Abstract

Reduced graphene oxide (RGO) was used to construct a bienzyme biosensor containing horseradish peroxidase (HRP) and glucose oxidase (GOx). A poly(toluidine blue) (pTB) film containing RGO acted as both enzyme immobilization matrix and electron transfer mediator. The bienzyme biosensor was characterized by electrochemical techniques and displays a highly sensitive amperometric response to glucose and hydrogen peroxide (H2O2) at a potential as low as −0.1 V (vs. SCE). It is shown that use of RGO causes a strong enhancement on the amperometric responses. H2O2 formed by the action of GOx in the presence of oxygen can be further reduced by HRP in the pTB film contacting the RGO modified electrode. In the absence of oxygen, glucose oxidation proceeds by another mechanism in which electron transfer occurs from GOx to the electrode and with pTB acting as the mediator. Amperometric responses to glucose and H2O2 follow Michaelis-Menten kinetics. The experimental conditions were optimized, and under these conditions glucose can be determined in the 80 μM to 3.0 mM range with a detection limit of 50 μM. H2O2, in turn, can be quantified in up to 30.0 μM concentration with a detection limit of 0.2 μM. The bienzyme biosensor is reproducible, repeatable and stable. Finally, it has been successfully applied to the determination of glucose in plasma samples.

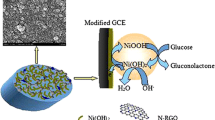

Schematic representation of glocuse detection at GCE/RGO/pTB-HRP-GOx.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There has been an explosion of interest in the use of nanomaterials for the development of biosensors, and carbon nanotubes (CNTs) are at the forefront [1]. As the thinnest but also the hardest nanomaterial, now graphene has attracted more and more attention since it was first reported in 2004 [2, 3]. However, the dispersibility of graphene in solvents is not good due to its hydrophobic nature, which is limited to its application in electrochemical analysis. To improve its dispersibility, some functional graphene have been synthesized and widely used in electrochemical analysis [4–6]. Most of them used in electrochemistry are produced by chemically reduction from graphene oxide (GO). Both GO and reduced graphene oxide (RGO) usually have abundant structural defects [7, 8] and functional groups [9] which are advantageous for electrochemical applications [4, 10, 11]. In 2009, Dong revealed that RGO as a kind of more robust and advanced carbon electrode material holds great promise for electrochemical biosensor design because RGO consists of a single sheet showing favorable electrochemical activity [5]. Up to now, many RGO-based electrochemical sensors and biosensors have been constructed for biochemical analysis such as the determination of a neurotransmitter dopamine (DA) and its coexisting species ascorbic acid (AA) and uric acid (UA) [12, 13], a cofactor of many dehydrogenases NADPH and a general enzymatic product of oxidases and a substrate of peroxidase H2O2 [14, 15]. Besides that, heavy metal ions and even DNA have been successfully analyzed by RGO -based biosensors [16, 17].

Enzyme biosensor continues to be a topic of interest in the field of electroanalytical techniques and devices because enzyme has high selectivity and respond quickly to the specific substrate [18]. Much attention has been paid to the development of high-performance enzyme sensors. As we know, enzyme activity is easily influenced in amperometric biosensors by operation conditions such as immobilization methods, electrode materials, electrolyte pH and temperature. So the establishment of electrical communication between redox centers of enzymes and common electrode is thought as key factor determining the performance of biosensor because the redox active site of enzyme is usually embedded deeply into the large three dimensional structure of enzyme molecules. Based on this consideration, many nanomaterials were applied to the enzyme-based biosensors to increase the conductivity and compatibility in terms of their unique chemical, electronic and mechanical properties [19–21]. Unsurprisingly, RGO with high electrocatalytic activity has also been involved in the preparation of enzyme biosensors due to its rich oxygen-containing functional groups and good dispersibility in water. Kinds of RGO-based glucose biosensors have been reported [22–27]. The high surface area is helpful in increasing the surface loading of the target enzyme molecules on the surface. The excellent conductivity and small bandgap are favorable for conducting electrons from the biomolecules [19]. In addition to using nanomaterials for electrical communication between redox centers of enzymes and electrode, the entrapment of enzymes in electropolymerized conductive films shows high efficiency in fabrication of biosensors due to simplicity of operation and low response time. Generally, electropolymerized films exhibit good uniformity and controllability. Moreover, some of them can also work as electron mediator to accelerate the electron transfer rate between enzyme and electrode. The aim of our work is the development of a bienzyme biosensor combining unique electronic properties of RGO and good uniformity and controllability of electropolymerized films for glucose or H2O2 determination.

