Abstract

We describe a method for displacement dispersive liquid-liquid microextraction (DLLME) along with graphite furnace atomic absorption spectrometry for the determination of Pd(II) in complex environmental samples. In this method, Cu(II) is first complexed with diethyldithiocarbamate (DDTC), and the resultant Cu-DDTC complex added to a sedimented phase and submitted to DLLME. In the second step, the sedimented phase is dispersed into the sample solution containing Pd, and another DLLME procedure is carried out. The Pd ions can displace Cu ions from the pre-extracted Cu-DDTC complex because the stability of the Pd-DDTC complex is higher than that of Cu-DDTC. As a result, Pd is preconcentrated. Potential interferences by transition metal ions of lower complex stability can be largely reduced as they cannot displace Cu from the Cu-DDTC complex. The tolerance limits for such ions are better by 2 to 4 orders of magnitude compared to conventional DLLME. The typical sample volume is 5 mL, and an enhancement factor of 96 and a detection limit (3 s) of 7.6 ng L-1 are achieved.

A displacement dispersive liquid-liquid microextraction is developed for the preconcentration of Pd(II) from complicated environmental samples. Potential interferences by transitional metal ions of lower complex stability can be largely reduced, and the tolerance limits for such ions were better by 2 to 4 orders of magnitude compared to conventional DLLME.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, palladium (Pd) has found a variety of applications including medicine and dentistry, electrical products, chemical industry, automotive industry and jewelry because of its attractive physical and chemical properties, and results in significant amounts of Pd being released into the environment which finally lead to bioaccumulation in the living organisms through diverse pathways [1–3]. So, the development of reliable analytical methods for the determination of Pd is of great importance for the effective monitoring of pollution levels in the environment and critical evaluation of the possible risks for human health. The direct determination of Pd in environmental samples by atomic spectrometric techniques is usually difficult, and an initial sample pretreatment, such as preconcentration of the analyte and matrix separation, is often necessary [4]. Several methods have been reported for the separation and preconcentration of Pd, such as coprecipitation [5], liquid-liquid extraction (LLE) [6], solid-phase extraction (SPE) [7–9] and cloud point extraction (CPE) [10, 11], but the disadvantages such as time-consuming, unsatisfactory enrichment factors and using large organic solvents, limit their applications.

Dispersive liquid-liquid microextraction (DLLME) is a novel liquid-liquid extraction protocol based on ternary component solvent systems [12]. DLLME method has the advantages of simplicity of operation, rapidity, low cost, high recovery and enrichment factors, and has been proved to be a suitable preconcentration procedure for various metal ions [13, 14]. In conventional DLLME preconcentration of metal ions, hydrophobic metal-chelate formation is the first step. Obviously, many ligands have little selectivity towards metal ions. In other words, competition for the complexing agent from other transitional metal ions with target analyte cannot be avoided, and this may cause undesirable interferences. In fact, all metal-chelate based preconcentration systems have encountered such problems. Adding of a masking agent or increasing the concentration of the complexing agent is a choice, but the effectiveness may be marginal and the risk of contamination could be created. Recently, Yan et al. have successfully developed a displacement-sorption preconcentration protocol for highly selective quantification of metal ions in complicated matrices [15]. The principle of this technique is based on the stability difference of metal complexes. The targeted metal (M1) with higher complex stability (M1-L, L is the ligand) can take the place the other metal (M2) with lower complex stability from its complex (M2-L), whereas the reverse reaction cannot occur. Through the displacement reaction, interferences from the co-existing ions due to the competition for the ligand could be greatly reduced. This displacement-sorption preconcentration method has been successfully applied for the determination of mercury, methylmercury, palladium and silver in various environmental and biological samples [16–20]. A displacement-cloud point extraction coupled was also developed by employing the same principle, and applied for the selective determination of silver [21].

