Abstract

Unnatural patterns in process control charts exhibit out-of-control conditions. Therefore, increase in sensitivities in control charts is mandatory to study these situations. Because of the existence of inevitable natural variations, real-time detection and analysis of the significant patterns is a problem, especially when sensitivity level of the process to unnatural patterns formation is high. In the previous studies, most researchers have applied neural networks techniques to monitor significant patterns. Although this approach is effective, but structures of networks are complex and their architectures are difficult. The current paper develops fitted line and fitted cosine curve of samples to recognize and analyze the unnatural patterns. This simpler solution is more efficient and consumes less feedback time. The proposed model alarms occurrence of single and concurrent patterns and estimates their corresponding parameters. These fitted line and curve facilitate recognition and analysis of significant patterns at different levels of sensitivity, while the presented models often face with patterns misclassification error when high level of sensitivity is desired for unnatural patterns discrimination. To implement the proposed model, S2 control chart has been selected as a case study. The accuracy and precision of the proposed tools are evaluated by simulated experiments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The seven tools of statistical process control (SPC) support its technical and statistical aspects. Among these tools, Shewhart’s process control charts play a very crucial role. These charts make online control of the attribute and variable qualitative characteristics possible. In the general applications, whenever all samples fall between the control limits of the charts, the process is considered under-control. This traditional conclusion was suitable to meet the primary needs; however, with the gradual introduction of significant patterns formation issue in process control charts, such analysis lost its adequacy. In other words, the formation of non-random behaviors in scattered samples between control limits associate out-of-control situations. Therefore, patterns recognition was selected as one of the most important tools to enhance the qualitative sensitivity of process control charts. Indeed, the emergence of significant patterns alarm some disorders in production processes and since Shewhart’s control charts only study samples individually and do not consider the obtained common data from consecutive samples, real-time recognition and continued analysis of behavioral patterns, accurately and precisely, is vital.

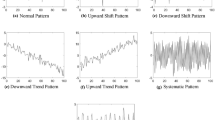

In the literature, shift (Sh.), trend (Tr.), cycle (Cyc.) and systematic (Sys.) patterns have been introduced as the “basic patterns,” since these behaviors have process roots and generally occur in most control charts (see Fig. 1). The basic patterns can appear as single or concurrent.

Illustrated formation of shift (upward, downward) pattern, trend (upward, downward) pattern, a mode of cycle pattern and a mode of systematic pattern. (In these control charts, the significant patterns start at 13th sample; the horizontal axes are the samples number, and the vertical axes are the samples value)

The various factors cause the formation of significant patterns in process control charts. For example, utilization of new operators, new production methods, new machinery and changes in inspections and standards are some occurrence reasons of the Sh. pattern [1]; the gradual wear of machinery and tools, and seasonal effects are some causative factors of Tr. pattern [1]; environmental changes, such as temperature variations, fatigue of operators, continuous displacement of operators and/or any variable related to production machinery, cause Cyc. pattern [1]; the alternative changes in production factors appear as Sys. pattern [1].

In addition to patterns recognition, the determination of desired qualitative sensitivity levels of production processes and the monitor of improvement plans progress are necessary. To make these possible, corresponding to each basic pattern, the numerical parameters (such as displacement magnitude, trend slope, amplitude, period) have been defined.

A very important point is that the concept of “patterns recognition” in control charts signifies whenever the limits of charts are same for all samples [1]. Therefore, when the sizes of samples are various and the chart limits are calculated separately for each sample, behavioral patterns and their simulations lose their meanings.

In the previous years, the numerous models have been presented to discriminate and analyze significant patterns in process control charts. In an overview, these researches are divided into two categories:

In the first category, artificial neural networks have been utilized widely, because of their abilities in patterns learning: Pham and Oztemel [2] applied the learning vector quantization (LVQ) network for the classification of unnatural patterns. Cheng [3] presented a multilayer network for detection of changes in the process mean. Cheng [4] used neural network approach to analyze control chart patterns. Hwarng [5] offered a model for study of elementary cyclic patterns. Chang and Aw [6] introduced a neural fuzzy control chart to discriminate and classify mean variations in production processes. Anagun [7] trained a multilayer neural network with back-propagation (BP) algorithm for patterns recognition in statistical process control. Pham and Sagiroglu [8], in their paper, compared four training algorithms of multilayer perceptron (MLP) networks for patterns recognition of process control chart. Chiu et al. [9] used BP and AR(1) time series models for architecture of a perceptron network to identify the changes in the process parameters. Guh and Hsieh [10] introduced a model based on neural networks for patterns recognition and estimation of their corresponding parameters in process control charts. Guh et al. [11] suggested a model for online detection of unnatural patterns in control charts. Guh and Tannock [12] trained perceptron networks with BP algorithm to recognize concurrent patterns. These networks simulate the simultaneous occurrence of some basic patterns. Guh [13] combined artificial intelligence technique with an expert system to implement SPC tasks automatically. Guh [14] used genetic algorithm to train the feed-forward neural networks to solve recognition issue. Guh [15] presented a model based on neural networks and expert systems for online detection and analysis of control chart patterns. Guh [16] presented a real-time model based on neural networks for the simultaneous recognition of patterns in both mean and variance control charts. Chen et al. [17] offered a combined model for recognition of concurrent patterns. Fatemi Ghomi et al. [18] analyzed basic and some concurrent patterns in process control charts through a LVQ network and seven two-layer perceptron networks. Ebrahimzadeh et al. [19] introduced a dual-phase model to analyze the basic patterns. This model has used the capabilities of several types of the neural networks algorithms. Yang et al. [20] suggested a hybrid model based on several types of networks for the simultaneous control of patterns in mean and variance charts. Lesany et al. [21] classified basic and all states of concurrent patterns in control charts via a LVQ network, a MLP network and fitted line of samples. The model proposed by the authors solves the problem of patterns misclassification error, acceptably. Cheng et al. [22] used a neural network-based pattern recognizer with extracted features from correlation analysis for study of patterns in control charts.

In the second category, other approaches have been utilized:

Yang and Yang [23] presented a model based on statistical correlation coefficient to identify patterns in control charts. Lin et al. [24] proposed a support vector machine (SVM) for online real-time recognition of unnatural patterns.

One of the problems that happens during patterns recognition of process control charts is called “patterns misclassification”. Particularly, when qualitative sensitivity level of the processes to the significant patterns formation is high, the probability of misclassification error increases in the models. Although the previous models have studied misclassification problem, they often face with patterns misclassification error when high level of sensitivity is desired for unnatural patterns detection. Most of the presented works have applied neural networks as recognition tool. According to the results of these models, the neural networks have uncertain reliability, when the sensitivity of processes to the appearance of unnatural patterns is high. Lesany et al. [21] via analysis of the samples’ fitted line decreased misclassification error of Sh. and Tr. patterns, at different levels of sensitivity, considerably.

The proposed model in this paper develops samples’ fitted line and samples’ fitted cosine curves for more accurate recognition of patterns type and more precise estimation of their corresponding parameters at different levels of sensitivity. These tools decrease misclassification error of Sh. (upward/downward) pattern, Tr. (upward/downward) pattern, Cyc. pattern (in all formation phases) and Sys. (in all formation phases) pattern, considerably. Moreover, the current model can alarm concurrent occurrence of basic patterns in all the forms.

The rest of this paper is organized as follows: Sect. 2 deals with definitions, expressions and notations used in this model and also introduces the simulator functions of process control charts patterns. Section 3 explains the general structure of the proposed model and describes its details. Section 4 implements the proposed model in S2 control charts as a case study. Section 5 evaluates the performance of the proposed model in recognition and analysis of control charts patterns. Section 6 presents comparative studies. And finally, Sect. 7 is devoted to conclusions and recommendation for further research.

2 Definitions, expressions and notations

2.1 Control box and control vector

To recognize and analyze the unnatural patterns, R random samples are entered into the model. Suppose this R-dimensional vector as a box. Since the aim is detection and interpretation of the significant patterns in this box, it is called “control box”; also the related vector is called “control vector.” After determination of the samples situation in a control box, R new random samples are replaced with the current samples. In this paper, each control box comprises 12 random samples. After determination of the situation of existing samples, 12 new random samples are replaced with 12 current samples.

2.2 Fitted line

Consider the scattered samples in a control box. The fitted line of these samples is a line which the sum of squared vertical intervals of samples points from it would be minimal. This method is called the “least squares method” [25].

2.3 Fitted cosine curve

The fitted cosine curve of samples (in a control box) is a cosine curve which the sum of squared vertical intervals of samples points from it would be minimal. See Fig. 2.

2.4 Simulation of natural variations

The existence of common cause variations in processes is natural and inevitable. These variations make accurate, precise and real-time recognition of unnatural behaviors difficult, because natural variations change significant patterns from their expected forms.

In applied statistics, there is a probability distribution function for each random variable [26]. Since common cause variations are random variables inherently, they have a probability distribution function. This theorem is the basis of natural behaviors simulation in process control charts.

The existence of natural variations in processes is unavoidable; therefore, simulated samples for an under-control process are always as follows:

In this equation, \(t\) determines the sample’s number; \(n(t)\) is the value of natural variation of process in tth sample, and its statistical distribution function is the same as distribution function of samples in its corresponding chart (for example, in a \(\bar{x}\) under-control chart, natural variations and samples have Normal distribution); \(x(t)\) is the value of tth sample.

