Abstract

We describe a method for ionic liquid based dispersive liquid-liquid microextraction of Co(II), Cu(II), Mn(II), Ni(II) and Zn(II), followed by their determination via flow injection inductively coupled plasma optical emission spectrometry. The method is making use of the complexing agent 1-(2-thenoyl)-3,3,3-trifluoracetone, the ionic liquid 1-hexyl-3-methyl imidazolium bis(trifluoromethylsulfonyl)imide, and of ethanol as the dispersing solvent. After extraction and preconcentration, the sedimented ionic liquid (containing the target analytes) is collected, diluted with 1-propanol, and introduced to the ICP-OES. Effects of pH, ionic strength, ligand to metal molar ratio, volumes of extraction and disperser solvents on the performance of the microextraction were optimized in a half-fractional factorial design. The significant parameters were optimized using a face-centered central composite design. The method has detection limits between 0.10 and 0.20 ng mL−1 of the metal ions, preconcentration factors between 79 and 102, linear responses in 0.25 to 200 ng mL−1 concentration ranges, and relative standard deviations of 3.4 to 6.0%. The method was successfully applied to the analysis of drinking water, a fish farming pond water, and waste water from an industrial complex.

Ionic liquid based dispersive liquid-liquid microextraction of Co, Cu, Mn, Ni and Zn followed by determination via flow injection inductively coupled plasma optical emission spectrometry

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The pollution of rivers and streams with chemical contaminants has become one of the most critical environmental problems of the century. Heavy metals as persistent environmental contaminants are of great importance amongst chemical pollutants. At trace levels several heavy metals such as Mn, Zn, Cu, Co and Ni are essential micronutrients for plants, living organisms and the human body whilst most of them are toxic or even carcinogenic at high concentrations. Typically they enter the body via the food chain, ambient air or drinking water. As a consequence, contamination levels in urban and industrial waste water need to be controlled and strict regulations have been drawn up and proposed in this regard. Compliance with the regulations requires evaluation of robust, reliable, sensitive and environmental friendly analytical methods and instruments. However, in many cases where the sample matrices are complex or the concentration of elements fall below the detection limit values of common techniques of trace metal determination such as flame or electrothermal atomic absorption spectroscopy (FAAS and ETAAS) and inductively coupled plasma-optical emission spectrometry (ICP-OES), a separation or preconcentration method such as solid phase extraction or microextraction [1–6], ion exchange [7, 8], cloud point [9, 10] and liquid-liquid extraction or microextraction [11] must be applied.

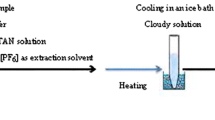

Dispersive liquid-liquid microextraction (DLLME) utilizes the use of a few milliliters of water-soluble disperser solvents such as methanol, acetonitrile or acetone to disperse microliter volume of water-immiscible extraction solvent into the aqueous medium [12]. In this method, a cloudy solution is formed right after injecting the mixture of extraction and disperser solvents into the aqueous sample where the distribution of the target analytes from sample into the organic solvent takes place. Since its introduction, DLLME has been successfully applied for extraction of organic [13–16] and inorganic [17–20] species in different samples. Despite its several powerful aspects, DLLME’s main drawback lays in the choice of the extraction solvent. In this microextraction technique, solvents of higher densities than water are preferred which are not often compatible with instruments such as ICP-OES and reversed-phase high-performance liquid chromatography (RP-HPLC).

Ionic liquids (ILs) applied at room or non-ambient (controlled) temperatures are considered as relatively recent chemicals of unique properties. Since the first use of an ionic liquid as an alternative to traditional volatile organic solvents for two-phase liquid-liquid separations in 1998 [21], in many cases ILs have demonstrated advantages compared to common solvents used in separation and extraction processes. Liu et al. reported that ILs can be used as extraction solvents in liquid-phase microextraction (LPME), the authors found that the ILs [C6mim] [PF6] and [C8mim] [PF6] both outperformed 1-octanol in direct-immersion and headspace LPME of United States Environmental Protection Agency (US-EPA) high priority polycyclic aromatic hydrocarbons (PAHs) [22]. Several studies have been carried out investigating extraction capability of various types of ILs in different liquid phase microextraction approaches isolating organic [23–32] and inorganic [33–37] species. ILs unique properties has led to evolution of new concepts of phase separation in microextraction techniques based on direct contact of extraction and sample phases such as temperature-controlled ionic liquid based dispersive liquid-liquid microextraction [38] and dispersive liquid–liquid microextraction using an in situ metathesis reaction to form an ionic liquid extraction phase [39].

