Abstract

Two novel arginine-based cationic surfactants were synthesized using as biocatalyst papain, an endopeptidase from Carica papaya latex, adsorbed onto polyamide. The classical substrate N α-benzoyl-arginine ethyl ester hydrochloride for the determination of cysteine and serine proteases activity was used as the arginine donor, whereas decyl- and dodecylamine were used as nucleophiles for the condensation reaction. Yields higher than 90 and 80 % were achieved for the synthesis of N α-benzoyl-arginine decyl amide (Bz-Arg-NHC10) and N α-benzoyl-arginine dodecyl amide (Bz-Arg-NHC12), respectively. The purification process was developed in order to make it more sustainable, by using water and ethanol as the main separation solvents in a single cationic exchange chromatographic separation step. Bz-Arg-NHC10 and Bz-Arg-NHC12 proved antimicrobial activity against both Gram-positive and Gram-negative bacteria, revealing their potential use as effective disinfectants as they reduced 99 % the initial bacterial population after only 1 h of contact. The cytotoxic effect towards different cell types of both arginine derivatives was also measured. Bz-Arg-NHCn demonstrated lower haemolytic activity and were less eye-irritating than the commercial cationic surfactant cetrimide. A similar trend could also be observed when cytotoxicity was tested on hepatocytes and fibroblast cell lines: both arginine derivatives were less toxic than cetrimide. All these properties would make the two novel arginine compounds a promising alternative to commercial cationic surfactants, especially for their use as additives in topical formulations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Antiseptics are biocides or products that destroy or inhibit the growth of microorganisms in or on living tissue (e.g., health care personnel hand washes and surgical scrubs), whereas disinfectants are similar but generally are products or biocides that are used on inanimate objects or surfaces. Infection control practices and prevention of nosocomial infections, as well as the potential microbial contamination and infection risks in food and other consumer markets have increased the use of antiseptics and disinfectants in general. These kind of compounds are also used as preservatives in many pharmaceutical formulations (Carmona-Ribeiro and de Melo Carrasco 2013). In this context, quaternary ammonium compounds, such as cetyl and hexadecyl trimethylammonium bromide (CTAB and HTAB, respectively), as well as the cetrimide (a mixture consisting mainly of tetradecyl trimethylammonium bromide together with smaller amounts of dodecyl and hexadecyl trimethylammonium bromides) are the most useful antiseptics and disinfectants. Solutions containing cetrimide 0.1–1 % are used for cleaning skin, wounds and burns, as well as contaminated catheters and sterilized surgical material storage (Florence and Attwood 2006). Many of these compounds are amphiphilic, i.e., they can reduce surface and interfacial tensions by accumulating at the interface of immiscible fluids and increase the solubility and mobility of hydrophobic or insoluble organic compounds. This kind of amphiphilic compounds are considered as surfactants (surface active agents) (Singh et al. 2007). Bio-based surfactants are synthetic amphipatic structures based on natural structures of biosurfactants (glycolipids, lipopeptides, phopholipids and fatty acids). Lipoamino acids and glycerolipids have been exhaustively studied, demonstrating their good surface activity, aggregation properties, broad biological activity and low toxicity profile (Pérez et al. 2002). In particular, amino acid-based surfactants constitute a class of tensioactive compounds with excellent adsorption and aggregation properties, high biodegradability, environmentally friendly and broad antimicrobial activity. Among them, arginine-based surfactants are an important group of cationic surfactants with antimicrobial activity against a broad spectrum of bacteria, biodegradability and low toxicity. All these properties turn them into interesting additives to be included as food preservatives and pharmaceutical formulations as well as active ingredients in dermatology and personal care products. In this sense, arginine-based cationic surfactants have been proposed as alternatives to quaternary ammonium halides, which have an important intrinsic toxicity as well as a questioned biodegradability (Castillo et al. 2004).

Arginine-based surfactants can be synthesized from raw materials as amino acids and fatty acids of amines (Castillo-Expósito 2006). Traditional chemical synthesis and purification methods of this kind of compounds involve steps of protection and deprotection reactions, use of dangerous organic solvents and other harmful chemicals, including BF3, strong organic bases and chlorinated solvents among others. Drastic conditions, such as high temperatures and pressures, as well as hydrogenation reactions could also be required depending on the desired final product (Pérez et al. 1996; Mitin et al. 1997; Piera et al. 1998; Castro et al. 2004). On the other hand, global yields for these syntheses were 45–60 % in the best case (Piera et al. 2000; Pérez et al. 2014). It is also important to point out that the use of this approach would not meet the standards of green chemistry, since this methodology of production could result in the presence of hazardous by-products coming from the starting materials that could be toxic in the final formulations. These drawbacks could be circumvented by the use of enzymes as biocatalysts, due to their selectivity and their ability to act under mild reaction conditions. In particular, for the synthesis of amino acid-based surfactants, hydrolases (lipases and proteases) were extensively studied (Valivety et al. 1997; Clapés et al. 1999; Morán et al. 2001a; Morcelle et al. 2009). It is important to point out that during the past decades, striking advances concerning the use of enzymes in the field of biocatalysis have impacted upon a wide range of industries ranging from pharmaceuticals and fine chemicals to different materials, polymers and food. Enzymatic strategies for diverse steps in chemical production are in agreement with the development of sustainable manufacturing processes.

Papain (E.C. 3.4.22.2) is a plant cysteine endopeptidase from Carica papaya and is mainly used in food, breweries, pharmaceuticals, cosmetics, leather and textile industries. It is less expensive than microbial enzymes and has a good thermal stability when compared to other proteases. Papain preferably cleaves peptide bonds involving basic amino acids in P1 position and aromatic or bulky aliphatic moieties in P2 position (Schechter and Berger nomenclature) (Schechter and Berger 1967). On the other hand, papain also displays esterase activity (Chamani and Heshmati 2008). As a biocatalyst in organic chemistry, papain is one of the most used peptidases for miscellaneous peptide and peptide derivative synthesis, including polymers of one single amino acid (Narai-Kanayama et al. 2008), peptide sweeteners (Nakaoka et al. 1998), peptide hormones (Klein and Cerovský 1996; Fité et al. 2002) and peptide isosteres (Lang et al. 2007), due to its broad specificity and robustness. Papain has also proved to be a suitable catalyst for the synthesis of arginine-N-alkylamides and arginine-O-esters derivatives, even at temperatures as high as 65 °C (Clapés et al. 1999). All these properties, including its easy preparation from the natural source, turn papain into a very versatile biocatalytic tool for condensation reactions involving the synthesis of amide and ester bonds between a broad range of amino acids and a plethora of simple nucleophiles bearing alcohol or amine moieties. In this context, papain adsorbed onto polyamide has demonstrated to be the optimum catalyst for the synthesis of many arginine-based surfactants. In this context, the aims of the present work were to obtain arginine alkylamide derivatives (Bz-Arg-NHC10 and Bz-Arg-NHC12) using papain adsorbed onto polyamide as biocatalyst and to evaluate some biological activities of these compounds, such as their antimicrobial properties, as well as their cytotoxicity and haemolytic activity. As starting materials, the synthetic substrate N α-benzoyl arginine ethyl ester (Bz-Arg-OEt, also known as BAEE), which is commonly employed to determine enzymatic hydrolytic activity of proteases such as papain and trypsin (Walsh and Wilcox 1970; Arnon 1970), and two fatty amines were used as acyl donor and nucleophiles, respectively.

