Abstract

The aim of this study was to evaluate the influence of the physical assessment of different light-curing units from 55 dental offices on the irradiance and composite microhardness top/bottom ratio, and the influence of the radiometers for LED or QTH light sources on irradiance measurement. The irradiance of each light-curing unit was evaluated with two radiometers, either for LED or QTH light. A questionnaire regarding the type of source (LED or QTH), time of use, date of last maintenance and light-curing performance assessment applied. The physical assessments were evaluated regarding damage or debris on the light tip. For each light-curing unit, three composite specimens were made (diameter = 7 mm; thickness = 2 mm) with polymerizing time of 20 s, in order to perform the microhardness (Knoop) test. Data were analyzed by Kruskal–Wallis and Dunn test (α = 0.01). There was wide variation in irradiance (0–1000 mW/cm2). Approximately 50 % of the light-curing units presented radiation lower than 300 mW/cm2; 10 % of light-curing units, especially those with LED source, presented values higher than 800 mW/cm2, and 43 % of light-curing units worked with adequate irradiance between 301 and 800 mW/cm2. In almost 60 % of cases, no maintenance of light-curing units was performed in a period of 3 to 10 years. The age of the light-curing units and the use of inadequate tips interfered negatively in irradiance. The data emphasize the importance of periodic maintenance of light-polymerizing, light-curing units.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The increasing interest in performing aesthetics restorations has led to an increase in the use of light-curing units for polymerizing composites, dental adhesives, resin cements and other light polymerizable materials [1–4]. This has driven the development of high-intensity light-curing units, such as quartz–tungsten–halogen (QTH), plasma arc (PAC) and light-emitting diode (LED) light [3–7]. Nevertheless, the most frequently used are the LED and QTH sources [3, 8].

The degree of conversion of monomer into polymer is a determining factor for the physical–mechanical properties of composites, and is directly related to irradiance [7, 9]. When a resin material is polymerized using light-curing units with low irradiance, they present greater wear, water absorption, solubility, accentuated staining, a higher incidence of cohesive fractures and of post-operative sensitivity, greater risk of pulp irritation and recurrent caries [3–6, 8, 9]. The more long polymer chains and cross-linked polymer networks are formed, the higher the final mechanical resistance of the resin material will be [6, 7, 9].

In order to guarantee an efficient degree of conversion, researchers have recommended a maximum thickness of 2 mm per increment of composite [9], which must be polymerized with a minimum irradiance of 300 mW/cm2 [10, 11]. The superficial hardness of a composite is not considered a good clinical indicator of the degree of conversion, because a low-intensity light source also promotes superficial hardness, even when the deeper layers are not polymerized [4, 5, 9].

In addition to the light intensity (power) and irradiance (intensity of light/area), other factors related to the light-curing unit, which influence the degree of conversion, are: nature of light source (LED/QTH/LASER/Plasma Arc), use of protective barriers on tips, heat generated, and state of conservation of the tip, lamp and filter. The degree of conversion is also influenced by factors related to the resin material and restorative technique, such as composition, color and opacity of the material; type of photoinitiators; thickness of composite layer; distance and angle between light source and resin; and exposure time [1, 4–7, 9].

The introduction of light-curing units with high light intensity (over 800 mW/cm2) also involves problems, such as higher polymerization stress and decrease of the pre-gel phase, which is essential for greater mobility of monomers, allowing the formation of a long polymer chain [7].

Portable dental radiometers are relatively simple and cheap means for monitoring the irradiance of light-curing units [4]. Some articles have reported that radiometers indicated for checking irradiance in LED light-curing units may be used in the QTH type, and vice versa [12]. Other authors [13] have affirmed that this exchange cannot be made, due to the specificities of readout of each appliance for different wavelengths of light.

The validity of this problem has been studied in international articles similar to the present one [2–6, 8, 15–17], which have sought to study the care taken in dental offices as regards the maintenance of light-curing units and the irradiance emitted by these units. In addition, they have discussed the consequences of inadequate irradiances on adhesive procedures, and have therefore suggested improvements in the dentist’s day-to-day practice. However, few of these studies have suggested a precise method for evaluating the degree of conversions of composites, such as microhardness. Moreover, the thickness of increments and the time of activation per increment differ from the parameters indicated at present in the restorative protocols (2 mm increment and 20 s polymerization per increment).