The major aim of this study is to find a substitute for common DLLME extraction solvents which can be introduced to ICP-OES without further need for either time-consuming evaporation, solidification or any manipulation. This paper represents the practical procedure, characteristics and application of conjoining a green ionic liquid based dispersive liquid-liquid microextraction (IL-DLLME) with FI-ICP-OES for determination of cobalt, copper, manganese, nickel and zinc in various environmental water samples.

Experimental

Apparatus

A radial view Varian Vista-Pro simultaneous inductively coupled plasma optical emission spectrometry (Springvale, Australia, www.varianinc.com) equipped with a V-groove nebulizer and Scott spray chamber utilizing a charge coupled device (CCD) as detector was applied for determination of target elements. The flow-injection (FI) manifold consisted of an adjustable injection loop, made of silicon tube, connected to a six-port two-position injection valve (Tehran University, Iran), in which the 1-propanol/water mixture (80:20% v/v) was used as the eluting solvent. The loop volume was adjusted in order to enable introduction of the entire extraction IL volume in each steps of optimization and real sample analysis. FI-ICP-OES optimal operating conditions and employed spectral lines of the elements are shown in Table 1.

The pH measurement and adjustment was performed using an Inolab WTW pH meter (Weilheim, Germany, www.wtw.com) equipped with a combined electrode.

Chemicals and reagents

Stock standard solutions (1000 mg L−1) of Co(II), Cu(II), Mn(II) and Y(III) were prepared by dissolving proper amounts of analytical grade CoCl2.6H2O, Cu(NO3)2.3H2O, MnCl2.4H2O and Y(NO3)3.H2O salts from Merck (Darmstadt, Germany, www.merck-chemicals.com) in ultra-pure water. Ni(II) and Zn(II) standard stock solutions (1000 mg L−1) were purchased from Sigma–Aldrich (Milwaukee, WI, USA, www.sigmaaldrich.com). Mixed working standard solutions were prepared by diluting the stock solutions with ultra-pure water and in case of the internal standard solution of 5 mg L−1 Y3+ with 1-propanol.

Solutions of chelating agents 1-(2-thenoyl)-3,3,3-trifluoracetone (TTA) and 1-(2-pyridilazo)-2-naphthol (PAN) (reagent grade, Merck) were prepared in methanol in 0.5 M concentration.

Ionic liquids 1-hexyl-3-methyl imidazolium bis(trifluoromethylsulfonyl)imide [C6mim][Tf2N] and 1-hexyl-3-methyl imidazolium hexafluorophosphate [C6mim][PF6] were purchased from KimiaExir (Tehran, Iran, www.kimiaexir.com). Ethanol, methanol, acetone, acetonitrile, ammonium acetate, nitric acid, sodium hydroxide and sodium chloride, were obtained from Merck. 1-Propanol was purchased from Panreac (Barcelona, Spain, www.panreac.es). The ultra-pure water was purified using an aquaMAX–Ultra Younglin Ultra-pure water purification system (Seoul, South Korea, www.younglin.com).

Peak area calculation and experimental design softwares

Integration was performed using the freeware CHROMuLAN version 0.79 from PiKRON Ltd (Prague, Czech Republic, www.pikron.com) to which the spectral data were loaded in txt format.

Experimental design data analysis was performed by using the software Design-Expert trial version 7.0.0 from Stat-Ease Inc (Minneapolis, MN, USA, www.statease.com).

Procedure of ionic liquid based dispersive liquid-liquid microextraction (IL-DLLME)

A 30.0 mL portion of sample containing 50 mM of ammonium acetate solution was placed in a 45 mL screw cap glass tube and spiked with 1-(2-thenoyl)-3,3,3-trifluoracetone (TTA), as complexing agent, after appropriate pH (8.0) adjustment, 4 mL of ethanol containing 210 μL of [C6mim][Tf2N] ionic liquid was injected into the sample solution. A cloudy solution was formed and extraction was completed rapidly. After centrifugation for 10 min at 4200 rpm, the upper solution was removed and the 100 μL sedimented IL containing target analytes was collected, diluted with 100 μL 1-propanol and introduced to ICP-OES by the flow injection manifold.

