Abstract

The temperature and Vickers Hardness (VH) at the top and bottom surfaces of three resin-based composites (RBCs) were measured when light-cured using five light-curing units (LCUs). The spectrum, power, and energy delivered to the top of the RBCs and transmitted through the RBCs were measured. Starting at 32℃, the temperature rise produced by the Monet Laser (ML—1 s and 3 s), Valo Grand (VG—3 s and 10 s), DeepCure (DC—10 s), PowerCure, (PC—3 s and 10 s) and PinkWave (PW—10 s) were measured at the bottom of specimens 2 mm deep × 6 mm wide made of Filtek Universal A2, Tetric Evoceram A2 and an experimental RBC codenamed Transcend UB. The VH values measured at the top and bottom of these RBCs were analyzed using ANOVA and Scheffe’s post hoc test (p < 0.05) to determine the effects of the LCUs on the RBCs. The transmitted power from the ML was reduced by 77.4% through 2 mm of Filtek Universal, whereas light from PW decreased by only 36.8% through Transcend. The highest temperature increases from the LCU combined with the exothermic reaction occurred for Transcend, and overall, no significant differences were detected between Filtek Universal and Tetric Evoceram (p = 0.9756). Transcend achieved the highest VH values at the top and bottom surfaces. The PinkWave used for 10 s produced the largest temperature increase (20.2℃) in Transcend. The Monet used for 1 s produced the smallest increase (7.8℃) and the lowest bottom:top VH ratios.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The resin used in light-activated resin-based composite restorations (RBCs) must be adequately photo-cured for the restoration to be clinically successful; otherwise, the RBC remains a liquid or soft paste. Therefore, good light-curing units (LCUs) have become indispensable in the dental office. Light-emitting diode (LED) LCUs are now the most popular [1, 2]. They deliver a narrow emission range of wavelengths, they do not require any filters, they are energy efficient, and they can be battery operated [1]. Clinicians may choose to use single-peak LED LCUs that deliver only a narrow band of wavelengths, or they may use multi-peak LED LCUs, also called polywave, that use several LEDs to emit multiple emission peaks that cover a broader range of wavelengths. Consequently, compared to single-peak LCUs, these multi-peak LED LCUs can activate a wider range of photoinitiators, as well as the commonly used camphorquinone initiator [3].

To achieve improved mechanical properties and reduce chair time, manufacturers make and promote LCUs that deliver irradiances greater than 2,000 mW/cm2 and offer short exposure times, some as short as 1 s [4, 5]. However, when using LCUs that deliver a high irradiance, there is a potential risk for heat-induced pulpal injury as the RBC polymerizes [6] because the LCU can deliver a considerable amount of energy [7] to the gingivae [8, 9] and the pulpal tissues [10,11,12,13,14,15,16]. In addition, the exothermic polymerization reaction produces additional heat that increases the magnitude of the temperature rise. Thus, the temperature rise in the tooth depends on the RBC, power (Watts), irradiance (mW/cm2), exposure time, amount of energy delivered (Joules), the rate at which the RBC polymerizes, and the wavelengths of light delivered from the LCU [3, 17,18,19,20,21,22]. It has been suggested that temperature increases greater than 5.5 °C inside the pulp chamber might be dangerous to the pulp [10]. For this reason, the heat generated when using LCUs that deliver an irradiance greater than 1,200 mW/cm2 has become a concern [22].

A new approach to the photo-activation of composites uses a fast, 1–3-s light exposure at a high irradiance [23,24,25]. A recent development uses a laser diode LCU to deliver such a high irradiance at 450 nm in a 1-s exposure (Monet, AMD). The manufacturer claims that this laser diode LCU has a collimated beam that allows the light to penetrate deeply into the RBC and photo-cure the RBC to a depth of 2 mm in only 1 s. Some blue diode lasers using 445 nm have already been tested as an alternative light source to photo-cure dental RBCs [26, 27]. Since they are a laser, they deliver a high photon density and a high irradiance even as the distance from the light tip increases, but their output is over a very narrow range of wavelengths [26]. A previous study reported that using one laser diode LCU for 1 s produced the shallowest depth of cure in all ten RBCs tested. This was attributed to the low radiant exposure delivered by this LCU in 1 s. [28]. Another new LCU is the PinkWave. This LCU has what the manufacturer describes as Quadwave technology to deliver four distinct bands of wavelengths over a wider range of wavelengths than conventional LCUs. In addition to blue and violet light, the PinkWave delivers near-infrared (NIR) and red light. However, there is currently no information regarding the temperature rise that occurs when using the Monet or the PinkWave LCUs.

Some previous laboratory studies have evaluated the heat generated on cylindrical RBC specimens made in Teflon molds at room temperature using both K- and T-type thermocouples [18, 19, 27, 29]. Alternatively, high-definition digital infrared imagery has been used to monitor the temperature [22, 30]. However, in these studies, the volume of RBCs used was often not well defined, the energy or the wavelengths delivered by the LCU were not reported, nor was a baseline temperature used that was similar to the intra-oral temperature found in a tooth [15, 30]. Therefore, this study recorded the real-time temperature rise produced at the bottom of standardized volumes of three RBCs using a fast response T-type thermocouple starting at a simulated intra-oral temperature of 32℃ [15] when light-cured using five different LCUs. In addition, the light transmission through the RBCs and the Vickers micro-hardness (VH) at the top and bottom surfaces were measured.