Thus, the aim of the present study was to evaluate the factors related to the maintenance and use of light-curing units (age and state of tips), which may affect the irradiance of the units in use in dental offices and private dental clinics, as assessed by the microhardness of resin composites. The tested hypothesis were that: (1) the type of light source, age of appliance, and state of tips do not interfere in the irradiance of light-curing units, and consequently, in the microhardness of resin composites; (2) there are no differences between the radiometers for LED or QTH light sources. The alternative hypothesis was (3) that type of light source, age of appliance and state of tips interfere in the irradiance of light-curing units and, consequently, in the microhardness of resin composites and (4) that there are differences between the radiometers.

Materials and methods

This study was approved by the Research Ethics Committee of the University of Ibirapuera (UNIB) Process No. 466/11.

The irradiance and maintenance of 67 light-curing units with LED and QTH light sources were evaluated in 55 dental offices and dental clinics in the city of Santos/SP, Brazil, in 2013, relating them to the depth of polymerization of the composite. The dental offices and clinics were randomly selected in different locations of the city, and data were collected by only 1 researcher. Each light-curing unit was checked, using two (2) radiometers specifically for checking LED and QTH sources (Demetron L.E.D. Radiometer and Demetron 100- Kerr). The irradiation values were obtained by means of 3 measurements of the light-curing units for each radiometer.

The radiometers were used according to the following requirements from the manufacturer: 1) the radiometer must only be used in the continuous polymerization cycle; 2) the tips must have a diameter of 7 mm or more and 3) one must wait for the indicator to stabilize before making the readout. The radiometer has a wavelength sensitivity of 400–510 nm, measures the irradiance of 100–1999 mW/cm2 and has a precision of 100 mW/cm2. According to the Demetron 100 Manual, the readout of irradiance data must be interpreted in the following manner:

-

below 200 mW/cm2—deficient discharge. The appliance must not be used. Examine the lamp, filters and tips, or proceed with changing the light-curing appliance.

-

200–300 mW/cm2—perform the previous steps and increase the time of polymerization. Provide maintenance or exchange the light-curing appliance.

-

300–800 mW/cm2—use the polymerization time recommended by the manufacturer of the material. Ideal range of polymerization between 500 and 700 mW/cm2.

-

above 800 mW/cm2—high discharge—use ramp-type, step polymerization techniques, or proceed with soft start mode (initial activation at a distance and continue approximating until the tooth is touched).

A questionnaire was distributed to the dentists, containing the following data about the maintenance and use of light-curing units: type of source (LED or QTH), time of appliance use (age), date of last maintenance, presence of radiometer in the dental office and state of tips. The researcher classified the tips as 1) clean and/or undamaged or 2) dirty and/or broken.

For each light-curing unit evaluated, three (3) composite specimens (Herculite Classic Enamel- Kerr Corporation, shade A3.5) were made in a metal cylinder mold, with the following dimensions: 7.0 mm in diameter and 2.1 mm thick. The composite was inserted in a single increment using an insertion spatula. A polyester strip was placed in contact with the composite on top of and underneath the cylinder mold, in order to achieve a smooth surface at the bottom and on top of the sample. The final height of each sample was 2 mm. The light-curing unit tips were kept in contact with the top of the sample, and the appliance was activated for 20 s (in accordance with the manufacturer’s instructions), a continuous polymerization cycle. Each sample received a mark on top, using a black pen, and was immediately stored dry at 37 °C in a sealed, numbered, opaque receptacle. After 48 h, the samples were submitted to the Knoop microhardness test (Microdurometer model HMV-2T, Shimadzu, Kyoto, Tokyo, Japan). Three (3) measurements were made on top and 3 on the bottom of the specimen, using a load of 50 g for 15 s [14].

In accordance with ANSI/ADA Specification No. 48-2 LED Curing Lights and ANSI/ADA Specification No. 48 Visible Light-Curing Units [9, 10], the irradiance must be at least 300 mW/cm2. Therefore, 2 groups of LED were determined, with irradiance below and above 300mW/cm2, denominated LED ≤300 and LED >300, respectively, and 2 groups of QTH with irradiance below and above 300mW/cm2, denominated QTH ≤300 and QTH >300, respectively.

