Abstract

The authors describe a nonenzymatic glucose sensor that was obtained by electrochemical deposition and oxidization of metallic nickel on the surface of nitrogen-doped reduced graphene oxide (N-RGO) placed on a glassy carbon electrode (GCE). An analysis of the morphology and chemical structure indicated the composite to possess a well-defined vermicular Ni(OH)2 nanorods combined with N-RGO. The electrochemical performance of the modified GCE with respect to the detection of glucose in 0.1 M NaOH was investigated by cyclic voltammetry and amperometry. The wrinkle and protuberance of N-RGO for loading of nanostructured Ni(OH)2 are found to increase electrical conductivity, surface area, electrocatalytical activity and stability. The modified GCE displays a high electrocatalytic activity towards the oxidation of glucose in 0.1 M NaOH solution. The lower detection limit is 0.12 μM at an applied potential of +0.45 V (vs Ag/AgCl) (S/N=3), and the sensitivity is 3214 μA mM−1 cm−2. The modified GCE possesses long-term stability, good reproducibility and high selectivity over fructose, sucrose and lactose.

The composite of vermicular Ni(OH)2 nanorods combined with N-doped reduced graphene oxide is a viable catalyst for non-enzymatic electrochemical sensing of glucose.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Enzymatic glucose sensors are outstandingly sensitive and selective. However, one of the most serious problems is insufficient long-term stability due to the nature of enzymes and its easily affected activity of the immobilized enzymes. Therefore, nonenzymatic glucose sensors have been developed and received great interests due to the advantages of low cost, high stability, easy immobilization procedure and low request for the detection condition [1,2,3]. A variety of nanomaterials have been explored as nonenzymatic electrocatalysts for glucose sensors, including Pt-based metals and alloys [4,5,6,7], common metals [8,9,10,11], transition metal oxides and hydroxides [3, 12,13,14], metal sulfides [15, 16] or metal-metal oxide [17]. The nonenzymatic sensors based on various catalysts may be sensitive to glucose in a wide range of pH from ~7 to 13. For example, MoS2-CuS [15], Co@Pt core-shell nanoparticles [5], or Pt3Pd nanoparticles [4] can work at near-neutral pH values in phosphate buffers for the nonenzymatic sensors. While a large amount of the reported catalysts act in alkaline solution. Moreover, most of catalysts based on precious metals [4,5,6, 18] may catalyze the glucose redox reactions at relative low potentials. However, the high cost and low kinetics of precious metal catalyst are still the big challenges for commercial application. Therefore, metal oxide or hydroxide nanomaterials have become popular candidates servicing as catalysts for the novel nonenzymatic sensors, which usually show good catalytic activity in alkaline solutions [3, 12,13,14].

In order to improve the sensitivity and selectivity of the nonenzymatic sensors, many efforts have been devoted to produce the electrocatalysts with large specific surface area [3], which can provide desirable active sensory platform. Moreover, the combination of conducting materials with the metal or metal compounds has become a popular strategy to further enhance the sensitivity, selectivity and stability due to the enhancement of the conductivity of electrode materials [13].

Nitrogen doped graphene is considered to be a potential catalyst for electrochemical sensors, due to the good conductivity of graphene and the controllable electronic properties and surface chemistry caused by the doped nitrogen [19,20,21]. N-doped graphene may be produced by chemical vapor deposition [20], arc discharge [22], and thermal annealing graphite oxide with NH3 [23] or melamine [24], while the soft-chemical approach is considered as the most promising route. For example, nitrogen doped reduced graphene oxide (N-RGO) can be obtained by a facile solution reduction process with urea as a bifunctional agent for sensors and energy materials [21, 25].

In addition, it has been reported that non-enzyme Ni-based (i.e., Ni, NiO, Ni(OH)2) sensors perform superior sensing due to the existence of the redox couple of Ni(OH)2/NiOOH formed on the electrode surface in alkaline medium [26,27,28,29]. The oxidation of glucose is catalyzed by the high-valent, oxyhydroxide species NiOOH. Also, nickel is natural abundance, which makes it an inexpensive electrocatalyst for glucose sensors. Herein, we firstly utilized a stable and sensitive non-enzymatic glucose sensor based on Ni(OH)2 decorated N-RGO composite for the determination of glucose. The Ni(OH)2/N-RGO composite was synthesized by electrochemical deposition and oxidization of metallic nickel on the N-RGO sheets modified GCE. The composite was characterized by scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS) and Raman spectra. The electrochemical performance of the modified GCE (Ni(OH)2/N-RGO/GCE) for the detection of glucose was investigated. It shows a low detection limit, excellent sensitivity and long-term stability, as well as high selectivity in the presence of interferences such as dopamine hydrochloride (DA), ascorbic acid (AA), uric acid (UA), fructose, sucrose and lactose.

