Abstract

This paper sets out an approach to assessing shear strength of rock joints at project scale based on measurement and analysis rather than empiricism. The role of direct shear testing in this process is discussed in detail and the need for dilation measurement and correction emphasised. Dilation-corrected basic friction angles are presented for various rock types. The characterisation of first and second order roughness features and their contribution to shear strength at project scale are discussed with reference to possible scale effects. The paper is illustrated by a case example of a spillway slope for a dam in the Himalayas.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Shear strength of discontinuities is an important parameter for many rock-engineering projects and requires the determination of fundamental frictional parameters together with characterisation and quantification of geological factors such as surface roughness, persistence and the nature and extent of infill for the discontinuity in situ. This paper discusses the practical assessment of shear strength and in particular the role of laboratory direct shear testing.

2 Definitions

There are significant differences between the terminology for rock and soil testing and as adopted in various publications and in ‘standards’ regarding rock mechanics, so the following terms can usefully be defined at this stage.

Discontinuity Definitions of what comprises a discontinuity or joint vary quite widely between geologists and engineers and between different international standards. Some current definitions are presented in Table 1. The International Society for Rock Mechanics (ISRM 1978) defines discontinuities as having zero or low tensile strength. This perception of a rock mass made up of rock blocks separated by extremely weak or open fractures is intrinsic in rock mass classifications including RQD (Deere 1968) and derivatives such as RMR & Q. The American Society for Testing Materials (ASTM 2008a) definition of ‘structural discontinuities’ encompasses features with considerable greater strength including cleavage and bedding. The current European standard lies somewhere in between.

In this paper the term discontinuity is used as the general term for a plane of relative weakness in rock such as a joint, fault, bedding plane, cleavage or schistosity––essentially the same definition as ASTM (2008a) and Hencher (1987). Hencher (2014) recommends classifying discontinuities as open, weak, moderate or strong, relative to the strength of the parent rock as an aid to categorising rock mass quality and to overcome the dilemma imposed by the narrow constraint of the ISRM definition. Obviously where infilled or mineralised (vein) this needs to be recorded as well.

Because joints are the most common discontinuities encountered in rock engineering, the word ‘joint’ is often used essentially synonymously and rather loosely with ‘discontinuity’ (other than faults) and that practice will be adopted here.

Most direct shear tests are carried out on open or infilled joints with zero or very low tensile strength, mostly because open defects are more critical for stability assessments. It is also far more difficult to interpret tests on incipient joints because strength depends so much on the degree of incipiency; this important but difficult subject area will not be dealt with any detail in this paper.

Peak shear strength is the maximum value of shear stress in the shear stress versus shear displacement curve for a given normal stress value. This often occurs relatively early on in a test run but under some conditions might occur later, for example where a thin, low friction veneer or polish is progressively damaged during testing. Where single values are selected for plotting as is common in commercial practice, care should be taken that the values selected are valid and representative. The procedure illustrated later in this paper whereby the stresses and stress ratios are plotted for a test run as a whole helps to isolate and identify any aberrant and unrepresentative data.

Residual or ultimate shear strength is the stress at which no further rise or fall in shear strength is observed with increasing shear displacement.

Basic friction is the frictional component of shear strength for a planar or effectively planar discontinuity i.e. independent of any roughness component causing dilation during shear.

Cohesion in the linear Mohr–Coulomb strength criterion is shear strength at zero normal load and is independent of normal stress level. Open rock discontinuities (with zero tensile strength) have no true cohesion. True cohesion occurs where the discontinuity has some tensile strength, for example where the discontinuity is incipient or where secondary mineralisation cements the two halves of the discontinuity. Apparent cohesion is the mathematical value of the intercept on the shear strength axis formed by the tangent to a non-linear shear strength envelope at a given level of normal stress. When shear strength data from a test on an open joint are corrected for dilation during shear, the apparent cohesion is generally zero.

3 Fundamentals of Shear Strength

3.1 Introduction

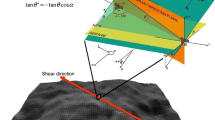

The factors contributing to the shear strength of rock discontinuities such as those illustrated in Fig. 1 are generally well understood empirically as illustrated schematically in Fig. 2. The main components are:

-

1.

True cohesion contributed by the strength of local ‘rock bridges’ consisting of intact rock or incipient defects.

-

2.

Roughness at a relatively large-field scale, causing interlocking and dilation. Large-scale undulations and waviness of the order of metres are termed first order; smaller scale roughness is termed second order (Patton and Deere 1970; ISRM 1978; Wyllie and Norrish 1996).

-

3.

Smaller asperity interaction and textural friction (basic friction) at the scale of rock core and laboratory test samples.

The contributions to shear strength made by persistence and first order (typically >0.5 m wavelength) and second order (typically 50–100 mm) roughness need to be characterised by field measurement. The contributions from relatively minor asperities over short profile lengths of 100 mm as incorporated in joint roughness coefficient (JRC), as presented in ISRM (1978), and from basic friction can be investigated using direct shear testing.

3.2 The Nature of ‘Basic Friction’

Open, planar discontinuities (non-dilating) exhibit purely frictional shear resistance that is directly proportional to normal stress. Remarkably, as for other materials, the basic friction angle of planar rock discontinuities is independent of the size of the surface being tested, in accordance with Amontons’ Second Law of friction (Amontons 1699). It is important to appreciate, however, that even apparently smooth surfaces are actually rough at a microscopic level as illustrated in Fig. 3.

3.3 Adhesion

The actual contact area between two surfaces deforms proportionally to carry the normal load (Archard 1958, 1974) and part of the basic frictional resistance is derived from adhesion at the actual areas of contact. Bowden and Tabor (1956) demonstrated this proportionality experimentally, primarily for metals. Power (1998) carried out similar experiments but used a rock-like model material that is electrically conductive. His results generally confirmed the importance of asperity contact deformation processes to rock friction (Power and Hencher 1996).

