Abstract

In this study, Co3O4/SiO2 nanocomposites have been successfully synthesized by citrate–gel method by utilizing SiO2 matrix for Co3O4 embedment. Spectroscopy analyses confirm the formation of high crystalline Co3O4 nanoparticles; meanwhile, microscopy findings reveal that the Co3O4 nanoparticles are embedded in SiO2 matrix. Electrochemical properties of the Co3O4/SiO2 nanocomposites were carried out using cyclic voltammetry (CV), galvanostatic charge–discharge, and electrochemical impedance spectroscopy (EIS) in 5 M KOH electrolyte. The findings show that the charge storage of Co3O4/SiO2 nanocomposites is mainly due to the reversible redox reaction (pseudocapacitance). The highest specific capacitance of 1,143 F g−1 could be achieved at a scan rate of 2.5 mV s−1 in the potential region between 0 and 0.6 V. Furthermore, high-capacitance retention (>92 %) after 900 continuous charge–discharge tests reveals the excellent stability of the nanocomposites. It is worth noting from the EIS measurements that the nanocomposites have low ESR value of 0.33 Ω. The results manifest that Co3O4/SiO2 nanocomposites are the promising electrode material for supercapacitor application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Supercapacitors, which are also known as ultracapacitors or electrochemical capacitors, are the energy storage devices that possess high power density (10 kW kg−1), which can be fully charged or discharged in seconds [1]. In terms of their performance, they can strategically fill in the gap between conventional capacitors and batteries to give better energy and power performance. The potential applications of supercapacitors vary from household electronic products to emergency doors in Airbus A380 planes [2, 3] owing to their excellent energy and power performance. Nonetheless, the energy performance of supercapacitors is still far below as compared to that of batteries. Various research efforts have been attempted in order to enhance the energy performance of the supercapacitors. The energy density of a supercapacitor is given as 0.5 CV 2, where C is the capacitance and V is the operating voltage. Maximizing capacitance value in a supercapacitor is a key factor in enhancing energy performance. Electrode material plays a vital role in this context. The supercapacitors electrode material can be categorized into carbon-based materials (activated carbon, carbon nanotubes, graphene, fullerene, and etc.) [4–7], transition metal oxides (MnO2, V2O5, Fe2O3, NiO, CuO, Co(OH)2, Co3O4, and etc.) [8–14] and conductive polymers (polyaniline, polypyrrole, and etc.) [15, 16]. Among all electrode materials, transition metal oxides are often preferred, owing to their low internal resistance that contributes to high power output. Furthermore, different oxidation states of the transition metal oxides could contribute to high pseudocapacitance in the system. They are particularly favored for supercapacitor application due to their cost advantages over noble metal oxides such as RuO2.

Among all transition metal oxides, Co3O4 is a promising electrode material for supercapacitor application by virtue of its high theoretical specific capacitance (3,560 F g−1) [17, 18], reversible surface redox reaction, low cost, and environmental friendliness [14, 19]. Various surface morphologies of Co3O4 such as nanoparticles, nanowires, and layered structure [14, 17, 18, 20–22] have been reported for supercapacitor application as the charge storage phenomenon is directly associated with surface properties. However, the reported specific capacitance values for Co3O4 are still far below its theoretical value. Therefore, integrated multi-component structure is proposed to provide synergistic effect on energy storage process. For instance, Co3O4/RuO2 · xH2O, Co3O4@MnO2, and Co3O4@Pt@MnO2 nanocomposites have been developed with enhanced electrochemical performance [23–26]. However, all the literature reports focus on the integration between Co3O4 and other metal or metal oxides. To the best of our knowledge, the integration of Co3O4 with non-metal oxide for supercapacitor application has not been reported yet.

Herein, we report the fabrication of Co3O4/SiO2 nanocomposites as electrode material for supercapacitor application. It has been proven that SiO2 could increase the specific capacitance of carbon substrate [27]. SiO2 is chosen as the non-metal oxide matrix for Co3O4 embedment in order to uniformly disperse Co3O4 nanoparticles and the electrochemical properties of the nanocomposites are studied.