In present work, one bienzyme-based amperometric biosensor with both glucose oxidase (GOx) and horseradish peroxidase (HRP) enzymes co-immobilized in ploy(toluidine blue) (pTB) film has been developed and characterized by electrochemical method on RGO modified GC electrode and its amperometric response for glucose and H2O2 at low potential was well-behaved with displaying Michaelis-Menten kinetics. RGO showed great enhancement effect on amperometric responses of this biosensor. As a two-electron redox mediator, toluidine blue (TB) also act as the polymer matrix to immobilize the enzymes remaining biologic activity under this condition. This biosensor offered high sensitivity, good selectivity and fast response. Finally, the biosensor was successfully applied to the glucose determination in plasma sample.

Material and methods

Chemicals and apparatus

Glucose oxidase (EC 1.1.3.4, type X-S, from Aspergillus niger, GOx), peroxidase (EC 1.11.1.7, type VI, from horseradish, HRP), toluidine blue (TB), ascorbic acid (AA), uric acid (UA), L-aspartic acid (L-Asp), L-tryptophan (l-Trp), γ-aminobutyric acid (GABA), l-Lysine (l-Lys) and polyvinylpyrrolidone (PVPy, Mw = 40,000) were obtained from Aladdin reagent Co. (Shanghai, China, www.aladdin-e.com), and used as received. Graphite oxide was synthesized from graphite (spectral pure, Sinopharm Chemical Reagent CO., China, en.reagent.com.cn) by Hummers method [28]. The glucose and hydrogen peroxide (H2O2) were purchased from Sinopharm Chemical Reagent CO. (Shanghai, China). The stock solution of hydrogen peroxide (H2O2) was freshly prepared daily by diluting 30 % H2O2 solution. Glucose stock solution was allowed to mutarotate for at least 24 h before use. Phosphate buffer (0.10 M, pH = 7.4) was prepared by mixing stock standard solutions of KH2PO4, KCl and NaOH. Other chemicals were of reagent-grade and were used as supplied without further purification. All solutions were prepared with deionized water.

All the electrochemical measurements were performed on a CHI 660D electrochemical workstation (CH Instruments, Chenhua, Shanghai, China, www.chinstr.com) in a conventional three-electrode arrangement, equipped with a platinum wire counter electrode, a saturated calomel electrode (SCE) reference electrode and the modified glassy carbon working electrode (GCE, φ = 3.0 mm). For the deoxygenated experiments, the electrolyte was bubbled with highly-purity (99.999 %) nitrogen for 15 min and the electrochemical experiments were conducted under inert atmosphere. All electrochemical experiments were carried out at room temperature. The scanning electron microscopy (SEM) was performed on LEO-1530 scanning electron microscope (LEO Electron Microscopy Inc., Cambridge, UK, www.smt.zeiss.com/nts).

Synthesis of reduced graphene oxide

Reduced graphene oxide (RGO), was prepared according to references [22, 29]. Synthesized GO was suspended in water to create a 0.50 mg · mL−1 dispersion. Exfoliation of GO was achieved by ultrasonication of the dispersion for 30 min. Then obtained brown dispersion was subjected to 30 min of centrifugation at 330 g to remove any unexfoliated GO. The homogeneous GO dispersion (5.0 mL) was mixed with 5.0 mL of 4 mg · mL−1 polyvinylpyrrolidone (PVPy) aqueous solution, and then stirred at 50 °C for 12 h. When it was cooled to room temperature, 3.5 μL of hydrazine and 40.0 μL of ammonia solutions were added into the dispersion. After being vigorously shaken or stirred for a few minutes, the vial was put in an oil bath (95 °C) for 1 h. The homogeneous black dispersion was obtained and then washed to neutrality by repetitive centrifugation and resuspension. The final volume of aqueous RGO dispersion was 2.5 mL.

