Abstract

This study assessed the Knoop hardness and temperature increase provided by three light curing units when using (1) the manufacturers’ recommended times of photo-activation and (2) standardizing total energy density. One halogen – XL2500 (3M/ESPE) – and two light-emitting diode (LED) curing units – Freelight (3M/ESPE) and Ultrablue IS (DMC) – were used. A type-K thermocouple registered the temperature change produced by the composite photo-activation in a mold. Twenty-four hours after the photo-activation procedures, the composite specimens were submitted to a hardness test. Both temperature increase and hardness data were submitted to ANOVA and Tukey’s test (5% significance). Using the first set of photo-activation conditions, the halogen unit produced a statistically higher temperature increase than did both LED units, and the Freelight LED resulted in a lower hardness than did the other curing units. When applying the second set of photo-activation conditions, the two LED units produced statistically greater temperature increase than did the halogen unit, whereas there were no statistical differences in hardness among the curing units.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Light-cured composites are set through an addition polymerization. The exposure to light of a suitable wavelength and power density initiates the generation of free radicals that propagate the polymerization [15, 20]. However, photo-activation causes a temperature increase due to an exothermic reaction process and to the light energy absorbed [21, 23].

The most widely used light curing units (LCUs) are based on quartz tungsten halogen (QTH) lamps. The main radiant output from a QTH LCU is infrared energy, which may be absorbed by composites and results in an increased molecular vibration and heat generation. Thus, QTH LCUs require heat-absorbing filters to reduce the passage of infrared energy from the LCU to the tooth. However, unfiltered infrared energy can result in heat generation at the pulp chamber [20].

The relatively new light-emitting diode (LED) LCUs emit a narrow light wavelength that correlates with the spectral absorbance range of camphorquinone (CQ) [4]. However, Price et al. [18] showed differences that exist among the light emitted by different LED LCUs and even for LED LCUs of the same model.

It has been advocated that blue LEDs have all the spectral purity for highly efficient curing of composites with the added advantage of preventing overheating, when compared with QTH LCUs [26]. However, the majority of studies that have compared temperature rises during photo-activation [10, 14] employed different energy densities and do not provide any information about mechanical properties. Knezevic et al. [12] evaluated the temperature rise in composite samples cured by LED and QTH LCUs and obtained lower temperature values with the LED LCU. However, in Knezevic’s study, the LED LCU obtained slightly lower values for the degree of cure. Therefore, it is important to characterize the temperature increase produced by different LCUs when producing a similar cure. A lower temperature production could be related to poor degree of conversion and, thus, to the poor mechanical properties of the photo-activated composite [22]. To achieve similar results for the degree of cure, a constant energy density (power density vs time of exposure) could be used, as it has been claimed that the photopolymerization process of dental composites seems to be energy density dependent [9, 17].

Therefore, the aim of this study was to investigate the temperature increase and the Knoop hardness of a composite that was photo-activated under two conditions: (1) using the time of photo-activation as indicated by the manufacturers and (2) maintaining a constant energy density value among the LCUs.

Moreover, this study accessed the power density of the light curing units in different regions of the spectrum (190–400, 400–515, 450–490, and above 515 nm).

Materials and methods

One restorative composite was used in this study: Filtek Z250 (3M/ESPE Dental Products, St Paul, MN 55144, USA).

Three LCUs were used: QTH LCU XL2500 (3M/ESPE), Freelight LED LCU (3M/ESPE), and Ultrablue IS LED LCU (DMC Equipamentos LTDA, São Carlos, 13562030, São Paulo, SP, Brazil).

The output power (mW) LCU measurements were made with a power meter (Ophir Optronics, Danvers, MA 01923, USA) and the diameters of the tips were measured with a digital caliper (Mitutoyo Tokyo, Japan) to determine the area of the light guide. The power density (mW/cm2) of each LCU was determined by dividing the output power by the area of the light guide.

