Abstract

We present a study on the application of magnetic nanoparticles (MNPs) prepared from Fe3O4 and functionalized with pyridine as an adsorbent for the solid-phase extraction of trace quantities of Pd(II) ion. The pyridine group was immobilized on the surface of the MNPs by covalent bonding of isonicotinamide. The modified MNPs can be readily separated from an aqueous solution by applying an external magnetic field. Effects of pH, the amount of functionalized MNPs, extraction time, type and quantity of eluent, desorption time, break-through volume and interfering ions on the extraction efficiency were optimized. The amount of Pd(II) was then determined using FAAS. Under the optimized conditions, the detection limit and preconcentration factor are 0.15 μg L-1 and 196, respectively, and the relative standard deviation (at 20 μgL−1; for n = 10) is 3.7 %. The method had a linear analytical range from 1 to 80 μg L-1 and was applied to determine Pd(II) in spiked tape water and soil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Palladium is an element with increasing demands in today’s industries. In 2007, an amount of 192 t of palladium has been sold in the world market. The main demands are automotive catalyst (55 %), electronics (17 %), jewellery (11 %) and dentistry (9 %) [1], especially due to the catalytic properties it is widely used in the synthesis of many materials. Unfortunately, elevated level of palladium compared to geochemical background [2] has been found in airborne particulate matter [3], road dust [4–6], soil [7, 8] and grass [9]. Anthropogenic palladium has been reported to be mobile and bioaccumulated by aquatic organisms and generally to a larger extent than other platinum group elements [10–13]. Moreover, metallic palladium has an allergenic potential on humans [14]. Therefore, monitoring of palladium in environmental samples has great importance with respect to estimation of the future risk of the human health and the ecosystem. The toxicity of palladium demands for practical techniques to remove it from environment. In addition, because of the high economical value of palladium, its separation even in trace amounts is beneficial. Some of the valuable techniques, including ET-AAS [15, 16], ICP-AES [17], FAAS [18], ICP-MS [19] and total reflection XRF-spectrometry [20] have been used for palladium determination. The above mentioned methods suffer from some sensitivity and selectivity limitations for real samples [15–20]. Preconcentration of palladium from dilute or complex samples increases sensitivity and selectivity. Liquid based extraction and solid phase extraction (SPE) are the two techniques which have found widespread applications on the determination of palladium. Liquid-liquid extraction [21], cloud point extraction [15–22] and dispersive liquid-liquid microextraction [23] are some liquid based methods which have been applied for preconcentration and determination of palladium. SPE is flexible in choice of adsorbent and operation, and is referred to liquid-liquid extraction in the viewpoint of simplicity, cleanness, low reagent and organic consumption and also high enrichment ability. SPE has been extended for the preconcentration of palladium traces prior to determination [24]. Different solid phases such as activated carbon [25], polyurethane foam [26], amberlite XAD resins [27] and modified silica gel [17–28] have been used for preconcentration-determination of palladium.

In recent years, magnetite nanoparticles (MNPs) have been widely used as an efficient class of adsorbents [29–31]. Using nano-size magnetic particles for selective separation and preconcentration in analytical chemistry may result in the development of a new methodology that is quicker, simpler and more precise than existing methodologies. The greatest advantage of this procedure is that the desired materials can be separated from sample solution by a simple and compact process producing fewer secondary wastes. Other advantages are the large active surface area for a given mass of particles; the ability to process solutions that contain suspended solids; the avoidance of channeling effects that are common in packed beds; and the ability to immobilize the target particles at a specific location in a column by the application of an external magnetic field. Earlier works suggest that magnetic micro- and nanoparticles have widespread application as separation tools in the purification of nucleic acids, proteins and peptides, bacteria, and metals, because of their ability to agglomerate quickly and re-suspend in response to changes in magnetic forces.

In this research, for the first time magnetic nanoparticles are functionalized with pyridine groups and used for extraction of trace amounts of palladium ions from real samples. The effects of the pH, the amount of functionalized magnetic nanoparticle, extraction time, type and the smallest amount of eluent for elution of palladium ions, desorption time, break through volume and effect of coexisting ions on the separation and determination of palladium ions were investigated. This method was applied to determine palladium ions in several environmental samples, and also the accuracy was confirmed by two standard materials.

