Abstract

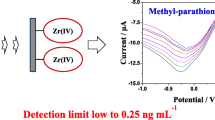

A glassy carbon electrode (GCE) modified with polymeric nanocomposite consisting of palladium nanoparticles and a conductive polymeric ionic liquid was prepared. The modified GCE was applied to sensitive and fairly selective electrochemical determination of the mycotoxin zearalenone. Electrocatalytic oxidation is performed in a solution containing 20 % (V/V) acetonitrile and 80 % (V/V) of 1 M perchloric acid. Cyclic voltammetry and square wave voltammetry revealed a well-defined electrocatalytic peak current at overpotential of +0.69 V versus Ag/AgCl. Under optimized experimental conditions, there is a linear relationship between anodic peak current and zearalenone concentration in the range from 0.03 to 35 ng⋅mL‾1, and the detection limit is 0.01 ng⋅mL‾1. The method was successfully applied to the analysis of zearalenone in spiked food samples and gave recoveries between 95.6 and 104.0 %.

The nanocomposite (PdVC-PIL) was prepared by polymerization of ionic liquid monomer (PIL) in presence of Pd nanoparticles on Vulcan XC-72R carbon (PdVC). The solution containing nanocomposite was placed on the glassy carbon electrode (GCE). The voltammetry activity of modified electrode (PdVC-PIL/GCE) was compared to a bare GCE for zearalenone determination.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Zearalenone (ZEA), Fig. 1, is a secondary fungal metabolite produced by several species of Fusarium, mainly by Fusarium graminearum and Fusarium culmorum [1]. The acute toxicity of ZEA is relatively low (oral LD50 > 20,000 mg kg−1 body weight) upon oral administration in animals [2]. Nevertheless, this mycotoxin causes alterations in the reproductive tract of laboratory and domestic animals and, in humans; it has been associated with precocious puberty, neoplastic and hyperplasic endometrium, and human cervical cancer [3, 4]. Several countries established regulations for ZEA in food and feed in 1996. In 2004, there were a total of 16 countries [5], which indicates its significance. However, the maximum tolerable level is different greatly between countries and a common international maximum limit has not been set for ZEA in foodstuff. The maximum levels set by the European Commission are 20, 75, and 100 μg kg−1 for baby food, cereal flour, and unprocessed cereals, respectively [6–8]. Due to the very important implications of ZEA presence in human beings and animal health as well as from economic aspects, it is need to have economic and rapid techniques for its quantification [9]. The main analytical techniques for ZEA analysis include immunochemical approach [10–12], immunochromatographic assay [13], gas chromatography-triple quadruple mass spectrometry [14], high-performance liquid chromatography using fluorescence detection [15], Liquid chromatography-mass spectrometry [16], liquid-chromatography tandem mass spectrometry and ultra-high performance liquid chromatography high-resolution mass spectrometry [17], High-throughput screening enzyme-linked immunosorbent assay [18] and capillary electrophoresis [19]. Recently, voltammetry techniques have been adopted to study the redox mechanism and behavior of zearalenone [20–22]. These voltammetry techniques are faster and need shorter processing time compared to the conventional techniques [23, 24]. The advantages of electrochemical detection are evident in the development of chemical and biological sensors [25]. Pd nanoparticles (PdNPs) have the reputation of being one of the most attractive metals in many fields including sensor modification due to their high catalytic activities to different types of reaction, excellent economic benefits, good electrical conductivity and optical properties [26, 27]. Furthermore, polymeric ionic liquids (PILs) exhibit the advantages of both ionic liquids and polymers, such as enhanced ionic conductivity, thermal stability and excellent mechanical properties [28]. Owing to their unique properties, PILs have attracted great attention especially in sensor modification [29].

Herein, a glassy carbon electrode (GCE) is modified with Pd nanoparticles/polymeric ionic liquid nanocomposite which revealed high electrocatalytic activity towards the oxidation of ZEA. Under optimized experimental conditions, ZEA showed a well-defined oxidation peak with high current at the modified electrode. The modified electrode provided a low overpotential in comparison with traditional electrodes. High sensitivity toward ZEA, allowed successful using of the electrode for determination of this mycotoxin at low concentration level in food samples.