Sample preparation

Sample collection, preservation and storage were all performed according to the US-EPA method 200.7 [40]. Samples were collected in polyethylene bottles, filtered through a 0.45 μm pore diameter membrane filter and acidified with nitric acid to pH below 2.0 following filtration. All samples were preserved at 4 °C before analysis.

Results and discussion

Ionic liquid as extraction solvent and its introduction to ICP-OES

Selection of the extraction solvent is considered a key step of all liquid phase microextraction techniques. In traditional DLLME organic solvents are selected on the basis of their higher density than water, extraction capability of interested compounds along with good instrumental behavior. As a result, halogenated hydrocarbons such as chlorobenzene, chloroform, carbon tetrachloride and tetrachloroethylene are the most widely used solvents. However, there have been reports on application of low density solvents, either collected by using especially designed vials [41] or solidification of the floating organic drop [42], still the traditional sedimentation is the most convenient and widely used way of collecting the organic solvent due to unavailability of the designed vials or the time-consuming solidification step.

Introduction of organic solvents to the ICP-OES usually results in plasma cooling, instability or even shut down due to high vapor pressure and intensive background emission of such solvents, whereas such phenomena are not observed for 1-propanol. Lower vapor pressure of 1-propanol (b.p. 98 °C) resembling water more than commonly used organic solvents such as methanol, ethanol and acetonitrile and its miscibility with both aqueous and organic media, either pure or mixed with water, has led to its application as the eluting solvent for easy introduction of different types of solvents to the ICP-OES without any plasma instability problem or need for further manipulation or evaporation of the solvent [43]. Nevertheless, with the use of 1-propanol as the eluting solvent not every type of organic solvents can be introduced to the ICP-OES. High vapor pressure and emissive behavior of the halogenated hydrocarbons, considered as the traditional DLLME extraction solvents, would lead to plasma shut down when applied directly and would result in plasma instability and baseline intensive drift when applied as a 1:1 mixture with 1-propanol. In this regard, non-volatile dense ionic liquids can be applied as the suitable substitutes of common halogenated extraction solvents. The ionic liquid used in the current study ([C6mim][Tf2N]) was selected due to its less solubility in water, less viscosity which enables volumetric measurements with high surface area syringes and better emissive behavior in ICP-OES compared to [C6mim][PF6]. Figure 1 compares the emissive behaviour of common dense solvents and the suggested IL introduced to the FI-ICP-OES. It represents injection of 1:1 mixture of CHCl3, CH2Cl2 and chlorobenzene in 1-propanol; each 2 injections in a row as well as the effect of [C6mim][Tf2N]/1-propanol 1:1 mixture injection on the FI-ICP-OES baseline. The smooth and stable baseline for IL injection proves its compatibility with ICP-OES.

Complexing agent effect

The ionic liquid was insufficient for extraction of the charged metal ions, it was necessary to improve their affinity for the IL phase by complex formation with a suitable reagent. Imidazolium based ILs present a high chemical affinity towards compounds containing one or more aromatic rings in their structures [44]. TTA and PAN, two complexing reagents containing aromatic rings, were tested and TTA was found to be more efficient one for extraction of target metal ions as shown in Fig. S1 (Electronic Supplementary Material, ESM). The extracted species were anionic M(TTA) -3 for M = Mn, Co, Ni and Zn and neutral M(TTA)2 in case of Cu [45].

Selection of disperser solvent

The choice of the disperser solvent was done considering its miscibility with the IL phase and aqueous sample. Two milliliters of acetonitrile, acetone, methanol and ethanol containing proper amount of the IL to obtain the same settled phase volume were evaluated and as demonstrated in Fig. S2 (ESM) ethanol yielded the highest peak area.

Experimental design and data analysis

A half fractional factorial design was employed in 20 runs containing 4 center points to investigate the most influential of the five variables including A: salt% (0-10%), B: pH (3.0–9.0), C: ligand to metal molar ratio (5.0–30.0), D: volume of the extraction solvent (100–250 μL) and E: volume of the disperser solvent (1.0–6.0 mL) affecting the extraction of the target elements. The total normalized peak area was used as the response. The normalization was done by using Eq. 1, where M j represents M = Co, Cu, Mn, Ni and Zn with j = 1–5 values, i refers to the run number (i = 1–20) and k refers to the run having the smallest peak area values amongst the entire runs. As the Pareto chart in Fig. 2 presents, all of the factors apart from salt% were evaluated influential at the 0.05% level so salt addition was excluded from the optimization step.