2.5 Simulation of unnatural patterns and introduction of their corresponding parameters

The formation of any unnatural pattern in control charts warns a special disorder and out-of-control situation in the production process. For this reason, each pattern must be studied separately and exactly. Therefore, the measurable criteria for basic patterns have been defined. The definition of numerical parameters makes the determination of desired qualitative sensitivity levels of production processes and the monitor of improvement plans progress possible. The generating functions of the basic patterns and their corresponding parameters are as follows:

2.5.1 The generating function of Sh. pattern

The Sh. pattern generating function (including natural variations) is as:

In this equation, \(b\) is the parameter of Sh. pattern and shows displacement magnitude (see Fig. 1). The value of this parameter can be positive (upward Sh.) or negative (downward Sh.).

2.5.2 The generating function of Tr. pattern

The Tr. pattern generating function (including natural variations) is as follows:

In this equation, \(s\) is the parameter of Tr. pattern and shows trend slope (see Fig. 1). The value of this parameter can be positive (upward Tr.) or negative (downward Tr.).

2.5.3 The generating functions of Sys. and Cyc. patterns (the periodic patterns)

Consider the following function:

When parameter of \(T\)(i.e., period) is equal to 2, Eq. (4) is Sys. pattern generating function (including natural variations), and \(a\) reflects the amplitude of fluctuations. In other cases, this function can be the generating function of Cyc. pattern (including natural variations), and \(a\) reflects amplitude of cycle. In the current paper, interval of \(8 \le T \le 12\) is considered as Cyc. pattern generating function. Note that the occurrence causative roots of Sys. and Cyc. patterns are completely different and technical concepts of these two behaviors have no relationship together!

In Eq. (4), \(k\) is a virtual parameter and represents the phase difference in the starting point of these patterns. This parameter does not play a role in process analysis, but accelerates accurate recognition of Sys. and Cyc. patterns and covers all states of their formations [18]. Figure 3 illustrates the concept of phase difference in starting point and displays the various formation modes of Cyc. pattern with a period 8 and \(k = 0,1,2, \ldots ,7\).

The numerical value of the parameter of \(T\)(period) is a subset of the natural numbers, and the parameter of \(k\)(phase difference) is a subset of nonnegative integer numbers, and always \(k < T\).

The reviewed models in the literature (except references of [18, 22] and [21]) have considered incomplete expression of \(\left[ {a.\sin \left( {\frac{2\pi .t}{T}} \right)} \right]\) and \(\left[ {a.( - 1)^{t} } \right]\) as generating functions of Cyc. and Sys. patterns, respectively. Fatemi Ghomi et al. [18] defined virtual parameter of the phase difference (\(k\)) and presented expression of \(\left[ {a.\cos \left( {\frac{2\pi t}{T} + \frac{2\pi k}{T}} \right)} \right]\) as generating function of Cyc. and Sys. patterns. However, the expression of \(\left[ {a.{ \cos }\left( {\frac{2\pi t}{T} + \frac{2\pi k}{T}} \right)} \right]\) (abbreviated as \(un(t)\)) cannot alone be the generating function of Cyc. and/or Sys. patterns.

Lesany et al. [21] developed the fitted line of samples for study of Sh. and Tr. patterns and completed the expression of \(un(t)\). See Fig. 4. Figure 4 (Part a) illustrates the expression of \(un(t)\)(with parameters of \(T \, = 12 \,\) and \(k = 3\)) in a control box. The fitted line intercept and slope of this curve’s points must be zero, because this curve should be generating function of Cyc. and Sys. patterns merely and these two elements indicate Sh. and Tr. patterns, respectively [21]. Therefore, the “modification expression” of \(\left[ {s_{cs} .t + b_{cs} } \right]\) is removed from it. In this case, the fitted line intercept and slope of the improved generating function are zero (see Fig. 4 (Part b)). Indeed, the modification expression is the fitted line of points of \(un(t)\) that has been calculated by least squares method. The slope (\(s_{cs}\)) and intercept (\(b_{cs}\)) of this line are as:

In these equations,\(n\) is number of samples (and dimension of control vectors).

2.5.4 Simulation of concurrent patterns

As mentioned in the literature, the basic patterns can occur singly or concurrently. The simulator function of each form of concurrent occurrence of the basic patterns is a result of addition of the terms including occurred patterns parameters and \(n(t)\). For instance, the simulator function of concurrent occurrence of Sh. and Tr. patterns, including natural variations, is as \(x(t) = n(t) + b + s.t\); and so on.

