Abstract

We describe an electrochemical sensor for hydrogen peroxide (H2O2) that is making use of Prussian Blue (PB) electrodeposited on a macroporous (mp) gold skeleton electrode. An mp-Cu film was first prepared as a template and the converted into an mp-Au film through a replacement reaction without destructing the structure. Next, a layer of PB was electrochemically deposited on the surface of the mp-Au film. The surface morphology of the electrode was characterized by scanning electron microscopy. Attenuated total reflection infrared spectroscopy and X-ray photoelectron spectroscopy were applied to confirm the structural features. The mp-PB/Au film electrode displays high electro-catalytic activity for the reduction of H2O2 at a working potential of −50 mV (vs. Ag/AgCl) and is very stable. It has a linear response to H2O2 in the 50 μM to 11.3 mM concentration range and a sensitivity of 767 μA∙mM−1 cm−2. The electrode also revealed good selectivity in the presence of electro-active species such as ascorbic acid and uric acid.

An electrochemical sensor for determination of hydrogen peroxide was fabricated by electrochemical deposition of Prussian Blue on the surface of a macroporous gold electrode.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Prussian Blue (PB) is usually regarded as an “artificial peroxidase” [1, 2]. Due to their high activity and selectivity toward the reduction of H2O2 at a low potential, PB modified electrodes have been widely used in electrochemical H2O2 sensors [3, 4] where PB acts not only as a catalyst, but also as a charge transfer mediator [2]. Since the first report on the synthesis of PB film through electro-deposition [5], electrochemical method is well known as the most commonly used technique for the preparation of PB. Recently, in order to enhance the analytical performances of PB film, template-assisted method has been developed to prepare macro/nano structured PB materials [6].

Macroporous (mp) structures are of considerable interest owing to the extremely large specific surface areas for charge and mass transport in electrochemistry [7–9]. Fabrication of mp film on the substrates by electrochemical deposition processes has been successfully performed by using hydrogen bubbles as the dynamic template [10, 11]. Li et.al [12] reported a galvanic replacing process by using hydrogen bubbles to fabricate mp gold films. A non-enzyme sensor by annealing the mp-Cu to obtain mp-CuO film for the electrochemical determination of glucose was prepared by Cherevko and co-workers [13]. Jia et.al [6] fabricated a porous gold electrode through alloying-dealloying approach which showed high sensitivity, outstanding repeatability and stability toward hydrogen peroxide. But, the gold electrode will be destroyed during the alloying-dealloying process.

Herein, we introduce a PB modified mp-Au (mp-PB/Au) film electrode for the electrochemical detection of H2O2. The film was fabricated by two electro-deposition steps: firstly, deposited mp-Cu film using hydrogen bubbles as dynamic template and then transformed it into Au through replacement reaction; secondly, electrodeposited PB onto the Au film matrix. Compared to the PB deposited smooth Au electrode, the mp-PB/Au film electrode can greatly improve the electrochemical response of H2O2. Moreover, The H2O2 sensor could exclude the interference of commonly coexisted uric acid (UA) and ascorbic acid (AA).

Experimental

Materials

Copper(II) sulfate, potassium ferricyanide (III) (K3Fe(CN)6), iron (III) chloride (FeCl3), potassium dicyanoaurate (KAu(CN)2), hydrochloric acid (HCl) and 30 % hydrogen peroxide (H2O2) were purchased from Sigma-Aldrich (http://www.sigmaaldrich.com), all the chemicals were of analytical grade and used as received.

Phosphate buffer (0.1 M) was freshly prepared by using KH2PO4, Na2HPO4 and KCl and the pH value adjusted to 6.5 by using HCl and/or NaOH solution. Stock solution of H2O2 (1 M) was prepared in phosphate buffer.

Preparation of Prussian Blue modified macroporous gold electrode

The gold electrode (area: 0.1 cm2) was polished by 0.3 and 0.05 μm alumina slurry, and then the electrode was washed ultrasonically in acetone, ethanol and distilled water for 20 min, respectively. Subsequently, the electrode was immersed in piranha solution (1: 3, 30 % H2O2/ 98 % H2SO4) for 2 h. After rinsing with distilled water and ethanol, the polished electrode was pre-treated by cyclic voltammetry (CV) with voltage range from −0.3 to +1.6 V (versus Ag, AgCl/KCl Sat’d) at the scan rate was 100 mV · s−1 in 0.5 M H2SO4 solution until a stable electrochemical response was obtained.