Materials and methods

Reagents and materials

D-(+)-glucose anhydrous, nickel(II) nitrate hexahydrate, NaOH, KCl, N,N-dimethyl formamide (DMF), AA, UA, DA, fructose, sucrose, lactose and other reagents were purchased from Sinopharm Chemical Reagent Co., Ltd. (www.reagent.com.cn). All chemicals were of analytical reagent grade and used as received without further purchased. Deionized distilled water was used to prepare all solutions and rinse the electrodes.

Apparatus

The morphologies of modified electrodes were studied by SEM (S-4800 II FESEM). XPS measurements were performed on a Scanning X-ray Microprobe PHI Quantera II (Ulvac-PHI, INC.) with C60 gun. Curve fittings assumed the standard non-Shirley background subtraction, and used component peaks based on 80% Gaussian and 20% Lorentzian shape. The Raman spectra were recorded from 100 to 2000 cm−1 on a Renishaw Invia Raman Microscope using a 514.5 nm argon ion laser.

Cyclic voltammograms (CVs), electrochemical impedance spectroscopy (EIS) and amperometric measurements were conducted using a CHI 660D electrochemical workstation (CH Instruments, Shanghai, China) with conventional three-electrode setup. Ni(OH)2/GCE, N-RGO/GCE, Ni(OH)2/N-RGO/GCE were employed as working electrode, an Ag/AgCl as reference electrode and a platinum wire as counter electrode. All experiments were carried out at room temperature.

Preparation of Ni(OH)2/N-RGO/GCE

Graphite oxide was synthesized from graphite powder (12,500, 500 mesh) by a modified Hummers method as we described previously [30]. The resulting solid was dispersed in water by sonication to form a graphene oxide (GO) dispersion (0.5 mg mL−1). For the reduction of graphene oxide, 50 mL of graphene oxide solution was added in a two-necked flask, and the pH was adjusted to 8.0 with dilute ammonia solution. Then, 1.5 g urea was added under vigorously stirring. The solution was then raised to 95 °C and refluxed for 10 h. Subsequent filtration, followed by repeated rinsing with ethanol and ultrapure water yielded solid N-doped RGO (N-RGO) sheets [25]. Finally, it was dried overnight in a vacuum oven at 80 °C. RGO was synthesized for comparison [31].

The N-RGO was dispersed in DMF by ultrasonication for 2 h, resulting in a homogeneous black suspension of 2.4 mg mL−1. Prior to the surface modification, GCE was polished to a mirror-like surface with 1.0, 0.3 and 0.05 μm α-Al2O3, respectively, and then rinsed with deionized distilled water. The N-RGO/GCE was prepared by dropping a 4 μL of the N-RGO suspension onto the GCE surface and then evaporating the solvent. For the preparation of Ni(OH)2/N-RGO/GCE, the N-RGO/GCE was immersed into a 5 mM Ni(NO3)2 solution containing 0.1 M KCl, and conditioned by CV scanning (0 ~ −1.1 V vs. Ag/AgCl, 20 scans, 100 mV s−1) for the electrodeposition of metallic nickel. Then, the oxidization of metallic nickel was processed in 0.1 M NaOH solution by CV scanning (30 scans) between 0.1 and 0.7 V at 100 mV s−1. The Ni(OH)2/GCE was prepared in the absence N-RGO by the same approach. And Ni(OH)2/RGO/GCE was also prepared just using RGO replaced N-RGO. When not in use, the modified electrodes were rinsed with water and stored in air under ambient conditions.

