Abstract

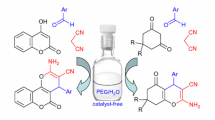

2-Amino-4H-pyrans and tetrahydro-4H-chromenes were readily prepared via a one-pot, three-component reaction of an aldehyde, malononitrile, and ethyl acetoacetate or 5,5-dimethyl-1,3-cyclohexanedione in the presence of anhydrous piperazine as an efficient and recyclable organocatalyst under solvent-free ball-milling at ambient temperature, with high to quantitative yields.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

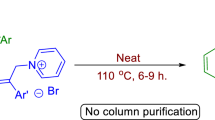

The development of new methods for the synthesis of biologically active compounds from both the environmentally friendly and economic points of view is an important challenge in current synthetic chemistry. The chemical industry is one of the major minatory factors to environmental and human health because of the manufacture, storage, use, and disposal of flammable and volatile solvents. Thus, omission or reduction of the use of solvents is one of the major goals of green chemistry [1, 2]. Subsequently, in recent years, transferring solution phase reactions to solid phase (ball-milling, grinding, and melting reactions) has attracted the attention of researchers because of the shorter reaction times, easy workup procedures, simpler reactors, and elimination of environmental pollutions [3–7]. Among these, ball-milling has been a low-tech, low price, but more efficient mechanical method for the grinding of metals and inorganic substances into fine particles. Besides the broad applications of ball-milling in inorganic synthesis in the past decades [8], the potential application and usefulness of ball-milling technology as a one-pot, solvent-free route in organic synthesis have largely been overlooked. Some of the reported examples include derivatization of carbonyl compounds [9], reduction of aldehydes and ketones [10], multicomponent synthesis of pyrano[2,3-d]pyrimidine-2,4(1H,3H)-diones [6], protection of alcohols and amines [11], synthesis of unsaturated amino esters [12], Baylis-Hillman reaction [13], Heck reaction [14], Knoevenagel condensation, and Michael additions [15], etc.

Multicomponent reactions (MCRs) as an effective synthetic methodology attracted some attention in combinatorial and medicinal chemistry for the synthesis of biologically active compounds owing to their flexibility, high atom economy, high product yield, as well as being time and energy saving. In its simplest definition, a multicomponent reaction involves combining three or more reactants in a single reaction flask to generate a desired product with no need to separate any reaction intermediate [16–18].

4H-Pyrans and 4H-chromenes are some of the most well-known synthetic heterocyclic compounds, and they have attracted considerable attention of chemists in recent years because of their extensive range of biological and pharmacological activities, such as anti-allergic, spasmolytic, diuretic, anti-cancer, and anti-anaphylactic activities [19–26]. They are also utilized in cosmetics, pigments, biodegradable agrochemicals, as well as photoactive materials [27, 28]. In addition, 4H-pyrans are also helpful as cognitive enhancers for the treatment of neurodegenerative disorders, including Alzheimer’s, Huntington’s, and Parkinson’s diseases and schizophrenia [29, 30]. Due to the wide range of biological and pharmaceutical applications, researchers have developed different methods for their synthesis including a regular two-component condensation of α-cyanocinnamonitriles with ethyl acetoacetate or 5,5-dimethyl-1,3-cyclohexanedione, or a three-component condensation of aldehydes and malononitrile with ethyl acetoacetate or 5,5-dimethyl-1,3-cyclohexanedione in the presence of various catalysts [31]. The three-component condensation methodology (3CR) has the advantage of reducing the number of synthetic steps and eliminating the previous preparation of unsaturated nitriles, which are in many cases toxic and lachrymatory [31]. Several catalysts and procedures have been used in the 3CR route, for example, 4-(dimethylamino)pyridine (DMAP) [32], tetrabutylammonium fluoride (TBAF) [33], piperidine/SDS [34], rare-earth perfluorooctanoate [RE(PFO)3] [35], Mg/La mixed metal oxides [36], silica bonded n-propyl-4-aza-1-azoniabicyclo[2.2.2]octane chloride (SB-DABCO) [37], baker’s yeast [38], diammonium hydrogen phosphate [39], silica nanoparticles (SiO2 NPs) [40], tetramethylguanidine/1-butyl-3-methylimidazolium tetrafluoroborate (TMG/[bmim][BF4]) [41], potassium phosphate [42], Cu(II) oxymetasilicate [43], N-methylimidazole [44], and 1-methyl-3-(2-aminoethyl)imidazolium hexafluorophosphate ([2-aemim] [PF6]) [45]. There is also one recent report on catalyst-free preparation of this class of compounds in glycerol at 80 °C [46]. In spite of their merits, most of these procedures suffer drawbacks, which involve low yields, long reaction times, harsh reaction conditions, use of volatile and flammable organic solvents, high reaction temperatures, and tedious workup procedures.