3.4 Textural Interlocking

The second component of basic friction is due to textural interlocking which leads to ploughing and deformation (Engelder and Scholtz 1976). Coulson (1971) demonstrated that frictional resistance of planar rock surfaces changes with textural roughness, rather like the tactile difference between fine and coarse sandpaper sheets. Polishing, either artificially or naturally as for a polished fault surface, will reduce the textural interlocking component of basic friction (Hencher 1976, 2012a, b). This component must be due to an increase in interlocking proportional to normal load, which is a slightly different mechanism than envisaged in the adhesional theory of friction as illustrated in Fig. 4.

For practical assessment of shear strength, the important observation is that the textural (tactile) component of basic friction can be increased (by roughening) up to the topological condition at which the upper block is forced to dilate under some particular applied normal stress. Conversely it can be reduced by polishing so that the basic friction is derived from adhesion alone, which is probably about 10° for most silicate minerals and rocks (see Lambe and Whitman 1979 for example).

The basic friction angle is a function of the surface texture, weathering and the mineral coating of the surface and can be very variable even for apparently planar surfaces. This may come as a surprise to many engineers and researchers, led to believe, from many papers and textbooks, that a unique lower bound friction angle can be measured for a flat discontinuity through rock. For example Alejano et al. (2012) found that the sliding angle of planar surfaces of rock in tilt tests can vary between 10° and 40° for a single granite block. Similar variability has perplexed other authors such as Nicholson (1994) who found that friction angles for saw-cut Berea Sandstone in direct shear tests varied by 12.5° despite great attention to sample preparation and reproducibility. Kveldsvik et al. (2008), in their investigations of the Åknes rock slope, found that the “basic friction angle” derived from tilt testing of core varied between 21° and 36.4°.

In summary it is a common misperception that a test on a saw-cut surface will (a) provide a unique basic friction angle, (b) be repeatable and (c) provide lower bound shear strength for some particular rock. It follows even more strongly that a basic friction angle relevant to the shear strength of a natural discontinuity cannot be measured on artificially prepared samples such as saw-cut surfaces as described in Hoek (2014) or by sliding drill core samples against one another (e.g. Simpson 1981), nor can it be measured by tilting table tests (USBR 2009). As an illustration of the importance that even minor textural variation can have on such tilt tests at low stress levels (let alone on rough interlocked rock surfaces), Fig. 5 shows two different tilt tests using blocks (steel, rock and brass), faced with sandpaper. In the first figure the brass slider in the foreground has slid at about 43° whilst the two blocks in the background are still stable. In the second test the rear blocks have slid at an angle of about 50°. The test was continued and the brass slider finally slid at 63°.

As illustrated in the rest of this paper, the way to derive meaningful basic friction angles for real geological discontinuities is by careful testing of natural joint samples and analysis of the results.

For completeness it is necessary to say something about ‘residual strength’ (some authors prefer the term “ultimate”). Some laboratories report the strength at the end of a direct shear test run (or sequence of test runs) on rock discontinuities as if it were some useful parameter in the same way as it is in some soil mechanics situations measured from a ring shear box (e.g. Skempton 1985). In the authors’ view the strength measured at the end of a test run on a natural rock joint sample is generally arbitrary, particular to that test, the original sample roughness and texture, the direction of testing and the normal stress under which the test was carried out, and has very little to do with any fundamental property of the rock discontinuity. Equating ‘residual strength’ with ‘basic friction’ or relating this to a test on a flat, machined surface of rock, as is sometimes proposed, makes even less sense. Of course some rock discontinuities, as per faults, in landslides or even as the result of inter-formational slip may have extremely low strength relating to the previous history of sliding. Determining realistic strengths for such features is, as ever, a matter of proper geological characterisation and appropriate testing and analysis.

4 Direct Shear Testing of Rock Discontinuities

4.1 Introduction

Laboratory testing is used for:

-

1.

Determination of the basic friction angle for naturally textured and coated discontinuities.

-

2.

Identification of surface features such as mineralogy and degree of polishing that affect shear strength over the applicable normal stress range.

-

3.

Observation of damage to minor asperities during shear at particular stress levels, thereby allowing judgement of which roughness features to allow for in design.

The ISRM gives some guidance on laboratory testing procedures (Brown 1981; Muralha et al. 2013), as does the American Society for Testing Materials (ASTM 2008b). Figure 6 shows idealised behaviour during a single stage of a direct shear test under constant normal load.

Idealised shear test data for a rough rock joint, with shear strength rising to a clear peak and then reducing to an “ultimate” or “residual” strength towards the end of the test run. It is redrawn from ISRM suggested method (Muralha et al. 2013). In this diagram, at peak strength the dilatancy angle, i°, is positive; at ultimate strength i° is negative

According to the ISRM suggested method, data from four different tests carried out at different normal loads can be combined to provide “peak” and “ultimate” or “residual” strength envelopes as shown in Fig. 7. It is then suggested that:

“The Mohr–Coulomb criteria are usually suitable to adequately model the results of rock joint shear tests. In this case, parameters of this linear failure criterion are defined as follows:

where c is apparent cohesion and \(\phi\) is friction angle”.

In practice direct shear tests on rock discontinuities seldom give such consistent results with well-defined shear strength envelopes. Different samples even with the same JRC can give very different strengths. The same is true for a single sample, tested in different directions (e.g. Kulatilake et al. 1999). This poses difficulties for interpretation. As an example, peak strength data from a recent commercial series of direct shear tests for a major European project, are presented in Fig. 8.

Data combined from four tests to derive peak and “ultimate” strength envelopes (redrawn from Muralha et al. 2013)

It would take a brave engineer to attempt to fit a Mohr–Coulomb equation to the data presented in Fig. 8 (yet this was done), let alone derive reliable design parameters.