Fabrication of the biosensor

Prior to preparation of modified electrode, a glassy carbon electrode (GCE) of 3.0 mm was mechanically polished to a mirror finish with wet microcloth containing 0.05 μm alumina powder, and then carefully cleaned in ethanol (C2H5OH) and water by ultra-sonication bath, each for 2 min. 8.0 μL of the uniform RGO suspension was cast on the GCE surface and air dried for several hours. Electropolymerization of TB on the RGO modified GCE (GCE/RGO) was carried out by cyclic voltammetry between −0.40 and +0.90 V at a scan rate of 50 mV · s−1 for 20 cycles in phosphate buffer (pH = 7.4) [23]. The concentration of TB is 5.0 mM. The horseradish peroxidase (HRP) - glucose oxidase (GOx) bienzyme electrode was prepared via electropolymerization of TB in the presence of HRP and GOx. It was signed as GCE/RGO/pTB-HRP-GOx. The modified electrodes were completely rinsed by deionized water and then stored in pH 7.4 phosphate buffer at 4 °C, when not in use.

Amperometric measurement of glucose or H2O2

Amperometric measurements of glucose or H2O2 were performed in a 0.10 M phosphate buffer (pH = 7.4) at the applied potentials of −0.10 V. The steady-state current response was recorded after the addition of glucose or H2O2 in stirred solution.

Results and discussion

SEM images

The RGO modified glassy carbon electrode (GCE/RGO) and the bienzyme biosensor based on this chemically modified electrode (GCE/RGO/pTB-HRP-GOx) were characterized using scanning electron microscopy (SEM). The SEM images of both GCE/RGO and GCE/RGO/pTB-HRP-GOx are respectively shown in Fig. 1a and b. It can be found that the RGO shown like layer film with some wrinkles has no aggregations, indicating that RGO can be uniformly dispersed in water (Fig. 1a). The GCE/RGO has high surface area offering much more active sites than the bare GC electrode. Combined with the special electronic characteristics of RGO, this film can be regarded as good carrier of bienzyme HRP and GOx. As shown in Fig. 1b, a very thin film appears and overlies on the RGO surface, suggesting that HRP and GOx have been successfully entrapped in the conductive pTB film on RGO sheets which have tightly attached to the electrode surface. RGO film with wrinkles can offer high accessible surface area to increase the loading of enzyme and then enhance the amperometric responses of corresponding substrates.

Biocatalytic schemes

Bienzyme electrode was fabricated by co-immobilizing GOx and HRP onto the RGO modified GCE via electropolymerization of toluidine blue (TB) as shown in Scheme 1c. The redox center of enzyme far away from the electrode surface can “contact” the modified electrode with the aid of conductive film pTB and RGO, resulting in fast responses of biosensor to corresponding substrates. There are two routes involved in this bienzyme biosensor for glucose detection. In the first route (Scheme 1b), the conductive pTB film acts as mediator to achieve the electrical connection between GOx and GCE/RGO without participation of O2 [23, 30]. Amperometric response for glucose detection displayed as anodic current via monitoring the oxidation of glucose by GOx.