Materials and methods

Chemicals

Papain (E.C. 3.4.22.2) from Carica papaya latex, crude powder (3.11 units/mg solid, one unit hydrolyzes 1.0 μmol of N α-benzoyl-arginine ethyl ester hydrochloride per min at pH 6.2 and 25 °C), dodecylamine and molecular sieves (4 Å) were obtained from Fluka. Bovine seroalbumin (BSA), Coomassie Brilliant Blue G-250, N α-benzoyl-arginine ethyl ester hydrochloride (Bz-Arg-OEt or BAEE), decylamine and N α-benzoyl-d,l-arginine p-nitroanilide hydrochloride (BAPNA) were from Sigma. Polyamide-6 (EP-700, particle size <800 μm, mean pore diameter 50–300 nm, specific surface area BET method 8.4 m2/g) was an Akzo (Obernburg, Germany) contribution. 1,4-Dithio-d,l-threitol (DTT) was purchased to Invitrogen (Carlsbad, CA, USA). Cetrimide was from Dishman Pharmaceuticals and Chemicals (India). Nutrient broth was obtained from Biokar Diagnostics (Beauvais, France). The rest of the chemicals and solvents used in this work were of analytical grade.

Microorganisms

Escherichia coli ATCC 11229, Bacillus cereus ATCC 10876, Staphylococcus aureus ATCC 6538, Pseudomonas aeruginosa ATCC 15442, Kocuria rhizophila ATCC 9341, Enterococcus faecalis ATCC 51299, Serratia marcescens ATCC 14756, Bacillus subtilis subsp. spizizenii ATCC 6633, Shigella flexneri ATCC 9199 and Enterococcus faecium ATCC 6569 from American Type Culture Collection (ATCC, Manassas, USA) were employed as indicator microorganisms.

Biocatalyst preparation

Protein content of crude papain was determined by means of the Bradford’s method (Bradford 1976) using a standard curve of BSA. The enzyme was immobilized by deposition onto polyamide according to the following procedure: First, the enzyme (100 mg) was dissolved in boric acid-sodium borate buffer 0.1 M pH 8.5 with EDTA.

1 mM (1 ml) in presence of DTT (150 mg); then, the solid support (1 g) was added and shaken vigorously with the enzymatic solution, and the mixture was finally lyophilized for 24 h (Morcelle et al. 2009). Determination of enzymatic activity was performed before and after immobilization using BAPNA as substrate (Ota et al. 1964; Morcelle et al. 2009), and it was expressed in terms of international units (IU), defined as the amount of p-nitroaniline (μmoles) released per min at 37 °C and pH 7.4. For this purpose, a calibration curve of p-nitroaniline was performed.

Microscale Nα-benzoyl-arginine dodecylamide (Bz-Arg-NHC12) enzymatic synthesis: optimization of the product extraction process

Bz-Arg-OEt·HCl (0.02 mmol) and dodecylamine (0.03 mmol) were dissolved in anhydrous acetonitrile (1 ml) containing 0.25 % v/v water. Papain adsorbed onto polyamide (100 mg) was added as biocatalyst. Reactions were carried out under nitrogen atmosphere at 37 °C in closed flasks vessels placed on an orbital shaker (150 rpm) for 72 h. They were stopped by addition of a methanol/acetic acid (MeOH/AcOH) 4:1 mixture, followed by a thorough wash of the biocatalyst (3 × 1 ml) with the same solvent mixture (Clapés et al. 1999). Solvent extraction mixture containing water instead of AcOH was also tested for extraction of Bz-Arg-NHC12 following the same procedure.

All the extracts were analysed by HPLC (Agilent 1100), after filtration through a 0.22-μm nylon membrane (Osmonics) using a LiChrosorb propyl cyano column (250 × 4 mm, 5 μm, Hibar). Chromatographic conditions were as follows: solvent A, 0.1 % (v/v) TFA (trifluoroacetic acid) in H2O; solvent B, 0.1 % (v/v) TFA in CH3CN/H2O 80:20; flow rate 1 ml/min; detection at 215 and 254 nm. For identification purposes, standards of Bz-Arg-OEt and Bz-Arg-OH were also analysed. Quantification was made from peak areas according to the external standard method. Retention times for each compound were as follows: Bz-Arg-OH, 4.7 min; Bz-Arg-OEt, 5.3 min; Bz-Arg-NHC10, 13.6 min; Bz-Arg-NHC12, 15.6 min.

Bz-Arg-OH standard was obtained by hydrolysis of Bz-Arg-OEt (30 mM in 0.1 M phosphate buffer pH 7.0 containing 5 mM EDTA and 5 mM cysteine) with papain (5 mg) after 30 min incubation (37 °C). Reaction was stopped by precipitation of papain with MeOH, and the precipitated protein was eliminated by centrifugation (10 min at 9000×g). The supernatant containing Bz-Arg-OH was evaporated and the remaining solid was redissolved in MeOH for further analysis.

Semipreparative Bz-Arg-NHC10 and Bz-Arg-NHC12 synthesis. Purification by cationic exchange chromatography