Experimental section

Sample preparation

The Co3O4/SiO2 nanocomposites were prepared as described in our previous report [28]. Briefly, 13.5 g cobalt chloride (Riedel deHaen, UK, 98 %), 1.85 mL of tetraethyl silicate (Merck, Germany, 99 %), and 1.6 g of citric acid (Adwic, Egypt, 33 %) were dissolved in absolute ethanol (Analar, BDH, 99.8 %), and ultrasonicated for 30 min. The hydrolysis of tetraethyl silicate was done by adding bidistilled water (1:3 volume ratio) into the alcoholic mixture and the pH of the mixture was adjusted to 5. The mixture was heated at 60 °C with continuous stirring for 3 h. A slightly blue gel was obtained and dried in an oven at 80 °C for 24 h. Finally, the dried sample was calcined at 400 °C for 3 h to obtain Co3O4 crystallites embedded in SiO2 matrix.

Sample characterization

Phase identification, and crystallinity of the nanocomposites were studied using an x-ray diffractometer (XRD; Philips PW1700, Netherlands) equipped with an automatic divergent slit. Diffraction pattern was obtained using Cu–Kα radiation (λ = 0.15418 nm) and a graphite monochromator in the 2θ range from 10 to 90 °. Infrared spectrum was measured in the range 400–4,000 cm−1 using a Fourier transform infrared spectrometer (FTIR; JASCO–480 Plus, Japan). The sample was prepared by KBr disc method. The morphology and elemental analyses of the nanocomposites were investigated using a field emission scanning electron microscope (FESEM; JEOL–JSM–7800 F, Japan), equipped with energy dispersive x-ray analysis (EDX).

Electrochemical measurements

For electrochemical measurements, Co3O4/SiO2 electrode was prepared with a final composition (weight percentage) of 80 % Co3O4/SiO2, 15 % carbon black (Alfa Aesar), and 5 % polytetrafluoroethylene (Aldrich, 60 %). The mixture was casted on nickel foam (Goodfellow) and dried at 60 °C for 30 min. After drying, the coated mesh was uni-axially pressed (5 t) and the weight of the active material was determined by a microbalance. Three-electrode electrochemical system was set up: Co3O4/SiO2 electrode as working electrode, Ag/AgCl (CH Instrument) as reference electrode, and Pt wire (CH Instrument) as counter electrode. Electrochemical data were collected using an electrochemical workstation (AUTOLAB PGSTAT30, Netherlands) equipped with frequency response analyzer. Cyclic voltammetry (CV) tests were performed in the potential range between 0 and 0.6 V vs. Ag/AgCl with scan rates from 2.5 to 30 mV s−1. Galvanostatic charge–discharge tests were performed at different current densities from 1 to 5 A g−1. Electrochemical impedance spectroscopy (EIS) data were collected from 100 kHz to 10 mHz, at open circuit potential with a.c. amplitude of 10 mV. KOH (5 M) was used as the electrolyte throughout all electrochemical measurements.

Results and discussion

Crystal structure and phase analyses

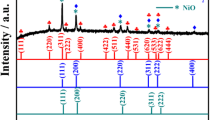

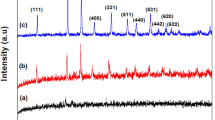

Figure 1 shows the XRD pattern of Co3O4/SiO2 nanocomposites and it can be seen that all the diffraction peaks are related to Co3O4 phase (ICDD card # 00–009–0418), suggesting the formation of pure crystalline Co3O4 nanoparticles. Diffraction peaks (Fig. 1 insets) were fitted using Lorentzian line shapes for accurate determination of apparent crystallite size and lattice constant. According to Scherrer formula [29], the apparent crystallite size of Co3O4 was calculated to be 26 nm with lattice constant and volume of 0.808 nm and 0.527 nm3, respectively. The values are slightly larger than those of bulk Co3O4 due to surface relaxation usually observed for such nanoparticles [30].