Experimental and methods

Reagents and materials

All analytical grade reagents were purchased from Merck (Darmstadt, Germany, www.merck.de) or from Fluka (Buchs SG, Switzerland, www.sigmaaldrich.com) and used without further purification. The following buffer solutions were used for various pHs: pH 1 and 2, KCl/HCl, pH 4–6 CH3COOH/CH3COONH4, pH 6–8 Na2HPO4/NaH2PO4 and pH 8–10 NH3/NH4Cl. The standard solution of palladium(II), 1000 mg L-1, 3-aminopropyltriethoysilane, oxalyl chloride and 4-pyridine carboxylic acid were purchased from Merck. All solutions were prepared using deionized water.

Apparatus

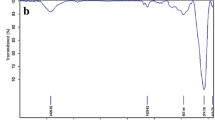

Palladium concentration was determined by an AA-680 Shimadzu (Kyoto, Japan) flame atomic absorption spectrometer (FAAS) in an air-acetylene flame, according to the user’s manual, provided by the manufacturer. Palladium hollow cathode lamp was used as the radiation source with wavelength of 244.8 nm. The pH was measured at 25 ± 1 °C with a digital WTW Metrohm 827 Ion analyzer (Herisau, Switzerland) equipped with a combined glass-calomel electrode. A vacuum pump was obtained from Leybold (Cologne, Germany) and an adjustable vacuum gauge and controller were obtained from Analytichem International (Harber City, CA). The Fourier Transform Infrared (FT-IR) spectrum was recorded on a BOMEM MB-Series FT-IR spectrometer in the form of KBr pellets. The morphology of Py-Fe3O4 was observed on a Philips XL-30 scanning electron microscope. The thermal stability study of the Py-Fe3O4 was carried out using a thermal analyzer (TGA/DTA BAHR: STA 503) under air with heating rate of 10 °C min-1. 1H NMR spectrum was recorded on a BRUKER DRX-300 AVANCE spectrometer at 300 MHz. The elemental analyses (CHN) were performed on a Thermo Finnigan Flash-1112EA microanalyzer. Specific surface area was measured by nitrogen adsorption technique using a Micrometitis ASPS 2010 analyzer.

Preparation of Fe3O4 magnetic nanoparticles

Fe3O4 nanoparticles were synthesized according to the previously reported procedure [32] and their formation was established by X-ray powder diffraction. X-ray diffraction pattern of the prepared adsorbent was shown in Electronic Supplementary Material (ESM, Figure S1). Single point BET analysis showed surface area of 319 m2·g-1 for the prepared Fe3O4 nanoparticles.

Preparation of pyridine functionalizing agent

N-3-(triethoxysilyl)propyl)isonicotinamide (TPI) was synthesized according to the earlier report [33, 34] and characterized by 1H NMR. For synthesis of TPI, in a 250 mL two-neck round-bottom flask, equipped with a magnetic stir bar and a reflux condenser, 2.0 g (16 mmol) of 4-pyridine carboxylic acid was suspended in 100 mL of dried CH2Cl2 under nitrogen atmosphere. To this solution 5 mL of oxalylchloride was slowly added from a dropping funnel and mixture was stirred for 12 h. Then CH2Cl2 was removed under reduced pressure, and the residue was suspended again in 100 mL of dried CH2Cl2. After addition of 7 mL triethylamine to reaction mixture, 4.0 g 3-aminopropyltrimethoxysilane was slowly added. The reaction mixture was stirred at room temperature for further 4 h and then the mixture was suspended in water in order to remove any impurities. The organic phase separated and solvent was removed under reduced pressure to obtain brownish viscose oil. The synthesis of TPI was confirmed by 1H NMR [0.61 ppm (t, 2H), 0.61 ppm (t, 2H), 1.65 ppm (m, 2H), 3.36 ppm (m, 2H), 3.72 ppm (q, 6H), 7.24 ppm (s, 1H), 7.57 ppm (d, 2H), 8.60 ppm (d, 2H)].