Results and discussion

Characterization of Ni(OH)2/N-RGO composite

Fig. 1 shows the SEM images of Ni(OH)2/GCE (a), N-RGO/GCE (b) and Ni(OH)2/N-RGO/GCE (c). As demonstrated in Fig. 1a, the well-defined vermicular Ni(OH)2 nanorods with the size of 30 × 100 nm are decorated homogeneously on the surface of GCE. Typical wrinkled graphene sheets can be clearly seen in Fig. 1b, indicating the presence of flexible graphene sheets of N-RGO. By incorporating N-RGO sheets, the size of vermicular Ni(OH)2 nanorods decreases to be ~20 × 60 nm, and the morphology of Ni(OH)2 tends to convert into nanoparticles. Obviously, a very thin layer of vermicular Ni(OH)2 nanorods or nanoparticles successfully grew on the wrinkled N-RGO sheets, moreover, the growth of Ni(OH)2 nanoparticles was refined by N-RGO. The smaller size of Ni(OH)2 nanoparticles on N-RGO may lead to the larger specific surface area, further contributing to the enhancement of the electrochemical performance for the modified electrode based on Ni(OH)2/N-RGO/GCE.

XPS was also carried out to analyze the N-RGO and Ni(OH)2/N-RGO composite. Figure 1d2 mainly shows carbon, oxygen, and nickel species in the Ni(OH)2/N-RGO composite. Compared to the obvious N peak of N-RGO in Fig. 1d1, the N peak of Ni(OH)2/N-RGO is almost invisible, due to the covered Ni(OH)2 hiding the low quantity of nitrogen. The Ni 2p XPS spectrum shows two major peaks at 873.5 and 855.9 eV, corresponding to Ni 2p1/2 and Ni 2p3/2, respectively, with a spin-energy separation of 17.6 eV, which is the characteristic of Ni(OH)2 and in good agreement with literature [32]. As shown in Fig. 1e, the C1s core level peak of the N-RGO shows one main peak at C1 284.4 eV (C–C), three small peaks at higher binding energies including C2, C3 and C4. C2 at 285.5 eV and C3 at 286.5 eV peaks are ascribed to C = N and C-N, respectively, and originate from the substitution of oxygen atoms by N atoms in graphene [33]. C4 at 289 eV is attributed to C = O, which indicates some residual oxygen-containing groups still on N-RGO sheets because of incomplete reduction. Fig. 1f shows the XPS spectrum of N 1 s energy level of N-RGO. The N 1s peak in N-RGO is broad and asymmetric, indicating there are different bonding configurations inserted into the graphene network. The curve can be divided into three peaks at 398.3, 399.5 and 401.2 eV, assigned to pyridinic-, pyrrolic- and graphitic-N, respectively. The pyridinic-N was believed to provide the effective electrons to enhance the catalytic performance of the materials [34]. It is linked in the edge of the graphene layer and a pair of lone electrons at the conjugate plane outside, while the graphitic-N and pyrrolic-N lone electrons were involved in the conjugation of graphene sheets.

Raman spectrum was used to characterize the Ni(OH)2/N-RGO composite. The result shows that N-RGO is successfully combined with Ni(OH)2 (Fig. S1 in the Electronic Supporting Material).

Electrochemical performance of glucose at modified electrodes

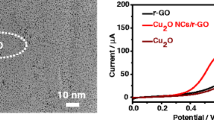

To investigate the electrochemical performance of glucose at various electrodes, CV was conducted in the potential window range of 0.1–0.7 V with scan rate of 100 mV s−1. Fig. 2a and b show the CVs of Ni(OH)2/GCE and Ni(OH)2/N-RGO/GCE, respectively, in the absence (a) and presence (b) of 2.0 mM glucose in 0.1 M NaOH solution. For comparison, the CVs obtained at the blank GCE, N-RGO/GCE and Ni(OH)2/RGO/GCE are shown in the insets of Fig. 2a and b.

CVs of Ni(OH)2/GCE a, Ni(OH)2/N-RGO/GCE (b) in the absence (a) and presence (b) of 2.0 mM glucose in 0.1 M NaOH. Inset: Comparison of CVs obtained at blank GCE and N-RGO/GCE a, Ni(OH)2/RGO/GCE (b). Scan rate: 100 mV s−1. c Nyquist diagrams recorded at Ni(OH)2/GCE, N-RGO/GCE and Ni(OH)2/N-RGO/GCE in 5.0 mM [Fe(CN)6]3−/4− containing 0.1 M KCl. The inset is the enlarged curve of N-RGO/GCE. d CVs of Ni(OH)2/N-RGO/GCE in the presence of 2 mM glucose at varying scan rates: (a) 3, (b) 5, (c) 8, (d-k) 10–80, (l-p) 100–500, respectively. Inset: Plots of anodic and cathodic peak currents vs. ν1/2