Bz-Arg-OEt (0.2 mmol, 68.4 mg) and decylamine (0.3 mmol, 47.2 mg) or dodecylamine (0.3 mmol, 55.7 mg) were dissolved in anhydrous acetonitrile (10 ml) containing 0.25 % v/v water. Papain adsorbed onto polyamide (1 g) was added as biocatalyst. Individual reactions were performed under nitrogen atmosphere in Erlenmeyer flasks (100 ml) placed on an orbital shaker (250 rpm) at 37 °C for 72 h. After incubation, the biocatalyst was removed by filtration and washed with acetonitrile (3 × 10 ml) and diethyl ether (3 × 10 ml), to eliminate the excess of fatty amine. Finally, reaction products were extracted from the biocatalyst surface using MeOH/H2O 4:1 (3 × 10 ml) and filtered through a nylon membrane filter (0.22 μm, Osmonics). Purification of each surfactant was achieved in an Äkta Purifier 10 (GE Healthcare) by cation exchange chromatography as follows: aliquots of the filtrate (1 ml) were loaded onto a SP Sepharose Fast Flow column (10 ml bed volume, GE Healthcare) preequilibrated with boric acid-sodium borate buffer 0.01 M pH 8.5/ethanol 1:1 (solvent A). Unbound material was eluted after washing the column with 2 bed volumes (BV) of the same solvent. Elution of each condensation product was accomplished by a step of 31 % of solvent B, consisting in boric acid-sodium borate 0.01 M pH 8.5 buffer/ethanol (1:1) with 1 M NaCl (2 BV). The column was washed with 100 % of solvent B (2 BV) and reequilibrated to the starting conditions. Flow rate was kept at 1 ml/min throughout the whole process. Eluted peaks were detected at 215 and 254 nm. Collected fractions containing the purified products were pooled and the solvent was evaporated. The resulting solid was desalted by precipitation with absolute ethanol and centrifugation. Supernatant was evaporated under vacuum. The purity of the products obtained was analysed by HPLC under the above conditions. Identities of both compounds were confirmed by 1H-NMR and 13C-NMR, using bidimensional techniques (HSQC and COSY, see Supplementary Material), as well as ESI MS. Theoretical exact masses were obtained using the ChemCalc online service (Patiny and Borel 2013) and compared with the experimental values obtained by ESI MS. Bz-Arg-NHC 10 , ESI (+)-TOF–MS [M + 1] calculated for C23H40N5O2: 418.31820; found: 418.31889. Bz-Arg-NHC 12 , ESI (+)-TOF–MS [M + 1] calculated for C25H44N5O2: 446.34950; found: 446.34924.

Bz-Arg-NHC 12 1H NMR (400 MHz, CH3OD) δ 7.88–7.85 (m, 2 H, Ph, H-2′, H-6′), 7.58–7.50 (m, 1 H, Ph, H-4′), 7.46 (ddt, J = 8.2, 6.7, 1.3 Hz, 2 H, Ph, H-3′, H-5′), 4.83 (s, 6 H, NH, COCHNH), 4.54 (dd, J = 8.9, 5.7 Hz, 1 H, (NH)2CHNH), 3.28–3.10 (m, 2 H), 2.89 (t, J = 7.0 Hz, 1H), 2.02–1.56 (m, 6 H), 1.49 (dd, J = 13.8, 6.9 Hz, 2 H), 1.40–1.22 (m, 20 H), 1.16 (t, J = 7.1 Hz, 1 H), 0.87 (t, J = 6.8 Hz, 3 H, CH 3). 13C NMR (101 MHz, CH3OD) δ 172.47 (NHCHCONH), 168.79 (PhCO), 157.17(Ph, C-1), 133.62 (Ph, C-4), 128.13 (Ph, C-3, C-5), 127.12 (Ph, C-2, C-6), 53.50, 40.56, 39.36, 39.06, 31.62, 29.34, 29.29, 29.27, 29.26, 29.03, 28.92, 27.20, 26.52, 26.02, 25.14, 22.28, 12.99.

Bz-Arg-NHC 10 1H NMR (400 MHz, CD3OH): δ 7.80–7.76 (m, 2H, Ph, H-2′, H-6′), 7.48–7.43 (m, 1H, Ph, H-4′), 7.40–7.34 (m, 2H, Ph, H-3′, H-5′), 4.74 (s, 6H, NH, COCHNH), 4.46 (dd, J = 8.9, 5.5 Hz, 1H, (NH)2CHNH), 3.18–3.12 (m, 2H, CH3(CH2)8CH 2NHCO), 3.10 (t, J = 7.0 Hz, 2 H), 2.84–2.74 (m, 1H), 1.91–1.80 (m, 1H), 1.79–1.69 (m, 1H), 1.68–1.48 (m, 2H), 1.48–1.34 (m, 2 H), 1.33–1.11 (m, 18 H), 1.10–1.03 (m, 1H), 0.79 (m, 4H, CH 3, NH). 13C NMR (101 MHz, CD3OD) δ 172.45 (NHCHCONH), 168.79 (PhCO), 157.17 (Ph, C-1), 133.63 (NHC(NH)(NH2), 131.55 (Ph, C-4), 128.14 (Ph, C-3, C-5), 127.11 (Ph, C-2, C-6), 53.47, 40.56, 39.06, 31.60, 29.26, 29.24, 29.01, 28.98, 28.93, 28.89, 26.52, 25.13, 22.28, 12.98.

Antimicrobial assays

Determination of minimum inhibitory and bactericidal concentrations

Antimicrobial activity of Bz-Arg-NHC10 and Bz-Arg-NHC12 against several bacterial strains was determined by the microdilution assay in 96-well flat-bottom plastic tissue culture plates (TCP-96T-SI, Axygen, USA). In each case, 125 µl of sterile nutritive broth (Biokar Diagnostics, Beauvais, France) was placed into second column’s wells of the microplate. Subsequently, 125 µl of the corresponding surfactant solution in sterile nutritive broth (800 µg/ml for Bz-Arg-NHC10 and 200 μg/ml for Bz-Arg-NHC12) was added to the first and second columns’ wells of the microplate. From the second well, 125 µl was transferred serially to the subsequent wells, discarding 125 µl of the mixture in the tenth column, so that the final volume contained in each well was 125 µl. This process resulted in twofold serial dilutions of the surfactant solution within the first ten columns. Columns 11 and 12 did not contain surfactant and served as negative and positive growth controls, respectively. All wells (except for the 11th column) were inoculated with 2.5 µl of a bacterial suspension adjusted to 0.5 McFarland (1.5 × 108 CFU/ml) in physiological solution. Microplates were covered and incubated for 24 h at 37 °C. Optical density at 600 nm (OD600) was determined with a spectrophotometer (ELISA Plate Reader SLT Lab instruments Rainbow Reader, Vienna, Austria). The minimum inhibitory concentration (MIC) was determined for each strain as the lowest concentration of surfactant that completely inhibits measurable growth (OD600 = 0 and GI % >95 %, where GI % means growth inhibition percentage). Samples of those wells that did not show visible growth were transferred to nutrient agar plates. Presence of colonies was analysed for after incubation at 37 °C for 24 h. Minimum bactericidal concentration (MBC) was defined as the lowest concentration of surfactant that completely inhibits bacterial growth (absence of colonies).

Effect of surfactants on pathogens survival

Pathogen survival in nutrient broth added with Bz-Arg-NHC10 or Bz-Arg-NHC12 at different concentrations was studied. For both compounds, the corresponding MIC and a concentration 50 % lower than that (1/2 MIC) were tested, using E. coli and S. aureus as indicator microorganisms. Overnight cultures of pathogenic bacteria were diluted in nutrient broth to reach a final concentration of approximately 1 × 106 CFU/ml. Surfactant solutions were prepared in sterile nutrient broth (4.5 ml) and inoculated with 500 µl of the bacterial suspension. At predetermined intervals (0, 30, 60 min, 3 and 6 h), aliquots were removed, serially diluted in 0.1 % v/v tryptone and plated on nutrient agar plates. Colony counts were performed after incubation at 37 °C for 24 h.