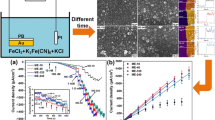

The mp-Au electrode was fabricated according to the previous literature [11, 12]. PB was electrodeposited on the surface of mp-Au film electrode by using CV between −0.2 and +0.6 V at a scan rate was 20 mV s−1 for 25 cycles, and the electrochemical deposition electrolyte contained 2.5 mM FeCl3, 2.5 mM K3Fe(CN)6, 0.1 M KCl and 0.1 M HCl [14]. Subsequently, the prepared MP-PB/Au film electrode was rinsed with distilled water and stored in phosphate buffer (pH = 6.5).

Characterization

All electrochemical measurements were performed on VSP potentiostat (Princeton Applied Research, USA) at room temperature. A three-electrode system was employed with the modified electrodes as the working electrodes, a platinum plate as the counter electrode, and an Ag/AgCl in saturated KCl solution as the reference electrode. Surface morphologies of the modified electrodes were examined by scanning electron microscopy (SEM, JEOL JSM-7000 F, Japan). Attenuated total reflection infrared spectroscopy (ATR-IR) was recorded by using infrared spectrophotometry with 4 cm−1 resolution and 100 scans, using an ATR platform by pressing the solid electrodes onto the diamond crystal. X-ray photoelectron spectroscopy (XPS) measurements were carried out using a VG Scientific ESCA 2000 spectrometer with a Mg-Kα X-ray source operating at a power of 170 W (13 mA and 13 kV).

Results and discussion

Characterization of macroporous gold electrode

In our research, we electro-deposited the mp-Cu film on a gold electrode, and then transformed it into mp-Au film through replacement reaction between Cu and aqueous KAu(CN)2 [11]. The fabricated films are illustrated in Fig. 1. From the SEM images, the films are comprised of numerous small branched deposits [10]. The size of surface pores is ranged from 80 to 120 μm and the pore-wall is about 20 μm. As seen in Fig. 1c and d, after the replacement reaction and electrochemical dealloying processes, the film did not destroy the mp structures. Because of the branches and sub-branches (~5 μm) depict in the typical mp structures of Cu and Au films, the materials could not only provide the larger surface area, but also suit for fast electrochemical reactions [12, 15, 16].

The typical CV of Au films were investigated in an aqueous solution of 0.5 M H2SO4 at a scan rate of 100 mV · s−1. As shown in Fig. 2, an anodic oxidation current of Au film electrode emerges at about +1.2 V while a reduction peak at +0.83 V in the negative potential scan, the result indicates the formation of Au oxide that is subsequently reduced [12]. By integration of the charge required for the reduction of Au oxide, the real surface area of mp electrode was 28 times larger than that of smooth Au electrode. Meanwhile, a slight anodic peak is observed during the sweep up to +0.28 V, which could attribute to the remaining Cu leaving behind the interconnected mp-Au film after dealloying processes.

Characterization of Prussian Blue modified macroporous gold electrode

Figure 3 shows the morphology of mp-PB/Au film electrode. The electro-deposition of PB reveals less effect on the well-defined mp structure. From high resolution, some nano/sub-nano particles on the branches of the pore wall are obtained. The result demonstrates that the structure of the mp-PB/Au film is mostly governed by the original mp-Au film [2].

The ATR-IR spectra of the mp-PB/Au is depicted in Figure 1S (Electronic Supplementary Material, ESM), a strong band that appears at 2077 cm−1 corresponds to the C ≡ N stretching vibrations of PB, it is in good agreement with the predicted structure of a Au film surface functionalized with PB [2, 17]. The deposition of PB on the surface of Au was also investigated by XPS. Figure 2S (ESM) shows the appearance of iron and nitrogen regions of the XPS spectrum of the mp-PB/Au film. The characteristic peak of Fe2p1/2 and Fe2p2/3 appears at 726.5 eV and 708.6 eV, and XPS of the Fe2p3/2 region of the film indicates that Fe existed in both Fe(II) (708.4 eV) and Fe(III) (711.8 eV) states (Figure 2S a) [18]. Moreover, the characteristic peak of N1s occurs at 397.8 eV corresponding to the C ≡ N group in PB (Figure 2S b) [2].