Given the example in Fig. 8, which is not atypical, it is not surprising that many geotechnical engineers have little confidence in rock shear testing to provide useable data. Attewell (1993) argued that results from direct shear tests are “unlikely to have significant relevance to the shear strengths of discontinuities in situ”. Goodman (1995) dismissed direct shear testing of samples from boreholes on the basis that “specimen size for acceptable shear tests is quite large”. This is echoed in the recent ISRM document (Muralha et al. 2013) where it is stated that: “The best shear strength estimates are obtained from in situ direct shear tests as they inherently account for any possible scale effect.” The authors disagree with this statement, for various reasons, based on their experience of in situ tests and laboratory testing within major rock engineering projects––but it illustrates a common misperception.

With such opinions from leading authorities in rock engineering, it is no surprise that geotechnical engineers often rely on empiricism and the literature review rather than following a sampling/testing/analysis route. However, empirical approaches or assumptions based on prior experience can give rise to considerable error partly because of the extreme variability of rock discontinuity shear strengths which can range from friction angles less than 10° to strengths (friction and true cohesion) approaching that of the intact rock. Empirical methods also lack sensitivity with respect to geological variability.

One of the main difficulties for the geotechnical profession is that published guidelines and rock mechanics textbooks fail to address the way that test data need to be analysed or interpreted meaningfully at project scale. Furthermore, in practice, many commercial labs fail even to follow the ISRM guidelines, particularly with respect to the need to measure and report vertical and horizontal displacement at very frequent intervals; without such measurements direct shear tests on natural joints are meaningless.

4.2 Larger Asperity Interaction

At stress levels typical of many engineering projects, rough interlocking rock joints dilate during shear as relatively large, strong asperities come into contact. Figure 9 shows one half of a piece of rock core (andesite) with a tightly interlocking natural joint, set up for direct shear testing.

Sections drawn on mm graph paper along the shearing direction of the basal surface of sample A are presented in Fig. 10. These sections were drawn using a simple profiling device as shown in Fig. 11.

The possible interaction between the two halves of sample A, along the central 2D profile when sheared is illustrated in Fig. 12. Whereas local minor asperity angles are very variable, the upper block will follow a dilation path that will override some asperities and shear through or deform others depending on the normal stress level and strength of the rock walls.

Interactions between two halves of a rock joint during shear (schematic). The lower diagram shows the discontinuity geometry along the central line of sample A. The upper diagram illustrates how the joint walls will interact at discrete locations causing damage and forcing the upper block to dilate as a rigid block

In reality the problem is 3D and even more complex so that accurate prediction of dilation is difficult even for a specific sample and test setup, although it has been attempted at a research level (e.g. Archambault et al. 1999). Currently such predictions are, however, of little practical use within a geotechnical project given that even a single sample (a tiny proportion of a discontinuity in situ) provides different shear strengths (and dilation behaviour) depending on the direction of shear.

Whilst dilation is difficult to predict it can be measured during a shear test and corrections made to derive the underlying basic friction. These data together with observations of asperity damage can then be used, in combination with field characterisation, in assessing the shear strength of the natural discontinuity at the field scale as discussed below.

4.3 Direct Shear Test Apparatus

There are few commercially available apparatus for rock shear testing. The most commonly used is the “portable” box developed at Imperial College in the early 1970s (and derivatives thereof) which uses jacks to apply normal and shear loads applied through wire slings (Hoek and Bray 1981). In practice the box is insensitive and difficult to control, especially if the joint is dilating so that the normal stress jack needs to be adjusted continuously to try to keep the load constant (Hencher and Richards 1989).

By comparison, a test apparatus that is easier to control is that developed by Golder Associates (GA) Vancouver office in the early 1970s and illustrated schematically in Fig. 13. To the author’s knowledge the box is not available commercially but many have been fabricated from the original drawings and are in use in the UK, Holland, Canada, USA, Hong Kong, South Africa and South Korea. Hencher and Richards (1982, 1989) describe the apparatus and its use in detail. An important feature of the GA box is that the normal load is applied by a dead weight through a lever system rather than by a jack or an actuator system. Vertical displacement is measured on the lever arm. Tests can be conducted on samples up to about 100 × 100 mm up to about 2 MPa normal stress which is the equivalent of about 70 m of rock and, therefore, adequate for most rock slope assessments and many other rock engineering projects.

The device is readily instrumented as illustrated in Fig. 14 where a load cell is placed between the yoke and jack to measure shear load and the yoke is also strain gauged as a check. LDVTs are used to measure shear and normal displacements. A new box is now in use at the University of Leeds, based on the original GA design but with a longer lever arm allowing higher normal loads to be applied and a motorised shearing system which improves control and the capability to take larger sample boxes. The working part of the Leeds Apparatus, arms connected to shearing motor and point of application of normal load, through a long lever, are shown in Fig. 15.

4.4 Test Methodology

It has to be accepted that it is not possible to test in the laboratory samples that will be truly representative of an in situ discontinuity. Conversely it is a fallacy to believe that an in situ test of perhaps 1 m length is more realistic and will somehow account for scale effects (Muralha et al. 2013). Such large-scale tests are very expensive, consequently few in number, often difficult to control and poorly constrained so that they are much more difficult to interpret than properly conducted laboratory tests. That said, there has been significant improvement in in situ testing in recent years that have permitted better interpretation (Barla et al. 2011).

Discontinuities typically vary in dip on a scale of millimetres, centimetres and metres and include variable roughness features that reflect their geological origin. Samples of similar dimensions from the same joint will often have quite different geometries and, as noted earlier, a single sample will demonstrate different degrees of interlocking and dilation when sheared in different directions which belies the concept of assigning a single JRC to a sample to characterise its roughness component during shear, other than for general characterisation purposes.