The null research hypotheses are that:

(1) The five LCUs would not deliver the same amount of energy (Joules);

(2) The combined effect of the light from the LCUs and the exothermic reaction would not produce the same temperature increase at the bottom of the three RBCs;

(3) There would be no differences in the exothermic temperature rise produced by different RBCs;

(4) The exothermic heat contribution to the temperature increase would not be greater than 5.5℃ [10]; and.

(5) There would be no differences in hardness values at the top and bottom of the RBCs when the different LCUs were used.

Materials and methods

Resin-based composites (RBCs) and light-curing units (LCUs)

Three conventional paste consistency RBCs whose manufacturers recommend a 2 mm maximum increment thickness were used in the study: Tetric Evoceram A2 (Ivoclar Vivadent, Schaan, Liechtenstein); Filtek Universal A2 (3 M Oral Care, St. Paul, MN, USA) and one experimental RBC codenamed Transcend UB (Ultradent, South Jordan, Utah, USA). The lot numbers and manufacturers are reported in Table 1.

Five contemporary high-output LCUs were used: DeepCure (DC, 3M Oral Care, St. Paul, MN, USA), PinkWave (PW, Vista Dental Products, Racine, WI, USA), PowerCure (PC, Ivoclar Vivadent, Schaan, Liechtenstein), Valo Grand (VG, Ultradent Products Inc., South Jordan, UT, USA), and Monet Laser (ML, AMD Lasers, West Jordan, UT, USA). The brand, serial number, manufacturer, type, emission spectrum (nm), the exposure modes recommended by the manufacturer to light cure 2 mm of RBC [4, 31,32,33,34] and their claimed irradiance outputs are reported in Supplemental Table 1.

Analysis of the light emitted by the LCUs and transmitted through the RBCs

A 2 mm thick semi-transparent Delrin (polyoxymethylene homopolymer) mold with a 6 mm diameter hole was used in the study to measure the temperature changes, the light received by the specimens from the LCU, and the amount of light transmitted through the RBCs. First, the irradiance was measured through the unfilled Delrin mold placed between the LCU tip and the entrance into a 6″ integrating sphere (Labsphere, North Sutton, NH, USA). This sphere was attached to a fiber-optic Flame spectrometer (Ocean Insight, Logan, FL, USA). This entire measurement system had been previously calibrated using an internal calibration lamp SCL-600 (Labsphere). Next, the tip of each LCU was centrally positioned at the entrance to the 6 mm diameter hole, and the light output from each LCU through the hole in the mold and into the sphere was measured. Of note, this was not the irradiance emitted at the tip of the LCU; instead, it was the same irradiance received by the 6 mm diameter specimens. Then, additional Delrin molds were filled with the RBCs used in the study and photo-activated with the PowerCure for 20 s. These molds were then placed at the entrance of the integrating sphere, and the light that passed through the cured RBC and into the sphere was measured for each LCU condition (Supplemental Table 1). Three measurements were made for each group to obtain the mean powers (mW), radiant exposures (J/cm2), and the attenuated powers of the light that reached the bottom of each RBC.

Temperature analysis

The same 2 mm thick semi-transparent Delrin mold with a 6 mm diameter hole (volume of 56.5 mm3 (V = πr2h) for each specimen) was placed on a block of cured Filtek Supreme Ultra Shade A2 RBC (3 M Oral Care, St. Paul, USA) that was 31 mm wide by 57 mm long. A fast response thermocouple T-type (Physitemp Instruments, Clifton, USA) was placed on the block, centrally at the bottom of the specimen, and the temperature was recorded in real-time (every 0.5 s) with the T-type thermocouple connected to a temperature acquisition software (T.C. Chart 1.03, Nomadics Inc., USA). The block was placed on top of a warming plate (Cimarec, Thermo Fisher Scientific, Waltham, USA) set at 32℃ and the temperature was monitored in real-time until it stabilized. A thin layer of zinc oxide thermal paste (Corsair Memory, Almere, Netherlands) was placed over the thermocouple to improve the temperature transfer from the RBC to the thermocouple. Once the baseline temperature had reached 32℃ [15], the 6 mm diameter hole in the Delrin ring was filled with RBC. This caused the temperature to fall, but once the baseline temperature had returned to 32℃, the RBCs in each group were exposed to light with the tip of the LCU positioned 0 mm from the surface of the RBC. An example of how the three temperature measurements were made is shown in Fig. 1. After the RBC specimens had been exposed to light, the LCU was taken out of contact with the surface of the RBC so that the light tip did not act as a thermal heat sink. The temperature was monitored in real-time until it returned to 32℃, at which time an additional light exposure was performed. The samples received this second light exposure to hopefully fully photo-polymerize the RBC. This was then followed by a third exposure. The resulting temperature rise was used to calculate the exothermic heat contribution from the RBCs by subtracting this temperature rise (ΔT3) from the first (ΔT1) temperature rise. The time to reach the maximum temperature (T1 peak) and then return to 32℃ was approximately 6 min. A total of five temperature measurements (n = 5) were made for each group.

Vickers micro-hardness (VH)

After temperature measurements had been made, the specimens (n = 5) were removed from the Delrin mold and stored in dry and dark conditions for 24 h. The RBCs were weighed using a Mettler AE 160 digital scale (Mettler Toledo Instruments, Ontario, Canada) to confirm that the specimens were similar. The Vickers hardness (VH) was then measured using a micro-hardness testing machine (HM 123, Mitutoyo, Kawasaki, Kanagawa, Japan) that applied a 300 g load for 8 s [35]. Three equidistant indentations were made close to the center of the unpolished top and bottom surfaces.