In order to overcome these obstacles and continue in our efforts to develop new environmentally friendly methods [5–11, 15, 47], we wish to report that anhydrous piperazine is an efficient organocatalyst for the preparation of 2-amino-4H-pyrans and tetrahydro-4H-chromenes via a 3CR condensation under solvent-free ball-milling conditions at ambient temperature.

Results and Discussion

Initially, the reaction of p-chlorobenzaldehyde (1g, Ar = 4-chlorophenyl), malononitrile (2), and ethyl acetoacetate (3) was selected as a model reaction to optimize the reaction conditions (Scheme 1). When the reaction was carried out under solvent-free ball-milling conditions in the absence of any catalyst, no reaction was observed, even at temperatures up to 80 °C (Table 1, entries 1, 2). We then attempted using various basic or acidic catalysts (entries 3–10). Of theses, anhydrous piperazine demonstrated the best catalytic activity. An excellent yield of product was obtained after 50-min ball-milling of an equimolar mixture of starting materials at ambient temperature in the presence of at least 10 mol% of piperazine (Table 1, entries 10–13). Thus, we found that 15 mol% piperazine was the optimal amount to promote the reaction (Table 1, entry 12).

The workup procedure was extremely simple. After completion of the reaction, confirmed by thin-layer chromatography (TLC), the crude solid was stirred with hot water to remove piperazine from the reaction mixture and filtered. The product was purified by recrystallization from ethanol. The piperazine was recycled from the aqueous solution by evaporation of water under reduced pressure and subsequent washing with diethyl ether.

With optimal conditions in hand, the reaction of malononitrile and ethyl acetoacetate with different aldehydes was examined to explore the scope of the reaction. Aryl aldehydes with electron-withdrawing groups (e.g., Table 2, entries 3–10) as well as those with electron-donating groups (e.g., entries 2, 11) reacted well and afforded the corresponding products with high to quantitative yields. Moreover, heteroaromatic aldehydes such as 2-furaldehyde (Table 2, entry 12) and 2-thiophenealdehyde (Table 2, entry 13) gave good yields of the corresponding products, with no by-products. All known compounds were identified by comparing their physical and/or spectral data with those reported in the literature, except for the new compound 4n (Table 2, entry 14). The structure of this compound was fully characterized by spectral and elemental analyses.

With the success obtained by this procedure, we were encouraged to replace ethyl acetoacetate with 5,5-dimethyl-1,3-cyclohexanedione in order to synthesize the tetrahydro-4H-chromenes (Scheme 2). Thus, a broad spectrum of aldehydes was used, and high yields of tetrahydro-4H-chromenes were obtained in relatively short reaction times in a similar procedure as in the synthesis of 2-amino-4H-pyrans. The results are tabulated in Table 3. Aromatic aldehydes having substituents including fluoro, chloro, bromo, nitro, methoxy, hydroxyl, methyl, cyano, as well as 2-furaldehyde and 2-thiophenealdehyde were used successfully in the synthesis of tetrahydro-4H-chromenes under solvent-free ball-milling at ambient temperature (Table 3). The electron-withdrawing groups accelerated the reaction rate because of the electronic nature of the substituents on the aromatic ring. In addition, we have investigated the efficiency and capability of the present procedure on 3-phenylpropionaldehyde (1p) as an aliphatic aldehyde and found that higher temperature (70 °C) was required to complete the reaction (Table 3, entry 16). Moreover, when trans-cinnamaldehyde (1n) was used, high yield of the product was obtained at ambient temperature (Table 3, entry 14), and no by-products were observed.