Experimental

Apparatus and chemicals

The electrochemical measurements were carried out with an Autolab potentiostat/galvanostat (PGSTAT 101, Eco Chemie, Netherlands, http://www.metrohm-autolab.com). A three-electrode cell was used at 22 ± 1 °C. An Ag/AgCl/KCl electrode, a platinum electrode and the PIL-Fe3O4/GCE were used as the reference, auxiliary and working electrodes, respectively. The conditions were controlled with Nov. 1.6 software. An ultrasonic water bath (Sonorex RK255, Germany, http://www.sonorex.com) was used for nanoparticles synthesis. The samples were characterized with a field emission scanning electron microscope (FESEM) (Hitachi S-4160) with gold coating.

Palladium (II) chloride (PdCl2), perchloric acid (HClO4), Zearalenone, Poly (ethylene glycol) methacrylate, 2-sulfobenzoic anhydride, 1-methylimidazole and azobis (2-methylpropionitrile) (AIBN) were purchased from Sigma-Aldrich (http://www.sigmaaldrich.com). Acetonitrile (ACN) was obtained from Merck (Darmstadt, Germany, http://www.merck.com). All solutions were freshly prepared with distilled water.

Synthesis of Pd nanoparticles

The chemical pretreatment of Vulcan XC-72R carbon (VC) powder was carried out using Senthil Kumar method [30]. The treated carbon support and ethylene glycol were added into a beaker and irradiated with strong ultrasonic wave (300 W, 30 % amplitude) for 30 min at room temperature while PdCl2 solution was dropped continuous to support solution. At end, the obtained blackish slurry was filtered, washed and dried in vacuum for 12 h at room temperature. The XRD patterns of obtained PdNPs/VC nanocomposites are shown in Fig. 2. The peak at 2θ value of 25° is related to carbon support. The three peaks, corresponding with the planes (111), (220) and (322) at ca. 40°, 47° and 68° respectively were characteristic of cubic crystalline PdNPs (JCPDS, Card No. 87–0639). The average sizes of the PdNPs were calculated 6.0 nm by Debye- Scherrer formula.

FESEM image of synthesized PdNPs is shown in the Supplementary content (Fig. S1). The white visible spots on the images are believed to be PdNPs which were deposited on the Vulcan carbon supports with compact and granulated structure.

Synthesis of PdVC-PIL nanocomposite

Monomer of ionic liquid was prepared and purified using the Ohno method [31]. Poly (ethylene glycol) methacrylate and 2-sulfobenzoic anhydride were mixed and stirred in chloroform at room temperature for 24 h. Then, 1-methylimidazole, equimolar to the vinyl group, was added slowly to this solution under stirring at 0 °C. After 12 h, this solution was dropped in excess diethyl ether for purification. The oily precipitate was washed several times with diethyl ether and dried in vacuum at room temperature. This monomer was polymerized in presence of AIBN and 1 % wt. PdNPs in ethanol. Polymerization of these ionic liquid monomers was initiated at 70 °C for 2 h under N2 atmosphere. Obtained polymer was washed with dehydrated ethanol two times and then dried in vacuum. FESEM image of nanocomposite is shown in the supplementary content (Fig. S2).

Preparation of the modified electrode

Prior to coating, the GC electrode was carefully polished with 3 μm alumina powder on polishing cloth and sonicated in 1:1 ethanol and distilled water ratio in order to remove adsorbed particles. After that, GCE surface was activated in 0.1 M NaHCO3 solution. 1 μL solution containing 0.5 mg mL−1 nanocomposite and 1 % nafion was cast on GCE surface and allowed to dry at room temperature. A PIL/GCE and a PdVC/GCE were fabricated under above conditions with 0.5 mg mL−1 polymer without PdNPs and 0.5 mg mL−1 PdVC without polymer, respectively.

Procedure of cereal derived products preparation

A total of 6 cereal-derived samples, including 2 baby food samples, 2 breakfast cereal samples and 2 beer samples were purchased randomly from different supermarkets and small shops in Kerman, Iran. The cereal contents in the baby food samples ranged from 30 to 80 % wt. Breakfast cereal samples included the following major ingredients, alone or mixed: maize, bran, chocolate, cereals (wheat and/or rice), fruits and oats. All of the beer samples were non-alcohol. 25 g of each Breakfast cereals and baby foods was extracted with 100 mL of methanol: water extraction solvent (80:20, v/v). The extract was filtered through a filter paper and then 10 mL of filtrate was diluted. 100 mL of beer samples were boiled for 15 min until foaming was stopped. Then the residue liquid was diluted. Then each sample was stirred for about 10 min and the pH was measured directly and adjusted to 7.2.