Preparation of pyridine functionalized Fe3O4 nanoparticles

In a typical reaction, 1.0 g of Fe3O4 nanoparticles was suspended in 70 mL of toluene, afterward 1.0 g of TPI was added and the mixture was refluxed for 24 h. The solid phase was filtered from the solvent and washed 3 times with 50 mL of ethanol in order to remove any impurities and then dried at room temperature. Functionalization of pyridine functionalized Fe3O4 nanoparticles was confirmed by XRD pattern, IR spectroscopy, thermal and elemental analyses.

Real sample pretreatment

The water samples were obtained from distilled, tap (Tehran, Iran), sea water (Caspian Sea and Persian Gulf), spring and lake water and soil sample was collected from Mouteh gold mine (Iran). Two mine stone samples with a certified palladium content, which was reported by the Geological Survey of Iran, were obtained. The water samples were stored in cleaned polyethylene bottles and were filtered through nylon filters (Millipore) before the analysis. Certified reference material and soil samples were digested in an 8 mL mixture of 5 % aqua regia with the aid of a microwave digestion system. Digestion was carried out for 2 min at 250 W, 2 min at 0 W, 6 min at 250 W, 5 min at 400 W, and 8 min at 550 W, and the mixture was then vented for 8 min. The residue from this digestion, as well as a control digestion was then diluted with deionized water [35]. Finally, the pH of each solution was adjusted to 3 to separate and preconcentrate Pd(II) ions from the water samples.

Extraction procedure

A portion of sample solution containing the studied ions was transferred to a 500 mL beaker, the pH values was adjusted to desired value with 0.1 mol L−1 HNO3 and 0.1 mol L−1 NH3·H2O, and the final volume was diluted to desired volume. Then, 15 mg of adsorbent was added, and the solution was shaken for 4 min to facilitate adsorption of the Pd(II) onto the modified MNP. Then the magnetic adsorbent was separated readily by using a strong flat permanent magnet and the supernatants were decanted directly, washed with 5 mL deionized water and then decanted directly. Finally, 2.5 mL of 0.5 mol L-1 thiourea in 0.4 mol L-1 HCl was added as eluent and shaken for 5 min and the eluted ions were determined by FAAS.

Results and discussion

Sorbent characterization

The Fe3O4 nano-particles and pyridine functionalizing agent (TPI) have been synthesized according to previous report [32, 33]. The reaction of pyridine functionalizing agent and Fe3O4 nano-particles caused formation of this sorbent. Formation of this pyridine functionalized nano-particles was confirmed by IR spectroscopy, elemental analysis, XRD, thermal analysis and SEM micrograph. IR spectrum in KBr matrix was as follow (cm-1): 3023 (CH, aromatic), 2918 (CH, aliphatic), 1563 and 1471(C=C, aromatic) and 1399 (C=N). The X-ray diffraction pattern shows that the Fe3O4 nanoparticles remained intact after functionalization (no decomposition or converting to Fe2O3). According to the thermal analysis, this sorbent has high thermal stability (up to 220 °C). The amount of pyridine concentration on the surface of Fe3O4 nanoparticles was determined by weight lose in the thermogram (ESM, Figure S2). About, 16 % weight loses showed a pyridine concentration of 0.96 mmol g-1. Elemental analysis of functionalized Fe3O4 with TPI (4-Py-Fe3O4) gave pyridine concentration of 0.973 mmol g-1. The SEM micrograph of 4-Py-Fe3O4 is illustrated in Fig. 1. A schematic diagram of pyridine-functionalized Fe3O4 is presented in Fig. 2.

Optimization experiments

Extraction and preconcentration of palladium ions on Py-Fe3O4 NPs were highly dependent on the different parameters such as pH of the sample, extraction time, type, volume and concentration of eluent, desorption time, sample volume and concentration of coexisting ions. In this context, the procedure was optimized for the various analytical parameters.

Effect of pH

To study the effect of pH on the extraction, the pH of 25 mL of different sample solutions containing 2 mg L−1 palladium was adjusted in the range of 2–8. The obtained results in Fig. 3 indicate that the Pd(II) ions could be retained quantitatively on functionalized Fe3O4 NPs in the pH range of 2–6. The results suggest that adsorption has two mechanisms: ion pair and coordination ability. In pH ranges from 2 to 6, pyridine is protonated and an ion-pair complex with PdCl 2-4 forms. Formation of this ion pair increases the sorption efficiency. In high pH conditions (pH > 6), pyridine is deprotonated and cannot produce ion-pair complex with PdCl 2-4 . Therefore, pH 3.0 was chosen as the optimum pH for further studies.