Roughness contributes considerable additional strength in shear tests for many natural discontinuities and consequently sample variability inevitably leads to scatter in peak strength. The common practice of testing a series of rough samples in the hope that the combined peak strengths might somehow represent the in situ strength of the joint without further analysis is invalid. The result (as in Fig. 8) is often a scatter plot that cannot be interpreted in a meaningful way, let alone extrapolated to field scale. Unfortunately this is a common approach even for major engineering projects and for data emanating from internationally recognised and accredited laboratories and this reflects the lack of adequate guidance in international standards and textbooks.

The method of testing and interpretation advocated here is derived from many years of practice. It is fundamentally important to make corrections to all test data essentially to normalise for the effect of individual sample roughness. By doing so a basic friction angle can be calculated for an essentially planar but naturally textured surface. The effect of the roughness of the natural joint (first and second order) can then be considered separately and additionally when assessing in situ strength.

4.5 Sampling

Samples should be selected so that they are representative of the in situ discontinuity in terms of surface texture, coating and mineralogy. Well-matched samples should be used if that is the nature of the discontinuity in situ. Of course if the in situ joints are weathered or infilled/coated then appropriate samples should be selected and tested. Because the recommended test procedure corrects for the effects of roughness, individual sample roughness is of only secondary importance. However, samples may be selected to contain particular roughness features of interest, for example step features from cross jointing might be targeted to see if they survive during shear at design stress levels. Observations of overriding or shearing of asperities during shear at different normal stress levels in the laboratory will help in judging the roughness angles to allow for at field scale.

4.6 Documentation

One of the weakest aspects of many testing programmes is the standard of documentation. The nature of the individual samples before and after testing needs to be recorded together with all pertinent details of the test programme itself. The descriptions need not be over detailed but should be at least sufficient to record those factors that influence the test results (see Fig. 16). Probably the most important descriptions for most tests will be those relating to surface mineralogy, morphology and tactile texture.

Example documentation sheet. Other example proformas for fuller documentation are given in Hencher and Richards (1989)

Surfaces should be photographed before and after shearing using low angle lighting to emphasise the relief. The general roughness of the surface can be recorded as illustrated in Figs. 10, 11 and 12. These measurements are taken for documentation purposes and for grouping similar samples. After testing, the surfaces and the nature of damage should be described and sketched.

4.7 Test Procedure

Following the initial sample setup and descriptions, the shear box should be assembled and the first normal load applied. The normal stress range should be selected to match the field conditions. Tests are generally carried out at natural water content, particularly if the discontinuity is clay-filled, although tests can also be carried out with the joint under water. Such a procedure might be appropriate for example when testing a discontinuity through weak and weathered rock.

Testing can be carried out following either single-stage or multistage procedures. Multistage testing involves testing the same discontinuity sample at a series of different normal loads. Such a testing strategy allows one to obtain maximum information from each sample. The normal load is generally increased after the shear resistance has remained constant or falling over a few mm or so of displacement. Another strategy is to reset samples at their original position prior to changing the normal load. This allows surfaces to be examined and photographed and for loose debris to be removed. Multistage tests can also be carried out with decreasing normal load at each stage, repeated stages at the same normal load or perhaps by repeating test runs at the same low load as earlier stages in between runs at higher loads to investigate how damage is occurring and affecting dilation. All these strategies have been adopted from time to time by the authors and in each case the data obtained are very helpful in explaining and understanding the factors contributing to shear strength. In all such tests it is inevitable that damage caused at earlier stages will affect results at later stages, but provided this is recognised and allowed for analysis and interpretation this is fine. When planning a series of multistage tests on different samples it is good practice to commence each individual test at different normal stress levels so that 1st stages (undamaged) can be used in isolation to interpret peak strength parameters.

The ISRM suggested method (Muralha et al. 2013) recommends very gradual application of normal load but from experience this is unnecessary unless testing a wet, clay infilled joint where pore pressures might be an issue. It is also recommended by the ISRM that shear displacement should be only 0.1–0.2 mm/min but from experience such low rates of shear are unnecessary. Rates of shearing below a few millimetres per minute do not affect test results generally (Hencher 1977). The tests reported in this paper were carried out at about 1 mm per minute.

To be able to analyse results properly, horizontal and vertical displacements must be recorded throughout the test frequently. In some test set-ups vertical displacement should be measured at each corner of the box and mean values used so that sample rotation does not affect calculated roughness angles. For the Golder Box, vertical displacement is measured through the point of application of normal load so no averaging is necessary. The correction method recommended here makes use of incremental roughness angles at each shear stress data point. All the test measurements must be taken at the same time and this is best achieved using displacement transducers and a shear load cell although good results can be obtained manually provided there are at least two laboratory technicians to read gauges and they have good coordination.

4.8 Test Data

Shear and normal loads are converted to average engineering stresses dividing by the gross contact area of the samples, which usually varies throughout each stage of the test. For samples taken from rock core, the area of contact can be calculated from the following equation (Hencher and Richards 1989):

where A is the gross area of contact, 2a the length of ellipse, 2b the width of ellipse, u the relative horizontal displacement.

Other samples can generally be represented as a rectangle or similar and changes in gross area calculated.

From the generally small areas of damage observed following a shear test it is evident that the actual stresses at asperity contacts are much higher than the calculated gross engineering stresses but these gross engineering stresses are also those that we use in engineering design. Asperities that survive in the laboratory at those calculated engineering stresses would also probably survive at field scale. Calculating stress changes with changing gross area throughout a test helps with visual presentation of data as seen later.

The raw data are best presented as in Fig. 17 with graphs showing measured shear stress versus horizontal displacement and vertical displacement versus horizontal displacement.

Shear stress and vertical displacement both plotted against horizontal displacement for the first stage of a multistage test on sample A shown in Fig. 9

These data are in the final presentation format recommended in the ISRM and ASTM suggested methods (see Fig. 6). As discussed below, however, there are several further steps to take in analysis if the data are to be useful for engineering design.

4.9 Measuring Dilation

Rough, matching joints dilate during shear at relatively low loads and work is done in lifting the upper sample. This increases the force required to continue shearing.

