nagaraj et al. (1994); Tan (1989); Zeng et al. (2011); Leroueil et al. (1990); Dolinar (2009); Siddique and Safiullah (1995); Tanaka et al. (2001, 2003) and many data from the author’s laboratory. Several data were excluded for not satisfying one or several requirements listed above, for example data by Olsen (1960), Raymond (1966), Ag and Silva (1998), Luczak-Wilamowska (2004), O’Kelly (2006), and Berilgen et al. (2006).

The comparison is presented in Fig. 8 as y = the percentage of cases smaller than x, where x = log (measured K sat/predicted K sat). The values predicted by the equations of Samarasinghe et al. (1982) and of Sivappulaiah et al. (2000), based on indirect determination of the K sat value (using the settlement curves and the old consolidation theory) are wrong (underestimated) by about 2 orders of magnitude when compared to directly measured K sat values, thus confirming statements presented in mistake No.5 of “Rigid- and flexible-wall permeameters, common mistakes”. The equations of Dolinar (2009) underestimate K sat whereas the equations of Nishida and Nakagawa (1969), Carrier and Beckman (1984), Nagaraj et al. (1991) overestimate K sat (Fig. 8). The equation of Berilgen et al. (2006), based on short duration tests using a forced constant flow rate (flow pump technique), leads to severe overestimates of K sat, thus confirming statements presented in mistake No.5 of Rigid- and flexible-wall permeameters, common mistakes. Finally, for natural inorganic clays, the method of Mbonimpa et al. (2002) is shown to have the best predictive capacity with a ratio K predicted/K measured usually between 0.5 and 2 (Fig. 8).

Comparing the performances of predictive equations for plastic soils. The equations were proposed by Nishida and Nakagawa (1969), Samarasinghe et al. (1982), Carrier and Beckman (1984), Nagaraj et al. (1991), Sivappulaiah et al. (2000), Mbonimpa et al. (2002), Berilgen et al. (2006), and Dolinar (2009)

Semi-log and power laws

The Kozeny-Carman equation predicts a proportionality between two scalars, K sat and e 3/(1 + e), the equation assuming implicitly an isotropic K tensor. However, real soils are not isotropic. Consider, for example, tests with kaolinite and kaolin. Proportionality is observed when the first invariant of the K tensor, I K1 = (K v + 2K h)/3, of the AW tests (Al-Tabbaa and Wood 1987) is plotted, but not when the AW vertical and horizontal test data are plotted (Fig. 9), although there is some linearity. Proportionality is also not observed for the data of other vertical tests (ML = Michaels and Lin 1954; D = Dolinar 2009). However, the Kozeny-Carman equation provides a fair match to the vertical K sat data of sensitive clay (Louiseville clay tested by Lapierre et al. (1990); and specimens of Lachenaie clay tested in the author’s laboratory as shown in Fig. 10. In the case of intact and remoulded London Clay, consolidated at very high pressures, to become mudstone (data from Dewhurst et al. 1999), the fit with a Kozeny-Carman equation is not very good for the direct and indirect K sat values; however, it gives the general trend (Fig. 11).

Example of a fair fit between the Kozeny-Carman equation and the measured vertical K sat of two sensitive clays (Louiseville clay: data from Lapierre et al. 1990; Lachenaie clay: data from the author’s laboratory)

Example of intact and remoulded London Clay, consolidated at very high pressures to become mudstone (data from Dewhurst et al. 1999). The fit with a Kozeny-Carman equation is inadequate for the directly and indirectly measured K sat values, but it gives the general trend

Terzaghi (1922b) and Zunker (1932) already noted some non-linearity when plotting e 3/(1 + e) versus experimental directional K sat data. The divergence may be due to a thin immobile water layer at the surface of clay particles (Carman 1939; Singh and Wallender 2008), to non-participating or dead-end pores or a percolation threshold (Mavko and Nur 1997). It is then possible to consider a reduced, or effective flow, porosity (Koponen et al. 1997), with the risk of confusing it with the effective porosity obtained using a non-reactive tracer test. Noting that the K sat value of clay may not be exactly proportional to e 3/(1 + e), Taylor (1948) proposed the semi-log empirical relationship

Equation 46 may also be written as

In Eqs. 46–47, e 0 and K 0(e 0) are reference values and C K is a permeability change index. Note that Eqs. 46–47 become predictive equations only if the K 0(e 0) value has either been predicted by some method or measured by a high quality direct laboratory test. As a result, it became usual, for highly compressible clay, silt and peat, to plot log(K) versus e and to investigate how this plot changes as the mechanical consolidation process proceeds. To characterize the decrease in K with the decrease in void ratio e, from an initial value e 0, the ratio C K is defined as

For natural clay and silt, with e between 0.8 and 3, and volumetric strains less than 20%, C K is close to 0.50 e 0 (Tavenas et al. 1983b; Mesri et al. 1994) or 0.41 e 0 (Babu et al. 1993). For peat, which differs from clay by its very high hydraulic conductivity at an initially very high e 0, and its large volumetric strains, C K is close to 0.25 e 0 (Mesri and Aljouni 2007).