Effect of the adsorbent amounts

Compared to conventional sorbents (microsized adsorbents), NPs offer a significantly higher surface area-to-volume ratio and a short diffusion route, which results in high extraction capacity, rapid extraction dynamics and high extraction efficiencies. Also, MNPs can be rapidly collected from sample solution by applying magnetically assisted separation, thus shorter extraction times can be achieved. Therefore, satisfactory results can be obtained with fewer amounts of these adsorbents. For the optimization of the amount of adsorbent, 5, 10, 15, 20, 25, and 30 mg of the MNP were tested. In the present work, by increasing amounts of the Py-Fe3O4 NPs due to increase in the surface area and accessible sites to the adsorption of the analytes, the extraction efficiency increased. Quantitative extraction of the palladium ions was achieved using only 15 mg of the Py-Fe3O4 NPs. At higher amounts of the adsorbent, the extraction efficiency was almost constant.

Equilibrium sorption time

In order to investigate the effect of shaking time on the extraction efficiency, extraction experiments were carried out at 2, 4, 7, 12, and 20 min time intervals. According to the results, an equilibration time of about 4 min was required for quantitative extraction of the analyte from solution into solid phase (ESM, Figure S3). Thus, the mixtures have been shaken for 4 min to reach equilibrium in the subsequent experiments.

Desorption condition

As the surface of Fe3O4 nano-particles coated with a silica layer, this composite is stable in high concentrations of acids without any leak of Fe3+ or Fe2+ in solution. So a series of selected eluent solutions, including HNO3, HCl, HCl/thiourea, HNO3/thiourea and CH3COOH were used for elution of palladium ions from Py-Fe3O4 NPs. The results show that 0.5 mol L-1 thiourea in 0.4 mol L-1 HCl is a suitable and effective eluent to elute palladium ions from Py-Fe3O4 NPs. The effect of eluent volume on the recovery of palladium ions was also studied (ESM, Table S1). Also the results show, quantitative recovery could be obtained with 2.5 mL of 0.5 mol L-1 thiourea in 0.4 mol L-1 HCl. Therefore, a 2.5 mL volume of eluent for desorption of palladium ions was used in the following experiments.

Desorption times were evaluated in the range of 2–20 min. The results showed that the time of 5 min is sufficient for quantitative desorption of the palladium ions by 2.5 mL of the 0.5 mol L-1 thiourea in 0.4 mol L-1 HCl.

Effect of sample volume

Due to the low concentrations of trace metals in real samples, by using samples with large volumes, the trace metals in these volumes should be taken into smaller volumes for high preconcentration factor. Hence, the maximum sample volume was optimized by the investigation of the recovery of palladium ion in various synthetic samples, volumes in the range of 50–1000 mL containing 0.01 mg of palladium was used to study. In the optimization of the sample volume, 15 mg of the sorbent was used. The recovery of Pd(II) ion from different volumes of aqueous solutions were shown in Electronic Supplementary Material (Figure S4). The recovery was found to be stable until 800 mL and was chosen as the largest sample volume to work.

Effect of interfering ions

Because of the presence of other elements in real samples, the determination and preconcentration of palladium ion is difficult. So, the effects of common coexisting cations and anions on the adsorption of palladium ions on the Py-Fe3O4 NPs were investigated. In these experiments, 100 mL of solution containing 0.01 mg palladium ions were added to interfering cations and anions and treated according to the recommended procedure. The results in Table 1 show that the vast majority of transition, alkaline, and earth alkaline metals do not interfere at environmentally relevant concentrations. This is due to the low capacity or rates of adsorption for interfering ions under optimum condition. Thus, these results confirm that the procedure using Py-Fe3O4 NPs is independent of matrix interferences.