The spectral distributions of light were obtained using a calibrated spectrometer (USB 2000, Ocean Optics, Dunedin, FL 34698, USA). The power density and the spectral distribution data were plotted using the Origin 6.1 software (OriginLab Northampton, MA 01060, USA) to obtain, by numerical integration over the wavelength, the specific power density in the regions 190–400, 400–515, 450–490, and above 515 nm of the spectrum. With the total power density values (Table 1), the total energy density could be standardized by different exposure times of photo-activation. Because the QTH LCU demonstrated the highest energy density values when the manufacturers’ recommended times of photo-activation were applied (13,400 mJ/cm2), this LCU was used as the control group.

Thus, five photo-activation treatments were accomplished:

-

1.

20 s of photo-activation by QTH LCU (manufacturer’s recommendations) — CONTROL

-

2.

20 s of photo-activation by Freelight LED (manufacturer’s recommendations)

-

3.

20 s of photo-activation by Ultrablue IS LED (manufacturer’s recommendations)

-

4.

50 s of photo-activation by Freelight LED (photo-activation time necessary to approach the Freelight LED total energy density with the QTH LCU total energy density—50 s×270 mW/cm2=13,500 mJ/cm2)

-

5.

30 s of photo-activation by Ultrablue IS LED (photo-activation time necessary to approach the Ultrablue IS LED total energy density with the QTH total energy density—30 s×453 mW/cm2=13,590 mJ/cm2).

Temperature test

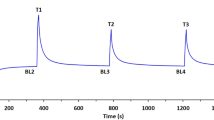

The temperature increase was recorded using a type-K thermocouple connected to a digital thermometer (Iopetherm 46, IOPE, São Paulo, SP 02712-050, Brazil). The composite was applied in a circular elastomer mold (3 mm in inner diameter and 2 mm in height) with the thermocouple positioned in the center of the mold. Between the thermocouple and the composite, a 0.5-mm dentin disc was positioned to simulate the leftover dentin (Fig. 1). The composite was then covered with a Mylar strip and digitally pressed. Ten specimens were prepared for each group (n=10). For the photo-activation, the LCU tips were positioned against the elastomer mold/composite.

For the temperature measurements, the initial temperature was recorded following temperature stabilization (20±0.5°C). The composite was then light cured and the temperature peak was registered. This peak was registered even after the light was turned off. The initial temperature was deducted from the final one to obtain the temperature variation. All measurements were taken in a temperature-controlled room, with a constant temperature of 20±1°C.

The temperature variation data were submitted to one-way ANOVA and the means were compared by Tukey’s test (5% of significance level). The statistical analyses were performed separately for the two photo-activation conditions.

Knoop hardness test

After the photo-activation procedure, the specimens were then placed in 3/4-in.-diameter PVC rings filled with self-curing polystyrene resin (Piraglass, Piracicaba, SP 13424-550, Brazil) to keep them fixed. After 24 h, at room temperature and light protected, each sample was flattened from the edge up to the center of the disc (1.5 mm of wear) with carbide sandpaper of decreasing grit (320, 400, 600, and 1,200) on a water-cooled automatic polisher APL-4 (Arotec Ind. Com., Cotia, SP 06709-150, Brazil) to obtain flattened surfaces. The Knoop hardness readings were performed with an indenter (HMV-2000, Shimadzu, Tokyo 101, Japan) under a load of 50 g for 15 s. Three indentations were made at three different depths: top (20-μm depth), middle (1,000-μm depth), and bottom (1,980-ìm depth), in a total of nine indentations for each specimen (Fig. 2). The values obtained in micrometers were converted to Knoop hardness number (KHN) by indenter software. The results were submitted to split-plot two-way ANOVA (LCU and depth) and the means were compared by Tukey’s test (5% significance level). The statistical analyses were performed separately for the two photo-activation conditions.

The mean KHN values and the mean temperature change values of all the five groups were submitted to Pearson’s correlation test.

Results

Table 2 shows mean values of KHN in each appraised depth when the time of photo-activation was used as indicated by the manufacturer. The three KHN averages obtained with the Freelight LED did not differ statistically. Whereas, the ones obtained with the Ultrablue IS LED and QTH LCUs varied with depth, where a significant increase in KHN values was found at the middle depth for the Ultrablue IS LED. Comparing the photo-activation methods at all depths, there were no statistically significant differences (p>0.05) between the QTH LCU and the Ultrablue IS LED. However, the Freelight LED LCU produced statistically lower KHN values than the others (p<0.05).