Further information about the chemical structure of Co3O4/SiO2 nanocomposites was obtained from FTIR data shown in Fig. 2. The FTIR bands at 460 and 1,090 cm−1 can be assigned to the asymmetric stretching vibration of the bond Si–O–Si in the SiO4 tetrahedron [30] within SiO2 matrix. The weak intensity band at 840 cm−1 can be attributed to the stretching of non-bridging oxygen atoms in Si–OH bond [28, 30, 31]. Additionally, the absorption bands at 3,440 and 1,635 cm−1 correspond to the O–H stretching and bending vibrations, respectively. These observations suggest the presence of absorbed water molecules within SiO2 matrix. Strong absorption bands can be seen at 560 and 660 cm−1, due to the vibrations of Co–O stretching in Co3O4 [30, 31].

The crystalline Co3O4 nanoparticles are distributed evenly in SiO2 matrix, as shown in the FESEM image (Fig. 3a). The findings match with our previous TEM observations [28, 30] of the Co3O4 nanoparticles embedded in SiO2 matrix. Figure 3b shows the EDX data and the Co3O4/SiO2 weight ratio was calculated to be 94.8:5.2. Figure 3c shows the Gaussian fitting of the mean particle size distribution obtained from FESEM image. The obtained mean particle size is 16.5 nm, which is consistent to that obtained from XRD analysis.

Electrochemical studies

The charge storage properties of Co3O4/SiO2 electrode were evaluated by CV, galvanostatic charge–discharge and EIS. Figure 4a shows the CV curves of Co3O4/SiO2 electrode in 5 M KOH under different scan rates. It can be seen from the CV curves that Co3O4/SiO2 electrode exhibits pseudocapacitance behavior with two pair of reversible redox peaks. The reversible redox reactions are as follows [17, 20]:

The first redox peaks (O1/R1) corresponding to Co2+/Co3+ are easily identified at 0.38:0.22 V; the second redox peaks (O2/R2) corresponding to Co3+/Co4+ occur at 0.46:0.28 V. However, the R2 reduction peaks are elusive as they just appear as the shoulder of R1 reduction peaks. Additionally, with an increase in the scan rate, the anodic (O1, O2) and cathodic (R1, R2) peaks shift to higher and lower potentials, respectively. The peak current densities of Co3O4/SiO2 electrode at different scan rates are summarized in Fig. 4b. Linear relationship between peak current density and scan rate could be observed, indicating the occurrence of surface redox reaction for Co3O4/SiO2 electrode.

To assess the feasibility of Co3O4/SiO2 electrode in the application of supercapacitor, galvanostatic charge–discharge tests were performed at various current densities (Fig. 5a). The shape of the charge–discharge curves is independent of the current density thereby indicating that the Co3O4/SiO2 electrode is suitable for the application of supercapacitor. The discharge curve of Co3O4/SiO2 electrode can be divided into two regions (Fig. 5b), corresponding to pseudocapacitance (region 1) and electrical double layer capacitance (region 2). Region 1 (0.22–0.50 V) with slope variation, contributes 83 % while region 2 (below 0.22 V) with linear slope, contributes only 17 % of the total capacitance. Obviously, large percentage of the specific capacitance in Co3O4/SiO2 electrode is contributed by the reversible redox reactions (pseudocapacitance), as suggested from CV data.