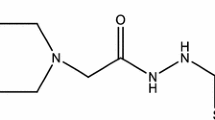

In this work, the displacement reaction principle was employed in dispersive liquid-liquid microextraction and a displacement-dispersive liquid-liquid microextraction (D-DLLME) method was developed for the selective determination of Pd. In the D-DLLME method, diethyldithiocarbamate (DDTC) was selected as the chelating agent and Cu was employed as the pre-extraction metal ion, and the DLLME procedure was carried out twice during a single sample pretreatment process: firstly, Cu was complexed with DDTC and subjected to DLLME process; then the obtained sedimented phase was dispersed into the sample solution containing Pd with methanol and another DLLME process was carried out. Because the stability of Pd-DDTC is greater than that of Cu-DDTC, Pd can replace Cu from the pre-extracted Cu-DDTC complex and enter the sedimented phase. After centrifugation, the sedimented phase was subjected to graphite furnace atomic absorption spectrometry (GFAAS) determination. The stability of metal-DDTC complex decreases in order: HgII>PdII>AgI>CuII>TlIII>NiII>BiIII>PbII>CoIII>CoII>CdII>TlI>ZnII>InIII>SbIII>FeIII>TeIV>MnIII>MnII [22, 23], only Hg, Pd and Ag can displace Cu from the complex of Cu-DDTC. Therefore, the interference arising from the competition for DDTC by transitional metal ions with Pd in conventional DLLME was largely reduced, while the selective preconcentration of Pd was achieved.

Experimental

Apparatus

A TBS-990 atomic absorption spectrophotometer (Beijing Purkinge General Instrument Co. Ltd, Beijing, China, www.pgeneral.com) with a deuterium background correction and a GF990 graphite furnace atomizer system was used. A palladium hollow-cathode lamp was used as radiation source at 247.6 nm. The optimum operating parameters for GFAAS are given in Table 1. All measurements were carried out in the integrated absorbance (peak area) mode. The pH values were measured with a Mettler Toledo 320-S pH meter (Mettler Toledo Instruments CO. LTD, Shanghai, China, cn.mt.com). A Model 0412–1 centrifuge (Shanghai Surgical Instrument Factory, Shanghai, P. R. China, www.jzsf.com) was used to accelerate the phase separation.

Standard solution and reagents

Stock standard solution (100 μg mL−1) of Pd was obtained from the National Institute of Standards (Beijing, China, www.nrccrm.org.cn). Working standard solutions were obtained by appropriate dilution of the stock standard solution. The solution of DDTC was prepared by dissolving appropriate amount of sodium diethyldithiocarbamate (AR, Shanghai Chemistry Reagent Company, Shanghai, China) in methanol. All other reagents used were of the highest available purity and of at least analytical reagent grade. Doubly distilled water was used throughout. Pipettes and vessels in the experiments were kept in 10% nitric acid for at least 24 h and subsequently washed four times with double distilled water.

Displacement dispersive liquid-liquid microextraction procedure

Aliquots of 5.0 mL sample solution containing 10 μg mL−1 Cu, 0.05 mg mL−1 DDTC and 0.03 mol L−1 HNO3 was placed in a 10 mL screw cap glass test tube with conic bottom. The amount of 0.5 mL of methanol (dispersive solvent) containing 48 μL of carbon tetrachloride (CCl4, extraction solvent) was injected rapidly into the sample solution by using 1.00 mL syringe. A cloudy solution (water, methanol, and CCl4) was formed in the test tube, and the complex of Cu with DDTC was extracted into the fine droplets of CCl4. Then, the solution was centrifuged at 3500 rpm for 5 min, and the dispersed fine droplets of CCl4 were deposited at the bottom of conical test tube (about 38 μL). After removing the aqueous phase, the sedimented phase was dissolved with 0.2 mL methanol and injected into 5.0 mL sample solution containing Pd and 0.1 mol L−1 HNO3, another cloudy solution was formed and incubated for 5 min. In this step, Pd can replace Cu from the pre-extracted Cu-DDTC complex and enter into the extraction solvent phase. After centrifuging, 20 μL of the sedimented phase (about 25 μL) at the bottom of conical test tube was removed using a 50 μL microsyringe and injected into GFAAS for the determination of Pd.

Calibration was performed against aqueous standards submitted to the same D-DLLME procedure. A blank submitted to the same procedure described above was measured parallel to the sample and calibration solutions.

Samples preparation

Three certified reference materials (GBW07289 soil, GBW07291 peridotite and GBW07293 low-grade platinpalladium ore, obtained from Perambulation Institute of Physical Geography and Geochemistry of Geological and Mineral Ministry, Langfang, P. R. China, www.iggeinfo.com) were used to check the accuracy of the developed method. The compositions of the reference materials could be found in the website of the supplier (www.gbw114.org). All samples were roasted in a temperature of 600 °C for 1 h. Portion (10.0 g) of the dried samples were accurately weighed into a PTFE vessel, treated with 20 mL of concentrated HCl and 10 mL of concentrated HNO3, and digested under pressure at a temperature of 150 °C for 3 h. The sample was evaporated with two portions of 5 mL concentrated hydrofluoric acid to remove silica. Finally, 5 mL of concentrated HCl were added and the solution was evaporated almost to dryness. The residue was dissolved in 0.1 mol L−1 HNO3, and the solution was made up to 50 mL with distilled water