Mesri and Olson (1971) found that Eq. 46 is acceptable only for a small range of void ratio and volumetric strain. For wide ranges, and either artificial or remoulded clays, they proposed

Equation 49 may be rewritten as a power law, with a constant dimensionless power b, such as

Other relationships were proposed to link K and total porosity n for rock cores, such as

The power law and other specific laws are used for rocks such as shale, sandstone, and mudstone (e.g., Walder and Nur 1984; Cao et al. 1986; Dutta 1987; Rajani 1988; Lerche 1991; Rice 1992; Neuzil 1994; Panda and Lake 1994; Nelson 1994, 2005; David et al. 1994; Dewhurst et al. 1999; Pape et al. 2000; Civan 2001; Yang and Aplin 1998, 2007, 2010).

Juárez-Badillo (1984) proposed Eq. 52 with a permeachange coefficient P K defined in Eq. 52

Equation 52 provided a good fit for a few, but not all, clays tested by Tavenas et al. (1983b). Then, Juárez-Badillo (1984) questioned the heterogeneity in local void ratio and effects of seepage forces on the void network, especially at low e values. In their reply, Tavenas et al. (1984) stated that obtaining the K 0 value in Eq. 52 was problematic for two reasons: it requires a doubtful extrapolation of data down to e = 0, and its physical meaning is not clear.

For fibre assemblies which experience large variations of porosity during compaction and excess pore pressure in successive lifts (Crawford et al. 2011; Nogai and Ihara 1978) proposed to use

where R and β are experimentally determined values.

Regional equations

For regional clay deposits, specific correlations can be obtained. According to Muhunthan (1991) there should be a correlation between 1/S s, and 1/w L. If this is a direct proportion, this would imply that, according to the Kozeny-Carman equation, K sat for a given clay specimen should be proportional to x = [e 3/(1 + e)]/w 2L , and also log (K sat) should be linearly related to log (x). Figure 12 shows four examples of straight line correlations between log (K sat) and log (x), for the kaolin of Al-Tabbaa and Wood (1987), and three Champlain Sea clay specimens tested by Tavenas et al. (1983b), Lapierre et al. (1990) and our laboratory (Lachenaie clay).

Besides showing linear correlations in a log–log plot, Fig. 12 indicates that the relationship is not unique for the three clay samples of same origin (Champlain Sea). Thus, one may try a linear relationship between 1/S s, and 1/w L, hoping it would be unique for a clay deposit. Therefore, the data of K sat should be plotted against the ratio x = [e 3/(1 + e)]/[w −1L + a]2. The parameter a can be found by using a least square method minimization process.

Figure 13 shows a regional correlation for Quebec Champlain Sea clay, using data of Tavenas et al. (1983b); Lapierre et al. (1990); Leroueil et al. (1990) and two Lachenaie specimens (among a few hundreds) of the authors laboratory. The least square method gave a = 0.00836. Many more test data from the laboratory, which are not used in Fig. 13, confirm this trend.

Figure 14 indicates that the local correlation (Fig. 13, Quebec Champlain Sea clays) provides a good estimate of K sat, usually between 1/3 and 3 times the measured value.

Example of local correlation (Champlain clays, Quebec): the power law Equation of Fig. 13 provides a good estimate of K sat. Many recent test data (to be published) confirm this trend

Compacted plastic soils with micro-fissures

Compacted plastic soils are used for liners and covers in waste management facilities. For non-swelling clay, it is well known that K sat depends on void ratio e, and on the preparation and compaction modes (Terzaghi 1922b; Lambe 1958; Mitchell et al. 1965). Plastic soil specimens compacted wet of optimum (in the Proctor test) may have K sat values 100–1,000 times lower than specimens compacted dry of the optimum. The K sat value of compacted non-swelling clay depends in large part on the secondary porosity between artificially formed clay clods. It then depends on a macrostructure resulting from remoulding during excavation, transport and handling including compaction, and weathering processes such as wetting–drying and freeze–thaw (e.g., Othman et al. 1994; Albrecht and Benson 2001). The primary porosity of the clay matrix, which corresponds to the fine structure at the micron scale, has little influence on K sat for compacted non-swelling clay. However, swelling clays (e.g., soil-bentonite mixtures) behave differently and can achieve fairly low K sat values even when compacted dry of optimum (e.g., Chapuis 1990a, b, 2002; Chapuis et al. 1992; Haug and Wong 1992). For natural clay, when the fractures are closed to residual aperture, the K sat value depends mostly on the clay matrix (Sims et al. 1996).

Chapuis (2002) assumed that at the end of compaction all water is held within the clods and none between the clods, the secondary porosity being filled with air only. Thus, the air volumetric fraction, or secondary porosity of the compacted plastic soil equals n c(1−S rc) where n c is the total porosity after compaction, and S rc the degree of saturation after compaction. When a compacted clay specimen is prepared for permeability testing, its degree of saturation is increased from S rc to S rt (usually close to 100 % when high back-pressuring is used). According to several authors, the size of laboratory compacted specimens (about 100 or 150 mm in diameter) is large enough to avoid the problem of scale effect that can appear with smaller specimens (e.g., Cazaux and Didier 2002). Using a cubic law and the data of several compacted clays (Lambe 1958; Mitchell et al. 1965), including clay liners in Quebec, Chapuis (2002) proposed to evaluate K sat with

The values of parameters a and b in Eq. 54 can be obtained by plotting a few high quality triaxial test data for the compacted plastic soil (Fig. 25 in Chapuis 2002). The K sat value predicted using Eq. 54 is retained if higher than 10−10 m/s, and taken as 10−10 m/s if lower than that value, unless triaxial test data for equivalent conditions are available and may be retained.