2.6 Sensitivity level

As mentioned, the main goal of unnatural patterns recognition in process control charts is the enhancement of charts’ sensitivities to detect and analyze out-of-control situations. The sensitivity specifies the value of required accuracy in a process and directly depends on the parameters of unnatural patterns. The determination of the boundary value of a parameter for approval of the formation of its corresponding unnatural pattern is called “determination of the sensitivity level.” The determination of the sensitivity levels for the study of the significant patterns is mandatory. For example, Table 1 determines sensitivity levels for the current model. According to this table, the sensitivity level of upward Sh. has been considered as \(b \ge 0.5\sigma\)(\(\sigma\) is the standard deviation of natural variations); therefore, the process is under-control, when the estimated magnitude for this parameter is less than \(0.5\sigma\).

As much as the qualitative sensitivity level to the occurrence of an unnatural pattern would be higher and process would be more sensitive to its formation, the absolute value of its corresponding parameter limit in “out-of-control” interval (see Table 1) is smaller, and vice versa. Generally, the determined intervals in Table 1 are considered as high levels of the qualitative sensitivities.

The determination of suitable sensitivity levels for a process is very important, because inaccurate determination of sensitivity levels increases incorrect discrimination risk of real situations. For instance, an under-control situation is decided as out-of-control falsely and vice versa. The technical knowledge of the production process affects suitable determination of sensitivity levels.

2.7 Standardization

In an overview, the “standardization” of the samples of a control vector is as follows:

In this equation,\(\mu_{n(t)}\) and \(\sigma_{n(t)}\) are the average and standard deviation of natural variations in its corresponding control chart, respectively.

2.8 Normalization

Generally, the “normalization” is elimination of the effects of unnatural pattern/patterns from the samples of a control vector. The meaning of the normalization in the proposed model is elimination of the effects of Sh. and Tr. patterns from the samples of a control vector as follows:

3 Introduction of the proposed model

In this section, the structure and details of the proposed model are introduced and described.

3.1 General structure of the proposed model

In an overview, Fig. 5 illustrates the loop of the proposed model. The following steps introduce the procedure of the proposed model:

-

Select 12 independent samples randomly (the size of each sample is \(m\)) and then calculate the corresponding statistic to each sample (as examples, this statistic in \(\bar{x}\) control chart is the average of the observations of each sample and in S2 control chart is the variance of the observations of each sample).

-

Consider 12 calculated samples (i.e., statistics) as components of a control vector.

-

Standardize the components (samples) of the control vector, according to Eq. (7).

-

Calculate the fitted line of the control vector’s samples. The slope and intercept of this line represent the parameters of Tr. and Sh. patterns, respectively [21]. With respect to the determined sensitivity levels, monitor the formation of these two patterns.

-

Normalize the components (standardized samples) of control vector, according to Eq. (8).

-

Calculate the fitted cosine curve of the normalized samples. With respect to the determined sensitivity levels, monitor the formation of Cyc. pattern or Sys. pattern.

Now, the users can judge about the situation of process. Indeed, the fitted line and curve have facilitated recognition and analysis of the basic and concurrent patterns at different levels of sensitivity.

When the unnatural patterns appear, the improvement plans are performed, and then the process control continues via new samplings and replacement of 12 new samples with the current samples.

3.2 Details of the proposed model

In this subsection, the cited steps are described, and the guideline of the calculation and analysis of the samples’ fitted line and also, the proposed algorithm of the calculation and interpretation of the samples’ fitted cosine curve are presented.

3.2.1 Standardization of samples

In the first step, the samples of the control vector are standardized, according to Eq. (7). This transformation is mandatory for utilization of the proposed model.

3.2.2 Calculation and analysis of the fitted line

As defined in Sect. 2.2, the fitted line of these samples (in a control box) is a line which the sum of squared vertical intervals of samples points from it would be minimal. This line’s equation is considered as \(x^{\prime}(t) = s.t + b\). The slope (\(s\)) and the intercept (\(b\)) of the fitted line (for 12-dimensional control vectors) are calculated as follows:

The fitted line’s intercept and slope represent the parameters of Sh. and Tr. patterns, respectively [21]. Indeed, the intercept indicates the mean of displacement (positive or negative) of samples, and the slope indicates trend slope (downward or upward) of samples. With respect to the determined sensitivity levels for a process, the user can monitor the formation of these two patterns via the values of the fitted line’s intercept and slope.

The fitted line’s elements alarm the occurrence of Sh. and Tr. patterns (singly or concurrently) accurately and estimate their corresponding parameters precisely.

3.2.3 Elimination of effects of Sh. and Tr. patterns

In this step, the elimination of the effects of Sh. and Tr. patterns from samples of the control vector is necessary, even if the values of their corresponding parameters are less than the determined sensitivity levels. Therefore, according to Eq. (8), the components of control vector are normalized.