Table 3 shows mean values of KHN at each appraised depth when the time was adjusted to maintain a constant energy density value among the LCUs. There was no decrease in hardness, as depth increased when the Freelight LED and Ultrablue IS LED were used (p>0.05). The results with QTH LCU were the same as Table 2 because the same values were used, as this method was used as a control. Comparing the LCUs, there were no statistically significant differences (p>0.05).

Table 4 shows mean values of temperature increase recorded (Celsius degree). When the time of photo-activation was used as indicated by the manufacturers, both LED LCUs produced lower temperature increase than the QTH LCU. However, when the time of photo-activation necessary to maintain a constant energy density value among the LCUs was applied, the Freelight LED LCU produced higher values (p<0.05) than the Ultrablue IS LED and the QTH LCUs, and the Ultrablue IS LED produced a greater temperature increase (p<0.05) than the QTH LCU.

Table 5 shows the power density (mW/cm2) of the LCUs in the different regions of the spectrum (190–400, 400–515, 450–490, and above 515 nm). In the 190- to 400-nm wavelength region and above 515 nm, the Ultrablue IS showed the highest values of power density of the three LCUs. In the 400- to 515- and 450- to 490-nm regions, the QTH LCU emitted the highest values of the three LCUs.

Figure 3 shows the spectral distribution emitted by all the LCUs. Higher values of power density were seen for the Ultrablue IS LED when compared with the Freelight LED. Moreover, the broader wavelength range of the QTH than both the LED LCUs can be seen.

Pearson’s correlation test showed, despite a positive correlation between temperature increase and Knoop hardness values (R=0.60816), that the correlation was not statistically significant (p=0.14).

Discussion

Thermal transfer from the outside environment to the pulp chamber is affected by dentin thickness [8]. Thus, thicker dentin specimens reduce the temperature increase [14], protecting the pulp tissues from temperature injuries. As dentine has a relatively low thermal conductivity, the potential for pulpal damage is greater in deep cavities where the residual dentin thickness is smaller and the tubular surface area increases [23]. Therefore, a 0.5-mm dentine disc was used to standardize the leftover dentin.

The effectiveness of the composite cure may be directly or indirectly assessed [19, 24, 28]. Direct methods that check the degree of conversion are complex, expensive, and time-consuming [20]. Moreover, the indirect methods, which include the hardness test, have been shown to be an indicator of the degree of conversion [1] and there seems to be a good correlation between Knoop hardness and infrared spectroscopy determinations of degree of conversion [6, 7, 27]. Thus, the Knoop hardness test was used to compare the cure promoted by the LCUs.

Many authors and manufacturers have stated that LED LCUs have a similar curing efficiency when compared with QTH LCUs and the advantage of preventing overheating. Using the manufacturer’s recommended time of photo-activation, the QTH LCU really produced higher temperature increase than the two LED LCUs. However, the Freelight LED not only produced a lower temperature increase but also lower KHN values. These findings may be explained by the low energy density provided by this LCU (5,400 mJ/cm2) due to the low power density emitted (270 mW/cm2). Thus, this lower temperature increase could not be considered an advantage. Despite a lower temperature increase, the Ultrablue IS LED resulted in KHN values that were not statistically lower than those obtained by the QTH LCU. These findings may be explained by the fact that the Ultrablue IS LED emitted a spectrum that was centered more in the 450- to 490-nm region – the most efficient CQ absorption region [16] – when compared with the QTH LCU. Moreover, the Ultrablue IS LED emitted a light with a power density of 322 mW/cm2 in the 450- to 490-nm range, which represents 71% of the total energy density (453 mW/cm2). These values were higher than the one promoted by the QTH LCU that represent only 53%. Thus, even with a lower total power density emitted by the Ultrablue IS LED, this LCU promoted similar KHN values to the QTH LCU.