The roughness angle can be calculated throughout the test by considering the incremental vertical (dv) and horizontal (dh) displacements as follows:

The vertical vs. horizontal displacement curve in Fig. 17 appears quite smooth so that an overall dilation angle, i°, might be drawn at peak strength as per the ISRM example (Fig. 6). In detail, however, the dilation varies continuously throughout the test as minor asperities come into contact, are damaged and overridden.

The software used by the authors for this analysis takes each shear stress data point in turn and calculates the dilation angle leading to that strength measurement over a selected horizontal displacement increment. If the increment is small then scatter can be great because of reading errors and the effects of strain energy; if too large then too much detail is lost. Optimal smoothing is achieved by trial and error.

In Fig. 18 incremental dilation angles are shown, calculated over horizontal increments of 0.75 mm, using the same data set as in Fig. 17. These data are plotted against measured shear strength, both against horizontal displacement. There is a marked similarity in pattern, which reflects the dependence of strength on incremental dilation. As an aside, the assertion by Grasselli and Egger (2003) that there is no dilation prior to peak strength is not a general truism.

4.10 Correcting Data for Dilation

In a direct shear test, shear load is measured in the horizontal plane and normal load measured vertically. These loads are converted to engineering stresses, \(\tau\) and σ by dividing by the gross area of contact of the samples as discussed earlier.

Where the sample is dilating or compressing, the horizontal and vertical stresses can be resolved tangentially and normally to the plane along with shearing is actually taking place, as illustrated in Fig. 19, using the equations below. The equations are for positive dilation (uphill movement); the signs should be reversed for downhill sliding.

where \(\tau_{i}\) is the dilation-corrected shear stress, \(\sigma_{i}\) is the dilation-corrected normal stress and i° is the incremental dilation angle as per the diagram. Measuring the incremental dilation angle i° allows the dilation effect to be corrected throughout the whole shear displacement of a test.

The effect of such corrections can be seen in Fig. 20, which is a plot of the ratios between shear and normal stress, both uncorrected (raw) and corrected, plotted against horizontal displacement for the same test data as presented in Figs. 17 and 18.

For the uncorrected data, the peak stress ratio, \(\tau /\sigma\), is greater than 1.8, which equates to ‘friction’ plus dilation angle in excess of 60°. Where data are corrected for incremental dilation the vast majority of data throughout the test provide corrected stress ratios of 0.8 ± 0.1. At peak corrected strength, the corrected stress ratio is still in excess of 1.2 and this reflects the fact that for the first stage of this particular test on a tightly interlocking joint, there is some considerable damage component from asperity interaction in addition to the work done in dilating the upper block.

In Fig. 21 shear stress is plotted against normal stress, both uncorrected and corrected for dilation over horizontal increments of 0.75 mm. The change in normal stress throughout the test run (in the set of uncorrected data) is calculated from the change in gross apparent contact between the samples with horizontal displacement (under constant normal load). Presenting the data in this way helps to visualise the test history. The dilation-corrected data cluster fairly closely and these data provide a reliable indication of the available basic friction for the naturally textured joint with roughness effects removed (from the first stage only of a multistage test). Much more information can be gained from examining the full test as discussed next.

The test on sample A, illustrated in Fig. 9, comprised four stages at nominal engineering stress levels: 150, 300, 400 and 100 kPa. The sample was reset in its original position for each change in applied normal load. The final stage at 100 kPa was conducted to investigate the effect of the earlier shear stages on surface topography as revealed from the displacement and dilation graphs.

In Fig. 22 the four stages of shear strength data of the test on sample A are plotted against horizontal displacement. It can be seen that the first two stages are similar in shape with an early rise to peak shear strength and then reduction. The corresponding data curves for vertical vs. horizontal displacement in the lower part of the graph are also similar to one another. However, in stage 3, under 400 kPa normal stress, the behaviour is very different. Instead of shear strength increasing to an early peak, strength rises then remains fairly constant until rising again from about 3.5 mm until the end of the test. The displacement path is also quite different from stages 1 and 2, and the path followed during the 4th stage at 100 kPa is almost the same as in the 3rd stage, which helps to confirm that the data are valid. Clearly some damage occurred (asperity failure), probably in the 3rd stage at about 0.5 mm horizontal displacement. The differences in surface damage after stages 2 and 3 can be seen in Fig. 23 although the specific feature that failed and caused the change in shearing behaviour between the two stages is unknown.

This test illustrates well the effect of damage and belies the over-simple concept that tests are going to yield a clear early peak followed by a ‘residual’ or ‘ultimate’. For this test, the 3rd stage shear displacement curve does not follow the ideal pattern of the ISRM guidelines illustrated earlier in Fig. 6 and it would be difficult to select data for plotting following the ISRM guidelines as in Fig. 7. A scatter plot would result, similar to that in Fig. 8 that could not be interpreted in any meaningful way. Rather more revealingly, in Fig. 24, test data from all four stages of the test on sample A are plotted following the same format as in Fig. 21. Remember that for this test, the 1st stage was with an applied normal stress of 150 kPa.

The first observation is that the corrected data for all stages can be used to define a basic friction line (non-dilational) of about 38°. Many of the corrected data, especially for stages 1 and 2 are stronger than this. Uncorrected strengths are much stronger again and for the first two stages the strength envelope could be interpreted as an equivalent \(\phi + i^\circ\) angle of about 62°. After the damage caused during stage 3, the \(\phi + i^\circ\) angle is closer to 45°. The fourth stage data, following the damage caused in earlier stages, confirms the basic friction angle of about 38° as reasonable. Note that even this last stage at a nominal normal stress of about 100 kPa is for a significant slab of rock with an equivalent burial depth of about 4 m (see Fig. 1 for illustration). Later in this paper these data are combined with those from other tests and discussed with respect to their use in an engineering project.