Haemolytic activity

Preparation of the erythrocyte suspension

Human red blood cells (RBCs) were obtained from the blood of healthy volunteers from our laboratory staff (CIPROVE, La Plata, Argentina) and EDTA was used to prevent the blood clotting. RBCs were separated by centrifugation at 1302×g for 15 min at room temperature and washed three times with a phosphate buffer solution (PBS) containing 123.3 mM NaCl, 22.2 mM Na2HPO4 and 5.6 mM KH2PO4 in MilliQ® nanopure water (pH 7.4; 300 mosmol/l). Cells were finally suspended in PBS at a density of 8 × 109 cells/ml (Pape et al. 1987).

Haemolysis assay

Haemolytic activity of Bz-ArgNHC10 and Bz-ArgNHC12 was contrasted to cetrimide, a commercial surfactant, according to Sanchez et al. (2006). Aliquots of the erythrocyte suspension (25 μl) were exposed to different concentrations of the surfactants (ranging from 1 to 1000 μg/ml) dissolved in PBS to a final volume of 1 ml. Following incubation at 37 °C for 10 min and centrifugation (1302×g, 10 min), the extent of haemolysis was quantified spectrophotometrically at 540 nm and contrasted to that of MilliQ® nanopure water (100 % haemolysis). The concentration inducing 50 % haemolysis (HC50) was calculated from the dosis–response curves determined for each compound.

Haemoglobin denaturation assay: evaluation of potential ocular irritation

The haemoglobin denaturation for the HC50 was assessed by monitoring the absorbance at 575 and 540 nm, against a blank containing only the sample diluted in PBS, using sodium lauryl sulphate (SDS) as a positive control. The denaturation index (DI) was calculated using the following formula: DI (%) = [(R1 − R3)/(R1 − R2)] × 100, where R1, R2 and R3 are the ratios between the absorbance readings of the haemoglobin released from the erythrocytes when in contact with (1) MilliQ® nanopure water, (2) SDS at 1 mg/ml and (3) the product under analysis, respectively. Irritation index was determined according to the lysis/denaturation ratio (L/D) obtained by dividing the HC50 by the DI. Surfactants can be classified according to this L/D ratio as follows: non-irritant, >100; slightly irritant, >10; moderately irritant, >1; irritant, >0.1 or very irritant, <0.1 (Sanchez et al. 2006).

Cytotoxicity evaluation

Cell cultures

The cytotoxicity of Bz-ArgNHC10, Bz-ArgNHC12 and cetrimide was tested in human HepG2 and human fibroblast 1BR.3.G cells. Human hepatocellular carcinoma HepG2 cell line ATCC HB-8065, derived from human hepatocytes, was maintained in a minimum essential medium (MEM) alpha supplemented with 10 % v/v heat inactivated foetal bovine serum (FBS). Human fibroblast 1BR.3.G cell line (catalog number EC90020507, European Collection of Cell Cultures, Salisbury, UK) was cultured in Dulbecco’s Modified Eagle’s Medium (DMEM) containing 4500 mg/ml glucose, GlutaMAX-I and 10 % v/v heat inactivated FBS. Both cell lines were cultured in a highly humidified atmosphere of 95 % air with 5 % CO2 at 37 °C.

Experimental treatments

Surfactants were dissolved in dimethyl sulfoxide (DMSO) at a stock concentration of 50–100 mM, sterilized by filtration and stored at −20 °C. Dilutions of these stock solutions were prepared in a range of concentrations from 2 to 400 μM using sterile culture medium suited for each cell line. Cells were seeded in 96-well plate at a cell density of 6 × 103 cell/well for HepG2 and 3 × 103 cell/well for 1BR.3.G and incubated for 24 h before 100 μl of the surfactant solutions was added. Controls, containing culture medium only, were included in each plate and they were independent for each of the different surfactants tested. Plates were incubated at 37 °C, 5 % CO2 and the growth inhibitory effect was evaluated after 24 or 72 h by the XTT assay.

XTT Assay

A modified version of the classical MTT assay (Mosmann 1983; Scudiero et al. 1988) was performed using the EZ4U reduction assay kit from Biomedica Corp. (Vienna, Austria). After treatment with the surfactants, 20 μl of the XTT solution was added to each well. Following 3 h incubation at 37 °C and 5 % CO2, the coloured formazan product formed was spectrophotometrically quantified at 490 nm in a microplate reader (Perkin Elmer Victor3 V).

Statistical analysis

Antimicrobial activity was expressed as a percentage of growth inhibition (GI %) compared with control wells (the mean optical density of untreated cells was set to 100 % viability). Both antimicrobial and XTT experiments were performed at least three times using four wells for each surfactant concentration tested. For the haemolysis assay, three replicate samples were tested. For the cytotoxicity calculation, we assumed that cell viability is proportional to the production of the red formazan derivative that is measured spectrophotometrically and, consequently, the percentage of cell viability was calculated by dividing the average absorbance of the cells treated with the surfactant by that of the control. Cytotoxicity of each surfactant was expressed in terms of its IC50 (concentration of surfactant causing 50 % death of the cell population or, similarly, at which 50 % of the cells are viable relative to the control), calculated from the concentration–response curves by linear regression analysis using the GraphPad Prism® software. Haemolytic activity was expressed as a percentage of haemolysis compared with control completely haemolyzed (the mean absorbance of RBCs treated with MilliQ® nanopure water was set to 100 % haemolysis) in terms of its HC50 (concentration of surfactant causing 50 % haemolysis), calculated from the concentration–response curves by linear regression analysis using the OriginPro 8® software.

All data were compared by one-way analysis of variance (ANOVA) and Student’s t test using the GraphPad Prism® software. P < 0.05 was considered to denote significance.

Results and discussion

Biocatalyst characterization

Enzyme immobilization is a very useful strategy in biocatalytic reactions occurring in organic media, since enzymatic dispersion is optimized, whereas there is an improved accessibility for the substrates and the aggregation of the hydrophilic protein particles is avoided (Hanefeld et al. 2009). On the other hand, immobilization allows an easy separation of the biocatalyst from the reaction mixture, facilitating product recuperation (Tischer and Wedekind 1999). Physical adsorption is considered as the best suited strategy for using enzymes in organic solvents because it consists in an easy and low cost procedure (Miletić et al. 2012). Polyamide EP-700 is an organic synthetic polymer of slight hydrophobicity which demonstrated to be an adequate support for enzymatic peptide and peptide derivative syntheses (Clapés et al. 1999; Morcelle et al. 2009). Polyamide has the property of absorbing water in such a proportion that reassures a good enzyme flexibility in high organic solvent-containing media with low concomitant hydrolysis reactions of the synthesis products (Adlercreutz 1991). Bearing all this information in mind, we chose polyamide EP-700 to immobilize papain to obtain a suitable catalyst for the synthesis of the Arg derivatives.