As shown in the inset of Fig. 2a, there are no obvious peaks found in the CVs of blank GCE and N-RGO/GCE, moreover both electrodes show almost no responses to the addition of 2 mM glucose, compared with the two curves obtained in absence and presence of glucose for each electrode. While all CVs of Ni(OH)2 based electrodes exhibit semi-reversible redox peaks in the absence of glucose (Fig. 2a and b and the inset of Fig. 2b), corresponding to the conversion of Ni(OH)2/NiOOH. Furthermore, the positive shift of the redox peaks, the enhancement of anodic current and the decrease of cathodic currents can be clearly observed for Ni(OH)2/GCE, Ni(OH)2/RGO/GCE and Ni(OH)2/N-RGO/GCE, when glucose is added. The results indicate that three Ni(OH)2 modified electrodes can catalyze the electrooxidation of glucose to gluconolactone due to the redox couple of Ni(OH)2/NiOOH, according to the following reactions as reported by other groups [2, 28].

First, Ni(II) is electro-oxidized to Ni(III) in alkaline solution with an anodic peak at around 0.47 V (Eq. 1), where the release of electron results in the formation of oxidation peak current. Then, glucose (C6H12O6) is oxidized to gluconic acid (C6H12O7) by Ni(III) reduced to Ni(II) simultaneously with an anodic peak at around 0.5 V (Eq. 2). In other words, the reproducibility of Ni(II) increases the oxidation current. Moreover, due to the two oxidation reactions close to each other, in the solution containing glucose, only a couple of merged redox peaks are shown in the CVs of Fig. 2 a and b.

It is worthy to note that the CV at Ni(OH)2/N-RGO/GCE demonstrates a pair of the most reversible redox peaks compared to those at Ni(OH)2/GCE and Ni(OH)2/RGO/GCE, and the current intensities of anodic peaks display a growing trend with Ni(OH)2/N-RGO/GCE > Ni(OH)2/RGO/GCE > Ni(OH)2/GCE. It is due to the improvement in the conductivity and surface area of Ni(OH)2/GCE by the introducing RGO, especially by nitrogen doped RGO as the support for Ni(OH)2. Nevertheless, for the electrode of Ni(OH)2/N-RGO/GCE, the enhancement in anodic peak current with the addition of glucose is remarkable larger than those at Ni(OH)2/RGO/GCE and Ni(OH)2/GCE, which indicates the increased catalytic ability of RGO by nitrogen atoms incorporating in carbon frameworks.

Fig. S2 shows the last five cycles of CV responses for the oxidation of metallic nickel modified GCE (a) and N-RGO/GCE (b) during 30 scans in 0.1 M NaOH solution at 100 mV s−1. The anodic and cathodic peaks corresponding to Ni(II)/Ni(III) couple observed at Ni(OH)2/N-RGO/GCE are more negative compared with those of Ni(OH)2/GCE. And the cathodic and anodic peak currents are increased significantly. In addition, the shape of CV curves tends to more stable than that for Ni(OH)2/GCE. The result is contributed to the incorporation of N-RGO with excellent mechanical property into the modified electrode.

As shown in Fig. 2c, the Nyquist diagrams of Ni(OH)2/GCE and Ni(OH)2/N-RGO/GCE include a semicircle region lying at higher frequencies, followed by a straight line at lower frequencies. The Nyquist plot of N-RGO/GCE in the frequency range of 0.1 Hz to 1 MHz, nearly displays a straight line indicating the diffusion-limiting step in the electrochemical process (Inset of Fig. 2c), which is due to its good conductivity. The semicircular part corresponds to the electron transfer limited process, and the diameter is equivalent to the electron transfer resistance which normally reflects the conductivity and the electron transfer process. A larger semicircle is observed for Ni(OH)2/GCE, implying that the electron transfer on the Ni(OH)2/GCE is confined. After combining with N-RGO, the semicircle is reduced obviously, which indicates N-RGO plays an important role in accelerating the electron transfer. Fig. 2d shows the CVs of Ni(OH)2/N-RGO/GCE recorded in 0.1 M NaOH solution in the presence of 2 mM glucose at different scan rates. The peak potentials move regularly with the increase of the scan rates, suggesting a kinetic limitation in the redox reactions between the redox sites of the Ni(OH)2/N-RGO and glucose. It resulted from the surface adsorption of glucose and the oxidized intermediates at the Ni(OH)2/N-RGO/GCE, and increased the interface resistance [13, 28]. Obviously, both anodic and cathodic peak currents increase linearly with the square root of the scan rate in the range 3–500 mV s−1 (the inset of Fig. 2d), indicating it is a diffusion-controlled process.