5 Typical Basic Friction Angles for Natural Joints

Example basic friction values from dilation-corrected tests on natural joints are presented in Table 2. Tests on rough, natural joints through silicate rocks, once corrected, typically give a textural frictional resistance of approximately 38°–40°. This value is the same as the value for friction of rough joints measured for a variety of rock types at high stress levels by Byerlee (1978) [\(\tau = 0.85 \sigma\)] where dilatancy was suppressed. Where discontinuities have smooth textural roughness and major asperities do not come into contact during shear, basic friction angles can be much lower. Mineral coatings and infill will also influence strength particularly at low stress levels typical of many engineering works, which makes it imperative that, when dealing with such discontinuities, a suitable programme of testing is carried out.

It should be noted that the basic friction angles given in Table 2 derived from tests on natural joints are often higher but sometimes much lower than published ‘basic’ or ‘residual’ values mostly derived from tests on saw-cut surfaces that are typically 25°–35°. Despite advice in the literature to the contrary (e.g. Hoek 2014; Simons et al. 2001), the dilation-corrected values measured from tests on natural joints listed in Table 1 are not interchangeable with the basic friction angle used in empirical strength criteria such as the Barton–Bandis empirical strength criterion.

6 Assessing Shear Strength at the Field Scale

As illustrated in Fig. 2 rock discontinuities have geometrical properties––impersistence and large-scale roughness––that cannot be investigated in the laboratory. These need to be characterised in the field if allowance is to be made for their positive contributions to shear strength.

6.1 Persistence and Rock Bridges

Prediction of persistence is extremely difficult but for modelling purposes it is generally assumed that discrete discontinuities exist as finite ellipses within intact rock or terminate against other fractures (e.g. Zhang and Einstein 2010).

As a separate source of true cohesion, rock bridges are discrete sections of intact rock or incipient discontinuities that have not yet fully developed as open fractures. One such rock bridge is seen in Fig. 25, revealed after shear testing an incipient joint. The cohesive contribution from the rock bridge, measured during a direct shear test, was about 750 kPa.

Intact rock bridge (light area) in an otherwise weathered joint through volcanic tuff (from Hencher 1984)

In practice, the only realistic approach is to make field observations of the extent of discontinuities, interpret these with respect to geological origin and interpreted geomorphological history of the site and then to use those observations to make informed judgements of the geometry of the discontinuities under consideration. The use of field observations to judge the persistence limit of discontinuities will be illustrated for a case study later.

6.2 Roughness and Scale Effects

Roughness is equally difficult to determine for rock discontinuities in the field, where they are hidden from view. Generally what is done is to examine exposed discontinuities within a set and then to assume that the roughness properties from those exposed surfaces apply to the set as a whole. Roughness varies through a huge range of scales from micro textural and minor asperities through to larger geological features such as steps and waves. The small asperity scales of roughness are amenable to laboratory testing and analysis as illustrated earlier.

Geotechnical engineers and engineering geologists generally characterise the range of scale of roughness of discontinuities by measuring dip and dip direction on a grid using plates of different size following the methods of Fecker and Rengers (1971), illustrated in ISRM (1978) and discussed with respect to a practical example by Richards and Cowland (1982, 1986). Typically plates with diameters ranging from about 100–500 mm are used as illustrated in Fig. 26.

Halcrow China Ltd. (HCL 2002) presents an example of the use of this method in the back-analysis of a landslide above Leung King Estate in Hong Kong. The landslide occurred during very heavy rainfall and involved the dislodgement of a large slab of rock to a depth of about 3 m overlying a sheeting joint (Fig. 27). The rock slab disintegrated to become a channelised debris flow that travelled downhill over 350 m to reach a housing estate at the foot of natural terrain.

The failure was the final stage of a progressive landslide that had been developing over many years involving dilation during rainstorms, the extension of proto-joints and development of new fractures and the intermediate washing in of sediments to apertures (Hencher et al. 2011). In the failed area, major waves on the sheeting joints had a wavelength of about 2 m and amplitude of about 0.15 m. Following the failure, roughness was measured using compass clinometers on 80 and 420 mm plates using a 0.1 m grid pattern in areas where the slope had failed and in areas that had not failed.

As illustrated in Fig. 28, the mean dip of the sheeting joint was about 42° in the direction of sliding. In the failed area the extreme i° value based on 80 mm plate data was about 19°; using a 420 mm plate the equivalent i° value was about 12°. Assuming a basic friction of 38° for granite sheeting joints in HK (Hencher and Richards 1982), for an effective dilation angle of 12° (broad wave geometry as measured using large plate) the operative friction would be \(\left( {\phi_{\text{b}} + i} \right) = 50^\circ\). Using that strength in back-analysis, a water pressure rise of about 1–2 m would be required to cause failure (HCL 2002). This was considered to have been the most likely condition at failure. In the unfailed area of slope the equivalent i° value was 28° for a 420 mm plate, leading to an effective friction angle locally of \(\left( {\phi_{\text{b}} + i} \right) = 6 6^\circ\). This helps to explain why the failure was limited to its actual dimensions.

Roughness survey at Leung King Estate failure (from HCL 2002)

6.3 Discussion of Scale Effects

The Fecker and Rengers plate method intrinsically encompasses the variation of roughness with scale across a discontinuity surface and can, therefore, characterise the variation in roughness characteristics from one area to another.

Barton and others, as an alternative, suggest that the effect of scale on shear strength and especially dilation might be addressed by reducing JRC (measured for a 100 mm sample) with length of joint, following an empirical relationship. Bandis et al. (1981) postulated a gradual reduction in effective roughness over 5 m of undulating surfaces; the concept is extended for up to 10 m of discontinuity length (Hoek 2014; Read and Stacey 2009) based on Barton (1982) so has some authority as a guideline and needs to be addressed here. The basis for the JRC reduction with length empiricism stems largely from research by Bandis (1980), published by Bandis et al. (1981). The research involved tests on plaster-based models, the summary results from which are illustrated in Fig. 29a.