Characterization of the free and adsorbed papain in terms of enzymatic (hydrolytic) activity is shown in Table 1. BAPNA was chosen as specific substrate to determine hydrolytic activity. BAPNA and Bz-Arg-OEt (the acyl donor substrate in the synthetic reaction catalyzed by papain) have the same acyl group (Bz-Arg). This fact is of utmost importance, since enzymatic units should be expressed according to the particular reaction a certain enzyme will catalyse.

As can be seen in Table 1 from the recovered amidolytic activity and amidolytic specific activity of the adsorbed enzyme, papain lost about 70 % of its initial activity after the immobilization process. According to Lartigue (1975), possible explanations for this behaviour include protein denaturation during the lyophilization step, occlusion of the enzyme active site and/or that the adsorption of the enzyme through residues required for the catalytic activity. In this particular case, the main advantage of enzyme immobilization is the ability to stop the reaction rapidly by removing the biocatalyst from the medium, as well as the simplification of the product purification process, as proposed by Messing (1975).

Microscale Bz-Arg-NHC12 enzymatic synthesis. Optimization of the extraction process of the product

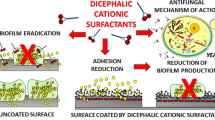

Syntheses of Bz-Arg-NHC10 and Bz-Arg-NHC12 was carried out using papain adsorbed onto polyamide as biocatalyst as described in “Materials and methods” section (Fig. 1). At the end of the reaction, the use of the solvent mixture MeOH/AcOH 4:1 has two aims: to stop the reaction and to extract the reaction products (Clapés et al. 1999). In this context, the low pH of the resulting mixture that had to be loaded onto the column could negatively affect the separation process of the analytes. In order to avoid this undesired effect, the extraction of the arginine derivatives was tested using a MeOH/H2O 4:1 mixture for the microscale synthesis of Bz-Arg-NHC12. All compounds present in the extract were analysed by HPLC, comparing the yields to those obtained when the extraction mixture was MeOH/AcOH.

As depicted in Fig. 2, there was no significant variation in Bz-Arg-NHC12 content for both extraction mixtures, as well as for the other arginine-containing analytes, indicating that the solvent mixture MeOH/H2O 4:1 could be used to remove the desired product from the biocatalyst surface and for further purification by cation exchange chromatography.

Semipreparative Bz-Arg-NHC10 and Bz-Arg-NHC12 synthesis. Purification by cationic exchange chromatography

Semipreparative synthesis of surfactants was accomplished as described in the “Materials and methods” section, using for the extraction step the mixture consisting on MeOH/H2O 4:1. In this case, the yield obtained for the condensation product was 86.17 ± 8.14 % for Bz-Arg-NHC12, almost 25 % higher than conversion observed for the microscale synthesis (69.62 ± 3.48 %), and 98.04 ± 4.90 % for Bz-Arg-NHC10 (Fig. 3). The increase in Bz-Arg-NHC12 yield could be attributed to the change in the reactor geometry.

Purification of the synthesized arginine-based surfactants was achieved by extraction and cationic exchange chromatography, using as stationary phase a column consisting in an hydrophilic matrix based on chains of agarose with different degrees of intra-chain cross-linking functionalized with sulfopropyl groups. Based on previous investigations (Torres et al. 2001), the mobile phase tested was boric acid-sodium borate buffer 0.01 M pH 8.5/ethanol 1:1. At the selected pH the hydrolysis product (Bz-Arg-OH) would be in its zwitterionic state, thus allowing for its separation as it would elute with the unbound material and washing fractions.

Elution of each condensation product (Bz-Arg-NHCn) was accomplished by a 31 % of solvent B step, as described in “Materials and methods” section. The use of ethanol as co-solvent for the product purification had two main goals: to keep the solutes in solution and to avoid hydrophobic interactions with the stationary phase. On the other hand, ethanol has low toxic potential and low cost, characteristics which turn it into one of the most used co-solvents for environmentally friendly synthesis methods.

Antimicrobial activity

Inhibitory effect of Bz-Arg-NHCn

Bacterial susceptibility tests for the arginine-derived surfactants were performed by measuring the growth inhibition percentages for several human pathogenic bacteria. From those experiments, MIC for each microorganism was determined and whenever possible, the MBC was also determined (Table 2). To compare more precisely the antimicrobial activity of both compounds, and taking into account their different molecular weight, MIC and MBC values were also expressed in µM. Both surfactants inhibit the growth of all the microorganisms tested, albeit to different degrees. Overall, the lowest MIC values (most potent antimicrobial activity) against both Gram-positive and Gram-negative bacteria were detected with Bz-Arg-NHC12. It has been observed for this kind of compounds that the shorter alkyl chains of a homologous series display a lower antimicrobial activity than those having longer alkyl chains. The combination of different physicochemical parameters, such as hydrophobicity, adsorption, aqueous solubility and transport in the test medium, depend on the alkyl chain length and determine the different antimicrobial efficiency of this kind of compounds, solubility being the most limiting step for the transport (Cornellas et al. 2011). In the case of Bz-Arg-NHC12, as well as for other homologous surfactants of 12 carbon atoms (Morán et al. 2001b), the cooperative interaction of these parameters enhances the surfactant’s tendency to be adsorbed at the bacterial/water interface and therefore exert its antimicrobial action at lower concentrations.

The antimicrobial activity of arginine-based surfactants with a certain structural similarity to the two synthesized Bz-Arg-NHCn has been reported, such as ACA (Arg-N-decylamide), CAM (N α-decyl-Arg-methyl ester), ALA (Arg-N-dodecylamide) and LAM (N α-dodecyl-Arg-methyl ester) (Morán et al. 2001b; Pérez et al. 2002). In this context, both Bz-Arg-NHCn demonstrated to be effective against almost all the microorganisms tested. Bz-Arg-NHC10 against E. coli showed a MIC value of 200 µg/ml, whereas ACA and CAM proved to be ineffective. Bz-Arg-NHC12 revealed a MIC value of 100 µg/ml, half of the inhibitory concentration of LAM (253 µg/ml) against E. coli. In this sense, the other Arg derivative having a 12 carbon alkyl chain, ALA, had no antimicrobial activity against this microorganism. Similarly, the MIC values for both Bz-Arg-NHCn registered against P. aeruginosa (see Table 2) were higher than those of LAM and ALA (32 and 128 µg/ml, respectively) (Morán et al. 2001b). The observed differences among the Arg-based compounds could be due to the some differences in their chemical structures: whereas ALA has two positive charges (lacking of the α-amino arginine moiety protecting group), LAM has the hydrophobic tail attached to the arginine α-amino group and its α-carboxyl function is involved in a methyl ester bond. The structural differences between these compounds and the Bz-Arg-NHCn could result in different interactions with bacterial cell membranes. Furthermore, these interactions could be influenced not only by the chemical structure of the surfactant molecule, but also by the composition of bacterial cell walls. Remarkably, Bz-Arg-NHCn showed higher inhibitory effect on Ps. aeruginosa, than cetrimide, an antimicrobial widely used as disinfectant in hospitals.