PB is quite stable in neutral and acidic supporting electrolyte solutions under CV conductions [19]. The electrochemical behavior of the mp-PB/Au film electrode was studied in an aqueous solution containing 0.1 M KCl and 0.1 M HCl, and the scan rate was 50 mV s−1. For comparison, a smooth PB/Au electrode with an equal geometrical area of Au was prepared at the same condition. As shown in Fig. 4, the mp-PB/Au (solid curve) and smooth PB/Au (dash curve) film electrodes display similar CV results, but the amount of PB deposited on the mp-Au electrode surface is 18 times larger than that of the smooth Au [20].

Electrocatalytic responses of H2O2 at the Prussian Blue modified macroporous gold electrode

PB is known to be a superior electro-catalyst H2O2 because of its reduced form, Prussian White, which has a capacity of catalyzing the reduction of H2O2 at a rapid catalytic rate with a low over-potential according to Eq. (1) [2]:

PB can be solubilized in alkaline solutions because the hydroxide ions are known to be able to break the Fe–(CN)–Fe bond [19]. In order to study the electro-catalytic performance of the mp-PB/Au electrodes, the electrochemical detection was explored under the weak acidic phosphate buffer solution (pH = 6.5).

Typical current-time response of the mp-PB/Au electrode at -50 mV in 0.1 M phosphate buffer (pH = 6.5) on successive addition of H2O2 concentration is presented in Fig. 5a. The current is increased rapidly after the addition of H2O2, and it can achieve a stable state (95 % of the maximum value) within 6 s, indicating a fast electron transfer rate between H2O2 and the modified electrode [2]. The calibration curve for the electrochemical response of the mp-PB/Au modified electrode shows in Fig. 5b. The linear range of H2O2 concentration is from 50 μM to 11.3 mM, following the linear regression equation Y = −0.018 −0.077X (R2 = 0.999), and the sensitivity is 767 μA mM−1 cm−2. Through comparison the sensing performance of the mp-PB/Au and the smooth PB/Au film electrodes (Figure 3S, ESM), the amperometric response of the mp-PB/Au film electrode is significantly larger than that of the smooth PB/Au film electrode, which attributes to the mp structure provide larger specific area and rapid transport rate of liquid with the structure. In order to compare with the mp-PB/Au electrode obtained in this study, electrochemical analytical parameters of some reported PB based electrodes using different modification approaches for hydrogen peroxide sensing are summarized in Table 1. Compared to the other electrodes, the mp-PB/Au electrode could not only provide good sensitivity, but also show widely electrochemical detection range toward H2O2.

Reproducibility and stability

The reproducibility of the H2O2 sensor was found to be excellent as evidenced by a relative standard deviation of 2.6 % from five separate measurements. The stability of the mp-PB/Au film was measured by CV. As shown in Figure 4S (ESM), the film was quite stable in a solution containing 0.1 M KCl and 0.1 M HCl under CV conduction. Due to no significant current changes in the CV profile after hundreds of cycles, the mp-PB/Au film could have appropriate stability for H2O2-sensing.

UA and AA are electro-active species in a biological sample and may interfere with the electrochemical determination of H2O2 [12]. Figure 6 shows the electrochemical signals of H2O2 at the mp-PB/Au film electrode under the interference of AA and UA. It is obvious that the electrode shows no or little signal to interferences, but a sharply increased current when adding H2O2. This result indicates that the negligible interferences from UA and AA during the electrochemical detection of H2O2 at the mp-PB/Au film electrode.

For practical purposes, the tap and drinking water was spiked with H2O2 standard solutions, in order to simulate the contaminated water. Fig. 5S (ESM) displays the electrochemical responses of the water spiked with and without H2O2. The amperometric responses of the electrode were significantly changed after spiked with H2O2, in the case of the original water, the electrode showed no clear electrochemical responses. The result demonstrates the mp-PB/Au electrode was potentially applicable for the determination of H2O2 in environmental water samples.