Descriptive statistics are presented in Table 1. The statistical software programs IBM SPSS Statistic Version 22 and Graphpad Prism version 5.01 were used. Data were analyzed using Kruskal–Wallis complemented with Dunn test for multiple comparisons, with global significance level set at 5 %. For each type of tips, the ANOVA test was complemented with the Scheffe test at 5 %.

Results

Of the sixty-seven (67) light-curing units evaluated, there were 39 QTH and 28 LED. There were 16 different brands in this sample. Table 1 contains the summarized descriptive data of the sample, as regards age and maintenance of the light-curing units, irradiance and microhardness values (top and bottom) and presence of radiometer.

The QTH group showed the following results: top ≤300 (38.62 ± 8.31), bottom ≤300 (18.55 ± 7.32), top >300 (45.15 ± 13.19) and bottom >300 (24.62 ± 7.41).

The LED group presented the following results: top ≤300 (36.61 ± 16.41), bottom ≤300 (19.46 ± 13.18), top >300 (45.72 ± 8.92) and bottom >300 (20.73 ± 8.38).

The result of Kruskal–Wallis complemented with Dunn test demonstrated significant differences for age between the LED and QTH light-curing units (p = 0.000), which probably interfered significantly in the irradiance of the LED and QTH light-curing units (p = 0.000). The power analysis between radiometers was 0.46.

The difference between the irradiance generated by dirty (p = 0.001) and broken tips (p = 0.001) and whole tips was statistically significant. There was no significant difference between the irradiance of dirty or broken tips (p = 0.560) (Scheffe Test- 5 %).

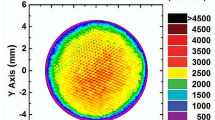

For the QTH source (Fig. 1), the top group presented a higher level (P < 0.05) than the bottom group in the Knoop microhardness test, for both irradiances (≤300 and >300 mW/cm2). Between top groups (≤300 and >300 mW/cm2) and between bottom groups (≤300 and >300 mW/cm2), there was no difference.

For LED source (Fig. 2), the top and bottom group 300 mW/cm2 irradiance) did not show a statistical difference. For >300 mW/cm2 irradiance, the top group presented a higher level (P < 0.05) than the bottom group. Between top groups there was no difference. The same occurred between bottom groups.

Discussion

Obtaining satisfactory restorations with an adequate light polymerization technique requires sufficient light energy intensity, light activation time and adequate wavelength, in order to achieve a degree of conversion that guarantees the maximum mechanical properties of the composite [1, 5–7, 9].

Laboratory studies occur in controlled situations, using specific and precise instruments and methodology. It is interesting to know the correlation between irradiance, degree of conversion and microhardness of resins [5–7, 9]. Nevertheless, in the day-to-day routine of the dental office, it is known that the dentist is not always able to work within the ideal standards, and it may be helpful to understand this clinical reality and its implications. Therefore, this study covered two stages. The first consisted of a survey of dental offices, and afterwards a laboratory study (Knoop microhardness) was conducted using the samples collected in the dental offices. The goal of the field research is to observe the facts, behaviors and phenomena exactly as they occur in real life, analyzing and interpreting the data collected, with the aim of understanding and explaining a certain reality. Collection in the field frequently brings in heterogeneous data; this is expected because there are different light-curing units on the market, and dentists conduct maintenance in different ways. Nevertheless, many of the problems evaluated, such as the lack of maintenance, failure to make frequent use of the radiometer and tips in an inadequate condition, often proved an important problem for professionals (Table 1).

Based on the data obtained in the dental offices, an effort was made to evaluate how maintenance could interfere in the irradiance of light-curing units, and its correlation with the microhardness of resin composites. The measurement of 2 (two) different types of radiometers for LED and QTH were also compared. In addition, descriptive statistics were performed in order to characterize and understand the sample.

In the fifty-five (55) dental offices participating in this study, it was possible to show evidence of problems in the day-to-day routine of these offices with regard to care of the light-curing units (n = 67). The variety of irradiance shown among the light-curing units used in dental offices has been studied by other authors [2–6, 8, 15–17]. This study aimed to investigate the influence of maintenance of light-curing units on their irradiance and hardness.