A face-centered central composite design (FC-CCD) consisting of 30 runs including 6 center points was applied to optimize the four factors of effectiveness chosen in the screening design. Some of the obtained response surfaces are shown in Fig. 3. As Table 2 represents the predicted optimal response and the observed experimental responses concurred.

Effect of potentially interfering elements

The impact of potentially interfering elements on the extraction and determination of heavy metals was investigated adding different amounts of Na+, K+, Li+, Mg2+, Ba2+, Ca2+, Al3+, Hg2+, Pb2+ and Fe3+ into the tested sample solution containing 100 ng mL−1 of the target elements. The experimental results are shown in Table 3. The tolerance limit is defined as the highest amount of potentially interfering element which results in the recovery of the studied species in the 90–110% interval. Amongst the aforesaid elements, two had to be masked with suitable masking agents; Al3+ was masked with F- in order to form soluble aluminum complexes preventing its precipitation as Al(OH)3 at the extraction pH of 8.0. Fe3+ was also masked with SCN- due to its high affinity for complex formation with TTA compared to those of target elements as a result of which extraction in its presence resulted in very low extraction recoveries of the desired elements.

Analytical performance

Under the optimized extraction conditions, the analytical performance of the developed method in terms of enhancement factor, detection limit, linearity and repeatability was evaluated in ultra-pure water, the results are shown in Table 4. The calibration curves were obtained after the standard series were subjected to the IL-DLLME followed by introduction to FI-ICP-OES as described previously. It is noteworthy to mention that the diluting 1-propanol contained Y3+ as internal standard, in this regard peak area of each point of the curves was divided to its analogous Y3+ peak area at 377.433 nm.

Table 5 offers a comparative vision of the characteristics of the current method with previously developed methods. As it shows, the evaluated method offers comparable analytical performance along with rapid and sensitive trace multi-element analysis.

Real sample analysis

To evaluate the practical applicability of the developed method, determination of target elements concentration was done in three different environmental water samples consisting of fish farming pond water, factory waste water and tap water. Farming pond water sample was collected from water outlets of a salmon farming pond constructed in one of the Haraz river branches in north of Iran. Factory waste water was the final outfall of waste water treatment plant of one of the Iran’s largest automobile industrial complexes. Tap water, the main source of the city inhabitants drinking water, was collected from Tehran city tap water. The results are given in Table S1 (ESM). As the recovery values of the spiked samples were not in the range of 90-110% for the last two samples, the standard addition approach was used for quantification of the target elements.

Conclusion

High sample throughput, low detection limits, sensitivity and reproducibility are some of the advantages offered by the IL-DLLME-FI-ICP-OES method, combining DLLME as an efficient, rapid preconcentration method and ICP-OES as a powerful sensitive multi-element determination technique has created a powerful method of trace metal analysis in different matrices. Application of the current method for determination of the target elements in different water samples showed satisfactory results, implying robustness of this combination. To the best of our knowledge, this is the first work reporting the introduction of the green unique ionic liquids to the ICP-OES. This can lead to the use of task-specific ILs for simultaneous selective extraction and speciation of different metallic species by the ICP-OES. Furthermore the current study introduces a new concept for introduction of ILs to the coupled separation-spectroscopic techniques such as HPLC-ICP-OES/MS widely used in drug-metabolite profiling [46]. Problems of introducing large amounts of organic solvents to the plasma in such systems may be overcome using 1-propanol, the plasma-compatible organic solvent, as the organic portion of the mobile phase [47].