Results and discussion

DLLME has been proved to be a suitable preconcentration procedure for various metal ions [7]. The optimal conditions of the extraction solvent and dispersive solvent for the DLLME preconcentration of Cu and Pd have been studied in the previous works [24, 25], and used directly in the first extraction process of this work. For this work, the extraction efficiency depends on the displacement reaction between Pd and Cu-DDTC. Systematic optimization of the conditions affecting the displacement reaction was therefore carried out to obtain the optimal performance of the D-DLLME procedure.

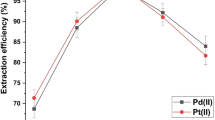

Pre-extraction solution acidity and sample solution acidity

The pre-extraction solution acidity (the acidity of Cu solution) influences the formation of the Cu-DDTC complex and its pre-extraction, and subsequent displacement extraction. Its effect on the absorbance signal of Pd was investigated in the range of 0–0.6 mol L−1 HNO3, and the result was shown in Fig. 1. The highest signal of Pd was obtained when HNO3 concentration was 0.03 mol L−1. Therefore, 0.03 mol L−1 HNO3 was selected for the pre-extraction process.

Effect of the acid concentration of the pre-extraction solution and the sample solution on the displacement DLLME of Pd. Other experimental conditions: Cu, 10 μg mL−1; Pd, 0.5 ng mL−1; sample volume, 5.0 mL; dispersive solvent (methanol) volume, the pre-extraction, 0.5 mL, the displacement extraction, 0.2 mL; extraction solvent (CCl4) volume, 48 μL; DDTC concentration, 0.05 mg mL−1

The sample solution acidity (the acidity of Pd solution) influences the stability of Pd-DDTC complex and the displacement reaction. The effect of sample acidity on the absorbance signal of Pd was investigated in the range of 0–0.6 mol L−1 HNO3, and the result was also present in Fig. 1. It can be seen that the high signal of Pd was obtained at a HNO3 concentration range of 0.05–0.5 mol L−1. So 0.1 mol L−1HNO3 was used for the sample solution in the second extraction process.

Effect of DDTC concentration

The concentration of DDTC has a direct effect on the formation of the Cu-DDTC complex and its pre-extraction, as well as the displacement reaction between Pd and Cu-DDTC. The effect of DDTC concentration on the absorbance signal of Pd was investigated in the range of 0–0.5 mg mL−1, and the result was shown in Fig. 2. It can be seen that the absorbance signal of Pd increased with the increase of DDTC concentration up to 0.05 mg mL−1, and then remained constant. In order to minimize the background caused by DDTC, a DDTC concentration of 0.05 mg mL−1 was selected for the further study.

Effect of DDTC concentration on the displacement DLLME of Pd. Other experimental conditions: Cu, 10 μg mL−1; Pd, 0.5 ng mL−1; sample volume, 5.0 mL; HNO3 concentration, 0.03 mol L−1 in the pre-extracted solution and 0.1 mol L−1 in the sample solution; dispersive solvent (methanol) volume, the pre-extraction, 0.5 mL, the displacement extraction, 0.2 mL; extraction solvent (CCl4) volume, 48 μL

Effect of Cu concentration

The Cu concentration influences the amount of pre-extracted Cu-DDTC and subsequent the displacement reaction. Studies on the effect of Cu concentration showed that the absorbance signal of Pd increased with the increase of Cu concentration until 10 μg mL−1 and then remained constant with further increase in Cu concentration up to 20 μg mL−1. For further experiments, a Cu concentration of 10 μg mL−1 was used.

Effect of volume of the dispersive solvent

In the second extraction process, the sedimented phase of the first extraction process was dispersed into the sample solution using methanol as the dispersive solvent. The effect of the volume of methanol on the absorbance signal of Pd was studied and shown in Fig. 3. As can be seen, the absorbance signal of Pd decreased remarkably after the volume of methanol exceeded 0.20 mL. In order to disperse the sedimented phase sufficiently, 0.20 mL methanol was used as the dispersive solvent in the second extraction process.