The data from the tests by Bandis et al. (1981) clearly showed reducing strength and reducing dilation curve with increasing length of sample. The data, however, were presented as mean values; in the smaller blocks case, the mean curves combine the results from 32 different tests with different roughness profiles. Without displacement curves for individual tests, dilation-correction analysis is not possible. To investigate the fundamental origins of the observed scale effects, series of tests were carried out by Toy (1993) and Papaliangas (1996) in an attempt to replicate the tests of Bandis. These tests were carried out using the same machine at the University of Leeds as Bandis had used and using similar plaster-based models replicating Bandis’ work as far as possible. The set up for these repeat tests used LVDTs and data loggers to measure incremental dilation throughout each individual test rather than dial gauges and manual reading as was done for the original research. As expected the repeat tests showed considerable scatter reflecting the variable roughness of individual samples as illustrated in Fig. 29b. Despite scatter that could be attributed to the nature of the modelling material and procedure (Papaliangas, op cit.), correcting for incremental dilation provided a fairly consistent basic friction angle for all tests and the overall conclusion was that the scale effect was a matter of the geometry of the tested samples and the resultant dilation during the tests (Papaliangas et al. 1994).

For a single section of a variably rough joint, it is no surprise that there will be a scale effect. If free to rotate, a longer slab will follow a shallower dilation path to overcome some dominant asperity than will a shorter slab (Fig. 30).

Conversely if a natural discontinuity has similar second order asperity features distributed over a wide surface area then these will act in unison. One might think in terms of a representative elemental area (REA) analogous to the REV concept for rock mass permeability (e.g. Hudson and Harrison 1997). If the shearing surfaces were uniformly covered in similar geometric ridges with constant geometry––like ripple marks––the whole slab would dilate through the small-scale angle, whatever the length of surface. This was demonstrated experimentally by Ohnishi et al. (1993). There is no scale effect for such surfaces. In the same way, if variation of dip can be established to have similar characteristics over a wide surface area at different scales, following the method of Fecker and Rengers (1971)––i.e. there are many roughness features that will jointly act to cause dilation, then this effectively deals with the scale effect as discussed in the following example. If the roughness characteristics vary across the plane, so be it––this is a similar dilemma as for a rock engineer dealing with different structural regimes within a single project.

7 Design Example

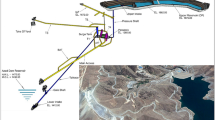

The assessment of shear strength at the scale of engineering works is best illustrated by an example, in this case, of a large rock slope being formed as part of a dam construction project in Kashmir.

7.1 Background

A large rock slope had to be excavated within a natural slope and designed not only for static conditions but also severe earthquake loading. During early stages of excavation parts of the slope failed back to an extensive persistent joint to the left side facing and locally in smaller rock slab failures to the right side as seen in Fig. 31. The situation was made even more hazardous by the existence of zones of colluvium and displaced rock at the crest of the slope, above the daylighting joints.

As part of the dam spillway design, a steep cutting was to be formed for the full length of the slope shown in Fig. 31. For this purpose it was necessary first to assess the geological nature of the daylighting joints and then to determine their shear strengths so that preventive measures could be designed to ensure an adequate factor of safety (FoS). Initially the works were to be designed following Eurocode 7 but it is difficult to apply this code to rock slope design and a more traditional FoS approach was adopted instead following methodologies essentially as set out in Hoek and Bray (1981).

7.2 Geological Nature of Daylighting Discontinuities

The rock comprises strong to extremely strong andesite. The daylighting discontinuities seen in Fig. 31 have many of the appearances of sheeting joints––persistent, with broad waves and roughly parallel to the natural hillside slopes (Hencher et al. 2011). On some of the surfaces there is localised slickensiding but this is not extensive enough to suggest that the features are faults. Some minor clay infilling was observed at some locations and this is interpreted as local washing in by groundwater throughflow. Samples selected for testing from the few available boreholes showed little evidence of weathering with patchy mineralisation of chlorite and iron oxides. Joints were examined in the face itself but also from the viewpoint of an adjacent valley running essentially at right angles to dip where lateral traces and terminations could be examined.

Figure 32 shows joints from the same set as those daylighting above the spillway cutting. Many are lensoid and pinching out. In the side valley, daylighting joints were seen terminating against cross-joints and within intact rock. It was judged that the geometry of the extensive, exposed discontinuity was essentially the worst-case.

With respect to the spillway design it was assumed conservatively that similar extensive and persistent joints might be encountered during downward cutting for the spillway and that the geometrical characteristics of such joints might be expected to be the same as the main exposed joint. Shear strength now needed to be assessed at all scales.

7.3 Laboratory Direct Shear Testing

7.3.1 Basic Friction

The results from a single multistage direct shear test from this site have been discussed in detail earlier as shown in Fig. 24. Three further sets of tests were conducted on similar matching samples. In each case, tests were carried out with three stages of ascending normal stress, resetting samples between each run. A fourth stage was carried out at a lower normal stress to investigate the damage that had been caused at higher stress levels. Dilation-corrected data from all stages are presented in Fig. 33 together with the uncorrected data from the 1st stages of each test. The other uncorrected data have been omitted for clarity. It can be seen that a lower bound for all corrected data is about 38°–40°. Many dilation-corrected data, especially for 1st stage tests are much higher. In this case it was decided to adopt a lower bound, basic friction of 38° for non-dilating surfaces.

7.3.2 Small-Scale Asperity Roughness

Once the dilation-corrected basic friction is determined, one needs to consider what additional dilational strength can be adopted for the joints in situ. One immediately attractive possibility for predicting additional dilational strength at the small scale is to adopt a JRC approach, following the equation of Barton and Choubey (1977).

Barton and Choubey suggested that the JRC component, modified by joint compressive strength (JCS) at the appropriate normal stress level, \(\sigma_{\text{n}}\), “gives a first approximation to the peak dilation angle”.