It is also noticeable that Bz-Arg-NHCn showed antimicrobial activity towards Gram-positive and Gram-negative strains in more or less the same extent, a fact that reveals a contrast with other Arg-based surfactants previously studied, which were in general more effective against Gram-positive bacteria. (Morán et al. 2001b; Pérez et al. 2014).

Effect of surfactants on pathogens survival

E. coli and S. aureus were used as indicator microorganisms for the study of pathogen survival in nutrient broth added with Bz-Arg-NHC10 or Bz-Arg-NHC12. To study the effect of the antimicrobial agents on the bacterial population, two concentrations were selected on an MIC basis: the first was the corresponding MIC and the second was 50 % of the MIC value (½ MIC). In each case, survival curves were constructed (Fig. 4).

Bz-Arg-NHC12 and Bz-Arg-NHC10 proved bactericidal effect for both microorganisms tested, even at concentrations equal to half the MIC, showing a remarkable decrease of the number of viable microorganism after 6 h of incubation when compared to that of the control in absence of the surfactant. In this sense, Bz-Arg-NHC10 showed a bacteriostatic effect at a concentration of ½ MIC up to 3 h. After that time, an increase of microbial growth was observed (Fig. 4a).

The performance of the killing kinetics of E. coli reported in literature using other related bromide halides (Vieira et al. 2008) was compared with that shown by Bz-Arg-NHCn.

Bz-Arg-NHC10 0.45 mM (MIC) caused a 2 log reduction (i.e., 99.0 % decrease) in bacteria population after 60 min of interaction, whereas decyl trimethylammonium bromide (C10TAB) 0.6 M caused a 70 % decrease of the initial inoculum for the same interaction time. In the case of Bz-Arg-NHC12, ½ MIC (0.1 mM) caused a 4 log reduction (99.99 % decrease) of the initial bacteria population in 60 min of interaction, whereas when dodecyl trimethylammonium bromide (C12TAB) 0.45 mM was tested in similar conditions, a pathogen survival of 11 % was achieved. A continuous decrease in S. aureus population could be also observed when both Bz-Arg-NHCn were tested: reductions up to 2 log and 4 log in the initial inoculums were achieved after 6 h of interaction with Bz-Arg-NHC10 and Bz-Arg-NHC12, respectively.

E. coli and S. aureus are microorganisms usually used for testing antimicrobial hand washing formulations, disinfectants, sanitizers and pharmaceutical and personal care formulations. Bearing this in mind and considering the fact that the synthesized compounds produce the elimination of microorganisms at MIC, it can be concluded that they could have a potential application as effective disinfectants.

Haemolytic activity

When the compounds were added to the erythrocyte suspension in aqueous medium, they could first distribute between the erythrocyte membrane and the solution by adsorption until equilibrium is reached. The interaction between the compound and erythrocyte membrane at sublytic concentration might be governed by the partition of the compound between the aqueous medium and the membrane. This partitioning is closely related to both the hydrophobicity of the compound and the ionic interactions present. Haemolysis probably begins when the erythrocyte membranes are saturated with the given compound (Castillo et al. 2006). In this context, antimicrobial agents that kill or inhibit the growth of microbial cells can also be cytotoxic to others such as red blood cells. The determination of haemolytic action is an accurate way to discriminate cytotoxic from non-cytotoxic compounds and also to assess the potential for acute eye irritation (Pape et al. 1987). All the surfactants showed haemolytic activity and the extent of haemolysis obtained at different concentrations were presented in a dose–response curve (Fig. 5). The values of HC50 (concentration of surfactant causing 50 % haemolysis) determined are presented in Table 3 along with the denaturation index (DI) and the lysis/denaturation ratio (L/D). Results showed that the haemolytic effect of.Bz-Arg-NHC10 was almost 50 % lower than that of Bz-Arg-NHC12. According to their L/D ratio, both compounds can be considered as non-irritant to eyes (Sanchez et al. 2006). In contrast, cetrimide showed a more toxic effect, since the value obtained for its L/D ratio allowed us to classify this disinfectant as a moderately irritant compound. Finally, all values obtained for the two novel surfactants demonstrated that they are less toxic than LAM, which is also, in contrast, moderately irritant (Martinez et al. 2006).

Cytotoxicity evaluation

The effect of Bz-Arg-NHCn on the viability of two cell lines was assessed using the XTT (2,3-bis-(2-methoxy-4-nitro-5-sulfophenyl)-2H-tetrazolium-5-carboxanilide) method. Cetrimide was also proved as the reference compound. The chosen cell lines for this assay were of different origins for a more reliable evaluation of the potential cytotoxicity of these compounds (Nogueira et al. 2011): HepG2 (human hepatocellular carcinoma cell line, ATCC HB-8065) and 1BR.3.G (human skin fibroblast cell line). The human hepatoblastoma line HepG2 exhibits many of the characteristic of a normal hepatocyte (Kelly and Darlington 1989), providing a good model for studying the toxic effect of exogenous compounds, since hepatic cells are specialized in metabolizing this kind of compounds. The human skin fibroblast 1BR.3.G cell line was selected for this assay since it constitutes an appropriate in vitro model for skin or transcutaneal irritation (Sanchez et al. 2004; Chimutengwende-Gordon et al. 2014).

The mentioned cell lines were exposed to the surfactants for 24 and 72 h and the cytotoxicity was tested by measuring the ability of viable cells to metabolize a tetrazolium salt to a soluble, brightly coloured orange formazan derivative product (XTT assay) as indirect measurements of cell viability. All the surfactants revealed cytotoxic effects, evidenced by the decrease in the reduction of XTT salt compared to the control in absence of the compounds. They also induced clear dose–response relationships (see Fig. 6) that allowed us to determine the half-maximal inhibitory concentrations or IC50 (Table 4). The lowest IC50 value (higher cytotoxic activity) for both cell lines and both incubation times tested was achieved by cetrimide, whereas Bz-Arg-NHC10 showed the least potent cytotoxicity effect of all three surfactants assayed. In this context, the IC50 of cetrimide is three to four times higher than those of Bz-Arg-NHC12, whereas it is five to six times higher than the IC50 values shown by Bz-Arg-NHC10. All the tested compounds revealed to be slightly more toxic towards the fibroblasts than towards the hepatocytes.