Maximum adsorption capacity

In order to determine how much sorbent was required to quantitatively remove a specific amount of a metal ion from the solution, the capacity of the sorbent was calculated. To evaluate this factor, 500 mL of a solution containing 25 mg palladium ions underwent the extraction procedure, and the maximum capacity was calculated. A maximum adsorption capacity of 42.0 ± 2.0 mg g−1 was obtained for Py-Fe3O4 NPs. In order to evaluate the maximum adsorption capacity, the difference between concentration of the solution before passing through the column and the concentration of the solution after passing through the column was calculated.

Analytical performance

Under the optimum conditions described, the calibration curve was linear over a concentration range of 1–80 μg L−1 for 500 mL of standard solution. The least square equation at above dynamic linear range was as follows:

The limit of detection (LOD) of this method in the determination of palladium ion was studied under the optimal experimental conditions. The limit of detection, which is defined as CLOD = 3Sb/m, where Sb is the standard deviation of 10 replicate blank signals and m is the slope of the calibration curve after preconcentration, for a sample volume of 500 mL, was found to be 0.15 μg L-1 for palladium ion. The repeatability of the method was assessed by analyzing the same sample ten times. A relative standard deviation (RSD) of 3.7 % was achieved for a mean palladium concentration of 20.0 μg L-1. Since 500 mL of the solution was preconcentrated to 2.5 mL, the preconcentration factor of 196 was obtained with 98 % recovery. Statistical and calibration parameters are shown in Table 2.

Real sample analysis

Finally, this method was performed on real samples to check its accuracy. Since the amounts of palladium ion in real samples are too low, some amount of palladium ion was also spiked in these samples. To test the reliability of the method for extraction and determination of palladium ion in the water, soil samples and mine stone were applied. The results demonstrate that quantitative recoveries of palladium for Py-Fe3O4 NPs are achievable. The results are listed in Table 3.

Conclusions

In this work, for the first time, Fe3O4 nanoparticle was functionalized by pyridine and it was utilized as an adsorbent for the separation of ultra-trace amounts of palladium ion. This method is simple, rapid and reliable and found as a selective and sensitive method for the determination of trace levels of palladium ion. The most important characteristic of the Py-Fe3O4 NPs were shown excellent selectivity toward palladium ion over other ions. The convenient data was founds for detection limit and preconcentration factor in the determination of palladium ion and confirmed that this method using modified Fe3O4 nanoparticles has high potential for extraction of metals. As a result, the LOD and maximum adsorption capacity of this method is comparable or better than some of the previously reported preconcentration methods (Table 4).

References

Banham J, Annual Report & Accounts, Johnson Matthey, 2008, pp.19–20. Available at: <http://www.matthey.com/AR08/JMAR08.pdf>

Helmers E, Schwarzer M, Schuster M (1998) Platinum group elements in the environment. Anthropogenic impact. Comparison of palladium and platinum in environmental matrixes. Palladium pollution by automobile emissions. Environ Sci Pollut Res Int 5:44–50

Tilch J, Schuster M, Schwarzer M (2000) Determination of palladium in airborne particulate matter in a German city. Fresenius’ J Anal Chem 367:450–453

Boch K, Schuster M, Risse G, Schwarzer M (2002) Microwave-assisted digestion procedure for the determination of palladium in road dust. Anal Chim Acta 459:257–265

Kovacheva P, Djingova R (2002) Ion-exchange method for separation and concentration of platinum and palladium for analysis of environmental samples by inductively coupled plasma atomic emission spectrometry. Anal Chim Acta 464:7–13

Lesniewska BA, Godlewska-Zylkievicz B, Bocca B, Caimi S, Caroli S, Hulanicki A (2004) Platinum, palladium and rhodium content in road dust, tunnel dust and common grass in Bialystok area (Poland): a pilot study. Sci Tot Environ 321:93–104

Patel KS, Sharma PC, Hoffman P (2000) Graphite furnace-atomic absorption spectrophotometric determination of palladium in soil. Fresenius’ J Anal Chem 367:738–741

Ravindra K, Bencs L, Van Grieken R (2004) Platinum group elements in the environment and their health risk. Sci Tot Environ 318:1–43

Ely JC, Neal CR, Kulpa CF, Schneegurt MA, Seidler JA, Jain JC (2001) Implications of platinum-group element accumulation along U.S. roads from catalyticconverter attrition. Environ Sci Technol 35:3816–3822