References

Hutchinson S, Kearney GA, Horne E, Lynch B, Glennon JD, Anthony McKervey M, Harris SJ (1994) Solid phase extraction of metal ions using immobilised chelating calixarene tetrahydroxamates. Anal Chim Acta 291(3):269–275

Ramesh A, Devi BA, Hasegawa H, Maki T, Ueda K (2007) Nanometer-sized alumina coated with chromotropic acid as solid phase metal extractant from environmental samples and determination by inductively coupled plasma atomic emission spectrometry. Microchem J 86(1):124–130

Narin I, Soylak M, Elçi L, Dogan M (2000) Determination of trace metal ions by AAS in natural water samples after preconcentration of pyrocatechol violet complexes on an activated carbon column. Talanta 52(6):1041–1046

Leepipatpiboon V (1995) Trace enrichment by solid-phase extraction for the analysis of heavy metals in water. J Chromatogr A 697(1–2):137–143

Kaur V, Aulakh JS, Malik AK (2007) A new approach for simultaneous determination of Co(II), Ni(II), Cu(II) and Pd(II) using 2-thiophenaldehyde-3-thiosemicarbazone as reagent by solid phase microextraction-high performance liquid chromatography. Anal Chim Acta 603(1):44–50

Bulut VN, Gundogdu A, Duran C, Senturk HB, Soylak M, Elci L, Tufekci M (2007) A multi-element solid-phase extraction method for trace metals determination in environmental samples on Amberlite XAD-2000. J Hazard Mater 146(1–2):155–163

López-García I, Viñas P, Romero-Romero R, Hernández-Córdoba M (2009) Ion-exchange preconcentration and determination of vanadium in milk samples by electrothermal atomic absorption spectrometry. Talanta 78(4–5):1458–1463

Wang J, Hansen EH (2000) Coupling on-line preconcentration by ion-exchange with ETAAS: a novel flow injection approach based on the use of a renewable microcolumn as demonstrated for the determination of nickel in environmental and biological samples. Anal Chim Acta 424(2):223–232

Yamini Y, Faraji M, Shariati S, Hassani R, Ghambarian M (2008) On-line metals preconcentration and simultaneous determination using cloud point extraction and inductively coupled plasma optical emission spectrometry in water samples. Anal Chim Acta 612:144–151

Farajzadeh MA, Fallahi MR (2006) Simultaneous cloud-point extraction of nine cations from water samples and their determination by flame atomic absorption spectrometry. Anal Sci 22(4):635–639

Han D, Row K. Trends in liquid-phase microextraction, and its application to environmental and biological samples. Microchimica Acta, 1–22. doi:10.1007/s00604-011-0678-0

Rezaee M, Assadi Y, Milani Hosseini MR, Aghaee E, Ahmadi F, Berijani S (2006) Determination of organic compounds in water using dispersive liquid-liquid microextraction. J Chromatogr A 1116(1–2):1–9

Berijani S, Assadi Y, Anbia M, Milani Hosseini MR, Aghaee E (2006) Dispersive liquid-liquid microextraction combined with gas chromatography-flame photometric detection. Very simple, rapid and sensitive method for the determination of organophosphorus pesticides in water. J Chromatogr A 1123(1):1–9

Farajzadeh MA, Bahram M, Jönsson JA (2007) Dispersive liquid-liquid microextraction followed by high-performance liquid chromatography-diode array detection as an efficient and sensitive technique for determination of antioxidants. Anal Chim Acta 591(1 SPEC. ISS):69–79

Chang CC, Huang SD (2010) Determination of the steroid hormone levels in water samples by dispersive liquid-liquid microextraction with solidification of a floating organic drop followed by high-performance liquid chromatography. Anal Chim Acta 662(1):39–43

Nagaraju D, Huang SD (2007) Determination of triazine herbicides in aqueous samples by dispersive liquid-liquid microextraction with gas chromatography-ion trap mass spectrometry. J Chromatogr A 1161(1–2):89–97

Shokoufi N, Shemirani F, Assadi Y (2007) Fiber optic-linear array detection spectrophotometry in combination with dispersive liquid-liquid microextraction for simultaneous preconcentration and determination of palladium and cobalt. Anal Chim Acta 597(2):349–356

Zeini Jahromi E, Bidari A, Assadi Y, Milani Hosseini MR, Jamali MR (2007) Dispersive liquid-liquid microextraction combined with graphite furnace atomic absorption spectrometry. Ultra trace determination of cadmium in water samples. Anal Chim Acta 585(2):305–311

Mohammadi SZ, Afzali D, Baghelani YM (2009) Ligandless-dispersive liquid-liquid microextraction of trace amount of copper ions. Anal Chim Acta 653(2):173–177