Effect of methanol volume on the displacement DLLME of Pd. Other experimental conditions: Cu, 10 μg mL−1; Pd, 0.5 ng mL−1; sample volume, 5.0 mL; HNO3 concentration, 0.03 mol L−1 in the pre-extracted solution and 0.1 mol L−1 in the sample solution; dispersive solvent volume in the pre-extraction, 0.5 mL; extraction solvent (CCl4) volume, 48 μL

Effects of extraction time

In the second DLLME procedure, the extraction time may affect the displacement reaction between Pd and Cu-DDTC and the extraction efficiency. The effect of extraction time was examined in the range of 30 s to 20 min with the constant experimental conditions. The obtained results showed that the absorbance signal of Pd remains constant after the extraction time exceeded 5 min. So an extraction time of 5 min was employed in the second DLLME procedure.

Effects of interfering ions

To demonstrate the selectivity of the developed D-DLLME method for the determination of Pd, the effects of several potentially interfering species on the determination of 1.0 ng mL−1 Pd were carefully studied and the results were shown Table 2, and the results for the conventional DLLME method were also present [25]. Compared with the conventional DLLME method, the developed D-DLLME method gave over two orders of magnitude improvement in the tolerable limit of transitional heavy metal ions. In the case of Hg, the low tolerable limit was observed due to its higher stability of DDTC complexes over Pd-DDTC. The low tolerable limit for Ag is due to the fact that Ag can also displace Cu from Cu-DDTC. However, the content of Hg and Ag is usually not higher than the tolerable limit in many common samples. Large amounts of alkaline and alkaline earth metal ions have no interferences on the D-DLLME extraction of Pd because they can not complex with DDTC or displace Cu from Cu-DDTC. These results clearly demonstrated the high selectivity of the developed D-DLLME method for the determination of trace Pd.

Detection limits and precision

For the purpose of quantitative analysis, a calibration curve for Pd with concentrations ranging over four orders was obtained and extracted under the optimal conditions. Linearity was observed over the range of 0.05–8.0 ng mL−1 with a correlation coefficient (r) of 0.9986. The limit of detection (LOD), based on a signal-to-noise ratio (S/N) of 3, was 7.6 ng L−1. The precision of this method was determined by analyzing standard solution at 0.1 ng mL−1 of Pd for seven times in continuous, and the relative standard deviation (R.S.D) was 4.5%. The enhancement factor, calculated as the ratio of the analytical signal of Pd obtained after and before extraction, was 96 for 5.0 mL sample solution.

Table 3 compares the characteristic data of the present method with those reported in literatures. Generally, the enrichment factor obtained by the present method is comparable to those reported methods, and the detection limit is better than them. The higher enrichment factor reported in reference 9 was obtained by using 500 mL of sample solution.

Analytical application

In order to establish the validity of the method, it has been applied to determine Pd in three environmental certified reference materials (GBW07289 soil, GBW07291 peridotite and GBW07293 low-grade platinpalladium ore). The analytical results are given in Table 4. As can be seen, the determined values were in good agreement with the certified values despite the complicated matrices of these samples.

Conclusion

The results obtained in this work demonstrated that the developed D-DLLME preconcentration with GFAAS determination is a simple, rapid, selective and sensitive method for the determination of Pd in complicated samples. The method effectively minimized the interference from transitional metal ions without the need of any masking reagents. The method was shown to be promising for routine application for the determination of trace amount of Pd in relatively complicated matrices.

References

Rao CRM, Reddi GS (2000) Platinum group metals (PGM); occurrence, use and recent trends in their determination. Trends Anal Chem 19:565–586

Merget R, Rosner G (2001) Evaluation of the health risk of platinum group metals emitted from automotive catalytic converters. Sci Total Environ 270:165–173

Ravindra K, Bencs L, Grieken RV (2004) Platinum group elements in the environment and their health risk. Sci Total Environ 318:1–43

Godlewska-Zylkiewicz B (2004) Preconcentration and separation procedures for the spectrochemical determination of platinum and palladium. Microchim Acta 147:189–210

Soylak M, Tuzen M (2008) Coprecipitation of gold(III), palladium(II) and lead(II) for their flame atomic absorption spectrometric determinations. J Hazard Mater 152:656–661

Anthemidis AN, Themelis DG, Stratis JA (2001) Stopped-flow injection liquid-liquid extraction spectrophotometric determination of palladium in airborne particulate matter and automobile catalysts. Talanta 54:37–43

Ojeda CB, Rojas FS, Pavon JMC (2007) On-line preconcentration of palladium(II) using a microcolumn packed with a chelating resin, and its subsequent determination by graphite furnace atomic absorption spectrometry. Microchim Acta 158:103–110