All the results above indicate that the Ni(OH)2/N-RGO modified electrode can be a novel sensory platform for fabrication of non-enzymatic glucose sensors.

Optimization of method

The following parameters were optimized: (a) amount of N-RGO; (b) content of Ni; (c) concentration of NaOH; (d) applied potential on the amperometric responses. Respective data and Figures are given in the Electronic Supporting Material(Fig. S3). The following experimental conditions were found to give best results: (a) 4 μL of N-RGO suspension (2.4 mg mL−1) used to modify the GCE; (b) twenty cycles of CVs used for the electrodeposition of metallic nickel; (c) 0.1 M NaOH as the supporting electrolyte; (d) 0.45 V as the optimal detection potential.

Amperometric determination of glucose at Ni(OH)2/N-RGO/GCE

Fig. 3 shows a typical amperometric response of the Ni(OH)2/N-RGO/GCE upon the successive addition of a certain concentration of glucose into stirred 0.1 M NaOH at the optimal potential of 0.45 V(vs Ag/AgCl). As the glucose was added into the stirred 0.1 M NaOH solution, the sensor gives a well-defined, stable and fast amperometric response. The inset of Fig. 3a is the enlargement of one step addition of glucose at low concentrations and clearly shows the response of the modified GCE after the addition of glucose. The electrode nearly responded immediately once glucose was added, and the time to achieve 95% steady-state current was no more than 3 s, indicating an extraordinarily fast and sensitive response toward glucose oxidation.

a Amperometric current response of Ni(OH)2/N-RGO/GCE upon the successive addition of glucose at low concentrations (0.5, 1, 2, 5, 20, 50 μM) into a gently stirred 0.1 M NaOH. Applied potential: +0.45 V(vs Ag/AgCl). b The plot of electrocatalytic current of glucose vs. the corresponding concentration. Error bars indicate standard deviations for five measurements at each glucose concentration

The calibration curve for the modified GCE is shown in Fig. 3b. The current response of the sensor exhibits two linear dependences on the low glucose concentration. The equation of curve a is I (μA) = 0.227 c (μM) + 1.844 (R = 0.9994) with the concentration of glucose in the range from 0.5 to 11.5 μM. The sensitivity is 3214 μA mM−1 cm−2 and the detection limit can reach as low as 0.12 μM based on a signal-to-noise ratio of 3. Therefore, the sensor exhibits the fast and sensitive catalytic performance, which may be due to the high conductivity of N-RGO and the increased active surface area of the electrode. The equation of curve b is I (μA) = 0.133 c (μM) + 3.284 (R = 0.9986) with the concentration of glucose in the range from 11.5 to 240 μM with the sensitivity of 1879 μA mM−1 cm−2.

The performance of the modified GCE is compared with other non-enzymatic glucose sensors based on representative metal compounds and nickel based composite materials in Table 1. Compared with nonenzymatic sensor that works at around pH 7, although the applied potential and pH of medium of our modified GCE are higher, the LOD and sensitivity of our sensor are superior. It can be seen that the applied potential of the modified GCE is lower than most of the sensors based on metal oxides or nickel materials working at high pH values, and therefore it can reduce the interference of other electrochemically active species. Although it is not yet as good as some of electrodes, the high sensitivity of this electrode in our work is an attracting point for the sensor construction.

Selectivity, stability and reproducibility of the modified GCE

In sample analysis, DA, AA and UA are the key species that interfere with the detection of glucose. The normal physiological level of glucose is several times higher than the concentrations of interfering species [35]. Thus, the interference study was carried out with a starting concentration of 1 mM for glucose and a concentration of 0.1 mM for the interfering species by amperometry at an applied potential of 0.45 V(vs Ag/AgCl) with the modified GCE, and the result is demonstrated in Fig. 4a.

a Amperometric response of Ni(OH)2/N-RGO/GCE at +0.45 V(vs Ag/AgCl) for the sequential addition of 0.1 mM fructose, sucrose, lactose, DA, AA, UA and 1 mM glucose. b Stability of the amperometric response of Ni(OH)2/N-RGO/GCE to 0.2 mM glucose in 0.1 M NaOH solution for a week. Each response represents standard deviations for three determinations

As shown in Fig. 4a, the current on the modified electrode shows almost no current response when 0.1 mM fructose, sucrose and lactose are added. The response increases significantly by addition of 1 mM glucose. Moreover, the addition of 0.1 mM DA, AA and UA induces slight increase in the response current. However, the intensity increased is much smaller than that of glucose and does not affect the determination of glucose. These results indicate that the modified GCE shows good selectivity toward glucose.