3.2.4 Calculation and interpretation of the fitted cosine curve

The fitted cosine curve of samples (in a control box) is a cosine curve which the sum of squared vertical intervals of samples points from it would be minimal (see Fig. 2); in other word:

When we take the partial derivatives of Eq. (11) as \(\frac{\partial \Delta }{\partial a} = 0\), \(\frac{\partial \Delta }{\partial T} = 0\) and \(\frac{\partial \Delta }{\partial k} = 0\), we have the required equations for calculation of the optimum fitted cosine curve (including optimum amplitude(s), optimum period and optimum phase difference). The cited curve is real optimum cosine curve.

Since the above solution to achieve the optimum parameters is very difficult, we have proposed a heuristic algorithm as following:

-

First, assume the parameters of \(k\) and \(T\) are constant values (because phase difference does not play a role in process analysis [18], moreover, the amplitude in Cyc. pattern and Sys. pattern is more important than the period). In this case, \(\tilde{a}_{T,k}\) is calculated as follows:

$$\tilde{a}_{T,k} = \frac{\partial \Delta }{\partial a} = 0 \Rightarrow \tilde{a}_{T,k} = \frac{{\sum\limits_{t = 1}^{12} {\left( {x^{\prime}_{\text{norm}} (t).\cos \left( {\frac{2\pi .t}{T} + \frac{2\pi .k}{T}} \right)} \right)} }}{{\sum\limits_{t = 1}^{12} {\cos^{2} \left( {\frac{2\pi .t}{T} + \frac{2\pi .k}{T}} \right)} }}$$(12) -

Then, calculate \(\tilde{a}_{T,k}\) for all alternatives of \(T\) and \(k\). (The list of all alternatives of \(T\) and \(k\) is shown in Table 2.)

Table 2 List of all periodic alternatives -

Now, calculate Eq. (11), i.e., the value of \(\Delta\), for each of \((T,k;\tilde{a}_{T,k} )\).

-

Finally, find the minimum value of \(\Delta\), and consider its corresponding parameters as optimum parameters (i.e., \(a^{h} ,T^{h} ,k^{h}\)).

We have run this algorithm using a spreadsheet application, simply.

According to the determined sensitivity levels for the parameters in this research (see Table 1), the interpretations of the algorithm outputs are as follows:

State (I): When \(T^{h} = 1\), the patterns of Cyc. and Sys. have not occurred.

State (II): When \(T^{h} = 2\) and \(a^{h} \ge 0.5\sigma\), the formation of Sys. pattern with the parameters of \(a^{h}\) and \(k^{h}\) is confirmed.

State (III): When \(2 < T^{h} < 8\) or \(a^{h} < 0.5\sigma\), the formation of Cyc. pattern is not confirmed.

State (IV): When \(T^{h} > 8\) and \(a^{h} \ge 0.5\sigma\), the formation of Cyc. pattern with the parameters of \(a^{h}\), \(T^{h}\) and \(k^{h}\) is confirmed.

4 Case study: recognition and analysis of unnatural patterns in S 2 control charts

In control charts of variable qualitative characteristics, the “process variability” and “process mean” are monitored simultaneously. Since, the control of process variability chart is the main prerequisite of the control of process mean chart [1]. In other word, change in the process mean affects only the mean control chart, while the process variability affects both the mean and variability control charts.

Typically, the mean is controlled by x-bar chart and the variability is controlled by one of S2 chart, S chart or R chart.

To implement the proposed model, S2 control chart has been selected as a case study. This chart control the process variability certainly. However, the proposed model is applicable for other control charts.

The upper control limit (UCL), center line (CL) and lower control limit (LCL) of S2 control chart are as follows [1]:

In this equation, \(m\) is sample size; \(\chi_{{\alpha^{\prime}/2,m - 1}}^{2}\) and \(\chi_{{(1 - \alpha^{\prime}/2),m - 1}}^{2}\) are \((\alpha^{\prime}/2)\%\) of upper and lower points of Chi-square distribution with the \(m - 1\) degree of freedom, respectively; and \(\sigma_{P}^{2}\) is the variance of corresponding statistical population. When the variance of statistical population is unknown, \(\bar{S}^{2}\)(i.e., the mean of the samples) is replaced with \(\sigma_{P}^{2}\). Note that the control limits in S2 control chart are probable limits.

4.1 Simulation of natural variations in S 2 control chart

The samples in S2 control chart are calculated as:

In this equation, \(t\) determines the sample’s number; \(m\) is sample size; \(o_{j}\) is the value of jth observation; and \(\bar{o}\) is the mean of observations in tth sample. The statistic of \(S_{t}^{2}\) is an unbiased estimator for the variance of statistical population.