A mechanism for the piperazine-catalyzed formation of product 6 is shown in Scheme 3. It is suggested that piperazine will act as an organic base and activate malononitrile, which in turn promotes the Knoevenagel condensation reaction, yielding unsaturated nitrile 9. Again, piperazine can enhance the nucleophilic property of dimedone via the formation of enamine 10, which is more reactive than dimedone itself. Then, the intermediate 11 will be formed by Michael condensation of the unsaturated nitrile 9 and the enamine 10, which after proton transfer will be converted to enolate 12. Succeeding intermolecular cyclization via a nucleophilic addition of the enolate oxygen to the nitrile group (hetero-Thorpe-Ziegler) will give the intermediate 13. Finally, after hydrolysis and tautomerization, tetrahydro-4H-chromene 6 is formed. To support this mechanism, two separate reactions were carried out; the reaction of 1a and 2 in the presence of piperazine, and the reaction between piperazine and 5, and their products were reacted together, which afforded the corresponding tetrahydro-4H-chromene 6a as the sole product.

In order to show the efficiency and capability of the present method, we compared our results with some of the previously reported and published procedures for the synthesis of compound 4a. The results, which are summarized in Table 4, clearly show that the present procedure is better than the others in terms of product yield, reaction time, solvent-free conditions, and reaction temperature.

Conclusion

In summary, we have described a simple, highly efficient, and facile procedure for the synthesis of 4H-pyran derivatives and tetrahydro-4H-chromenes using piperazine as an effective organocatalyst via one-pot, three-component condensation of an aldehyde with malononitrile and either ethyl acetoacetate or 5,5-dimethyl-1,3-cyclohexanedione by ball-milling, mostly at room temperature, with excellent yields. Moreover, the other significant features of this procedure include (1) a solvent-free method, (2) elimination of by-products, (3) short reaction time, (4) simple workup procedure, and (5) inexpensive, readily available, and recyclable catalyst.

Experimental

All reagents used were purchased from Sigma-Aldrich and Merck. The ball mill was a Retch MM 2000 horizontal mill with a 20 cm3 stainless-steel vessel. Three stainless-steel balls of 12 mm diameter were used. Melting points were measured with an Electrothermal 9200 apparatus. Infrared spectra were recorded on a Shimadzu 8400 s FT-IR spectrometer using KBr pellets. 1H NMR and 13C NMR spectra were recorded on a 500 MHz Bruker DRX-500 AVANCE spectrometer in CDCl3 or DMSO-d 6 using tetramethylsilane (TMS) as an internal standard. Elemental analysis was recorded on a Perkin-Elmer 2400 II CHNS/O elemental analyzer. Mass spectrum was recorded on an Agilent Technology (HP) 5973 spectrometer at an ionization potential of 70 eV.

Typical procedure for the synthesis of 4 or 6

A mixture of an aldehyde (1.0 mmol), malononitrile (1.0 mmol), ethyl acetoacetate or 5,5-dimethyl-1,3-cyclohexanedione (1.0 mmol), and piperazine (15 mol%) was poured into a 20 cm3 stainless-steel ball-mill container along with three stainless-steel balls. The container was sealed and stirred at 20–25 Hz for the time given in Table 2 and Table 3 and at the given temperature. After completion of the reaction, confirmed by thin-layer chromatography (TLC), the solid was washed with hot water to remove piperazine from the reaction mixture and filtered. The product was purified by recrystallization from ethanol, if necessary. Piperazine was recycled from the aqueous phase by evaporation of water under reduced pressure and washing with diethyl ether.

Experimental procedure for investigating the proposed mechanism illustrated in Scheme 3

A mixture of benzaldehyde (1a, 1.0 mmol), malononitrile (2, 1.0 mmol), and piperazine (15 mol%) was poured into a 20-cm3 stainless-steel ball-mill container along with three stainless-steel balls. The container was sealed and stirred at 20–25 Hz for 10 min at room temperature. Thin-layer chromatography (TLC) confirmed that both the starting materials were completely reacted. The solid was washed with hot water to remove piperazine from the reaction mixture and filtered. The yield of the product was quantitative (>98 %) and identified as 9a (R=Ph) by comparison of its melting point with those in the literature. In a similar procedure, dimedone and piperazine (1:1) were reacted together in a ball-mill container for 15 min. The reaction was completed as revealed by TLC. The crude product was reacted with 9a in a ball-mill for 15 min at room temperature. After washing with hot water, filtration, and drying, the product was identified as 6a with quantitative yield.