Statistical analysis

The present study consisted of 2 independent variables (“RBC” and “LCU”), with the factor “RBC” containing 3 sublevels and “LCU” with 8 sublevels. The factorial scheme resulted in 24 experimental groups, with 5 repetitions for each group (n = 5). The ΔT values were subjected to a two-way, repeated-measures analysis of variance (ANOVA) test with “RBC” and “exposure modes” as the independent variables, followed by Scheffe’s post hoc tests. The specimen weight, time to take the maximum temperature, exothermic heat contribution and VH values among the products were compared using one-way ANOVA followed by Scheffe’s post hoc test. All statistical testing and post hoc analyses were conducted using a preset α of 0.05. Logarithmic regression analyses were performed (Excel, Microsoft, Redmond, WA, USA) for each RBC temperature rise at the different exposure modes using either the Power (Watts) or the Energy (Joules) delivered from the LCUs to the RBCs.

Results

Weight

Overall, the specimens made using Tetric Evoceram had the highest mean ± standard deviation weight value of 0.120 ± 0.005 g, followed by Transcend UB at 0.117 ± 0.005 g and Filtek Universal A2 at 0.115 ± 0.004 g. These differences of ± 0.005 g represented, at most, a 4% difference in the weight of the RBCs in each group. No significant differences were found between the Filtek Universal A2 and Transcend UB groups of RBC (p = 0.2658), but Scheffe’s post hoc test detected a significant difference for the specimens of Tetric Evoceram (p < 0.05).

Analysis of the light emitted by the LCUs and transmitted through the RBCs

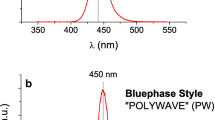

Figure 2 shows the total power (mW) and emission spectra from the LCUs. The Valo Grand, PowerCure and PinkWave were multi-peak broadband LED lights. The PowerCure delivered two wavelength peaks, and the Valo Grand had three peaks. One peak was in the violet range (Valo Grand = 393 nm and PowerCure = 408 nm), and the others were in the blue wavelength region (Valo Grand at 448 and 461 nm and PowerCure = 451 nm). The PinkWave LCU emitted four distinct bands of wavelengths, three were in the range of visible light (λ1 = 410 nm; λ2 = 471 nm, λ3 = 631 nm), and one was in the near-infrared spectral range (thermal radiation) with an emission peak (λ4) at 860 nm. The Monet and DeepCure LCUs delivered only a single emission peak (Fig. 2). The DeepCure emitted a broader range of wavelengths with a peak emission at 448 nm. Since the Monet is a laser, it emitted a very narrow band of wavelengths with an emission peak at 451 nm.

The power (mW) transmitted through the empty mold and through the molds filled with RBC are reported in Table 2. The transmitted power from the ML was reduced by 77.4% when passing through 2 mm of Filtek Universal A2, whereas the power of the light from the PW decreased by only 36.8% after passing through 2 mm of Transcend UB. Figure 3 shows the emission spectra from PinkWave and Valo Grand through the empty ring and the ring filled with the RBCs. Note the greater reduction of the lower wavelengths of violet light. Table 3 reports the irradiance and radiant exposure received by the RBCs in the 6 mm diameter mold. Note that the radiant exposure delivered in every single exposure ranged from a little as 5.4 J/cm2 to a high of 31.0 J/cm2, depending on the LCU and exposure time. This value must be multiplied by 3 to give the total radiant exposure delivered to the RBCs after they had received 3 light exposures.

Temperature analysis

The greatest mean temperature (± Standard Deviation) increases during the first light exposure of the RBCs, regardless of the exposure mode, occurred at the bottom of Transcend UB (mean ΔT1 = 17.2℃, SD = 4.4), followed by Tetric Evoceram A2 (mean ΔT1 = 13.1℃, SD = 3.1) and Filtek Universal A2 (mean ΔT1 = 13.0℃, SD = 3.1). Scheffe’s test detected a significant difference for Transcend (p < 0.0001), but there was no significant difference between the temperature increase for Filtek Universal and Tetric Evoceram (p = 0.9756).

The greatest temperature increase was found when the PinkWave was used for 10 s (mean ΔT1 = 20.2℃, SD = 2.2), regardless of the RBC used. The smallest temperature increase was from the Monet when used for 1 s (mean ΔT1 = 7.8℃, SD = 0.6). No significant differences were found between PowerCure used for 10 or 3 s, Valo Grand used for 10 or 3 s, DeepCure used for 10 s, and the Monet used for 3 s (Fig. 4). Except for Monet used for 1 s, the temperature rises on the two subsequent exposures of the now cured RBC were significantly lower, but again the PinkWave used for 10 s produced the greatest overall temperature increase (Table 4 and Fig. 4).

Overall mean temperature increase (ΔT) as the three uncured RBCs were exposed to the different exposure modes. The line over the columns shows where there was no significant difference between exposure modes (Scheffe’s post hoc test p ≥ 0.05). Note that the largest increase in the temperature occurred using the PinkWave for 10 s

Logarithmic regression analyses examined the relationship between the combined exothermic and LCU temperature rises and either the Power (Watts) or the Energy (Joules) delivered by the LCUs to the RBCs. For all the RBCs, Fig. 5 shows no correlation between the power output from the LCUs and the temperature rise (R2 = 0.0067 for Filtek Universal, R2 = 0.0177 for Tetric Evoceram and R2 = 0.0027 for Transcend). However, there was an excellent positive correlation between the energy delivered from the LCU and the temperature rise at the bottom of the RBC (R2 = 0.827 for Filtek Universal, R2 = 0.763 for Tetric Evoceram and R2 = 0.721 for Transcend).