The specific capacitance of Co3O4/SiO2 electrode with respect to scan rate and current density are summarized in Fig. 6. The calculation method can be found in the Supplementary Data. The CV data of Co3O4/SiO2 electrode shows the highest specific capacitance of 1,143 F g−1 at a scan rate of 2.5 mV s−1. Apparently, the Co3O4/SiO2 in this study has relatively high specific capacitance value as compared to that of the previous reported values (Table 1) for Co3O4 nanocomposites. This could be ascribed to the even distribution of Co3O4 nanoparticles in SiO2 matrix, renders facile electrolyte penetration in the matrix and better surface utilization of the active material for Faradaic reactions. Control experiment had been conducted on Co3O4/SiO2 nanocomposites with higher SiO2 loading (40 %) to investigate the effect of SiO2 towards charge storage in nanocomposites (Supplementary data Fig. S1). It shows lower specific capacitance at higher SiO2 loading, possibly due to lower electroactive material in the nanocomposites. In addition, the specific capacitance of Co3O4/SiO2 electrode is dependent of the scan rate as the specific capacitance increases at a lower scan rate. At lower scan rate, the OH− ions could diffuse into the inner pores of SiO2 matrix and more OH− ions are in contact with the Co3O4 nanoparticles that are embedded in the matrix, contributing to higher feasible redox reactions as shown in Eqs. 1 and 2. On the other hand, the specific capacitance values of Co3O4/SiO2 electrode derived from galvanostatic charge–discharge are lower than those from CV data. It could be attributed to the low surface accession by OH− ions under high discharge current density conditions.

Utilization efficiency of the Co3O4/SiO2 electrode had been calculated by comparing the highest attained specific capacitance with the theoretical value. It was calculated as 29.3 %, higher than the reported value for Co3O4 nanoparticles (17.5 %) [17], which can be understood as higher surface utilization of Co3O4 nanoparticles in SiO2 matrix. The electrochemical cycling stability is a crucial factor for the supercapacitor application. Figure 7 shows the cycling stability test for Co3O4/SiO2 electrode at a current density of 7 A g−1. High current density is selected for cycling stability test in order to reflect the practical viability of the electrode material for supercapacitor application. It can be noticed that the capacitance retention remains stable (>92 %) up to 900 cycles and only drops to 80.5 % at the 1,000th cycle. This value is higher than that reported for pure Co3O4 (65 % after 1,000 cycles and 74 % after 500 cycles) [20, 35], indicating better electrochemical stability of the Co3O4/SiO2 nanocomposites in this work. Such high-capacitance retention suggests that the Co3O4/SiO2 nanocomposites are the good electrode material for supercapacitor application.

The EIS data was analyzed with Nyquist plot. It shows the frequency response at the electrode/electrolyte interface and is a profile of imaginary component (Z′′) of the impedance against the real component (Z′). The Nyquist plot of Co3O4/SiO2 electrode (Fig. 8) features a semicircle at high frequency followed by a near 45 ° line at low frequency. The EIS data were analyzed by the CNLS fitting method based on a Randles equivalent circuit, as depicted in Fig. 8 inset, where R s and R ct are solution and charge transfer resistances, respectively. C dl and C ps represent double layer capacitance and pseudocapacitance, respectively. The interfacial diffusive resistance (Warburg) is designated as W. The solution resistance (R s) or better known as equivalent series resistance (ESR) is a combination of ionic resistance of electrolyte, intrinsic resistance of active material, and contact resistance of the active material/current collector interface. The low ESR value (0.33 Ω) in this study suggests the good conductivity of Co3O4/SiO2 electrode which contributes to higher redox current. The relatively higher C ps value (258.51 mF) as compared to that of C dl value (0.289 mF) support the galvanostatic charge–discharge findings that the main storage mechanism in the Co3O4/SiO2 electrode is mainly based on Faradaic reaction (pseudocapacitance). The Warburg impedance at low frequency is due to the OH− ions diffusion within the SiO2 matrix. All the above–mentioned results demonstrate that Co3O4/SiO2 nanocomposites have good frequency response with low impedance and are suitable to be used as electrode material for supercapacitor application.

Conclusions

The present work reports the integration of Co3O4 with non-metal oxide in energy storage application. High crystalline Co3O4 nanoparticles are embedded and distributed evenly in SiO2 matrix, using citrate–gel method. The obtained Co3O4/SiO2 nanocomposites show excellent charge storage properties (1,143 F g−1 at 2.5 mV s−1; 679 F g−1 at 1 A g−1), together with excellent cycling stability, which are attributed to the facile electrolyte penetration in SiO2 matrix and better Co3O4 electroactive surface utilization for redox reactions. Such excellent charge storage properties with low ESR value render Co3O4/SiO2 nanocomposites as promising electrode material for energy storage application.