Ethyl 6-amino-5-cyano-4-[4-(methoxycarbonyl)phenyl]-2-methyl-4H-pyran-3-carboxylate (4n, C18H18N2O5)

IR (KBr): \(\bar{\nu} \) = 3,394, 3,332, 3,217, 2,981, 2,198, 1,714, 1,683, 1,604, 1,286, 1,257, 1,224, 1,070 cm−1; 1H NMR (500 MHz, CDCl3): δ = 1.11 (t, 3H, J = 7.1 Hz), 2.42 (d, 3H, J = 0.86 Hz), 3.93 (s, 3H), 4.04 (m, 2H), 4.53 (s, 1H), 4.60 (br s, 2H),7.30 (dd, 2H, J = 1.7, 6.6 Hz), 8.00 (dd, 2H, J = 1.7, 6.6 Hz) ppm; 13C NMR (125 MHz, CDCl3): δ = 13.86, 18.46, 38.76, 52.07, 60.77, 61.61, 107.23, 118.53, 127.55, 129.02, 129.08, 148.84, 157.43, 157.49, 166.52, 166.84 ppm; MS: m/z calcd for C18H18N2O5 (M+) 342.4, found 342.0.

References

Sheldon RA (1996) J Mol Catal A 107:75

Horváth IT, Anastas PT (2007) Chem Rev 107:2169

Kaupp G (2003) CrystEngComm 5:117

Kaupp G (2006) CrystEngComm 8:794

Naimi-Jamal MR, Mashkouri S, Sharifi A (2010) Mol Divers 14:473

Mashkouri S, Naimi-Jamal MR (2009) Molecules 14:474

Kaupp G, Schmeyers J, Naimi-Jamal MR, Zoz H, Ren H (2002) Chem Eng Sci 57:763

Kaupp G, Naimi-Jamal MR, Ren H, Zoz H (2003) Process Worldwide 6:24

Mokhtari J, Naimi-Jamal MR, Hamzeali H, Dekamin MG, Kaupp G (2009) ChemSusChem 2:248

Naimi-Jamal MR, Mokhtari J, Dekamin MG, Kaupp G (2009) Eur J Org Chem 21:3567

Kaupp G, Naimi-Jamal MR, Stepanenko V (2003) Chem Eur J 9:4156

Baron A, Martinez J, Lamaty F (2010) Tetrahedron Lett 51:6246

Mack J, Shumba M (2007) Green Chem 9:328

Tullberg E, Peters D, Frejd T (2004) J Organomet Chem 689:3778

Kaupp G, Naimi-Jamal MR, Schmeyers J (2003) Tetrahedron 59:3753

Lutz W (2002) Drug Discovery Today 7(Suppl.2):143

Gerencsér J, Dormán G, Darvas F (2006) QSAR Comb Sci 25:439

Ramón DJ, Yus M (2005) Angew Chem Int Ed 44:1602

Green GR, Evans JM, Vong AK (1995) In: Katritzky AR, Rees CW, Scriven EFV (eds) Comprehensive Heterocyclic Chemistry II, vol 5. Permagon Press, Oxford, p 469

Martínez-Grau A, Marco J (1997) Bioorg Med Chem Lett 7:3165

Wang JL, Liu D, Zhang ZJ, Shan S, Han X, Srinivasula SM, Croce CM, Alnemri ES, Huang Z (2000) Proc Natl Acad Sci 97:7124

Zhang YL, Chen BZ, Zheng KQ, Xu ML, Zhang LZ, Lei XH (1982) Acta Pharm Sinica 17:17

Bonsignore L, Loy G, Secci D, Calignano A (1993) Eur J Med Chem 28:517

Foye WO (1991) Prinicipi di Chimica Farmaceutica. Piccin, Padova, p 416

Witte EC, Neubert P, Roesch A (1986) 7-(Piperazinylpropoxy)-2H-1-benzopyran-2-ones. Ger Offen DE3427985, Jan 30, 1986