Table 5 reports the mean and standard deviation time (s) the RBCs took to reach their respective maximum temperatures and then return to 37℃. After the initial first exposure, Filtek Universal exposed to the Deep Cure for 10 s (11.8 s ± 1.6) and Transcend exposed to the PinkWave for 10 s (11.0 s ± 0.5) took the longest to reach their maximum temperature. The RBCs exposed to the PinkWave used for 10 s took the longest time to return to 37℃ (32.4 s ± 3.5 for Transcend, 29.6 s ± 3.5 for Filtek and 29.0 s ± 3.0 for Tetric Evoceram).

The exothermic heat contribution from each RBC was calculated by subtracting the third temperature rise (ΔT3) from the first temperature rise (ΔT1). Figure 6 shows the exothermic heat contribution for each group. Except for Monet used for 1 s (1.4℃ ± 0.3), the highest exothermic heat contributions from the RBC were found at the bottom of Transcend (temperatures ranging between 8.2℃ ± 0.7 and 11.2℃ ± 1.0).

Overall, when comparing the RBCs, irrespective of which LCU was used, Transcend produced the greatest (p < 0.05) exothermic temperature rise (8.1℃ ± 2.8). However, Scheffe’s post hoc test found no significant difference (p = 0.4935) between the overall exothermic temperature increases of Filtek Universal (6.4℃ ± 1.4) and Tetric Evoceram (5.8℃ ± 1.0).

Vickers micro-hardness (VH)

Table 6 reports the mean and standard deviation VH values at the top and bottom surfaces of the 2 mm thick specimens after they had received three light exposures. The bottom:top ratio for each RBC and LCU was calculated by dividing the bottom to the top values for the same condition of RBC and LCU. In addition, the bottom:top ratio for each RBC was calculated based on the greatest mean VH value at the top achieved using any LCU for that RBC, divided by the bottom VH value. Scheffe’s post hoc test detected a significant difference between the surfaces for Filtek Universal and Tetric Evoceram (p = 0.0015). No difference between top and bottom was detected for Transcend (p = 0.3594). Although a significant difference was detected for Filtek Universal and Tetric Evoceram, the percentage differences between the top and bottom were low (Filtek Universal = 3.3% and Tetric Evoceram = 7.6%).

Figure 7 shows the mean VH values for each exposure mode used in the study, regardless of the RBC used. Overall, the Valo Grand used for 10 s produced the highest VH values, whereas the Monet, used for both 1 s and 3 s, achieved the lowest VH values. Although the specimens were harder after a 3-s exposure, there were no significant differences between the 1 and 3-s exposure (p = 0.1825).

Discussion

This study evaluated different types of LCUs and exposure times: one curing laser, one monowave LED and three polywave LEDs. Thus, it was not unexpected that the five LCUs would not deliver similar irradiances and radiant exposures (Fig. 2 and Table 3). However, the magnitude of the differences was unexpected. There was a threefold difference in power (408–1538 mW), and a sixfold range in the radiant exposure delivered (5.4–31.0 J/cm2). Therefore, the first hypothesis that the five LCUs would not deliver the same amount of energy (Joules) during light-curing was accepted. Unfortunately, many dentists do not recognize how large these differences are, and many use the same exposure time to photo-cure everything [2, 36, 37].

The second hypothesis that the combined effects of the light from the LCUs and the exothermic reaction would not produce the same temperature increase at the bottom of the three RBCs was accepted. In the present study, the PinkWave used for 10 s caused a significant increase in the temperature at the bottom of the RBCs during photo-activation (Fig. 4). This can be attributed to the higher amount of energy delivered and the different wavelengths emitted by this LCU. The spectral analysis reported in Fig. 2 shows the four wavelength bands from the PinkWave: of note, one wavelength band had an emission peak at 631 nm and another was at 860 nm in the near-infrared region. Light in these regions can cause a heating effect. Figure 3 shows the transmission spectrum (mW/nm) from the PinkWave and Valo Grand through the empty molds and through the molds filled with each RBC. Note that for the PinkWave, there was a significant attenuation of the violet light at 410 nm (λ1) and the blue light at 471 nm (λ2) when light passed through the RBCs, which cannot be seen for the other two bands wavelengths with peaks at 631 nm (λ3) and 860 nm (λ4). Thus, Fig. 3 shows that most of the red and near-infrared light penetrated through the RBC. This explains why the reduction (%) in power from the Pinkwave (Table 2) was much less than the other LCUs. This infrared radiation from the PinkWave is likely responsible for the larger increase in temperature observed when this LCU was used (Table 4).