Results and discussion

Choice of materials

VC powder was chemical treatment before nanoparticles synthesis. Acid treatment creates surface oxygen groups which form anchoring sites for metallic precursors as well as for metals on the carbon surface. The pretreatment VC provides excellent conductivity in a range of applications at relatively low loading levels. Therefore, measured amounts of PdCl2 and VC powder were used in reaction to make 30 wt.% of the metal content in the final product. Pd nanoparticles were synthesized by sonochemical reactions in ethylene glycol on carbon support. It must be noted that the reactions have been run without any additives. The solvent ethylene glycol functions as a surface stabilizer as well as the expected reducing agent. The use of conductive polymeric ionic liquid for synthesis of nanocomposite can increase the modified electrode conductivity.

Electrocatalytic oxidation of ZEA at modified GCE

The voltammetry activity of modified GCE was studied in 20 % ACN + 80 % 1 M HClO4 aqueous solution and scan rate of 20 mV s−1. Figure 3 illustrates the cyclic voltammograms (CV) of a) bare GCE, b) PdVC/GCE, d) PIL/GCE and e) PdVC-PIL/GCE in 35.0 ng mL−1 ZEA. No peaks were observed at the reverse scan which suggests that the oxidation process is chemically irreversible for ZEA under the experimental conditions. As shown, the anodic peak potential of ZEA on bare, PdVC, PIL and PdVC/PIL GCE surface is ~1.1, ~1.0, ~0.8, ~0.69, respectively. Also, it can be seen that the peak current is enhanced in case of the modified GCE. Therefore the PdVC/PIL can catalyze the electrode reaction by decreasing overpotential. This modified electrode increases the measurements sensitivity in comparison to other electrodes.

Calibration curve and detection limit

Square wave voltammetry (SWV) method was applied to determine the concentration of ZEA (Fig. 4). The plot of peak current vs. concentration was linear in the concentration ranges of 0.03 to 35.0 ng mL−1 with slopes of 0.092 ng mL−1 (inset). The detection limit of ZEA was calculated by making seven replicate current measurements for a blank solution, the detection limit based on the mean of these measurements and 3σ gave a value of 0.01 ng mL−1. The relative standard deviations from seven determinations of zearalenone at each of two concentrations of 1.0 and 20.0 ng mL−1 were 3.5 and 2.0 % respectively.

SWV of PdVC-PIL/GCE in 20 % ACN + 80 % 1 M HClO4 aqueous solution containing different concentrations of ZEA. Numbers 1–8 correspond to 0.03, 0.5, 5.0, 10.0, 15.0, 20.0, 25.0 and 35.0 ng mL−1 zearalenone. Inset: Plot of the electrocatalytic peak current at the working potential of +0.69 V versus Ag/AgCl as a function of zearalenone concentration

Interference study

In order to check the selectivity of the modified electrode, the influence of various interferences on the determination of ZEA was studied under optimum conditions in the concentration of 35.0 ng mL−1. The tolerance limit was defined as the maximum concentration of the interfering substance that caused an error of less than ±5 % in the determination of ZEA. The results showed that less than 1000 fold excess of Na+, K+, Ca2+, Mg2+, CO3 2−, PO4 3−, SO4 2−, Cl−, Br−, NO3 −, ClO4 −, ACN, Ethanol; 500 fold excess of ascorbic acid, citric acid, sucrose, lactic acid; 5 fold excess of Aflatoxin, Ochratoxin and Deoxynivalenol did not have any significant effect on the ZEA signal.

Real sample analysis

This method was applied to the determination of ZEA in food samples. The analytical results are shown in Table 1, 2, and 3. The method was checked by spiking ZEA in samples. Also, the accuracy of method was evaluated by analyzing a Maize Reference Material (ERM-BC717) with zearalenone content of 83 ± 9 μg kg−1.

Comparison of the method with literature methods

A comparison of the main characteristics of this method with others reported in the literatures is given in Table 4. Generally, the results obtained by the present method are comparable to or better than the other methods.

Conclusion

This article described the development of an electrochemical sensor for zearalenone detection by the facility construction of a conductive polymeric ionic liquid containing the synthesized palladium nanoparticles on Vulcan XC-72R carbon. In presence of this nanocomposite, the surface area of electrode is increased and more active sites are provided for adsorption of zearalenone. The contribution of each component in the nanocomposite was specified to increase the response of the electrode. This nanocomposite decrease oxidation potential and accelerate the oxidation of ZEA. These properties make this modified electrode very useful for accurate determination of ZEA in food samples. The approach is compatible with high throughput analysis, saving time, labor, and money. While the using toxic solvent, acetonitrile is a method limitation, but 1 M HClO4 containing 20 % acetonitrile, as electrolyte, increased the electrode response and method sensitivity.