Although the light-curing unit is one of the most important appliances in a dental office, its periodic maintenance is often neglected [3, 5].

In the present study, 58.2 % (39/67) of the light-curing units evaluated were of the QTH type and 41.8 % (28/67), were LED. When we analyzed the distribution of light-curing units by age, a trend could be observed for the acquisition of LED appliances over the last few years, since approximately 87 % (34/39) of the sample of QTH was between 6 and 18 years old, and 71.5 % (20/28) of the LED light-curing units were less than 6 years old. In the Item Radiometer, in Table 1, dentists reported frequently checking only 4.48 % (3/67) of the light-curing units with a radiometer. Other studies [3, 6, 17] have also reported low percentages (0–8.5 %) of dental offices that have a radiometer. In almost 60 % of cases, no maintenance of light-curing units had been performed in a period of 3–10 years. A variance in irradiation between 15 and 980 mW/cm2 was observed for QTH light-curing units, and between 0 and 1000 mW/cm2 for the LED type.

A significant number (47.7 %) of light-curing units presented irradiance equal to or lower than 300 mW/cm2 and should be exchanged or repaired. Other authors [6, 8] also reported high numbers of light-curing units working below this parameter. Approximately 45 % of the light-curing units were working with an adequate irradiance (301–800 mW/cm2). Meanwhile, approximately 11 % of the light-curing units, especially in the LED group, presented values higher than 800 mW/cm2, and in these cases, when a direct restoration is being made, the dentists should be using ramp, step or soft start types of polymerization techniques (activation at a distance and approximating continually until the tooth is touched). The dentist may be mistaken when selecting light-curing units with very high irradiance values, since irradiance and degree of conversion do not present a linear relationship; in other words, the increase in degree of conversion is not necessarily associated with high irradiance values.

It has been postulated that the LED and QTH light-curing units had a similar polymerization performance [18]. In the present study, there was no intent to make intergroup (LED and QTH) comparisons, because a higher number of QTH light-curing units (87.3 %) were between 6 and 18 years old, while the LED light-curing units (28.5 %) (being a more recent technology) were 6 to 13 years old (Table 1). The appliance age could act as a confounding factor, because it interferes in the irradiance and consequently in the microhardness. The results demonstrated significant differences for age between the LED and QTH light-curing units, which probably interfered significantly in their irradiance. Other authors [3] have also found a strong negative association between irradiance and age. This problem may have been accentuated by the lack of maintenance and care in handling the light-curing units over time, such as the inadequate state of the tip in older light-curing units and wear of lamps, among other types of cumulative damage. The age of light-curing units would probably interfere very little if measurement with a radiometer was periodically performed, and maintenance was provided. After checking with the radiometer, maintenance must include evaluation of the lamps, tips and filter [2].

Around 36 % (24/67) of the sample presented inadequate tips (Table 1), and the difference between the irradiance generated by dirty and broken tips and that generated by whole tips was statistically significant. The adherence of resin composite and adhesive to the tip of the light-curing unit is also negatively correlated with irradiance [3], ratifying the result found in the present study, because there was a significant correlation between the irradiance and state of whole tips and those of broken or dirty tips. Nevertheless, there was no significant difference between the irradiances of dirty or broken tips. These data corroborate previous findings, in which it was affirmed that physical damage and presence of resin on the tips significantly reduce the power of the light-curing units.

The dentist should observe the polymerization time recommended by the manufacturer. However, this time was estimated for the light sources considered adequate. Increasing the polymerization time could be an alternative resource for improving polymerization, but in addition to increasing clinical time, this maneuver may result in thermal damage to the tooth, and even so, a poor light source might not achieve in-depth polymerization [7, 9].