As explained in Sect. 2.2, the statistical distribution function of the natural variations in a control chart is the same as distribution function of its samples. The samples in S2 control chart have Gamma distribution function with parameters of \(\frac{m - 1}{2}\) (shape parameter) and \(\frac{{2\sigma_{P}^{2} }}{m - 1}\) (scale parameter) [18]; therefore, the natural variations in an under-control S2 chart have Gamma distribution function with parameters of \(\frac{m - 1}{2}\) and \(\frac{{2\sigma_{P}^{2} }}{m - 1}\).

4.2 The numerical values of the corresponding parameters to unnatural patterns in control charts

The numerical parameters make the determination of desired qualitative sensitivity levels of production processes and the monitor of improvement plans progress possible.

Usually, the parameters values of \(b\)(displacement magnitude), \(s\)(trend slope) and \(a\)(amplitude of cycle and amplitude of fluctuations) are determined in terms of “coefficients of standard deviation of natural variations (abbreviated as \(\sigma\)).”

As explained in Sect. 3.2.1, the standardization of samples is mandatory in the current model. Since the standard deviation of standardized random variables is always equal to 1 [25], the numerical values of the cited parameters, in our model, are independent of \(\sigma\) (see the footnote of Table 1).

Moreover, the numerical value of the parameter of \(T\)(period) is a subset of the natural numbers and the parameter of \(k\)(phase difference) is a subset of nonnegative integer numbers and always \(k < T\).

4.3 A numerical example

This subsection reviews the procedure of the proposed model for recognition and interpretation of unnatural patterns in S2 control chart as a numerical example.

To control the variability of a qualitative characteristic, 12 samples (each sample including 5 independent observations) have been selected, randomly (Table 3, row 2)

The documentaries of the production process indicate \(\sigma_{P}^{2} = 25\) unit. To calculate the upper and lower control limits, \(\alpha^{\prime} = 0.05\) has been assumed. Thus, UCL, CL and LCL of corresponding S2 control chart are equal to 69.65, 25.00 and 3.03, respectively.

Figure 6 (Part A) shows the scattered samples in S2 control chart. As illustrated, all samples are between control limits and apparently the process variability is under-control.

Now, the occurrence of the significant patterns is controlled, according to the proposed model procedure:

In the first step, the samples are standardized. In S2 control chart, the samples and the natural variations have Gamma distribution function with parameters of \(\frac{m - 1}{2}\) (abbreviated as \(\alpha\)) and \(\frac{{2\sigma_{P}^{2} }}{m - 1}\) (abbreviated as \(\beta\)) [18]; since the average and variance of Gamma distribution function are \(\alpha .\beta\) and \(\alpha .\beta^{2}\), respectively [25]; therefore:

Table 3 (row 3) and Fig. 6 (Part B) indicate the standardized samples values and standardized control box.

In the next step, the fitted line’s equation of the standardized samples is calculated. The intercept and slope of this line are − 0.29 and 0.06, respectively. With respect to the determined sensitivity levels in Table 1, the analysis of these values alarms the appearance of upward Tr. pattern. The slope of the fitted line (i.e., Tr. pattern parameter) is greater than 0.05. On the other hand, the intercept of the fitted line (i.e., Sh. pattern parameter) is greater than -0.5, so the occurrence of downward Sh. pattern is not confirmed.

The elimination of the effects of Sh. and Tr. patterns from samples of the control vector is necessary, even if the values of their corresponding parameters are less than the determined sensitivity levels. Therefore, according to Eq. (8), the components of control vector are normalized (see Table 3, row 4).

In the final step, the fitted cosine curve of the normalized samples is calculated and interpreted, via the proposed algorithm. Since the algorithm outputs are \(a^{h} = 0.704\), \(T^{h} = 9\) and \(k^{h} = 1\), the formation of Cyc. pattern with the cited parameters is confirmed.

Thus, the primary conclusion is rejected by the study of the significant patterns. Concurrent occurrence of upward Tr. pattern (\(s = 0.06\)) and Cyc. pattern (\(a = 0.704, \, T = 9, \, k = 1\)) reflects out-of-control situations.

In this time, the quality control department specifies the causative roots of the formation of these patterns and performs the improvement plans. Then the process control continues via new samplings and replacement of 12 new samples with the current samples.

5 Evaluation of the proposed model

This section presents the statistical details of the performance of the proposed model in recognition and analysis of process control charts patterns. The simulated vectors have been applied to evaluate the performance of the proposed model. The model’s outputs have been compared with the expected results. The main indices to evaluate the proposed model are “accurate recognition of pattern type” and “precise estimation of pattern parameter(s)”.

5.1 Performance of fitted line in recognition and analysis of Sh. and Tr. patterns

The proposed model monitors the occurrence of Sh. and Tr. patterns via calculation of the fitted line’s equation of the standardized samples and analysis of its elements (i.e., fitted line’s intercept and slope).