The only limitation of this method is using of the toxic solvent, acetonitrile, as the electrolyte, that increased the electrode response and method sensitivity.

References

Weidenborner M (2001) in Encyclopedia of Food Mycotoxins, Springer, Berlin, 267.

Zinedine A, Soriano JM, Molto JC (2007) Review on the toxicity, occurrence, Metabolism, detoxification, regulations and intake of zearalenone: an estrogenic mycotoxin. J Manes Food Chem Toxicol 45:1–18

Ingle MB, Martin BW (1986) Precocious puberty in Puerto Rico. J Pediatr 109:390–391

Kuiper GGIJ, Lemmen JG, Carlsson B, Corton C, Safe SH, Van der Saag PT, Van der Burg B, Gustafsson JA (1998) Interaction of estrogenic chemicals and phytoestrogens with estrogen receptor β Endocrinology 139: 4252–4263.

Food Agriculture Organization (FAO), Worldwide Regulations for Mycotoxins in Food and Feed in 2003, FAO of the United Nations, Rome, Italy, 2004 (Food and Nutrition Paper No. 81).

European Commission, Commission Regulation (EC) No. 856/2005 of 6 June 2005, amending Regulation (EC) No 466/2001 as regards Fusarium toxins, Off J Eur Union 143 (2005) 3–8.

European Commission, Commission Regulation (EC) No.1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs, Off. J. Eur. Union L364 (2006) 5–24.

European Commission, Commission Regulation (EC) No. 1126/2007 of 28 September 2007, amending Regulation (EC) No. 1881/2006 setting maximum levels for certain contaminants in foodstuffs as regards Fussarium toxins in maize and maize products, 2007, off. J. Eur. Union L255, 14–17.

Opinion of the Scientific Panel on Contaminants in the Food Chain on a request from the Commission related to Zearalenone as undesirable substance in animal feed, 2004, European Food Safety Authority journal, 89: 1–35.

Beloglazova NV, De Boevre M, Goryacheva IY, Werbrouck S, Guo Y, De Saeger S (2013) Immunochemical approach for zearalenone-4-glucoside determination. Talanta 106:422–430

Wang YK, Yan YX, Mao ZW, Wang HA, Zou Q, Hao QW, Sun JH (2013) Highly sensitive electrochemical immunoassay for zearalenone in grain and grain-based food. Microchim Acta 180(3–4):187–193

Regiart M, Seia MA, Messina GA, Bertolino FA, Raba J (2015) Electrochemical immunosensing using a nanostructured functional platform for determination of α-zearalanol. Microchim Acta 182(3-4):531–538

Duan H, Chen X, Xu W, Fu J, Xiong Y, Wang A (2015) Quantum-Dot submicrobead-based immunochromatographic assay for quantitative and sensitive detection of zearalenone. Talanta 132:126–131

Qian M, Zhang H, Wu L, Jin N, Wang J, Jiang K (2015) Simultaneous determination of zearalenone and its derivatives in edible vegetable oil by gel permeation chromatography and gas chromatography–triple quadrupole mass spectrometry. Food Chem 166:23–28

Porto-Figueira P, Camacho I, Camara JS (2015) Exploring the potentialities of an improved ultrasound-assisted quick, easy, cheap, effective, rugged, and safe-based extraction technique combined with ultrahigh pressure liquid chromatography-fluorescence detection for determination of Zearalenone in cereals. J Chromatogr A 1408:187–196

Moreno V, Zougagh M, Rios A (2015) Hybrid nanoparticles based on magnetic multiwalled carbon nanotube-nanoC18SiO2 composites for solid phase extraction of mycotoxins prior to their determination by LC-MS. Microchim Acta 183(2):871–880

De Baere S, Osselaere A, Devreese M, Vanhaecke L, De Backer P, Croubels S (2012) Development of a liquid–chromatography tandem mass spectrometry and ultra-high performance liquid chromatography high-resolution mass spectrometry method for the quantitative determination of zearalenone and its major metabolites in chicken and pig plasma. Anal Chim Acta 756:37–48

Pei CS, Lee WJ, Zhang GP, Hu XF, Eremin SA, Zhang LJ (2013) Development of anti-zearalenone monoclonal antibody and detection of zearalenone in corn products from China by ELISA. Food Control 31:65–70