When analyzing the Logarithmic Regression for the RBCs temperature rise recordings for Power and Energy (Fig. 5), only the Energy (Joules) delivered had a significant positive correlation (R2 = 0.827 for Filtek, R2 = 0.763 for Tetric Evoceram and R2 = 0.721 for Transcend) with the temperature rise in the RBCs. The results from previous studies support that it is the radiant energy that mainly determines temperature rise and not the irradiance [18]. The greater the amount of energy delivered, the greater the temperature rise. In contrast, no correlation was found between the Power (Watts) and the Temperature (℃). The greater the amount of energy delivered, the greater the temperature rise. Thus, despite delivering the highest power (1,538 mW) and the highest irradiance (5,441 mW/cm2) to the RBCs (Table 3), using the Monet Laser produced the smallest temperature increase. Since the energy delivered is related to the exposure time, the short, 1-s exposure delivered the lowest low radiant exposure values (5.4 J/cm2) when the Monet Laser was used. This likely explained why the Monet Laser produced the lowest temperature increase in the RBCs. However, this was likely because the RBCs were not as well photo-activated. Of note, the exothermic temperature rises (Fig. 6) when the Monet laser was used were also low probably because there was less polymerization of the RBCs. This is supported by the observation that the Monet Laser used for 1 s produced the lowest hardness values in the RBCs (Table 6). Thus, photo-curing most RBCs for 1 or 3 s does not appear advisable because, in addition to the observation that less energy was delivered when the LCUs were used for shorter times, the polymerization shrinkage forces may develop more rapidly [38]. This may cause increased debonding between the tooth and the RBC to occur. Therefore, clinicians should only use a fast-curing protocol with RBCs that use high-yielding photoinitiators and that have been specifically designed to be photo-cured in 1 to 3 s [24, 28].

The samples were made in identical 2 mm thick Delrin rings, and this thickness did not exceed the manufacturer’s instructions for the RBCs. The specimens were weighed to verify that the RBCs in each group were almost identical, and there was only ± 0.005 g (4%) difference in the weight of the RBCs in each group. Thus, any differences in the temperature could only be attributed to the light or to the RBC, and not to any differences in the amount of RBC in the specimens. The decision to use a block of cured RBC was made to provide reflective and thermal backgrounds similar to the cavity floor instead of using white filter paper or a glass slab. Table 4 shows that the choice of RBC affected the temperature rise. Thus, the third hypothesis that there would be no differences in the exothermic temperature rise produced by different RBCs was rejected. Due to the COVID pandemic, the experimental RBC codenamed Transcend has not yet been released to the public, and this is the first report about this experimental RBC from Ultradent. Although some studies show that fillers are chemically inert and do not affect the temperature rise [21] and that there is a high correlation between matrix ratio and temperature rise [39], the highest temperature rise occurred in Transcend UB, regardless of the exposure mode used, even though the manufacturer claims that Transcend had the highest filler content (77.5% per weight—Table 1) among the RBCs tested. This can be explained by the greater translucency (Table 2) of the experimental RBC, Transcend, which allows more light to pass through the RBC. This results in a greater temperature rise [40] at the bottom and better photo-activation at the bottom (Table 6) of this RBC, but this also produces more exothermic heat from the more complete polymerization reaction (Table 4 and Fig. 6).

If the same exposure time is used, the LCU that delivers a high irradiance can cause a high thermal transfer and increase the risk of pulpal damage [41]. When the irradiance is the same, the longer the exposure time, the greater radiant exposure delivered Consequently, there is also a greater the risk of pulpal damage. Thus, it is important to know the exposure time and the radiant exposure received by the specimens. Unfortunately, most contemporary research publications lack an adequate description of the light received by the RBC specimens [36]. Despite these limitations, previous studies have reported that temperature increases of 5.5℃ or more in the pulp can lead to irreversible pulp damage [10, 42]. The present study found that the combination of the light and the exothermic reaction produced an increase in the temperature at the bottom of all three RBCs as they photo-cured that was greater than 5.5℃. Thus, all the RBCs could potentially cause some thermal damage to the pulp when they were photo-cured. However, hopefully, pulpal damage should not happen because the dentin between the RBC and the pulp is an excellent thermal insulator [43]. Reducing the exposure time or the irradiance may reduce the risk of tissue damage, since less energy is delivered. However, Tables 2 and 6 show this can adversely affect the mechanical properties of the RBC [22]. Therefore, it seems preferable to use a 10-s exposure time from a conventional LCU to deliver an adequate amount of energy, produce an adequately cured RBC, and an acceptable temperature rise [18].

Figure 1 and Table 4 show that the photo-curing reaction is exothermic, and this exothermic component is RBC-dependent [16]. Thus, the temperature increase is a cumulative result of this exothermic reaction and the exposure to light from the LCU. In contrast, for the post-cured RBCs (T3 in Fig. 1 and Table 4), the temperature increase was only a result of the effect of the light from the LCU [16]. Therefore, the fourth hypothesis that this exothermic heat contribution to the temperature increase would be less than 5.5℃ [10] was rejected. Except for these groups: Transcend UB + Monet used for 1 s, Filtek Universal A2 + Monet used for 1 s, Tetric Evoceram A2 + Monet used for 1 s Tetric Evoceram A2 + PC 10 s, all the other combinations of LCU and RBC produced temperature increases that were greater than the 5.5℃ threshold (Fig. 6). Transcend generated the highest temperature values using the other 4 LCUs (Table 4) and consistently had the greatest exothermic temperature rise (Fig. 6). The reader can easily test the results by placing some RBC on the back of the hand and then light-curing the RBC. The RBC gets hot. When this is repeated using the cured RBC, the temperature rise is less.