Microhardness is highly sensitive to these variations in irradiance, and these differences were accentuated when the top and bottom of specimens were measured [7]. Surprisingly, some light-curing units (10.44 %) emitted irradiance between 0 and 100 mW/cm2 and resulted in hardness of 5.7–34.4 at the top of the sample. In Figs. 1 and 2 in the QTH and LED groups, irrespective of irradiance, the microhardness at the top of samples did not differ statistically. This hardness at the top could be translated by the clinician as being satisfactory. On the other hand, the bottom of these samples obtained a hardness of 1.0–17.7, revealing that the bottom layer could be unacceptably polymerized, and may result in problems such as pulp irritation, greater staining, less mechanical strength, and leakage leading to early failures of the restorations [3, 4, 6, 8, 9]. The correlations, which may be seen in Figs. 1 and 2, confirm these data. In the QTH and LED groups, irrespective of irradiance, the loss of hardness along the 2 mm of resin could be shown, with Group LED ≤300 presenting mean irradiance values lower than those of the QTH light-curing units. This was probably because among the LED samples, there were light-curing units with very low irradiance values, since 0 (zero) irradiance was measured in two light-curing units.

The reduction in energy production of an LED device is significantly higher than it is in a QTH device when the tip of light is placed at a distance of 10 mm from a radiometer, which may influence the polymerization capacity in a similar clinical situation [20].

An analysis of the market reality may also explain the presence of LED sources with such low irradiances. Today, in Brazil, various generations of LED light-curing units coexist, and some of the first LEDs introduced had very low irradiance values, which may have worsened with use and the lack of maintenance. An interesting datum observed was that even when obtaining zero irradiance, blue light was nevertheless emitted by the appliance, which could lead to the dentist being mistaken, particularly in the case of LED in which the light is brighter, thinking that his/her appliance is in good conditions of use and that adequate polymerization would be extended throughout the depth of the resin.

Light sources are means of propagating cross-contamination, and one of the simplest forms used for preventing this is the use of disposable transparent barriers, which also prevent damage to the tips of light-curing units [19]. However, the use of disposable barriers may reduce the light intensity by up to 35 % [21].

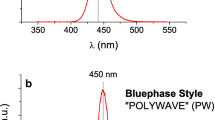

With regard to radiometers, specifically for the LED and QTH light-curing units that were used in this study (Fig. 3), there were no significant differences between the measurements of irradiance taken of all the LED and QTH light-curing units, which makes them interchangeable for checking LED or QTH light-curing units.

Although the power analysis of radiometers was 0.46, it is an expected result because there is a high heterogeneity in the data. For this standard deviation, it would be necessary for 74 samples to capture a difference of 50 mW/cm2, but the radiometers used in offices have a precision that can range up to 100 mW/cm2. Furthermore, 50mW/cm2 is not a significant improvement in the properties of the polymerized material.

This may encourage dentists to acquire radiometers and incorporate them into routine use. Although the two radiometers (LED and QTH) used in this study produced similar mean irradiance values overall lights, it is not a valid conclusion to affirm that radiometers in general are interchangeable for specific light types [22]. The accuracy of the radiometer used in practice is not as precise, but it is an important tool for measuring parameters within acceptable and safe limits [22].

These data may guide professionals as to the importance of periodic maintenance of their light-curing units, emphasizing the use of the radiometer for periodic monitoring, along with the importance of protecting and cleaning the tips, with a view to the relevance of irradiation in the longevity of resin composite restorations.

Within the limitations of this study, the hypotheses 1 and 2 can be accepted, and it can be concluded that:

-

There was wide variation in irradiance (0–1000 mW/cm2), with approximately half of the light-curing units presenting irradiation lower than 300mW/cm2; 10 % (7/67) of the light-curing units, especially those with LED sources, presented values higher than 800 mW/cm2, and 43 % of the light-curing units worked with adequate irradiance between 301 and 800 mW/cm2.

-

In 50 % of the cases, no maintenance whatsoever of light-curing units had been performed in a period of 3–10 years.

-

The microhardness at the top was not so much affected by variations in irradiance.

-

Regardless of irradiance, the loss of hardness along the 2 mm of resin was shown to be more critical for QTH light-curing unit with low irradiance.

-

The age of the appliance and the use of inadequate (dirty or broken) tips interfered negatively in the irradiance of the light-curing units.

-

The radiometers used in this research, which are indicated for checking irradiance in LED light-curing units, may be used in the QTH type and vice versa, making them interchangeable.

References

Price RB, Labrie D, Kazmi S, Fahey J, Felix CM. Intra- and inter-brand accuracy of four dental radiometers. Clin Oral Investig. 2012;16(3):707–17.