Farajzadeh MA, Bahram M, Vardast MR (2009) Optimization of dispersive liquid-liquid microextraction of Co(II) and Fe(III) as their oxinate chelates and analysis by HPLC: application for the simultaneous determination of Co(II) and Fe(III) in water samples. J Sep Sci 32(23–24):4200–4212

Huddleston JG, Willauer HD, Swatloski RP, Visser AE, Rogers RD (1998) Room temperature ionic liquids as novel media for ‘clean’ liquid-liquid extraction. Chem Commun 16:1765–1766

Liu JF, Jiang GB, Chi YG, Cai YQ, Zhou QX, Hu JT (2003) Use of ionic liquids for liquid-phase microextraction of polycyclic aromatic hydrocarbons. Anal Chem 75(21):5870–5876

Liu J, Chi Y, Jiang G, Tai C, Peng J, Hu J (2004) Ionic liquid-based liquid-phase microextraction, a new sample enrichment procedure for liquid chromatography. J Chromatogr A 1026(1–2):143–147

Andre M, Loidl J, Laus G, Schottenberger H, Bentivoglio G, Wurst K, Ongania KH (2005) Ionic liquids as advantageous solvents for headspace gas chromatography of compounds with low vapor pressure. Anal Chem 77(2):702–705

Peng JF, Liu JF, Hu XL, Jiang GB (2007) Direct determination of chlorophenols in environmental water samples by hollow fiber supported ionic liquid membrane extraction coupled with high-performance liquid chromatography. J Chromatogr A 1139(2):165–170

Aguilera-Herrador E, Lucena R, Cárdenas S, Valcárcel M (2008) Direct coupling of ionic liquid based single-drop microextraction and GC/MS. Anal Chem 80(3):793–800

Basheer C, Alnedhary AA, Madhava Rao BS, Balasubramanian R, Lee HK (2008) Ionic liquid supported three-phase liquid-liquid-liquid microextraction as a sample preparation technique for aliphatic and aromatic hydrocarbons prior to gas chromatography–mass spectrometry. J Chromatogr A 1210(1):19–24

Cruz-Vera M, Lucena R, Cárdenas S, Valcárcel M (2008) Ionic liquid-based dynamic liquid-phase microextraction: application to the determination of anti-inflammatory drugs in urine samples. J Chromatogr A 1202(1):1–7

Zhou Q, Bai H, Xie G, Xiao J (2008) Trace determination of organophosphorus pesticides in environmental samples by temperature-controlled ionic liquid dispersive liquid-phase microextraction. J Chromatogr A 1188(2):148–153

Liu Y, Zhao E, Zhu W, Gao H, Zhou Z (2009) Determination of four heterocyclic insecticides by ionic liquid dispersive liquid-liquid microextraction in water samples. J Chromatogr A 1216(6):885–891

Mao T, Hao B, He J, Li W, Li S, Yu Z (2009) Ultrasound assisted ionic liquid dispersive liquid phase extraction of lovastatin and simvastatin: a new pretreatment procedure. J Sep Sci 32(17):3029–3033

Tao Y, Liu JF, Hu XL, Li HC, Wang T, Jiang GB (2009) Hollow fiber supported ionic liquid membrane microextraction for determination of sulfonamides in environmental water samples by high-performance liquid chromatography. J Chromatogr A 1216(35):6259–6266

Xia L, Li X, Wu Y, Hu B, Chen R (2008) Ionic liquids based single drop microextraction combined with electrothermal vaporization inductively coupled plasma mass spectrometry for determination of Co, Hg and Pb in biological and environmental samples. Spectrochim Acta Part B 63(11):1290–1296

Li S, Cai S, Hu W, Chen H, Liu H (2009) Ionic liquid-based ultrasound-assisted dispersive liquid-liquid microextraction combined with electrothermal atomic absorption spectrometry for a sensitive determination of cadmium in water samples. Spectrochim Acta Part B 64(7):666–671

Abdolmohammad-Zadeh H, Sadeghi GH (2010) Combination of ionic liquid-based dispersive liquid-liquid micro-extraction with stopped-flow spectrofluorometry for the pre-concentration and determination of aluminum in natural waters, fruit juice and food samples. Talanta 81(3):778–785