References

Conway BE (1999) Electrochemical supercapacitors scientific fundamentals and technological applications. Kluwer Academic/Plenum Press, New York

Martin W, Brodd RJ (2004) What are batteries, fuel cells, and supercapacitors. Chem Rev 104(10):4245–4269

Patrice S, Gogotsi Y (2008) Materials for electrochemical capacitors. Nat Mater 7:845–854

Kim M-H, Yang J-H, Kang Y-M, Park S-M, Han JT, Kim K-B, Roh KC (2014) Fluorinated activated carbon with superb kinetics for the supercapacitor application in nonaqueous electrolyte. Colloids Surf A 443:535–539

Wei S, Kang WP, Davidson JL, Huang JH (2008) Supercapacitive behavior of CVD carbon nanotubes grown on Ti coated Si wafer. Diam Relat Mater 17(4–5):906–911

Liu C, Yu Z, Neff D, Zhamu A, Jang BZ (2010) Graphene-based supercapacitor with an ultrahigh energy density. Nano Lett 10(12):4863–4868

Okajima K, Ikeda A, Kamoshita K, Sudoh M (2005) High rate performance of highly dispersed C60 on activated carbon capacitor. Electrochim Acta 51(5):972–977

Lee M-T, Chang J-K, Hsieh Y-T, Tsai W-T, Lin C-K (2010) Manganese oxide thin films prepared by potentiodynamic electrodeposition and their supercapacitor performance. J Solid State Electrochem 14(9):1697–1703

Qu QT, Shi Y, Li LL, Guo WL, Wu YP, Zhang HP, Guan SY, Holze R (2009) V2O5 · 0.6H2O nanoribbons as cathode material for asymmetric supercapacitor in K2SO4 solution. Electrochem Commun 11(6):1325–1328

Kulal PM, Dubal DP, Lokhande CD, Fulari VJ (2011) Chemical synthesis of Fe2O3 thin films for supercapacitor application. J Alloys Compd 509(5):2567–2571

Nathan T, Aziz A, Noor AF, Prabaharan SRS (2007) Nanostructured NiO for electrochemical capacitors: synthesis and electrochemical properties. J Solid State Electrochem 12(7–8):1003–1009

Li Y, Chang S, Liu X, Huang J, Yin J, Wang G, Cao D (2012) Nanostructured CuO directly grown on copper foam and their supercapacitance performance. Electrochim Acta 85:393–398

Yuan C, Yang L, Hou L, Li D, Shen L, Zhang F, Zhang X (2011) Synthesis and supercapacitance of flower-like Co(OH)2 hierarchical superstructures self-assembled by mesoporous nanobelts. J Solid State Electrochem 16(4):1519–1525

Meher SK, Rao GR (2011) Ultralayered Co3O4 for high-performance supercapacitor applications. J Phys Chem C 115(31):15646–15654

Mi H, Zhang X, Yang S, Ye X, Luo J (2008) Polyaniline nanofibers as the electrode material for supercapacitors. Mater Chem Phys 112(1):127–131

Jureviciute I, Bruckenstein S (2003) Electrochemical activity of chemically deposited polypyrrole films. J Solid State Electrochem 7(9):554–560

Wang X, Sumboja A, Khoo E, Yan C, Lee PS (2012) Cryogel synthesis of hierarchical interconnected macro-/mesoporous Co3O4 with superb electrochemical energy storage. J Phys Chem C 116(7):4930–4935

Cheng H, Lu ZG, Deng JQ, Chung CY, Zhang K, Li YY (2010) A facile method to improve the high rate capability of Co3O4 nanowire array electrodes. Nano Res 3(12):895–901

Meher SK, Rao GR (2011) Effect of microwave on the nanowire morphology, optical, magnetic, and pseudocapacitance behavior of Co3O4. J Phys Chem C 115(51):25543–25556

Li Y, Huang K, Yao Z, Liu S, Qing X (2011) Co3O4 thin film prepared by a chemical bath deposition for electrochemical capacitors. Electrochim Acta 56(5):2140–2144