According to all the manufacturers’ instructions, all the exposure times used in the study should have adequately photo-activated the 2 mm thick specimens of all the RBCs tested. Transcend was the most transparent RBC (Table 2), and there were no significant differences in the VH between the top and bottom surfaces (Table 6). After the RBCs had received three repeated exposures, the bottom:top hardness ratios of Transcend were 0.90 or greater using four of the five LCUs. However, even when the Monet was used three times, for a total of 9 s, the bottom:top ratio was only 0.84, and it was only 0.65 when three 1-s exposures were used with the Monet. This may occur because the extent of polymerization has an exponential relationship with the amount of transmitted light received by the RBC [44]. Since there was so much more light at the bottom of the RBC, the RBC was well photo-activated at the bottom. Finally, when analyzing the LCUs, regardless of the RBC used and even after three repeated exposures, the Monet Laser produced the lowest VH values in the RBCs (Fig. 7 and Table 6). Although the Monet Laser delivered a high irradiance of 5,441 mW/cm2 at 451 nm, the radiant exposure delivered to the RBCs in the 1-s exposures was only 5.4 J/cm2. This was less than from the other LCUs (Table 3). This 2 mm increment of RBC should receive approximately 16 J/cm2 of radiant exposure [45]. Thus, it is not surprising that when the Monet was used for 1 s, the Vickers Hardness values were low. When comparing the bottom:top VH values from the top and bottom of the RBCs, there were significant differences between the surfaces for Filtek Universal and Tetric Evoceram (p = 0.0015) despite the low difference between the bottom and bottom values (Table 3). When the VH values at the bottom for each RBC were compared against the LCU that produced the highest value at the top for that specific RBC, the differences in the bottom:top ratios became even more apparent (Table 6). Thus, because not all of the LCUs tested produced the same hardness values at the top and bottom of the RBCs, the fifth hypothesis of the study was rejected. Table 6 also highlights the importance of using the highest value reached at the top surface under any condition for that RBC when determining the overall bottom:top ratios.

The clinicians should be aware that the choice of the LCU or RBC can affect the temperature rise of the bottom of RBCs by the energy delivered from the LCU (Fig. 5) and that there can be a significant exothermic contribution from the RBC itself (Fig. 6). This becomes more important when placing restorations in children with deep cavities because the amount of thermal transfer to the pulp is affected by the remaining dentin thickness [46]; the thinner the thickness of dentin remaining, the greater the thermal transfer. Therefore, to prevent irreversible pulpal damage [10], it is recommended to blow a stream of air over the tooth during exposure [13] and to use a cavity liner [47].

Although this was a well-controlled study using known volumes of RBC exposed to well-defined amounts of light, it is important to note that the study did not consider other factors that could affect the temperature rise. Future in vitro or in vivo studies should examine the temperature rise in teeth, the effect of dentin thickness [21], and the consequences of different pulpal fluid flow rates [48]. In addition, the impact of other LCUs and exposure times on the mechanical properties of other RBCs should be studied and reported.

Conclusion

Dentists should be aware that the choice of LCU, the exposure time, and the exothermic contribution from the RBC will affect the temperature rise and hardness values. Within the limitations of this in vitro study, it was concluded that: (1) the energies delivered (J) from the five LCUs were not the same, and different LCUs produced different changes in the temperature as the RBC is photo-activated; (2) the temperature rise is related to the amount of energy delivered and not to the power or the irradiance from the LCU; (3) the combined effect of the light from the LCU and the exothermic reaction of the RBC produced an increase in the temperature that was greater than 5.5℃. The PinkWave caused a significant increase in the temperature of the RBC due to the amount of energy delivered and the energy delivered in the near-infrared region. The Monet Laser used for 1 s delivered the lowest radiant exposure and produced the smallest temperature rise and lowest Vickers hardness values; (4) the translucency of RBCs affects the temperature rise and hardness.

References

Jandt KD, Mills RW. A brief history of LED photopolymerization. Dent Mater. 2013;29(6):605–17. https://doi.org/10.1016/j.dental.2013.02.003.

Ernst CP, Price RB, Callaway A, Masek A, Schwarm H, Rullmann I, et al. Visible light curing devices–irradiance and use in 302 German dental offices. J Adhes Dent. 2018;20(1):41–55. https://doi.org/10.3290/j.jad.a39881.

Rueggeberg FA, Giannini M, Arrais CAG, Price RBT. Light curing in dentistry and clinical implications: a literature review. Braz Oral Res. 2017;31(suppl 1): e61. https://doi.org/10.1590/1807-3107BOR-2017.vol31.0061.

AMD. Monet Laser Curing Light. The 1 second revolution. 2021. https://www.amdlasers.com/pages/monet-laser-curing-light-intro. Accessed 12 October 2021.

CMS. FlashMax2 product description. Copenhagen: CMS Dental; 2016. http://www.cmsdental.com/?id=415&c=Function%20Curing%20lights&ulang=2. Accessed Jun 14 2018.

Wahbi MA, Aalam FA, Fatiny FI, Radwan SA, Eshan IY, Al-Samadani KH. Characterization of heat emission of light-curing units. Saudi Dent J. 2012;24(2):91–8. https://doi.org/10.1016/j.sdentj.2012.01.003.

Rueggeberg FA. State-of-the-art: dental photo-curing–a review. Dent Mater. 2011;27(1):39–52. https://doi.org/10.1016/j.dental.2010.10.021.

Maucoski C, Zarpellon DC, Dos Santos FA, Lipinski LC, Campagnoli EB, Rueggeberg FA, et al. Analysis of temperature increase in swine gingiva after exposure to a Polywave((R)) LED light curing unit. Dent Mater. 2017;33(11):1266–73. https://doi.org/10.1016/j.dental.2017.07.021.

Spranley TJ, Winkler M, Dagate J, Oncale D, Strother E. Curing light burns. Gen Dent. 2012;60(4):e210–4.

Zach L, Cohen G. Pulp response to externally applied heat. Oral Surg Oral Med Oral Pathol. 1965;19(4):515–30. https://doi.org/10.1016/0030-4220(65)90015-0.