Van de Velde K, Barbante C, Cozzi G, Moret I, Bellomi T, Ferrari C, Boutron C (2000) Changes in the occurrence of silver, gold, platinum, palladium and rhodium in Mont Blanc ice and snow since the 18th century. Atmos Environ 343:117–3127

Sures B, Zimmermann S, Messerschmidt J, von Bohlen A, Alt F (2001) First report on the uptake of automobile catalyst emitted palladium by European eels (Anguilla anguilla) following experimental exposure to road dust. Environ Pollut 113:341–345

Sures B, Thielen F, Zimmermann S (2002) Investigations on the bioavailability of traffic-related platinum group elements (PGE) to the aquatic fauna with special consideration being given to palladium. Umweltwissenschaften und Schadstoff-Forschung 14:30–36

Sures B, Zimmermann S, Messerschmidt J, Von Bohlen A (2002) Relevance and analysis of traffic related platinum groupmetals (Pt, Pd, Rh) in the aquatic biosphere, with emphasis on palladium. Ecotoxicology 11:385–392

Van Ketel WG, Ntebber C (1981) Allergy to palladium in dental alloys. Contact Dermatitis 7:331–357

Borges DLG, Silva da Veiga MAM, Frescura VLA, Welz B, Curtius AJ (2003) Cloud-point extraction for the determination of Cd, Pb and Pd in blood by electrothermal atomic absorption spectrometry, using Ir or Ru as permanent modifiers. J Anal At Spectrom 18:501–507

Zeini Jahromi E, Bidari A, Assadi Y, Milani Hosseini MR, Jamali MR (2007) Anal Chim Acta 585:305–311

Malyutina TM, Alekseeva TY, Dyachkova AV, Kudryavtseva GS, Berliner LD, Karpov YA (2010) Dispersive liquid–liquid microextraction combined with graphite furnace atomic absorption spectrometry: ultra trace determination of cadmium in water samples. Inorg Mater 46:1479–1482

Imamoglu M, Aydin AO, Dundar MS (2005) Determination of gold, palladium and copper by flame atomic absorption spectrometry after preconcentration on silica gel modified with 3-(2-aminoethylamino) propyl group. J Chem 3:252–262

Krishna MV, Ranjit M, Chandrasekaran K, Venkateswarlu G, Karunasagar D (2009) On-line preconcentration and recovery of palladium from waters using polyaniline (PANI) loaded in minicolumn and determination by ICP-MS; elimination of spectral interferences. Talanta 79:1454–1463

Van Meel K, Smekens A, Behets M, Kazandjian P, Van Grieken R (2007) Determination of platinum, palladium, and rhodium in automotive catalysts using high-energy secondary target X-ray fluorescence spectrometry. Anal Chem 79:6383–6389

Jamali MR, Assadi Y, Rahnama Kozani R, Shemirani F (2009) Homogeneous liquid-liquid extraction method for selective separation and preconcentration of trace amounts of palladium. E-J Chem 6:1077–1084

Ghaedi M, Shokrollahi A, Niknam K, Niknam E, Nijibi A, Soylak M (2009) Cloud point extraction and flame atomic absorption spectrometric determination of cadmium(II), lead(II), palladium (II) and silver(I) in environmental samples. J Hazard Mater 168:1022–1027

Ahmadzadeh Kokya T, Farhadi K (2009) Optimization of dispersive liquid–liquid microextraction for the selective determination of trace amounts of palladium by flame atomic absorption spectroscopy. J Hazard Mater 169:726–733

Rastegarzadeh S, Purreza N, Kiasat AR, Yahyavi H (2010) Selective solid phase extraction of palladium by adsorption of its 5(p-dimethylaminobenzylidene)rhodanine complex on silica-PEG as a new adsorbent. Microchim Acta 170:135–140

Chakrapani G, Mahanta PL, Murty DSR, Gomathy B (2001) Preconcentration of traces of gold, silver and palladium on activated carbon and its determination in geological samples by flame AAS after wet ashing. Talanta 53:1139–1147

Kang SW, Lee SS (1983) The extraction of palladium by polyurethane foam impregnated with β-diphenylglyoxime. J Korean Chem Soc 27:268–272