Amino acid-based surfactants are, in general, less cytotoxic than quaternary ammonium halides. Lysine-based surfactants are about one hundred times less toxic than the commercial cationic tensioactive HTAB (hexadecyl trimethylammonium bromide) when tested using the mouse fibroblast 3T6 cell line (Sanchez et al. 2006). A similar behaviour was observed for a family of dicationic arginine-diglyceride surfactant compounds (Benavides et al. 2004). The results we obtained are in concordance with those found in the literature. These findings suggest that Bz-Arg-NHCn would be less skin irritant than cetrimide, turning them into very interesting compounds to be tested in skin formulations.

Conclusions

Syntheses of two arginine-based cationic surfactants (Bz-Arg-NHC10 and Bz-Arg-NHC12) were achieved in mild conditions by means of enzymatic catalysis. Purification steps involved low cost materials and minimal amount of solvents with low toxicity. Antimicrobial activity of Bz-Arg-NHC10 and Bz-Arg-NHC12 was proved against both Gram-positive and Gram-negative bacteria: in this context, both compounds demonstrated to have broad biocidal ability, revealing their potential use as disinfectants. In addition, cytotoxic effect was compared to that of a commercial cationic surfactant (cetrimide) using both human erythrocytes and cell cultures. The results obtained in both assays showed the following order in the magnitude of cytotoxicity: cetrimide > Bz-Arg-NHC12 > Bz-Arg-NHC10. In general, it can be concluded that both synthesized compounds were less eye-irritating and less toxic than cetrimide. Moreover, Bz-Arg-NHC10 can be considered as non haemolytic (HC50 > 1000 μg/mL), whereas both Bz-Arg-NHCn are non-eye-irritants (L/D > 100). Overall, the evidence from this preliminary study would indicate that these arginine-based surfactants represent a promising alternative to commercial cationic surfactants, with biological properties that make them interesting candidates as additives in topical formulations.

References

Adlercreutz P (1991) On the importance of the support material for enzymatic synthesis in organic media. Support effects at controlled water activity. Eur J Biochem 199:609–614. doi:10.1111/j.1432-1033.1991.tb16161.x

Arnon R (1970) Papain. In: Perlmann GE, Lorand L (eds) Methods in Enzymology, vol 19., Proteolytic EnzimesAcademic Press, New York, pp 226–244

Benavides T, Mitjans M, Martínez V et al (2004) Assessment of primary eye and skin irritants by in vitro cytotoxicity and phototoxicity models: an in vitro approach of new arginine-based surfactant-induced irritation. Toxicology 197:229–237. doi:10.1016/j.tox.2004.01.011

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. doi:10.1016/0003-2697(76)90527-3

Carmona-Ribeiro AM, de Melo Carrasco LD (2013) Cationic antimicrobial polymers and their assemblies. Int J Mol Sci 14:9906–9946. doi:10.3390/ijms14059906

Castillo JA, Pinazo A, Carilla J et al (2004) Interaction of antimicrobial arginine-based cationic surfactants with liposomes and lipid monolayers. Langmuir 20:3379–3387. doi:10.1021/la036452h

Castillo JA, Infante MR, Manresa A et al (2006) Chemoenzymatic synthesis and antimicrobial and haemolytic activities of amphiphilic bis (phenylacetylarginine) derivatives. ChemMedChem 1:1091–1098. doi:10.1002/cmdc.200600148

Castillo-Expósito JA (2006) Studies on antimicrobial activity of arginine-based surfactants and chemo- enzymatic synthesis of novel amphiphiles based on l-arginine and d-fagomine. Ph D Thesis, Universidad Autónoma de Barcelona

Castro M, Griffiths D, Patel A et al (2004) Effect of chain length on transfection properties of spermine-based gemini surfactants. Org Biomol Chem 2:2814–2820. doi:10.1039/B410240A

Chamani J, Heshmati M (2008) Mechanism for stabilization of the molten globule state of papain by sodium n-alkyl sulfates: spectroscopic and calorimetric approaches. J Colloid Interface Sci 322:119–127. doi:10.1016/j.jcis.2008.03.001

Chimutengwende-Gordon M, Pendegrass C, Bayston R, Blunn G (2014) Preventing infection of osseointegrated transcutaneous implants: incorporation of silver into preconditioned fibronectin-functionalized hydroxyapatite coatings suppresses Staphylococcus aureus colonization while promoting viable fibroblast growth in vitro. Biointerphases 9:031010. doi:10.1116/1.4889977

Clapés P, Morán C, Infante MR (1999) Enzymatic synthesis of arginine-based cationic surfactants. Biotechnol Bioeng 63:333–343. doi:10.1002/(SICI)1097-0290(19990505)63:3<333:AID-BIT10>3.0.CO;2-G

Cornellas A, Perez L, Comelles F et al (2011) Self-aggregation and antimicrobial activity of imidazolium and pyridinium based ionic liquids in aqueous solution. J Colloid Interface Sci 355:164–171. doi:10.1016/j.jcis.2010.11.063

Fité M, Clapés P, López-Santín J et al (2002) Integrated process for the enzymatic synthesis of the octapeptide PhAcCCK-8. Biotechnol Prog 18:1214–1220. doi:10.1021/bp0256465

Florence AT, Attwood D (2006) Physicochemical principles of pharmacy, 4th edn. Pharmaceutical Press, London

Hanefeld U, Gardossi L, Magner E (2009) Understanding enzyme immobilisation. Chem Soc Rev 38:453–468. doi:10.1039/b711564b

Kelly JH, Darlington GJ (1989) Modulation of the liver specific phenotype in the human hepatoblastoma line Hep G2. Vitr Cell Dev Biol 25:217–222. doi:10.1007/BF02626182

Klein JU, Cerovský V (1996) Protease-catalyzed synthesis of Leu-enkephalin in a solvent-free system. Int J Pept Protein Res 47:348–352

Lang A, Hatscher C, Kuhl P (2007) Papain-catalysed synthesis of Z-l-aminoacyl-antipyrine amides from Z-protected amino acid esters and 4-aminoantipyrine. Tetrahedron Lett 48:3371–3374. doi:10.1016/j.tetlet.2007.03.067

Lartigue DJ (1975) Characteristics of free vs. immobilized enzymes. In: Messing RA (ed) Immobilized enzymes for industrial reactors. Academic Press, New York, pp 125–127

Martinez V, Corsini E, Mitjans M et al (2006) Evaluation of eye and skin irritation of arginine-derivative surfactants using different in vitro endpoints as alternatives to the in vivo assays. Toxicol Lett 164:259–267. doi:10.1016/j.toxlet.2006.01.005

Messing RA (1975) Introduction and general history of immobilized enzymes. In: Messing RA (ed) Immobilized enzymes for industrial reactors. Academic Press, New York, pp 2–3

Miletić N, Nastasović A, Loos K (2012) Immobilization of biocatalysts for enzymatic polymerizations: possibilities, advantages, applications. Bioresour Technol 115:126–135. doi:10.1016/j.biortech.2011.11.054