Some studies suggest that the cure temperature increase of a photo-activated composite is based on the total energy density applied to the composite [20, 28]. However, in this study, the Freelight LED promoted the highest increase of temperature values, followed by the Ultrablue IS LED and then the QTH LCU. Although the same total energy density of light was applied, the findings in this study could be explained by the low thermal conductivity of composites and the different pattern of energy density distribution along time. Thus, the effect of energy density on the temperature increase may be dependent on how energy density is distributed and dissipated. The relation of these aspects within time may be responsible for the difference among these three photo-activation methods. Furthermore, the standardization of energy density resulted in no difference in Knoop hardness values, corroborating with previous studies [9, 17].

When the Ultrablue IS LED was used (when the time of photo-activation was used as indicated by the manufacturers), the KHN values in the middle region were statistically higher than those of the top and bottom regions. Asmussen and Peutzfeldt [2] suggested that, in these cases, the heat of polymerization inside the bulk produced by the conversion of double bonds might have an influence on these values.

One of the qualities attributed to LED LCUs is that there is basically no infrared light transmission to the tooth; therefore, no excessive heat is produced [13]. The ISO TS 10650 standard [11] proposes that the upper limit of power density above 515 nm is 50 mW/cm2 for QTH LCUs. The QTH LCU used in the present study emitted only 6.64 mW/cm2, showing the efficiency of the infrared filter of the QTH LCU.

Another determination of the current ISO standard [11] is that the upper limit of light power density in the 190- to 385-nm wavelength range, the ultraviolet (UV) region, is 100 mW/cm2, as the UV radiation can generate ocular damage [5]. In the present study, the Ultrablue IS LED emitted the highest power density value in the UV region—5.18 mW/cm2, showing that the LCUs used in the present study can be safely used, with regard to UV radiation emission.

The Pearson’s correlation test showed that the correlation between temperature increase and Knoop hardness was not statistically significant. This may be due to the fact that the temperature was recorded beneath a dentin disk and that, due to heat dissipation, it was not possible to estimate the temperature within the composite.

Over the years, studies [3, 29] have tried to verify the effect of external heat application on the pulpal tissues. However, the exact extent of thermal trauma that can be tolerated by the dental tissues remains unknown [25]. Thus, clinicians should be aware of the factors that are involved in the temperature increase, such as light energy density, light power density, emitted spectrum, and leftover dentin thickness. Moreover, they should be aware of the possibility of overheating when using lower power density values for long exposure periods (when aiming for good photo-activation) because composites are materials with low thermal conductivity and the effect of energy density on the temperature increase may be dependent on how this energy density is distributed, regarding the time of photo-activation and heat dissipation.

Conclusions

Using the manufacturers’ recommended times of photo-activation, the QTH LCU produced a higher temperature increase than did both LED units. However, the Freelight LED resulted in a lower hardness than did the other curing units.

Standardizing total energy density, the two LED units produced greater temperature increase than did the QTH LCU, whereas there were no statistical differences among hardness values.

References

Asmussen E (1982) Factors affecting the quantity of remaining double bonds in restorative resin polymers. Scand J Dent Res 90:490–496

Asmussen E, Peutzfeldt A (2003) Influence of specimen diameter on the relationship between subsurface depth and hardness of a light-cured resin composite. Eur J Oral Sci 111:543–546

Baldissarra P, Catapano S, Scotti R (1997) Clinical and histological evaluation of thermal injury thresholds in human teeth: a preliminary study. J Oral Rehab 24:801–971

Caughman WF, Rueggeberg FA (2002) Shedding new light on composite polymerization. Oper Dent 27:636–638

Čejková J, Típek S, Crkovská J, Ardan T, Láteník J, Èejka È, Midelfart A (2004) UV rays, the prooxidant/antioxidant imbalance in the cornea and oxidative eye damage. Physiol Res 53:1–10

DeWald JP, Ferracane JL (1987) A comparison of four modes of evaluating depth of cure of light-activated composites. J Dent Res 66:727–730

Ferracane JL (1995) Current trends in dental composites. Crit Rev Oral Biol Med 6:302–318