Elci L, Soylak M, Buyuksekerci EB (2003) Separation of gold, palladium and platinum from metallurgical samples using an amberlite XAD-7 resin column prior to their atomic absorption spectrometric determinations. Anal Sci 19:1621–1624

Tokalioglu S, Oymak T, Kartal S (2004) Determination of palladium in various samples by atomic absorption spectrometry after preconcentration with dimethylglyoxime on silica gel. Anal Chim Acta 511:255–260

Afkhami A, Saber-Tehrani M, Bagheri H, Madrakian T (2011) Flame atomic absorption spectrometric determination of trace amounts of Pb(II) and Cr(III) in biological, food and environmental samples after preconcentration by modified nano-alumina. Mirochim Acta 172:125–136

Zhang N, Peng H, Wang Sh HuB (2011) Fast and selective magnetic solid phase extraction of trace Cd, Mn and Pb in environmental and biological samples and their determination by ICP-MS. Microchim Acta 175:121–128

Eskandari H, Khoshandam M (2011) Sensitive and selective spectrophotometric determination of palladium(II) ion following its preconcentration using modified magnetite nanoparticles and 3-phasic backextraction. Microchim Acta 175:291–299

Liu X, Ma Z, Xing J, Liu H (2004) Preparation and characterization of amino–silane modified superparamagnetic silica nanospheres. J Magn Magn Mater 270:1–6

Hoogbomm J, Garcia PML, Otten MB et al (2005) Tunable command layers for liquid crystal alignment. J Am Chem Soc 127:11047–11052

Ebrahimzadeh H, Tavassoli N, Sadeghi O, Mn A, Jamali M (2011) Comparison of novel pyridine-functionalized mesoporous silicas for Au(III) extraction from natural samples. Microchim Acta 172:479–487

Zheng H, Zhang D, Wang WY, Fan YQ, Li J, Han HP (2007) Highly selective determination of palladium(II) after preconcentration using Pd(II)-imprinted functionalized silica gel sorbent prepared by a surface imprinting technique. Microchim Acta 157:7–12

Praveen RS, Daniel S, Rao TP, Sampath S, Rao KS (2006) Flow injection on-line solid phase extractive preconcentration of palladium(II) in dust and rock samples using exfoliated graphite packed microcolumns and determination by flame atomic absorption spectrometry. Talanta 70(2):437–443

Venkatesh G, Singh AK (2007) Enrichment and flame atomic absorption spectrometric determination of palladium using chelating matrices designed by functionalizing Amberlite XAD-2/16 and silica gel. Microchim Acta 159:149–155

Jamali MR, Assadi Y, Shemirani F, Salavati-Niasari M (2007) Application of thiophene-2-carbaldehyde-modified mesoporous silica as a new sorbent for separation and preconcentration of palladium prior to inductively coupled plasma atomic emission spectrometric determination. Talanta 71:1524–1529

Di P, Davey DE (1995) An optimized on-line preconcentration system for analysis of trace gold in ore samples. Talanta 42(5):685–692

Daniel S, Gladis JM, Prasada Rao T (2003) Synthesis of imprinted polymer material with palladium ion nanopores and its analytical application. Anal Chim Acta 488:173–178

Daniel S, Rao PP, Rao TP (2005) Investigation of different polymerization methods on the analytical performance of palladium(II) ion imprinted polymer materials. Anal Chim Acta 536:197–206

Yuan CG, Zhang Y, Wang Sh, Chang A (2011) Separation and preconcentration of palladium using modified multi-walled carbon nanotubes without chelating agent. Microchim Acta 173:361–367

Liang P, Zhao E (2011) Determination of trace palladium in complicated matrices by displacement dispersive liquid-liquid microextraction and graphite furnace atomic absorption spectrometry. Microchim Acta 174:153–158

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 457 kb)

Rights and permissions

About this article

Cite this article

Bagheri, A., Behbahani, M., Amini, M.M. et al. Preconcentration and separation of ultra-trace palladium ion using pyridine-functionalized magnetic nanoparticles. Microchim Acta 178, 261–268 (2012). https://doi.org/10.1007/s00604-012-0815-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-012-0815-4