Mitin Y, Braun K, Kuhl P (1997) Papain catalyzed synthesis of glyceryl esters of N-protected amino acids and peptides for the use in trypsin catalyzed peptide synthesis. Biotechnol Bioeng 54:287–290. doi:10.1002/(SICI)1097-0290(19970505)54:3<287:AID-BIT9>3.0.CO;2-B

Morán C, Infante MR, Clapés P (2001a) Synthesis of glycero amino acid-based surfactants. Part 1. Enzymatic preparation of rac-1-O-(Nα-acetyl-l-aminoacyl) glycerol derivatives. J Chem Soc Perkin Trans l 1:2063–2070. doi:10.1039/b103132p

Morán C, Clapés P, Comelles F et al (2001b) Chemical structure/property relationship in single-chain arginine surfactants. Langmuir 17:5071–5075. doi:10.1021/la010375d

Morcelle SR, Liggieri CS, Bruno MA et al (2009) Screening of plant peptidases for the synthesis of arginine-based surfactants. J Mol Catal B Enzym 57:177–182. doi:10.1016/j.molcatb.2008.08.013

Mosmann T (1983) Rapid colorimetric assay for cellular growth and survival: application to proliferation and cytotoxicity assays. J Immunol Methods 65:55–63. doi:10.1016/0022-1759(83)90303-4

Nakaoka H, Miyajima Y, Morihara K (1998) papain-catalyzed synthesis of aspartame precursor: a comparison with thermolysin. J Ferment Bioeng 85:43–47. doi:10.1016/S0922-338X(97)80351-0

Narai-Kanayama A, Koshino H, Aso K (2008) Mass spectrometric and kinetic studies on slow progression of papain-catalyzed polymerization of l-glutamic acid diethyl ester. Biochim Biophys Acta 1780:881–891. doi:10.1016/j.bbagen.2008.03.009

Nogueira DL, Mitjans M, Infante MR, Vinardell MP (2011) Comparative sensitivity of tumor and non-tumor cell lines as a reliable approach for in vitro citotoxicity screening of lysine-based surfactants with potential pharmaceutical applications. Int J Pharm 420:51–58. doi:10.1016/j.ijpharm.2011.08.020

Ota S, Moore S, Stein WH (1964) Preparation and Chemical Properties of Purified Stem and Fruit Bromelains. Biochemistry 3:180–185. doi:10.1021/bi00890a007

Pape WJW, Pfannenbecker U, Hoppe U (1987) Validation of the red blood cell test system as in vitro assay for the rapid screening of irritation potential of surfactants. Mol Toxicol 1:525–536

Patiny L, Borel A (2013) ChemCalc: a building block for tomorrow’s chemical infrastructure. J Chem Inf Model 53:1223–1228. doi:10.1021/ci300563h

Pérez L, Torres JL, Manresa A et al (1996) Synthesis, aggregation, and biological properties of a new class of gemini cationic amphiphilic compounds from arginine, bis (Args). Langmuir 12:5296–5301. doi:10.1021/la960301f

Pérez L, García MT, Ribosa I et al (2002) Biological properties of arginine-based gemini cationic surfactants. Environ Toxicol Chem 21:1279–1285

Pérez L, Pinazo A, Pons R, Infante M (2014) Gemini surfactants from natural amino acids. Adv Colloid Interface Sci 205:134–155. doi:10.1016/j.cis.2013.10.020

Piera E, Comelles F, Erra P, Infante MR (1998) New alquil amide type cationic surfactants from arginine. J Chem Soc Perkin Trans 2:335–342. doi:10.1039/a705565j

Piera E, Infante MR, Clapés P (2000) Chemo-enzymatic synthesis of arginine-based gemini surfactants. Biotechnol Bioeng 70:323–331. doi:10.1002/1097-0290(20001105)70:3<323:AID-BIT9>3.0.CO;2-N

Sanchez L, Mitjans M, Infante MR, Vinardell MP (2004) Assessment of the potential skin irritation of lysine-derivative anionic surfactants using mouse fibroblasts and human keratinocytes as an alternative to animal testing. Pharm Res 21:1637–1641

Sanchez L, Mitjans M, Infante MR, Vinardell MP (2006) Potential irritation of lysine derivative surfactants by hemolysis and HaCaT cell viability. Toxicol Lett 161:53–60. doi:10.1016/j.toxlet.2005.07.015

Schechter I, Berger A (1967) On the size of the active site in proteases. I Papain Biochem Biophys Res Commun 27:157–162. doi:10.1016/S0006-291X(67)80055-X

Scudiero DA, Shoemaker RH, Paul KD et al (1988) Evaluation of a soluble tetrazolium/formazan assay for cell growth and drug sensitivity in culture using human and other tumor cell lines. Cancer Res 48:4827–4833

Singh A, Van Hamme JD, Ward OP (2007) Surfactants in microbiology and biotechnology: part 2. Application aspects. Biotechnol Adv 25:99–121. doi:10.1016/j.biotechadv.2006.10.004

Tischer W, Wedekind F (1999) Biocatalysis—from discovery to application 200:95–126. doi:10.1007/3-540-68116-7

Torres JL, Piera E, Infante MR, Clapés P (2001) Purification of non-toxic, biodegradable arginine-based gemini surfactants, bis (Args), by ion exchange chromatography. Prep Biochem Biotechnol 31:259–274. doi:10.1081/PB-100104908

Valivety R, Jauregi P, Gill I, Vulfson E (1997) Chemo-enzymatic synthesis of amino acid-based surfactants. J Am Oil Chem Soc 74:879–886. doi:10.1007/s11746-997-0232-8

Vieira OV, Hartmann DO, Cardoso CMP et al (2008) Surfactants as microbicides and contraceptive agents: a systematic in vitro study. PLoS One 3:e2913. doi:10.1371/journal.pone.0002913

Walsh KA, Wilcox PE (1970) Proteolytic enzymes. Methods Enzymol 19:31–41. doi:10.1016/0076-6879(70)19005-7

Acknowledgments

This research was supported by projects PIP 0150 (CONICET), X-613 (UNLP), CTQ2012-31605 and BIO2013-44973-R (MINECO, Spain). Mass spectra were performed in the Unidad de Microanálisis y Métodos Físicos Aplicados a la Química Orgánica (UMYMFOR), CONICET-FCEN-UBA, Buenos Aires, Argentina. The valuable contribution of Dr. Alicia S. Cánepa (LADECOR, Depto. de Química, Fac. Cs. Exactas, UNLP) in the analysis of NMR spectra is also acknowledged. MEF was awarded CONICET fellowship. GLG and SRM are members of CONICET Researcher Career.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: P. Meffre.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fait, M.E., Garrote, G.L., Clapés, P. et al. Biocatalytic synthesis, antimicrobial properties and toxicity studies of arginine derivative surfactants. Amino Acids 47, 1465–1477 (2015). https://doi.org/10.1007/s00726-015-1979-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00726-015-1979-0