El-Mowafy O, El-Badrawy W, Lewis DW, Shokati B, Kermalli J, Soliman O, Encioiu A, Zawi R, Rajwani F. Intensity of quartz-tungsten-halogen light-curing units used in private practice in Toronto. J Am Dent Assoc. 2005;136(6):766–73 (quiz 806-7. 2).

Hao X, Luo M, Wu J, Zhu S. A survey of power density of light-curing units used in private dental offices in Changchun City, China. Lasers Med Sci. 2013 May 23. (Epub ahead of print).

Pilo R, Oelgiesser D, Cardash HS. A survey of output intensity and potential for depth of cure among light-curing units in clinical use. J Dent. 1999;27(3):235–41.

Barghi N, Fischer DE, Pham T. Revisiting the intensity output of curing lights in private dental offices. Compend Contin Educ Dent. 2007;28(7):380–4 (quiz 385-6.).

Maghaireh GA, Alzraikat H, Taha NA. Assessing the irradiance delivered from light-curing units in private dental offices in Jordan. J Am Dent Assoc. 2013;144(8):922–7.

Calheiros FC, Kawano Y, Stansbury JW, Braga RR. Influence of radiant exposure on contraction stress, degree of conversion and mechanical properties of resin composites. Dent Mater. 2006;22(9):799–803.

Hegde V, Jadhav S, Aher GB. A clinical survey of the output intensity of 200 light curing units in dental offices across Maharashtra. J Conserv Dent. 2009;12(3):105–8.

Rueggeberg FA, Caughman WF, Curtis JW Jr. Effect of light intensity and exposure duration on cure of resin composite. Oper Dent. 1994;19(1):26–32.

ANSI/ADA Specification No. 48 Visible Light Curing Units (2004, R2009).

ANSI/ADA Specification No. 48-2 LED Curing Lights (2010).

Roberts HW, Vandewalle KS, Berzins DW, Charlton DG. Accuracy of LED and halogen radiometers using different light sources. J Esthet Restor Dent. 2006;18(4):214–22 (discussion 223-4).

Leonard DL, Charlton DG, Hilton TJ. Effect of curing-tip diameter on the accuracy of dental radiometers. Oper Dent. 1999;24(1):31–7.

Tango RN, Sinhoreti MA, Correr AB, Correr-Sobrinho L, Henriques GE. Effect of light-curing method and cement activation mode on resin cement knoop hardness. J Prosthodont. 2007;16(6):480–4.

Martin FE. A survey of the efficiency of visible light curing units. J Dent. 1998;26(3):239–43.

Miyazaki M, Hattori T, Ichiishi Y, Kondo M, Onose H, Moore BK. Evaluation of curing units used in private dental offices. Oper Dent. 1998;23(2):50–4.

Santos GC Jr, Santos MJ, El-Mowafy O, El-Badrawy W. Intensity of quartz-tungsten-halogen light polymerization units used in dental offices in Brazil. Int J Prosthodont. 2005;18(5):434–5.

David JR, Gomes OM, Gomes JC, Loguercio AD, Reis A. Effect of exposure time on curing efficiency of polymerizing units equipped with light-emitting diodes. J Oral Sci. 2007;49(1):19–24.

McAndrew R, Lynch CD, Pavli M, Bannon A, Milward P. The effect of disposable infection control barriers and physical damage on the power output of lightcuring units and light curing tips. Br Dent J. 2011;210(8):E12.

Meyer GR, Ernst CP, Willershausen B. Decrease in power output of new light-emitting diode (LED) curing devices with increasing distance to filling surface. J Adhes Dent. 2002;4(3):197–204.

Warren DP, Rice HC, Powers JM. Intensity of curing lights affected by barriers. J Dent Hyg. 2000;74(1):20–3.

Price RB, Labrie D, Kazmi S, Fahey J, Felix CM. Intra-and inter-brand accuracy of four dental radiometers. Clin Oral Investig. 2012;16(3):707–17.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Morimoto, S., Zanini, R.A.M., Meira, J.B.C. et al. Influence of physical assessment of different light-curing units on irradiance and composite microhardness top/bottom ratio. Odontology 104, 298–304 (2016). https://doi.org/10.1007/s10266-015-0229-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10266-015-0229-y