Goodis HE, White JM, Andrews J, Watanabe LG (1989) Measurements of temperature generated by visible-light-cure lamps in an in vitro model. Dent Mater 5:230–234

Halvorson RH, Erickson RL, Davidson CL (2002) Energy dependent polymerization of resin-based composite. Dent Mater 18:463–469

Hannig M, Bott B (1999) In-vitro pulp chamber temperature rise during composite resin polymerization with various light-curing LCUs. Dent Mater 15:275–281

International Organization for Standardization Specification, ISO TS 10650 (1999) Dental equipment-powered polymerization activators. Geneva, Switzerland

Knezevic A, Tarle Z, Meniga A, Sutalo J, Pichler G, Ristic M (2001) Degree of conversion and temperature rise during polymerization of composite resin samples with blue diodes. J Oral Rehabil 28:586–591

Kurachi C, Tuboy AM, Magalhães DV, Bagnato VS (2001) Hardness evaluation of a dental composite polymerized with experimental LED-based devices. Dent Mater 17:309–315

Loney RW, Price RB (2001) Temperature transmission of high-output light-curing units through dentin. Oper Dent 26:516–520

Lovell LG, Newman SM, Donaldson MM, Bowman CN (2003) The effect of light intensity on double bond conversion and flexural strength of a model, unfilled dental resin. Dent Mater 19:458–465

Nomoto R (1997) Effect of light wavelength on polymerization of light-cured resins. Dent Mater J 16:60–73

Peutzfeldt A, Sahafi A, Asmussen E (2000) Characterization of resin composites polymerized with plasma arc curing units. Dent Mater 16:330–336

Price RB, Felix CA, Andreou P (2005) Knoop hardness of ten resin composites irradiated with high-power LED and quartz-tungsten-halogen lights. Biomaterials 26:2631–2641

Rueggeberg FA, Craig RG (1988) Correlation of parameters used to estimate monomer conversion in a light-cured composite. J Dent Res 67:932–937

Rueggeberg F (1999) Contemporary issues in photocuring. Compend Contin Educ Dent 20:S4–S15

Schneider LF, Cavalcante LM, Tango RN, Consani S, Sinhoreti MA, Correr-Sobrinho L (2005) Pulp chamber temperature changes during resin composite photoactivation. Braz J Oral Sci 4:685–688

Schneider LF, Consani S, Sinhoreti M, Correr Sobrinho L, Milan F (2005) Temperature change and hardness with different resin composites and photo-activation methods. Oper Dent 30:516–521

Shortall AC, Harrington E (1998) Temperature rise during polymerization of light-activated resin composites. J Oral Rehab 25:908–913

Stansbury JW (2000) Curing dental resins and composites by photopolymerization. J Esthet Dent 12:300–308

Stewardson DA, Shortall ACC, Harrington E, Lumley PJ (2004) Thermal changes and cure depths associated with a high intensity light activation unit. J Dent 32:643–651

Uhl A, Mills RW, Jandt KD (2003) Polymerization and light-induced heat of dental composite cured with LED and halogen technology. Biomaterials 24:1809–1820

Vandewalle KS, Ferracane JL, Hilton TJ, Erickson RL, Sakaguchi RL (2004) Effect of energy density on properties and marginal integrity of posterior resin composite restorations. Dent Mater 20:96–106

Yap AU, Seneviratne C (2001) Influence of light energy density on effectiveness of composite cure. Oper Dent 26:460–466

Zach L, Cohen G (1965) Pulp response to externally applied heat. Oral Surg Oral Med Oral Pathol 16:515–530

Acknowledgement

The authors thank the Institute of Physics at the São Paulo University (USP, São Carlos Campus), especially to Prof. Dr. Cléber Renato Mendonça, for the spectrometer collaboration.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schneider, L.F., Consani, S., Correr-Sobrinho, L. et al. Halogen and LED light curing of composite: temperature increase and Knoop hardness. Clin Oral Invest 10, 66–71 (2006). https://doi.org/10.1007/s00784-005-0028-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-005-0028-x