Runnacles P, Arrais CA, Pochapski MT, Dos Santos FA, Coelho U, Gomes JC, et al. In vivo temperature rise in anesthetized human pulp during exposure to a polywave LED light curing unit. Dent Mater. 2015;31(5):505–13. https://doi.org/10.1016/j.dental.2015.02.001.

Zarpellon DC, Runnacles P, Maucoski C, Gross DJ, Coelho U, Rueggeberg FA, et al. Influence of class V preparation on in vivo temperature rise in anesthetized human pulp during exposure to a Polywave((R)) LED light curing unit. Dent Mater. 2018;34(6):901–9. https://doi.org/10.1016/j.dental.2018.03.003.

Zarpellon DC, Runnacles P, Maucoski C, Coelho U, Rueggeberg FA, Arrais C. Controlling in vivo, human pulp temperature rise caused by LED curing light exposure. Oper Dent. 2019;44(3):235–41. https://doi.org/10.2341/17-364-C.

Gross DJ, Davila-Sanchez A, Runnacles P, Zarpellon DC, Kiratcz F, Campagnoli EB, et al. In vivo temperature rise and acute inflammatory response in anesthetized human pulp tissue of premolars having class V preparations after exposure to Polywave(R) LED light curing units. Dent Mater. 2020;36(9):1201–13. https://doi.org/10.1016/j.dental.2020.05.015.

Zarpellon DC, Runnacles P, Maucoski C, Gross DJ, Coelho U, Rueggeberg FA, et al. In vivo pulp temperature changes during class V cavity preparation and resin composite restoration in premolars. Oper Dent. 2021. https://doi.org/10.2341/20-098-C.

Nilsen BW, Mouhat M, Haukland T, Ortengren UT, Mercer JB. Heat development in the pulp chamber during curing process of resin-based composite using multi-wave LED light curing unit. Clin Cosmet Investig Dent. 2020;12:271–80. https://doi.org/10.2147/CCIDE.S257450.

Price RB, Ferracane JL, Shortall AC. Light-curing units: a review of what we need to know. J Dent Res. 2015;94(9):1179–86. https://doi.org/10.1177/0022034515594786.

Par M, Repusic I, Skenderovic H, Milat O, Spajic J, Tarle Z. The effects of extended curing time and radiant energy on microhardness and temperature rise of conventional and bulk-fill resin composites. Clin Oral Investig. 2019;23(10):3777–88. https://doi.org/10.1007/s00784-019-02807-1.

Wang WJ, Grymak A, Waddell JN, Choi JJE. The effect of light curing intensity on bulk-fill composite resins: heat generation and chemomechanical properties. Biomater Investig Dent. 2021;8(1):137–51. https://doi.org/10.1080/26415275.2021.1979981.

Balestrino A, Verissimo C, Tantbirojn D, Garcia-Godoy F, Soares CJ, Versluis A. Heat generated during light-curing of restorative composites: effect of curing light, exotherm, and experiment substrate. Am J Dent. 2016;29(4):234–2240.

Akarsu S, Aktug KS. Influence of bulk-fill composites, polimerization modes, and remaining dentin thickness on intrapulpal temperature rise. Biomed Res Int. 2019;2019:4250284. https://doi.org/10.1155/2019/4250284.

Mouhat M, Mercer J, Stangvaltaite L, Ortengren U. Light-curing units used in dentistry: factors associated with heat development-potential risk for patients. Clin Oral Investig. 2017;21(5):1687–96. https://doi.org/10.1007/s00784-016-1962-5.

Ilie N, Watts DC. Outcomes of ultra-fast (3 s) photo-cure in a RAFT-modified resin-composite. Dent Mater. 2020;36(4):570–9. https://doi.org/10.1016/j.dental.2020.02.007.

Garoushi S, Lassila L, Vallittu PK. Impact of fast high-intensity versus conventional light-curing protocol on selected properties of dental composites. Materials (Basel). 2021. https://doi.org/10.3390/ma14061381.

Algamaiah H, Silikas N, Watts DC. Polymerization shrinkage and shrinkage stress development in ultra-rapid photo-polymerized bulk fill resin composites. Dent Mater. 2021;37(4):559–67. https://doi.org/10.1016/j.dental.2021.02.012.

Drost T, Reimann S, Frentzen M, Meister J. Effectiveness of photopolymerization in composite resins using a novel 445-nm diode laser in comparison to LED and halogen bulb technology. Lasers Med Sci. 2019;34(4):729–36. https://doi.org/10.1007/s10103-018-2651-1.

Kouros P, Dionysopoulos D, Deligianni A, Strakas D, Sfeikos T, Tolidis K. Evaluation of photopolymerization efficacy and temperature rise of a composite resin using a blue diode laser (445 nm). Eur J Oral Sci. 2020;128(6):535–41. https://doi.org/10.1111/eos.12742.

Rocha MG, Maucoski C, Roulet JF, Price RB. Depth of cure of 10 resin-based composites light-activated using a laser diode, multi-peak, and single-peak light-emitting diode curing lights. J Dent. 2022;122:104141. https://doi.org/10.1016/j.jdent.2022.104141.

Spanovic N, Par M, Skendrovic H, Bjelovucic R, Prskalo K, Tarle Z. Real-time temperature monitoring during light-curing of experimental composites. Acta Stomatol Croat. 2018;52(2):87–96. https://doi.org/10.15644/asc52/2/1.