The stability of the modified GCE was also explored. The sensor was sealed and stored in the refrigerator (4 °C). The amperometric responses to 0.2 mM glucose in 0.1 M NaOH solution was tested once a day (Fig. 4b). After a week, the response was still retained 97.6% value of the initial response, which indicates good long-term stability of the sensor. The reproducibility of the sensor was investigated by successively detecting 2 mM glucose in 0.1 M NaOH for 10 times. The measurements were carried out in the same solution every 10 min. After ten measurements, no obvious current decline was observed in the CVs. The relative standard deviation (RSD) of the currents is 0.45%, which shows the modified electrode possessed good reproducibility and can be used repeatedly for the detection of glucose. And the performance is superior to most of non-enzymatic glucose sensors discussed in the literature. The good stability and reproducibility make the modified electrode feasible for practical applications.

Application in serum sample

The applicability of the glucose sensor was assessed by the determination of glucose concentration in real samples by the standard addition method. The blood serum sample was collected from a local hospital and the concentration of glucose in the original sample was 4.66 mM. The sample was examined in 0.1 M NaOH solution by amperometric measurement at a potential of 0.45 V(vs Ag/AgCl). In the determination process, 10 μL of blood serum sample was added into 10 mL of 0.1 M NaOH solution, and then standard glucose solution was successively added into the solution at an interval of 60 s for the recovery tests. The results are summarized in Table S1. As shown, the results are in good agreement with that measured in the local hospital and the recovery is satisfied.

Conclusions

A high performance Ni(OH)2/N-RGO modified GCE was fabricated by an electrochemical deposition and oxidization method. The presence of wrinkled N-RGO sheets increased the conductivity, stability and surface area of the modified electrode. The results of electrochemical detection of glucose indicate that the modified GCE exhibits high sensitivity (3214 μA mM−1 cm−2) and low detection limit (0.12 μM based on a signal-to-noise ratio of 3) toward the oxidation of glucose, compared with the other related non-enzymatic glucose sensors based on Ni(OH)2 reported in the literature. Additionally, the low cost of the material, very fast response time, good stability and selectivity of the modified electrode make it a potential candidate for glucose analysis.

References

Chen X, Wu G, Cai Z, Oyama M, Chen X (2014) Advances in enzyme-free electrochemical sensors for hydrogen peroxide, glucose, and uric acid. Microchim Acta 181:689–705

Wang G, He X, Wang L, Gu A, Huang Y, Fang B, Geng B, Zhang X (2013) Non-enzymatic electrochemical sensing of glucose. Microchim Acta 180:161–186

Zheng M, Li L, Gu P, Lin Z, Xue H, Pang H (2017) A glassy carbon electrode modified with ordered nanoporous Co3O4 for non-enzymatic sensing of glucose. Microchim Acta 184:943–949

Zhao L, Wu G, Cai Z, Zhao T, Yao Q, Chen X (2015) Ultrasensitive non-enzymatic glucose sensing at near-neutral pH values via anodic stripping voltammetry using a glassy carbon electrode modified with Pt3Pd nanoparticles and reduced graphene oxide. Microchim Acta 182:2055–2060

Mei H, Wu W, Yu B, Li Y, Wu H, Wang S, Xia Q (2015) Non-enzymatic sensing of glucose at neutral pH values using a glassy carbon electrode modified with carbon supported co@Pt core-shell nanoparticles. Microchim Acta 182:1869–1875

Nayak P, Nair SP, Ramaprabhu S (2016) Enzyme-less and low-potential sensing of glucose using a glassy carbon electrode modified with palladium nanoparticles deposited on graphene-wrapped carbon nanotubes. Microchim Acta 183:1055–1062

Dhara K, Thiagarajan R, Nair BG, Thekkedath GSB (2015) Highly sensitive and wide-range nonenzymatic disposable glucose sensor based on a screen printed carbon electrode modified with reduced graphene oxide and Pd-CuO nanoparticles. Microchim Acta 182:2183–2192