The fitted line’ elements alarm the appearance of Sh. and Tr. patterns (singly or concurrently) accurately and estimate their corresponding parameters precisely. Tables 4 and 5 represent these abilities at different levels of sensitivity [21].

5.2 Performance of fitted cosine curve in recognition and analysis of Sys. and Cyc. patterns

The proposed model monitors the formation of the periodic patterns (i.e., Sys. and Cyc. patterns) via calculation of the fitted cosine curve of the normalized samples and interpretation of its corresponding algorithm outputs.

The capabilities of the proposed model in periodic patterns recognition and estimation of their parameters, at different levels of sensitivity, have been tested by 5940 simulated vectors. The results are shown in Table 6.

6 Comparative studies

This section compares the performance of the proposed model with the previous models.

6.1 Comparison of performance of the proposed model with the developed models based on neural networks

As mentioned in the literature, the previous models have studied misclassification problem, but they often face with patterns misclassification error when high level of sensitivity is desired for unnatural patterns identification. Most of the presented works have utilized neural networks as recognition tool. According to the results of these models, the neural networks have uncertain reliability, when the sensitivity of processes to the occurrence of unnatural patterns is high. Moreover, the architectures of the neural networks are difficult and their learning algorithms are time-consuming.

The proposed model in this paper develops the samples’ fitted line and the samples’ fitted cosine curves for more accurate classification of patterns and more precise estimation of their corresponding parameters at different levels of sensitivity. These tools have decreased feedback time of the model.

Two main indices have compared the performance of the proposed model with the developed models based on neural networks:

6.1.1 Patterns misclassification error

To evaluate the performance of the proposed model in patterns classification, the results of our model have been compared with the developed models of [18] and [21]. Table 7 shows the average of patterns misclassification error (alongside corresponding recognition tools) in the proposed model and two cited models. As shown, for common patterns in three models, the average of patterns misclassification error in the proposed model has decreased, considerably.

6.1.2 Parameters estimation error

Table 8 compares the average and standard deviation of estimation error of the periodic patterns parameters in the proposed model with reference of [21]. The results show that our model has decreased the aggregated average and standard deviation of the parameters estimation error, in all formation phases.

6.2 Support of all formation modes of Cyc. and Sys. patterns

The proposed model has applied the improved generating function of Cyc. and Sys. patterns, according to Eq. (4), practically (see Tables 6, 7, 8). This equation considers the modification expression and also the virtual parameter of phase difference (in the starting point of these patterns) and therefore covers all formation modes of Cyc. and Sys. patterns. The previous models have introduced incomplete expressions of \(\left[ {a.\sin \left( {\frac{2\pi .t}{T}} \right)} \right]\) (such as references of [8, 10,11,12, 15,16,17, 20, 23, 24]) and \(\left[ {a.\cos \left( {\frac{2\pi .t}{T} + \frac{2\pi .k}{T}} \right)} \right]\) (reference of [18]) as generating function for Cyc. pattern and incomplete expression of \(\left[ {a.( - 1)^{t} } \right]\) (such as references [11, 15, 17, 23, 24]) as generating function for Sys. pattern.

Although the reference of [22] has considered the phase difference for the generating functions of Cyc. and Sys. patterns, this paper has not reported the statistical results of the study of their various formation modes.

6.3 Recognition and analysis of concurrent patterns

The proposed model can alert the concurrent occurrence of two or three unnatural patterns and estimate corresponding parameters to appeared patterns, separately. Indeed, the analysis of fitted line’s elements and then the interpretation of fitted cosine curve’s elements make this capability accessible. The reviewed models in the literature (except reference of [21]) have not such capability.

7 Conclusions and suggestion for future research

Unnatural patterns recognition and analysis in process control charts is necessary, since the traditional rules cannot assure access to real under-control situations.

The proposed model in the current paper was designed to recognize and analyze the significant patterns in process control charts. To achieve these purposes, this model developed the fitted line of samples (calculated by least squares method) and the fitted cosine curve of samples (calculated by a heuristic optimization method). To implement the procedure of the proposed model, S2 control chart was selected as a case study.

The results indicated that the samples’ fitted line analyzes the patterns of Sh. and Tr., accurately, and also the samples’ fitted cosine curve interprets the patterns of Cyc. and Sys., precisely.

One of the main goals of the current model was considerable decrease in patterns misclassification error. When sensitivity of the processes to unnatural patterns formation is high, fitted line and fitted cosine curve enhance the capability of the model in classification of the significant patterns and estimation of their corresponding parameters.