Vijayakumar S, Ponnalagi AK, Nagamuthu S, Muralidharan G (2013) Microwave assisted synthesis of Co3O4 nanoparticles for high-performance supercapacitors. Electrochim Acta 106:500–505

Xie L, Li K, Sun G, Hu Z, Lv C, Wang J, Zhang C (2012) Preparation and electrochemical performance of the layered cobalt oxide (Co3O4) as supercapacitor electrode material. J Solid State Electrochem 17(1):55–61

Liu Y, Zhao W, Zhang X (2008) Soft template synthesis of mesoporous Co3O4/RuO2 · xH2O composites for electrochemical capacitors. Electrochim Acta 53(8):3296–3304

Huang M, Zhang Y, Li F, Zhang L, Wen Z, Liu Q (2014) Facile synthesis of hierarchical Co3O4@MnO2 core-shell arrays on Ni foam for asymmetric supercapacitors. J Power Sources 252:98–106

Kim SH, Kim YIL, Park JH, Ko JM (2009) Cobalt–manganese oxide–carbon–nanofiber composite. Int J Electrochem Sci 4:1489–1496

Xia H, Zhu D, Luo Z, Yu Y, Shi X, Yuan G, Xie J (2013) Hierarchically structured Co3O4@Pt@MnO2 nanowire arrays for high-performance supercapacitors. Sci Rep 3:2978–2986

Leonard KC, Suyama WE, Anderson MA (2011) Improvement of electrochemical capacitor electrodes using SiO2 nanoparticles. Electrochim Acta 56(27):10137–10144

Fouad OA, Ali GAM, El–Erian MAI, Makhlouf SA (2012) Humidity-sensing properties of cobalt oxide/silica nanocomposites prepared via sol–gel and related routes. Nano 7(5):1250038–1250049

Patterson A (1939) The Scherrer formula for x–ray particle size determination. Phys Rev 56(10):978–982

Fouad OA, Makhlouf SA, Ali GAM, El–Sayed AY (2011) Cobalt/silica nanocomposite via thermal calcination–reduction of gel precursors. Mater Chem Phys 128(1–2):70–76

Esposito S, Turco M, Ramis G, Bagnasco G, Pernice P, Pagliuca C, Bevilacqua M, Aronne A (2007) Cobalt–silicon mixed oxide nanocomposites by modified sol–gel method. J Solid State Chem 180(12):3341–3350

Veerasubramani GK, Krishnamoorthy K, Radhakrishnan S, Kim N-J, Kim SJ (2014) Synthesis, characterization, and electrochemical properties of CoMoO4 nanostructures. Int J Hydrogen Energy 39(10):5186–5193

Li L, Zhang YQ, Liu XY, Shi SJ, Zhao XY, Zhang H, Ge X, Cai GF, Gu CD, Wang XL, Tu JP (2014) One–dimension MnCo2O4 nanowire arrays for electrochemical energy storage. Electrochim Acta 116:467–474

Kuang M, Zhang W, Guo XL, Yu L, Zhang YX (2014) Template-free and large-scale synthesis of hierarchical dandelion-like NiCo2O4 microspheres for high–performance supercapacitors. Ceram Int. doi:10.1016/j.ceramint.2014.02.099

Wang L, Liu X, Wang X, Yang X, Lu L (2010) Preparation and electrochemical properties of mesoporous Co3O4 crater-like microspheres as supercapacitor electrode materials. Curr Appl Phys 10(6):1422–1426

Acknowledgments

KF Chong and co-workers would like to acknowledge the funding from the Ministry of Education Malaysia in the form of MTUN–COE grant RDU121212 and RDU121213.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 125 kb)

Rights and permissions

About this article

Cite this article

Ali, G.A.M., Fouad, O.A., Makhlouf, S.A. et al. Co3O4/SiO2 nanocomposites for supercapacitor application. J Solid State Electrochem 18, 2505–2512 (2014). https://doi.org/10.1007/s10008-014-2510-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-014-2510-3