As for the second route (Scheme 1a), the principle of present bioenzyme electrode is based on electrochemical reduction of the hydrogen peroxide (H2O2) generated by the enzymatic reaction in the presence of O2. Active oxidants compound I was formed in catalytic reaction of HRP with H2O2 and then it was reduced to be compound II by pTB film. Compound II was further reduced to generate the HRP by accepting a second electron from pTB film [30, 31]. In this bienzymatic system, pTB film serves as electrons donor to contribute to the generation of ferric enzyme HRP. The corresponding details can be described as follows:

Considering practicability and convenience of the biosensor, only the second route was used for further investigation on its electrochemical performance. Following this principle, the cathodic current response can be observed when some amount of glucose was injected in supporting electrolyte.

pTB coating on bare GCE and GCE/RGO

The electropolymerization process was carried out by cyclic potential sweep from −0.40 to +0.90 V at a scan rate of 50 mV · s−1 in phosphate buffer (pH 7.4) containing 5.0 mM TB in the presence of HRP and GOx. TB species were used as not only enzyme-immobilization material but also electron transfer mediator and showed different cyclic voltammetric behaviors at between bare GCE and GCE/RGO surface. The results are illustrated in Fig. 2.

The electropolymerization of TB at graphite electrode has been reported in details [30] and but shows a slightly different here. At GCE/RGO (Fig. 2a), a well-defined oxidation peak with large current can be observed at about −0.20 V when potential initially sweeps from −0.40 to +0.90 V. Corresponding reduction peak can be observed at about −0.30 V on reverse scan. Maybe it was relevant to the adsorption of TB species onto electrode surface and then the redox of TB monomers. On the following potential scans the polymer of TB is formed in RGO film and the redox peak currents of TB monomer decrease slowly and disappear at the last. At the same time, a new couple of redox peaks appear at about 0.00 and −0.10 V with the growth of polymer film, which is attributed to oxidation and reduction of generated intermediate compounds in process of electropolymerization of TB [30]. The less obvious shoulder redox peaks at about 0.20 V and 0.10 V appear based on the same reason. Similar redox process of TB monomers can be obtained at bare GCE and but the other two couple of redox peaks from intermediate compounds are almost not found during the following voltammetric sweeps (Fig. 2b). So it can be concluded that the electronic properties of polymerized TB film at RGO are more appropriate than that at bare GCE for biosensor construction. It was the large surface area and special electronic characteristics of RGO film that greatly enhance the polymerization rate of TB and the amount of enzyme (HRP and GOx) entrapped in pTB film. Amperometric response currents in Fig. 2c and d have confirmed the above conclusion. At the same glucose concentration of 1 mM, the current response at GCE/RGO (Fig. 2c) is much larger than that obtained at bare GCE (Fig. 2d). These results indicated that the cooperation of RGO film and pTB film meant a great deal to the high-performance of this bienzyme biosensor.

PTB film thickness

As an immobilization matrix for GOx and HRP, thin pTB film is beneficial to the diffusion of substrates or products and but amount of enzyme loading will decrease. Meanwhile, if pTB film is a redox mediator for electron transfer between active sites of enzyme and electrode, thick film will benefit the performance of this biosensor. Therefore, effect of pTB film thickness controlled by the number of voltammetric cycles on current response of glucose was investigated in the range of 5 to 25. The current response increased greatly from 5 to 15 cycles and then remained stable after 20 cyclic potential sweeps. So electropolymerization of TB was carried out at 20 cyclic potential sweeps.

Amperometric response of the bienzyme biosensor to glucose and H2O2

Amperometric currents of GCE/RGO/pTB-HRP-GOx to glucose and H2O2 are respectively recorded in Fig. 3a and b at a detection potential of −0.10 V in air-saturated phosphate buffer.

It can be found that the currents increase with successive addition of glucose and H2O2 and then finally they reach a saturation value. The response was very fast and the current reached steady state within 5 to 8 s. As for the glucose determination, the response current would reach a saturated value when the concentration of glucose was higher than 4.0 mM. If the concentration was further increased, the response signals would change to be anodic current, which may be influenced by the concentration of dissolved O2 in buffer solution. After the substrate was added in solution, the O2 near the electrode surface was consumed to produce H2O2 during enzymatic oxidation of glucose. If the O2 in bulk solution did not diffuse to the electrode surface in time, the enzymatic oxidation of glucose would proceed by the other route in (Scheme 1b) utilizing the mediator role of pTB film on GCE/RGO and production of H2O2 would become slow, and lastly the current response changed. Anyway, the linear range of this enzyme electrode extended to 1.0 mM of glucose (Fig. 4a). The detection limit of this biosensor was estimated to 0.05 mM at a sigal-to-niose of 3 (S/N = 3). Similarly, the H2O2 response is shown in Fig. 4b. The linear range is up to 5.0 μM and the detection limit was estimated to be 0.2 μM (S/N = 3). This bienzyme electrode showed a typical Michaelis-Menten kinetics [32], as it was shown in Fig. 4. According to the Lineweaver–Burk equaton:

where, Iss is the steady-state current after the addition of glucose, c is the bulk concentration of the substrate, and Imax is the maximum current measured under saturated glucose conditions, the apparent Michaelis–Menten constant Km app, can be derived to be 1.79 mM according to the Lineweaver-Burke plot (1/c vs. 1/I).

As for the responses of bienzyme biosensor to H2O2, the data were illustrated in Fig. 4b. In the same way, the Km app for the catalytic reaction of HRP to H2O2 was calculated to be 6.34 μM. The low Km values indicated high enzymatic activity of HRP and GOx in pTB film. This bienzyme system exhibited high biologically affinity to glucose and H2O2, and electropolymerized TB film on RGO modified electrode provided appropriate environment for Michaelis-Menten equilibrium.

Biosensor performance

A low detection potential of −0.10 V was chosen for glucose determination, which can greatly reduce the interference from some small biological molecules that usually present in the typically samples. As it shown in Fig. 5, common interferences by some small biological molecules such as ascorbic acid (AA) and uric acid (UA, 0.01 M, not shown) have been greatly weakened on the response of this biosensor. Some kinds of amino acids including l-tryptophan (l-Trp), l-aspartic acid (l-Asp), l-lysine (l-Lys) and γ-aminobutyric acid (GABA) have almost no influence on the performance of biosensor.

Reproducibility and repeatability are important factors for evaluation of biosensor performance. In present work, reproducibility and repeatability of fabricated sensor were investigated by manufacture of two biosensors at a time and 5 times repeat of detection. The relative standard deviation (RSD) for 5 times parallel detection of each sample including glucose or H2O2 was less than 5.0 %. The RSD for 5 times parallel detection of 0.1 mM glucose and 0.01 mM H2O2 is calculated as 4.8 % and 3.4 %, respectively. These data suggest excellent reproducibility and repeatability of this bienzyme biosensor.

In addition, the stability of this bienzyme biosensor was tested in 0.10 M phosphate buffer (pH = 7.4) containing 1.0 mM glucose. The current response was deteriorated gradually and maintained at a level of about 70 % of the original after a week and about 50 % after 2 weeks, which may be resulted by the denaturation of HRP and GOx. Also, the performance of this biosensor is compared with other RGO based glucose biosensors. The results are illustrated in Table 1. The fabricated biosensor for glucose determination shows a wider linear range. The beauty of this sensor is the low applied potential of −0.10 V which can not only reduce the interferences from coexisting biomolecules in sample at high potential but also can avoid the effect of oxygen reduction at cathodic potential. Lastly, our biosensor has been successfully applied to the real sample analysis. The glucose concentration of 5.7 mM in plasma sample confirmed reliability of this method.

Conclusions

An amperometric biosensor for glucose and H2O2 determination was developed by co-immobilization HRP and GOx immobilized in pTB film on RGO modified glassy carbon electrode. Thanks to RGO film with special electronic characteristics and pTB film as electron transfer mediator, this biosensor performed sensitive detection of glucose and H2O2 at a very low potential of −1.0 V (vs. SCE), which can greatly reduce the interference from ascorbic acid (AA), uric acid (UA, 0.01 M) l-tryptophan (l-Trp), l-aspartic acid (l-Asp), l-lysine (l-Lys) and γ-aminobutyric acid (GABA). Moreover, amperometric responses of glucose and H2O2 were well-behaved with displaying Michaelis-Menten kinetics. The Low Km values indicated that high enzymatic activity of HRP and GOx can be maintained in pTB film, suggesting that this bienzyme system exhibited high biologically affinity to glucose and H2O2. Under optimized experimental conditions glucose can be determined in the 80 μM to 3.0 mM range with a detection limit of 50 μM. H2O2, in turn, can be quantified in up to 30.0 μM concentration with a detection limit of 0.2 μM. Based on wide linear range, good stability and reproducibility of the biosensor, it was applied to glucose determination in real sample. The result of 5.7 mM in plasma sample was satisfactory and confirmed reliability of this method.