Maragos CM, Appell M (2007) Capillary electrophoresis of the mycotoxin zearalenone using cyclodextrin-enhanced fluorescence. J Chromatogr A 1143:252–257

Afzali D, Padash M, Mostafavi A (2015) Determination of trace amounts of zearalenone in beverage samples with an electrochemical sensor. Mycol Res 31(4):203–208

Liu L, Chao Y, Cao W, Wang Y, Luo C, Pang X, Fan D, Wei Q (2014) A label-free amperometric immunosensor for detection of zearalenone based on trimetallic Au-core/AgPt-shell nanorattles and mesoporous carbon. Anal Chim Acta 847:29–36

Regiart M, Pereira SV, Spotorno VG, Bertolino FA, Raba J (2014) Food safety control of zeranol through voltammetric immunosensing on Au–Pt bimetallic nanoparticle surfaces. Analyst 139:4702

Chanique GD, Arevalo AH, Zon MA, Fernandez H (2013) Electrochemical reduction of patulin and 5-hydroxymethylfurfural in both neutral and acid non-aqueous media. Their electroanalytical determination in apple juices. Talanta 111:85

Mohamad Nasir MZ, Pumer M (2014) Mycotoxins: Simultaneous Detection of Zearalenone and Citrinin by Voltammetry on Edge Plane Pyrolytic Graphite Electrode. Electroanalysis 26:1901–1904

Afzali D, Fathirad F, Ghaseminezhad S (2015) Food Sci. Technol Int. doi:10.1007/s13197-015-2016-8

Valtchev V, Tosheva L (2013) Porous nanosized particles: preparation, properties, and applications. Chem Rev 113:6734–6760

Chen LG, Lemma BE, Rich JS, Mack J (2013) Freedom: a copper-free, oxidant-free and solvent-free palladium catalysed homocoupling reaction. Green Chem 16:1101–1103

Marcilla R, Alcaide F, Sardon H, Pomposo JA, Gonzalo CP, Mecerreyes D (2006) Tailor-made polymer electrolytes based upon ionic liquids and their application in all-plastic electrochromic devices. Electrochem Commun 8:482–488

Wang X, Zheng K, Feng X, Xu C, Song W (2015) Polymeric ionic liquid functionalized MWCNTs as efficient electrochemical interface for biomolecules simultaneous determination. Sensors Actuators B Chem 219:361–369

Senthil Kumar SM, Soler Herrero J, Keith Scott SI (2010) The effect of pretreatment of Vulcan XC-72R carbon on morphology and electrochemical oxygen reduction kinetics of supported Pd nano-particle in acidic electrolyte. J Electroanal Chem 647:211–221

Ohno H, Yoshizawa M, Ogihara W (2004) Development of new class of ion conductive polymers based on ionic liquids. Electrochim Acta 50:255–261

Panini NV, Bertolino FA, Salinas E, Messina GA, Raba J (2010) Zearalenone determination in corn silage samples using an immunosensor in a continuous flow/stopped-flow systems. Biochem Eng J 51:7

Brenn-Struckhofova Z, Fureder C, Cichna-Markl M, Razzazi-Fazeli E (2009) Co-isolation of deoxynivalenol and zearalenone with sol–gel immunoaffinity columns for their determination in wheat and wheat products. J Chromatogr A 1216:5828

Andreu Y, Castillo JR, de Marcos S, Galban J (2004) Evaluation of a fluorometric–enzymatic method based on 3α-hydroxysteroid dehydrogenase for the mycotoxin zearalenone determination in corn. Talanta 64:196

Andrés F, Zougagh M, Castañeda G, Ríos A (2008) Determination of zearalenone and its metabolites in urine samples by liquid chromatography with electrochemical detection using a carbon nanotube-modified electrode. J Chromatogr A 1212: 54.

Acknowledgments

We gratefully acknowledge the financial support provided for this project (No. 4617) by Institute of Science and High Technology and Environmental Sciences, Graduate University of Advanced Technology, Kerman, Iran.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author(s) declare that they have no competing interests.

Electronic supplementary material

ESM 1

(DOCX 345 kb)

Rights and permissions

About this article

Cite this article

Afzali, D., Fathirad, F. Determination of zearalenone with a glassy carbon electrode modified with nanocomposite consisting of palladium nanoparticles and a conductive polymeric ionic liquid. Microchim Acta 183, 2633–2638 (2016). https://doi.org/10.1007/s00604-016-1907-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-016-1907-3