Jamali MR, Assadi Y, Shemirani F, Salavati-Niasari M (2007) Application of thiophene-2-carbaldehyde-modified mesoporous silica as a new sorbent for separation and preconcentration of palladium prior to inductively coupled plasma atomic emission spectrometric determination. Talanta 71:1524–1529

Hassanien MM (2009) FAAS determination of palladium after its selective recovery by silica modified with hydrazone derivative. Microchim Acta 167:81–89

Shemirani F, Kozani RR, Jamali MR, Assadi Y, Hosseini MRM (2006) Cloud-point extraction, preconcentration, and spectrophotometric determination of palladium in water samples. Inter J Environ Anal Chem 86:1105–1112

Tavakoli L, Yamini Y, Ebrahimzadeh H, Nezhadali A, Shariati S, Nourmohammadian F (2008) Development of cloud point extraction for simultaneous extraction and determination of gold and palladium using ICP-OES. J Hazard Mater 152:737–743

Herrera-Herrera AV, Asensio-Ramos M, Hernandez-Borges J, Rodriguez-Delgado MA (2010) Dispersive liquid-liquid microextraction for determination of organic analytes. Trends Anal Chem 29:728–751

Zang XH, Wu QH, Zhang MY, Wang Z (2009) Developments of dispersive liquid-liquid microextraction technique. Chinese J Anal Chem 37:161–168

Anthemidis AN, Ioannou KIG (2009) Recent developments in homogeneous and dispersive liquid-liquid extraction for inorganic elements determination: A review. Talanta 80:413–421

Yan XP, Li Y, Jiang Y (2002) A flow injection on-line displacement/sorption preconcentration and separation technique coupled with flame atomic absorption spectrometry for the determination of trace copper in complicated matrices. J Anal Atom Spectrom 17:610–615

Li Y, Jiang Y, Yan XP, Ni ZM (2002) Determination of trace mercury in environmental and foods samples by online coupling of flow injection displacement sorption preconcentration to electrothermal atomic absorption spectrometry. Environ Sci Technol 36:4886–4891

Dong LM, Yan XP, Li Y, Jiang Y, Wang SW, Jiang DQ (2004) On-line coupling of flow injection displacement sorption preconcentration to high-performance liquid chromatography for speciation analysis of mercury in seafood. J Chromatogr A 1036:119–125

Yan XP, Li Y, Jiang Y (2003) Selective measurement of ultratrace methylmercury in fish by flow injection on-line microcolumn displacement sorption preconcentration and separation coupled with electrothermal atomic absorption spectrometry. Anal Chem 75:2251–2255

Fang J, Jiang Y, Yan XP, Ni ZM (2005) Selective quantification of trace palladium in road dusts and roadside soils by displacement solid-phase extraction online coupled with electrothermal atomic absorption spectrometry. Environ Sci Technol 39:288–292

Christou CK, Anthemidis AN (2009) Flow injection on-line displacement/solid phase extraction system coupled with flame atomic absorption spectrometry for selective trace silver determination in water samples. Talanta 78:144–149

Wu P, Gao Y, Cheng GL, Yang WS, Lv Y, Hou XD (2008) Selective determination of trace amounts of silver in complicated matrices by displacement-cloud point extraction coupled with thermospray flame furnace atomic absorption spectrometry. J Anal At Spectrom 23:752–757

Bode H (1954) Systematische untersuchungen uber die anwendbarkeit der diathyldithiocarbaminate in der analyse. Fresenius Z Anal Chem 142:414–423

Briscoe GB, Humphries S (1969) An investigation of the diethyldithio-carbamates of palladium, including the determination of their stability constants. Talanta 16:1403–1419

Farajzadeh MA, Bahram M, Mehr BG, Jonsson JA (2008) Optimization of dispersive liquid-liquid microextraction of copper (II) by atomic absorption spectrometry as its oxinate chelate: Application to determination of copper in different water samples. Talanta 75:832–840

Liang P, Zhao EH, Li F (2009) Dispersive liquid-liquid microextraction preconcentration of palladium in water samples and determination by graphite furnace atomic absorption spectrometry. Talanta 77:1854–1857

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, P., Zhao, E. Determination of trace palladium in complicated matrices by displacement dispersive liquid-liquid microextraction and graphite furnace atomic absorption spectrometry. Microchim Acta 174, 153–158 (2011). https://doi.org/10.1007/s00604-011-0611-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-011-0611-6