Conclusion

An electrochemical sensor for determination of H2O2 was fabricated by electrochemical deposition of PB on the surface of mp-Au electrode matrix. mp-Cu film was electrodeposited using hydrogen bubbles as template, and then transformed into Au film through replacement reaction using potassium dicyanoaurate. The Prussian Blue modified Au electrode was used for determination of H2O2 at a low applying potential in the linear range of H2O2 from 50 to 11.3 mM. The mp-PB/Au film electrode showed excellent sensitivity and rapid response due to its larger surface area and rapid transport of liquid provided by the structure of mp gold.

References

Gong H, Sun M, Fan R, Qian L (2013) One-step preparation of a composite consisting of graphene oxide, Prussian blue and chitosan for electrochemical sensing of hydrogen peroxide. Microchim Acta 180:295–301. doi:10.1007/s00604-012-0929-8

Lin M, Yang J, Cho M, Lee Y (2011) Hydrogen peroxide detection using a polypyrrole/Prussian Blue nanowire modified electrode. Macromol Res 19:673–678. doi:10.1007/s13233-011-0707-1

Doroftei F, Pinteala T, Arvinte A (2014) Enhanced stability of a Prussian blue/sol–gel composite for electrochemical determination of hydrogen peroxide. Microchim Acta 181:111–120. doi:10.1007/s00604-013-1076-6

Ricci F, Amine A, Tuta CS, Ciucu AA, Lucarelli F, Palleschi G, Moscone D (2003) Prussian Blue and enzyme bulk-modified screen-printed electrodes for hydrogen peroxide and glucose determination with improved storage and operational stability. Anal Chim Acta 485:111–120. doi:10.1016/S0003-2670(03)00403-3

Liu Y, Chu Z, Zhang Y, Jin W (2009) Amperometric glucose biosensor with high sensitivity based on self-assembled Prussian Blue modified electrode. Electrochim Acta 54:7490–7494. doi:10.1016/j.electacta.2009.08.002

Jia FL, Yu CF, Gong JM, Zhang LZ (2008) Deposition of Prussian blue on nanoporous gold film electrode and its electrocatalytic reduction of H2O2. J Solid State Electron 12:1567–1571. doi:10.1007/s10008-008-0521-7

Chai GS, Yoon SB, Yu JS, Choi JH, Sung YE (2004) Ordered porous carbons with tunable pore sizes as catalyst supports in direct methanol fuel cell. J Phys Chem B 108:7074–7079. doi:10.1021/jp0370472

Chen X, Chen Z, Tian R, Yan W, Yao C (2012) Glucose biosensor based on three dimensional ordered macroporous self-doped polyaniline/Prussian blue bicomponent film. Anal Chim Acta 723:94–100. doi:10.1016/j.aca.2012.02.032

Paula RM, Pallone EMJA, Neves S (2006) A new approach to obtain lithium nickel cobalt oxide porous films. Electrochim Acta 51:6419–6425. doi:10.1016/j.electacta.2006.04.026

Shin HC, Dong J, Liu ML (2003) Nanoporous structures prepared by an electrochemical deposition process. Adv Mater 15:1610–1614. doi:10.1002/adma.200305160

Li Y, Jia WZ, Song YY, Xia XH (2007) Superhydrophobicity of 3D porous copper films prepared using the hydrogen bubble dynamic template. Chem Mater 19:5758–5764. doi:10.1021/cm071738j

Li Y, Song YY, Yang C, Xia XH (2007) Hydrogen bubble dynamic template synthesis of porous gold for nonenzymatic electrochemical detection of glucose. Electrochem Commun 9:981–988. doi:10.1016/j.elecom.2006.11.035

Cherevko S, Chung CH (2010) The porous CuO electrode fabricated by hydrogen bubble evolution and its application to highly sensitive non-enzymatic glucose detection. Talanta 80:1371–1377. doi:10.1016/j.talanta.2009.09.038