Liu X, Yang W, Chen L, Jia J (2016) Synthesis of copper nanorods for non-enzymatic amperometric sensing of glucose. Microchim Acta 183:2369–2375

Zhang B, He Y, Liu B, Tang D (2015) Nickel-functionalized reduced graphene oxide with polyaniline for non-enzymatic glucose sensing. Microchim Acta 182:625–631

Zhong A, Luo X, Chen L, Wei S, Liang Y, Li X (2015) Enzyme-free sensing of glucose on a copper electrode modified with nickel nanoparticles and multiwalled carbon nanotubes. Microchim Acta 182:1197–1204

Mei L, Zhang P, Chen J, Chen D, Quan Y, Gu N, Zhang G, Cui R (2016) Non-enzymatic sensing of glucose and hydrogen peroxide using a glassy carbon electrode modified with a nanocomposite consisting of nanoporous copper, carbon black and nafion. Microchim Acta 183:1359–1365

Zhang C, Ni H, Chen R, Zhan W, Zhang B, Lei R, Xiao T, Zha Y (2015) Enzyme-free glucose sensing based on Fe3O4 nanorod arrays. Microchim Acta 182:1811–1818

Yu H, Jian X, Jin J, Zheng X, Liu R, Qi G (2015) Nonenzymatic sensing of glucose using a carbon ceramic electrode modified with a composite film made from copper oxide, overoxidized polypyrrole and multi-walled carbon nanotubes. Microchim Acta 182:157–165

Shackery I, Patil U, Pezeshki A, Shinde NM, Im S, Jun SC (2016) Enhanced non-enzymatic amperometric sensing of glucose using co(OH)2. Microchim Acta 183:2473–2479

Gao Z, Lin Y, He Y, Tang D (2017) Enzyme-free amperometric glucose sensor using a glassy carbon electrode modified with poly (vinyl butyral) incorporating a hybrid nanostructure composed of molybdenum disulfide and copper sulfide. Microchim Acta 184:1–8

Lin Y, Chen X, Lin Y, Zhou Q, Tang D (2015) Non-enzymatic sensing of hydrogen peroxide using a glassy carbon electrode modified with a nanocomposite made from carbon nanotubes and molybdenum disulfide. Microchim Acta 182:1803–1809

Wang Y, Zhang S, Bai W, Zheng J (2016) Layer-by-layer assembly of copper nanoparticles and manganese dioxide-multiwalled carbon nanotubes film: a new nonenzymatic electrochemical sensor for glucose. Talanta 149:211–216

Ye J-S, Hong B-D, Wu Y-S, Chen H-R, Lee C-L (2016) Heterostructured palladium-platinum core-shell nanocubes for use in a nonenzymatic amperometric glucose sensor. Microchim Acta 183:3311–3320

Shi L, Niu X, Liu T, Zhao H, Lan M (2015) Electrocatalytic sensing of hydrogen peroxide using a screen printed carbon electrode modified with nitrogen-doped graphene nanoribbons. Microchim Acta 182:2485–2493

Feng X, Zhang Y, Zhou J, Li Y, Chen S, Zhang L, Ma Y, Wang L, Yan X (2015) Three-dimensional nitrogen-doped graphene as an ultrasensitive electrochemical sensor for the detection of dopamine. Nano 7:2427–2432

Lei W, Si W, Hao Q, Han Z, Zhang Y, Xia M (2015) Nitrogen-doped graphene modified electrode for nimodipine sensing. Sensors Actuat B- Chem 212:207–213

Panchakarla L, Subrahmanyam K, Saha S, Govindaraj A, Krishnamurthy H, Waghmare U, Rao C (2009) Synthesis, structure and properties of boron and nitrogen doped graphene. arXiv preprint arXiv:09023077

Li X, Wang H, Robinson JT, Sanchez H, Diankov G, Dai H (2009) Simultaneous nitrogen doping and reduction of graphene oxide. J Am Chem Soc 131:15939–15944

Sheng Z, Shao L, Chen J, Bao W, Wang F, Xia X (2011) Catalyst-free synthesis of nitrogen-doped graphene via thermal annealing graphite oxide with melamine and its excellent electrocatalysis. ACS Nano 5:4350–4358

Xia X, Lei W, Hao Q, Wang W, Sun Y, Wang X (2013) One-pot synthesis and electrochemical properties of nitrogen-doped graphene decorated with M(OH)x (M= FeO, Ni, co) nanoparticles. Electrochim Acta 113:117–126