Witte EC, Neubert P, Roesch A (1986) Chem Abstr 104:224915

Hafez EA, Elnagdi MH, Elagamey AA, El-Taweel FA (1987) Heterocycles 26:903

Armesto D, Horspool WM, Martin N, Ramos A, Seoane C (1989) J Org Chem 54:3069

Konkoy CS, Fick DB, Cai SX, Lan NC, Keana JFW (2000) Substituted 5-oxo-5,6,7,8-tetrahydro-4H-1-benzopyrans and benzothiopyrans and their use as potentiators of AMPA. Patent WO 2000075123, Dec 14, 2000

Konkoy CS, Fick DB, Cai SX, Lan NC, Keana JFW (2000) Chem Abstr 134:29313

Litvinov YM, Shestopalov AM (2011) Synthesis, Structure, Chemical Reactivity, and Practical Significance of 2-Amino-4H-pyrans. In: Katritzky AR (ed) Advances in Heterocyclic Chemistry, vol 103. Academic Press, Oxford, p 175

Khan AT, Lal M, Ali S, Khan MM (2011) Tetrahedron Lett 52:5327

Gao S, Tsai CH, Tseng C, Yao C-F (2008) Tetrahedron 64:9143

Lu G-P, Cai C (2011) J Heterocycl Chem 48:124

Wang L-M, Shao J-H, Tian H, Wang Y-H, Liu B (2006) J Fluorine Chem 127:97

Seshu Babu N, Pasha N, Venkateswara Rao KT, Sai Prasad PS, Lingaiah N (2008) Tetrahedron Lett 49:2730

Hasaninejad A, Shekouhy M, Golzar N, Zare A, Doroodmand MM (2011) Appl Catal A 402:11

Pratap UR, Jawale DV, Netankar PD, Mane RA (2011) Tetrahedron Lett 52:5817

Balalaie S, Bararjanian M, Sheikh-Ahmadi M, Hekmat S, Salehi P (2007) Synth Commun 37:1097

Banerjee S, Horn A, Khatri H, Sereda G (2011) Tetrahedron Lett 52:1878

Peng Y, Song G, Huang F (2005) Monatsh Chem 136:727

Pore DM, Undale KA, Dongare BB, Desai UV (2009) Catal Lett 132:104

Heravi MM, Beheshtiha YS, Pirnia Z, Sadjadi S, Adibi M (2009) Synth Commun 39:3663

Lian XZ, Huang Y, Li YQ, Zheng WJ (2008) Monatsh Chem 139:129

Peng Y, Song G (2007) Catal Commun 8:111

Safaei HR, Shekouhy M, Rahmanpur S, Shirinfeshan A (2012) Green Chem 14:1696

Sharifi A, Mirzaei M, Naimi-Jamal MR (2006) Monatsh Chem 137:213

Kumar D, Reddy VB, Sharad S, Dube U, Kapur S (2009) Eur J Med Chem 44:3805

Wang X-S, Zeng Z-S, Zhang M–M, Li Y-L, Shi D-Q, Tu SJ, Wei X-Y, Zong Z-M (2006) J Chem Res 2006:228

Marco JL, de los Ríos C, García AG, Villarroya M, Carreiras MC, Martins C, Eleutério A, Morreale A, Orozco M, Luque FJ (2004) Bioorg Med Chem 12:2199

Elgemeie GEH, Gohar AEKM, Regaila HA, Elfahham HA (1988) Arch Pharm 321:131

Shestopalov AM, Niazimbetova ZI, Evans DH, Niyazymbetov ME (1999) Heterocycles 51:1101

Sabitha G, Arundhathi K, Sudhakar K, Sastry BS, Yadav JS (2009) Synth Commun 39:433

Dyachenko VD, Chernega AN (2006) Russ J Org Chem 42:567

Acknowledgments

We acknowledge Iran University of Science and Technology (IUST) for financial support of this work and Prof. Gerd Kaupp from the University of Oldenburg, Germany, for his kind donation of some of the chemicals and the ball-mill apparatus.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amirnejad, M., Naimi-Jamal, M.R., Tourani, H. et al. A facile solvent-free one-pot three-component method for the synthesis of 2-amino-4H-pyrans and tetrahydro-4H-chromenes at ambient temperature. Monatsh Chem 144, 1219–1225 (2013). https://doi.org/10.1007/s00706-013-0938-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-013-0938-2