References

Yang W, Ratinac KR, Ringer SP, Thordarson P, Gooding JJ, Braet F (2010) Carbon nanomaterials in biosensors: should you use nanotubes or graphene. Angew Chem 49(12):2114–2138

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2007) Electric field effect in atomically thin carbon films. Science 306(5969):666–669

Lei W, Si W, Xu Y, Gu Z, Hao Q (2014) Conducting polymer composites with graphene for use in chemical sensors and biosensors. Microchim Acta 181:707–722

Chen D, Feng H, Li J (2012) Graphene oxide: preparation, functionalization, and electrochemical applications. Chem Rev 112:6027–6053

Zhou M, Zhai Y, Dong S (2009) Electrochemical sensing and biosensing platform based on chemically reduced graphene oxide. Anal Chem 81:5603–5613

Li D, Muller MB, Gilje S, Kaner RB, Wallace GG (2008) Processable aqueous dispersions of graphene nanosheets. Nat Nano 3(2):101–105

Park S, Ruoff RS (2009) Chemical methods for the production of graphenes. Nat Nanotechnol 4(4):217–224

Schniepp HC, Li JL, McAllister MJ, Sai H, Herrera-Alonso M, Adamson DH, Prud’homme RK, Car R, Savill DA, Aksay IA (2006) Functionalized single graphene sheets derived from splitting graphite oxide. J Phys Chem B 110(17):8535–8539

Stankovich S, Dikin DA, Piner RD, Kohlhaas KA, Kleinhammes A, Jia Y, Wu Y, Nguyen ST, Ruoff RS (2007) Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45(7):1558–1565

Yang S, Lu Z, Luo S, Liu C, Tang Y (2013) Direct electrodeposition of a biocomposite consisting of reduced graphene oxide, chitosan and glucose oxidase on a glassy carbon electrode for direct sensing of glucose. Microchim Acta 180:127–135

Shao Y, Wang J, Wu H, Liu J, Aksay IA, Lin Y (2010) Graphene based electrochemical sensors and biosensors: a review. Electroanal 22(10):1027–1036

Liu S, Yan J, He G, Zhong D, Chen J, Shi L, Zhou X, Jiang H (2012) Layer-by-layer assembled multilayer films of reduced graphene oxide/gold nanoparticles for the electrochemical detection of dopamine. J Electroanal Chem 672:40–44

Palanisamy S, Ku S, Chen S-M (2013) Dopamine sensor based on a glassy carbon electrode modified with a reduced graphene oxide and palladium nanoparticles composite. Microchim Acta 180:1037–1042

Bai J, Jiang X (2013) A facile one-pot synthesis of copper sulfide-decorated reduced graphene oxide composites for enhanced detecting of H2O2 in biological environments. Anal Chem 85:8095–8101

Teymouriana H, Salimia A, Khezriana S (2013) Fe3O4 magnetic nanoparticles/reduced graphene oxide nanosheets as a novel electrochemical and bioeletrochemical sensing platform. Biosens Bioelectron 49:1–8

Sudibya HG, He Q, Zhang H, Chen P (2011) Electrical detection of metal ions using field-effect transistors based on micropatterned reduced graphene oxide films. ACS Nano 5(3):1990–1994

Du M, Yang T, Li X, Jiao K (2011) Fabrication of DNA/graphene/polyaniline nanocomplex for label-free voltammetric detection of DNA hybridization. Talanta 88:439–444

Wang J (2005) Carbon-nanotube based electrochemical biosensors: a review. Electroanal 17:7–14