Hui N, Wang S, Xie H, Xu S, Niu S, Luo X (2015) Nickel nanoparticles modified conducting polymer composite of reduced graphene oxide doped poly (3, 4-ethylenedioxythiophene) for enhanced nonenzymatic glucose sensing. Sensors Actuat B-Chem 221:606–613

Yuan B, Xu C, Deng D, Xing Y, Liu L, Pang H, Zhang D (2013) Graphene oxide/nickel oxide modified glassy carbon electrode for supercapacitor and nonenzymatic glucose sensor. Electrochim Acta 88:708–712

Karikalan N, Velmurugan M, Chen S-M, Karuppiah C (2016) Modern approach to the synthesis of Ni(OH)2 decorated sulfur doped carbon nanoparticles for the nonenzymatic glucose sensor. ACS Appl Mater Interfaces 8:22545–22553

Liu Y, Pang H, Wei C, Hao M, Zheng S, Zheng M (2014) Mesoporous ZnO-NiO architectures for use in a high-performance nonenzymatic glucose sensor. Microchim Acta 181:1581–1589

Wang H, Hao Q, Yang X, Lu L, Wang X (2010) Effect of graphene oxide on the properties of its composite with polyaniline. ACS Appl Mater Interfaces 2:821–828

Stankovich S, Dikin DA, Piner RD, Kohlhaas KA, Kleinhammes A, Jia Y, Wu Y, Nguyen ST, Ruoff RS (2007) Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45:1558–1565

Li H, Yu M, Wang F, Liu P, Liang Y, Xiao J, Wang C, Tong Y, Yang G (2013) Amorphous nickel hydroxide nanospheres with ultrahigh capacitance and energy density as electrochemical pseudocapacitor materials. Nat Commun 4:1894

Wei D, Liu Y, Wang Y, Zhang H, Huang L, Yu G (2009) Synthesis of N-doped graphene by chemical vapor deposition and its electrical properties. Nano Lett 9:1752–1758

Wang Z, Jia R, Zheng J, Zhao J, Li L, Song J, Zhu Z (2011) Nitrogen-promoted self-assembly of N-doped carbon nanotubes and their intrinsic catalysis for oxygen reduction in fuel cells. ACS Nano 5:1677–1684

Ko C-Y, Huang J, Raina S, Kang WP (2013) A high performance non-enzymatic glucose sensor based on nickel hydroxide modified nitrogen-incorporated nanodiamonds. Analyst 138:3201–3208

Zhao Y, Gu G, You S, Ji R, Suo H, Zhao C, Liu F (2015) Preparation of Ni(OH)2 nanosheets on Ni foam via a direct precipitation method for a highly sensitive non-enzymatic glucose sensor. RSC Adv 5:53665–53670

Yang J, Cho M, Lee Y (2016) Synthesis of hierarchical Ni(OH)2 hollow nanorod via chemical bath deposition and its glucose sensing performance. Sensors Actuat B-Chem 222:674–681

Lu P, Liu Q, Xiong Y, Wang Q, Lei Y, Lu S, Lu L, Yao L (2015) Nanosheets-assembled hierarchical microstructured Ni(OH)2 hollow spheres for highly sensitive enzyme-free glucose sensors. Electrochim Acta 168:148–156

Acknowledgements

The work was supported by the National Natural Science Foundation of China (Nos. 51572127, 21576138), China-Israel Cooperative Program (S2016G5243), Program for NCET-12-0629, Ph.D. Program Foundation of Ministry of Education of China (No.20133219110018), Six Major Talent Summit (XNY-011), Natural Science Foundation of Jiangsu Provience (BK20160828), Postdoctoral Science Foundation (1501016B) and PAPD of Jiangsu Province, and the program for Science and Technology Innovative Research Team in Universities of Jiangsu Province, China.

We also thank Dr. Wanying Tang at Analysis and Test Center Nanjing University of Science and Technology for the Raman data collection.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The author(s) declare that they have no competing interests.

Electronic supplementary material

ESM 1

(DOC 3620 kb)

Rights and permissions

About this article

Cite this article

Zhang, Y., Lei, W., Wu, Q. et al. Amperometric nonenzymatic determination of glucose via a glassy carbon electrode modified with nickel hydroxide and N-doped reduced graphene oxide. Microchim Acta 184, 3103–3111 (2017). https://doi.org/10.1007/s00604-017-2332-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-017-2332-y