Yang J, Algamaiah H, Watts DC. Spatio-temporal temperature fields generated coronally with bulk-fill resin composites: a thermography study. Dent Mater. 2021;37(8):1237–47. https://doi.org/10.1016/j.dental.2021.06.008.

Ivoclar Vivadent I. Bluephase® PowerCure. https://www.ivoclar.com/en_US/downloadcenter/?dc=us&lang=en#search-text=powercure&details=34342 (2019). Accessed 22 Feb 2022.

Apex V. Pinkwave. https://vistaapex.com/wp-content/uploads/2021/03/91037-I-AP-ENG5.pdf. Accessed 22 Feb 2022.

3M. EliparTM DeepCure-S. https://multimedia.3m.com/mws/media/1393794O/elipar-deepcure-s-curing-light-ifu.pdf (2015). Accessed 22 Feb 2022.

Ultradent Products I. Valo Grand. https://www.ultradent.com/products/categories/equipment/curing-lights/valo-grand (2017). Accessed 22 Feb 2022.

Kaiser C, Price RB. Effect of time on the post-irradiation curing of six resin-based composites. Dent Mater. 2020;36(8):1019–27. https://doi.org/10.1016/j.dental.2020.04.024.

Watts DC, Kaiser C, O’Neill C, Price RB. Reporting of light irradiation conditions in 300 laboratory studies of resin-composites. Dent Mater. 2019;35(3):414–21. https://doi.org/10.1016/j.dental.2018.12.001.

Frazier K, Bedran-Russo AK, Lawson NC, Park J, Khajotia S, Urquhart O, et al. Dental light-curing units: an American dental association clinical evaluators panel survey. J Am Dent Assoc. 2020;151(7):544-545.e2. https://doi.org/10.1016/j.adaj.2020.03.001.

Par M, Marovic D, Attin T, Tarle Z, Taubock TT. Effect of rapid high-intensity light-curing on polymerization shrinkage properties of conventional and bulk-fill composites. J Dent. 2020;101: 103448. https://doi.org/10.1016/j.jdent.2020.103448.

Hori M, Fujimoto K, Hori T, Sekine H, Ueno A, Kato A, et al. Development of image analysis using python: relationship between matrix ratio of composite resin and curing temperature. Dent Mater J. 2020;39(4):648–56. https://doi.org/10.4012/dmj.2019-163.

Lempel E, Ori Z, Kincses D, Lovasz BV, Kunsagi-Mate S, Szalma J. Degree of conversion and in vitro temperature rise of pulp chamber during polymerization of flowable and sculptable conventional, bulk-fill and short-fibre reinforced resin composites. Dent Mater. 2021;37(6):983–97. https://doi.org/10.1016/j.dental.2021.02.013.

Kim MJ, Kim RJ, Ferracane J, Lee IB. Thermographic analysis of the effect of composite type, layering method, and curing light on the temperature rise of photo-cured composites in tooth cavities. Dent Mater. 2017;33(10):e373–83. https://doi.org/10.1016/j.dental.2017.07.007.

Lynch CD, Roberts JL, Al-Shehri A, Milward PJ, Sloan AJ. An ex-vivo model to determine dental pulp responses to heat and light-curing of dental restorative materials. J Dent. 2018;79:11–8. https://doi.org/10.1016/j.jdent.2018.08.014.

Lipski M, Woźniak K, Szyszka-Sommerfeld L, Borawski M, Droździk A, Nowicka A. In vitro infrared thermographic assessment of temperature change in the pulp chamber during provisionalization: effect of remaining dentin thickness. J Healthc Eng. 2020;2020:8838329. https://doi.org/10.1155/2020/8838329.

Par M, Repusic I, Skenderovic H, Sever EK, Marovic D, Tarle Z. Real-time light transmittance monitoring for determining polymerization completeness of conventional and bulk fill dental composites. Oper Dent. 2018;43(1):E19–31. https://doi.org/10.2341/17-041-L.

Anusavice KJ, Phillips RW, Shen C, Rawls HR. Phillips’ science of dental materials. In: Chapter 13. 12th ed. St. Louis: Elsevier/Saunders; 2013. p. 290.

Armellin E, Bovesecchi G, Coppa P, Pasquantonio G, Cerroni L. LED curing lights and temperature changes in different tooth sites. Biomed Res Int. 2016;2016:1894672. https://doi.org/10.1155/2016/1894672.

Lakhani J, Agrawal V, Mahant R, Kapoor S, Vaghamshi D, Shah A. Pulpal temperature rise: evaluation after light activation of newer pulp-capping materials and resin composite. Contemp Clin Dent. 2018;9(4):644–8. https://doi.org/10.4103/ccd.ccd_504_18.

Braga S, Oliveira L, Ribeiro M, Vilela A, da Silva GR, Price RB, et al. Effect of simulated pulpal microcirculation on temperature when light curing bulk fill composites. Oper Dent. 2019;44(3):289–301. https://doi.org/10.2341/17-351-L.

Acknowledgements

The authors would like to thank Braden Sullivan for his assistance in collecting the data and Professor D. Labrie for his input into the study design. This study was supported by Mitacs travel grant (IT26826). It was also financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brazil (CAPES) – Finance Code 001 and an internal research fund grant from the Faculty of Dentistry, Dalhousie University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maucoski, C., Price, R.B. & Arrais, C.A.G. Temperature changes and hardness of resin-based composites light-cured with laser diode or light-emitting diode curing lights. Odontology 111, 387–400 (2023). https://doi.org/10.1007/s10266-022-00745-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10266-022-00745-1