Kang X, Wang J, Wu H, Aksay IA, Liu J, Lin Y (2009) Glucose oxidase-graphene-chitosan modified electrode for direct electrochemistry and glucose sensing. Biosens Bioelectron 25(4):901–905

Lei C, Hu S, Shen G, Yu R (2003) Immobilization of horseradish peroxidase to a nano-Au monolayer modified chitosan-entrapped carbon paste electrode for the detection of hydrogen peroxide. Talanta 59(5):981–988

Manesh KM, Kim HT, Santhosh P, Gopalan AI, Lee KP (2008) A novel glucose biosensor based on immobilization of glucose oxidase into multiwall carbon nanotubes-polyelectrolyte-loaded electrospun nanofibrous membrane. Biosens Bioelectron 23(6):771–779

Shan C, Yang H, Song J, Han D, Ivaska A, Niu L (2009) Direct electrochemistry of glucose oxidase and biosensing for glucose based on graphene. Anal Chem 81(6):2378–2382

Wang W, Wang F, Yao Y, Hu S, Shiu KK (2010) Amperometric bienzyme glucose biosensor based on carbon nanotube modified electrode with electropolymerized poly(toluidine blue O) film. Electrochim Acta 55(23):7055–7060

Cheng N, Wang H, Li X, Yang X, Zhu L (2012) Amperometric glucose biosensor based on integration of glucose oxidase with palladium nanoparticles/reduced graphene oxide nanocomposite. Am J Anal Chem 3(4):312–319

Palanisamy S, Karuppiah C, Chen S (2014) Direct electrochemistry and electrocatalysis of glucose oxidase immobilized on reduced graphene oxide and silver nanoparticles nanocomposite modified electrode. Colloids Surf B: Biointerfaces 114:164–169

Yang MH, Choi BG, Park HS, Park TJ (2011) Directed self-assembly of gold nanoparticles on graphene-ionic liquid hybrid for enhancing electrocatalytic activity. Electroanalysis 23(4):850–857

Bai X, Chen G, Shiu KK (2013) Electrochemical biosensor based on reduced graphene oxide modified electrode with Prussian blue and poly(toluidine blue O) coating. Electrochim Acta 89:454–460

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80(6):1339

Guo S, Dong S, Wang E (2008) Gold/platinum hybrid nanoparticles supported on multiwalled carbon nanotube/silica coaxial nanocables: preparation and application as electrocatalysts for oxygen reduction. J Phys Chem C 112(7):2389–2393

Matsumoto R, Mochizuki M, Kano K, Ikeda T (2002) Unusual response in mediated biosensors with an oxidase/peroxidase bienzyme system. Anal Chem 74(14):3297–3303

De Benedetto GE, Palmisano F, Zambonin PG (1996) One-step fabrication of a bienzyme glucose sensor based on glucose oxidase and peroxidase immobilized onto a poly(pyrrole) modified glassy carbon electrode. Biosens Bioelectron 11(10):1001–1008

Kamin RA, Wilson GS (1980) Rotating ring-disk enzyme electrode for biocatalysis kinetic studies and characterization of the immobilized enzyme layer. Anal Chem 52(8):1198–1205

Luo Z, Yuwen L, Han Y, Tian J, Zhu X, Weng L, Wang L (2012) Reduced graphene oxide/PAMAM–silver nanoparticles nanocomposite modified electrode for direct electrochemistry of glucose oxidase and glucose sensing. Biosens Bioelectron 36:179–185

Acknowledgments

This work was supported by the National Scientific Foundation of China (NSFC NOs. 21375101 and 60801020), the Fundamental Research Funds for the Central Universities (2042014kf0295), and Natural Science Foundation of Hubei Province (ZRY2014000492), Wuhan Science and Technology Bureau (No: 20140601010057).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, F., Gong, W., Wang, L. et al. Enhanced amperometric response of a glucose oxidase and horseradish peroxidase based bienzyme glucose biosensor modified with a film of polymerized toluidine blue containing reduced graphene oxide. Microchim Acta 182, 1949–1956 (2015). https://doi.org/10.1007/s00604-015-1535-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-015-1535-3