Majidi B, Shemirani F. Salt-assisted liquid-liquid microextraction of Cr(VI) ion using an ionic liquid for preconcentration prior to its determination by flame atomic absorption spectrometry. Microchimica Acta, 1–9. doi:10.1007/s00604-011-0711-3

Zeeb M, Sadeghi M (2011) Modified ionic liquid cold-induced aggregation dispersive liquid-liquid microextraction followed by atomic absorption spectrometry for trace determination of zinc in water and food samples. Microchimica Acta 175(1):159–165. doi:10.1007/s00604-011-0653-9

Bai H, Zhou Q, Xie G, Xiao J (2010) Temperature-controlled ionic liquid-liquid-phase microextraction for the pre-concentration of lead from environmental samples prior to flame atomic absorption spectrometry. Talanta 80(5):1638–1642

Yao C, Anderson JL (2009) Dispersive liquid-liquid microextraction using an in situ metathesis reaction to form an ionic liquid extraction phase for the preconcentration of aromatic compounds from water. Anal Bioanal Chem 395(5):1491–1502

US-EPA Method 200.7, Determination of metals and trace elements in water and wastes by inductively coupled plasma-atomic emission spectrometry, Revision 4.4, 1994

Saleh A, Yamini Y, Faraji M, Rezaee M, Ghambarian M (2009) Ultrasound-assisted emulsification microextraction method based on applying low density organic solvents followed by gas chromatography analysis for the determination of polycyclic aromatic hydrocarbons in water samples. J Chromatogr A 1216(39):6673–6679

Leong MI, Huang SD (2009) Dispersive liquid-liquid microextraction method based on solidification of floating organic drop for extraction of organochlorine pesticides in water samples. J Chromatogr A 1216(45):7645–7650

Saleh A (2006) MSc thesis: Extraction and measurement of total inorganic selenium in aqueous samples by on-line SPE ICP-AES, Tarbiat Modares University

Cassol C, Umpierre A, Ebeling G, Ferrera B, Chiaro S, Dupont J (2007) On the extraction of aromatic compounds from hydrocarbons by imidazolium ionic liquids. Int J Mol Sci 8(7):593–605

Kidani K, Hirayama N, Imura H (2008) Extraction behavior of divalent metal cations in ionic liquid chelate extraction systems using 1-alkyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imides and thenoyltrifluoroacetone. Anal Sci 24(10):1251–1254

Gammelgaard B, Packert Jensen B (2007) Application of inductively coupled plasma mass spectrometry in drug metabolism studies. J Anal At Spectrom 22(3):235–249

Faraji M, Yamini Y, Saleh A, Rezaee M, Ghambarian M, Hassani R (2010) A nanoparticle-based solid-phase extraction procedure followed by flow injection inductively coupled plasma-optical emission spectrometry to determine some heavy metal ions in water samples. Anal Chim Acta 659(1–2):172–177

Baliza PX, Teixeira LSG, Lemos VA (2009) A procedure for determination of cobalt in water samples after dispersive liquid-liquid microextraction. Microchem J 93(2):220–224

Jiang H, Qin Y, Hu B (2008) Dispersive liquid phase microextraction (DLPME) combined with graphite furnace atomic absorption spectrometry (GFAAS) for determination of trace Co and Ni in environmental water and rice samples. Talanta 74(5):1160–1165

Xia L, Wu Y, Hu B (2007) Hollow-fiber liquid-phase microextraction prior to low-temperature electrothermal vaporization ICP-MS for trace element analysis in environmental and biological samples. J Mass Spectrom 42(6):803–810. doi:10.1002/jms.1216

Farajzadeh MA, Bahram M, Mehr BG, Jönsson JÅ (2008) Optimization of dispersive liquid-liquid microextraction of copper (II) by atomic absorption spectrometry as its oxinate chelate: application to determination of copper in different water samples. Talanta 75(3):832–840

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 104 kb)

Rights and permissions

About this article

Cite this article

Ranjbar, L., Yamini, Y., Saleh, A. et al. Ionic liquid based dispersive liquid-liquid microextraction combined with ICP-OES for the determination of trace quantities of cobalt, copper, manganese, nickel and zinc in environmental water samples. Microchim Acta 177, 119–127 (2012). https://doi.org/10.1007/s00604-011-0757-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-011-0757-2