Ahmadalinezhad A, Kafi AKM, Chen A (2009) Glucose biosensing based on the highly efficient immobilization of glucose oxidase on a Prussian blue modified nanostructured Au surface. Electrochem Commun 11:2048–2051. doi:10.1016/j.elecom.2009.08.048

Chen S, Yuan R, Chai Y, Hu F (2013) Electrochemical sensing of hydrogen peroxide using metal nanoparticles: a review. Microchim Acta 180:15–32. doi:10.1007/s00604-012-0904-4

Sanghavi BJ, Wolfbeis OS, Hirsch T, Swami NS Nanomaterial-based electrochemical sensing of neurological drugs and neurotransmitters. Microchim Acta doi: 10.1007/s00604-014-1308-4

Zhao G, Feng JJ, Zhang QL, Li SP, Chen HY (2005) Synthesis and characterization of Prussian Blue modified magnetite nanoparticles and its application to the electrocatalytic reduction of H2O2. Chem Mater 17:3154–3159. doi:10.1021/cm048078s

Lisowska-Oleksiak A, Nowak AP, Jasulaitiene V (2006) Poly(3,4-ethylenedioxythiophene)-Prussian Blue hybrid material: evidence of direct chemical interaction between PB and pEDOT. Electrochem Commun 8:107–112. doi:10.1016/j.elecom.2005.10.028

Karyakin AA, Karyakina EE, Gorton L (1999) On the mechanism of H2O2 reduction at Prussian Blue modified electrodes. Electrochem Commun 1:78–82. doi:10.1016/S1388-2481(99)00010-7

Yu H, Sheng QL, Li L, Zheng JB (2007) Rapid electrochemical preparation of a compact and thick Prussian blue film on composite ceramic carbon electrode from single ferricyanide solution in the presence of HAuCl4. J Electroanal Chem 606:55–62. doi:10.1016/j.jelechem.2007.04.014

Jin E, Lu X, Cui L, Chao D, Wang C (2010) Fabrication of graphene/prussian blue composite nanosheets and their electrocatalytic reduction of H2O2. Electrochim Acta 55:7230–7234. doi:10.1016/j.electacta.2010.07.029

Du D, Wang MH, Qin YH, Lin YH (2010) One-step electrochemical deposition of Prussian Blue–multiwalled carbon nanotube nanocomposite thin-film: preparation, characterization and evaluation for H2O2 sensing. J Mater Chem 20:1532–1537. doi:10.1039/B919500A

Razmi H, Mohammad-Rezaei R, Heidari H (2009) Self-assembled Prussian Blue nanoparticles based electrochemical sensor for high sensitive determination of H2O2 in acidic media. Electroanalysis 21:2355–2362. doi:10.1002/elan.200904687

Zou YJ, Sun LX, Xu F (2007) Prussian Blue electrodeposited on MWNTs–PANI hybrid composites for H2O2 detection. Talanta 72:437–442. doi:10.1016/j.talanta.2006.11.001

Kumar SS, Joseph J, Phani KL (2007) Novel method for deposition of gold-prussian blue nanocomposite films induced by electrochemically formed gold nanoparticles: characterization and application to electrocatalysis. Chem Mater 19:4722–4730. doi:10.1021/cm050929o

Li NB, Park JH, Park K, Kwon SJ, Shin H, Kwak J (2008) Characterization and electrocatalytic properties of Prussian blue electrochemically deposited on nano-Au/PAMAM dendrimer-modified gold electrode. Biosens Bioelectron 23:1519–1526. doi:10.1016/j.bios.2008.01.009

Acknowledgments

This work was supported by Ministry of Science, ICT & Future Planning of Korea (Grant no. 2012–002285) and Basic Science Research Program through the National Research Foundation of Korea Grant funded by the Ministry of Science, ICT & Future Planning (2009–0083540).

Author information

Authors and Affiliations

Corresponding author

Additional information

Jiao Yang and Meng Lin equally contributed to this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 189 kb)

Rights and permissions

About this article

Cite this article

Yang, J., Lin, M., Cho, M. et al. Determination of hydrogen peroxide using a Prussian Blue modified macroporous gold electrode. Microchim Acta 182, 1089–1094 (2015). https://doi.org/10.1007/s00604-014-1433-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-014-1433-0