This paper applied the improved generating function of Cyc. and Sys. patterns and considered the modification expression and the phase differences, practically. Indeed, this improved generating function covers all formation modes of Cyc. and Sys. patterns and increases the flexibility of the proposed model in patterns recognition.

The proposed model had reliable performance during the concurrent occurrence of the basic patterns. The control of these situations is very important, since apparent views do not reflect the simultaneous formation of unnatural patterns and therefore patterns recognition and analysis are more difficult.

The implementation of the proposed model procedure for recognition and analysis of the unnatural patterns in other process control charts is suggested for future researches.

References

Montgomery DC (2001) Introduction to statistical quality control, 4th edn. Wiley Publishing Company, New York

Pham DT, Oztemel E (1994) Control chart pattern recognition using learning vector quantization networks. Int J Prod Res 32(3):721–729

Cheng CS (1995) A multi-layer neural network model for detecting changes in the process mean. Comput Ind Eng 28(1):51–61

Cheng CS (1997) A neural network approach for the analysis of control chart patterns. Int J Prod Res 35(3):667–697

Hwarng HB (1995) Proper and effective training of a pattern recognizer for cyclic data. IIE Trans 27(6):746–756

Chang SA, Aw C (1996) A neural fuzzy control chart for detecting and classifying process mean shifts. Int J Prod Res 34(8):2265–2278

Anagun AS (1998) A neural network applied to pattern recognition in statistical process control. Comput Ind Eng 35(1–2):185–188

Pham DT, Sagiroglu S (2001) Training multilayered perceptron for pattern recognition: a comparative study of four training algorithms. Int J Mach Tools Manuf 41(3):419–430

Chiu C, Chen M, Lee K (2001) Shifts recognition in correlated process data using a neural network. Int J Syst Sci 32(2):137–143

Guh RS, Hsieh YC (1999) A neural network based model for abnormal pattern recognition of control charts. Comput Ind Eng 36(1):97–108

Guh RS, Zorriassatine F, Tannock JDT, O’Brien C (1999) On line control chart pattern detection and discrimination—a neural network approach. Artif Intell Eng 13(4):413–425

Guh RS, Tannock JDT (1999) Recognition of control chart concurrent patterns using a neural network approach. Int J Prod Res 37(8):1743–1765

Guh RS (2003) Integrating artificial intelligence into on-line statistical process control. Qual Reliab Eng Int 19(1):1–20

Guh RS (2004) Optimizing feed forward neural networks for control chart pattern recognition through genetic algorithms. Int J Pattern Recognit Artif Intell 18(2):75–99

Guh RS (2005) A hybrid learning-based model for on line detection and analysis of control chart patterns. Comput Ind Eng 49(1):35–62

Guh RS (2010) Simultaneous process mean and variance monitoring using artificial neural network. Comput Ind Eng 58(4):739–753

Chen Z, Lu S, Lam S (2007) A hybrid system for SPC concurrent pattern recognition. Adv Eng Inform 21(3):303–310

Fatemi Ghomi SMT, Lesany SA, Koockakzadeh A (2011) Recognition of unnatural patterns in process control charts through combining two types of neural network. Appl Soft Comput 11(8):5444–5456

Ebrahimzadeh A, Addeh J, Rahmani Z (2012) Control chart pattern recognition using K-MICA clustering and neural networks. ISA Trans 51(1):111–119

Yang W, Yu G, Liao W (2013) A hybrid learning based model for simultaneous monitoring of process mean and variance. Qual Reliab Eng Int 31(3):445–463

Lesany SA, Koochakzadeh A, Fatemi Ghomi SMT (2013) Recognition and classification of single and concurrent unnatural patterns in control charts via neural networks and fitted line of samples. Int J Prod Res 52(6):1771–1786

Cheng CS, Huang KK, Chen PW (2015) Recognition of control chart patterns using a neural network-based pattern recognizer with features extracted from correlation analysis. Pattern Anal Appl 18(1):75–86

Yang JH, Yang MSh (2005) A control chart pattern recognition system using a statistical correlation coefficient method. Comput Ind Eng 48(2):205–221

Lin SY, Guh RS, Shiue YR (2011) Effective recognition of control chart patterns in autocorrelated data using a support vector machine based approach. Comput Ind Eng 61(4):1123–1134

Freund JE (1992) Mathematical statistics, 5th edn. Prentice-Hall Publisher, New Jersey

Grant EG, Leavenworth RS (1996) Statistical quality control, 7th edn. McGraw Hill Book Company, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lesany, S.A., Fatemi Ghomi, S.M.T. & Koochakzadeh, A. Development of fitted line and fitted cosine curve for recognition and analysis of unnatural patterns in process control charts. Pattern Anal Applic 22, 747–765 (2019). https://doi.org/10.1007/s10044-018-0682-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10044-018-0682-7