For the joint samples tested here, the estimated JRC values were between 8 and 14, given the high rock strength (100–200 MPa) and estimated normal stress at 10 m depth (250 kPa), the predicted dilation angle would be somewhere between 20° and 40°.

However, it would be dangerous to use such dilation angles for design because:

-

1.

Prediction of peak dilation angle from JRC in the above equation is prone to considerable scatter as evident from Fig. 34, and

Fig. 34 Relationship between peak dilation angle and asperity component. Redrawn from Barton and Choubey (1977)

-

2.

If the Barton and Choubey premise was reliable, then correcting for dilation in direct shear tests should result in the residual friction angle––typically about 30°. In reality tests on rough, dilatant rock joints yield basic friction angles typically 10° higher and sometimes considerably lower. In the authors’ opinion, these problems preclude the use of JRC analytically in combination with direct shear test data.

The preferred approach for predicting dilation at the small scale is by direct examination of the shear test data. For the 1st stage shown in Fig. 33 it can be seen that the peak strength data exceed the adopted basic friction angle of 38° by between 16° and 30°. Peak strength exceeded basic friction by more than 10° generally even for 2nd and 3rd stages and a minimum of 7° in one final stage (after failure of asperities). It was, therefore, decided to adopt a small-scale i° value of 7°, i.e. a total friction angle of 38° + 7° = 45°.

7.3.3 Larger Scale Roughness and Waviness

The major joints exhibit both first and second order roughness as evident in Figs. 35 and 36. The hazardous nature of the slope, however, prevented the characterisation using plates as advocated earlier. Furthermore the remoteness of site and lack of terrestrial Lidar equipment (and restrictions on helicopter flights) limited the possibility of remote measurement. A broad estimate in the field was that the main waviness (first order) resulted in local lessening and steepening of the average dip by about 10°.

To obtain reasonable topographic surveys of the slope’s temporary condition and to measure sections along the joints under investigation, a series of photographs were taken from the opposite side of the valley, at about 10 paces apart along a contour path. Later these photos were stitched together and used to create a 3D image of the slope as illustrated in Fig. 37. Several control points were established and surveyed to improve accuracy.

Cross-sections were drawn at intervals down the slope and these confirmed a general first order variability of dip of about 10°.

7.3.4 Design Implications

The overall dip of the major extensive sheet joint was about 45°, i.e. much the same as the small-scale friction. For sections of the joint where the first order roughness (waviness) was favourable, in effect reducing the dip to about 35°, then the FoS was shown to be adequate without reinforcement. The worst-case was to assume a slab, daylighting in the spillway cut, where the dip of the plane increased by 10°–55° and extended back by about 20 m from the cutting (based on waviness geometry). The engineering design adopted was to install dowel bars and cable anchors to achieve an adequate FoS under static and dynamic loading conditions over the lower part (20 m) of the sheet joint. Reinforcing the lower part of the slope would provide an adequate buttress to higher sections of the same, postulated joint slab. For the downstream section, where joints are less persistent, a combination of concrete buttressing and local anchoring was adopted.

8 Conclusions

To assess the shear strength of rock joints, a process of field characterisation and laboratory shear testing is recommended. Tests must be carried out with great care and data corrected for dilation so that the basic friction value can be determined.

The basic friction angle is not the same as the residual friction angle and cannot be determined from tests on saw-cut or milled surfaces.

Once basic friction for essentially flat and naturally textured joints has been derived, the contribution from field-scale roughness can be added in. To do so requires measurement of field roughness at first and second orders. Some contribution from small-scale roughness (at the scale of profiles of 100 mm) can be added to basic friction, judged by performance of such small-scale asperities during direct shear tests, as well as through observation that such asperities are generally present across the area of discontinuity under consideration. Large-scale first order roughness can be relied to effectively reduce dip where the up-wave opposes the direction of shear. Where a down-wave might exist causing local steepening, the design needs to cope with this possibility. This may well be an important factor to allow for where daylighting joints are exposed in the slope face. The authors consider that the current Eurocode 7 approach of applying partial factors of 1.25 to ‘cohesion’ and ‘friction’ within slope stability assessment, as done for soil, is far too simplistic for rock slope stability assessment and that a FoS approach allows far broader, less prescriptive and more realistic judgements to be made.

References

Alejano LR, Javier G, Muralha J (2012) Comparison of different techniques of tilt testing and basic friction angle variability assessment. Rock Mech Rock Eng 45:1023–1035

Amontons G (1699) De la résistance causée dans les machines. Memoires de l’Academie Royale A, 257–282

Archambault G, Verreault N, Riss J, Gentier S (1999) Revisiting Fecker–Renger–Barton’s methods to characterize joint shear dilatancy. In: Amadei, Kranz, Scott, Smeallie (eds) Rock mechanics for industry. Balkema, Rotterdam, pp 423–430

Archard JF (1958) Elastic deformation and the laws of friction. Proc R Soc Sect A 243:190–205

Archard JF (1974) Surface topography and tribology. Tribology 7:213–220

ASTM (2008a) Standard guides for using rock-mass classification systems for engineering purposes. American Society for Testing Materials. ASTM D 5878-08, p 30

ASTM (2008b) Standard test method for performing laboratory direct shear tests of rock specimens under constant normal force. ASTM International, West Conshohocken, p 12

Attewell PB (1993) The role of engineering geology in the design of surface and underground structures. In: Brown ET (ed) Comprehensive rock engineering, vol 1, Fundamentals, pp 111–154

Bandis S (1980) Experimental studies of scale effects on shear strength, and deformation of rock joints. Unpublished PhD thesis, the University of Leeds, 385p plus appendices

Bandis S, Lumsden AC, Barton NR (1981) Scale effects on the shear behavior of rock joints. Int J Rock Mech Min Sci Geomech Abstr 18:1–21

Barla G, Robotti F, Vai L (2011) Revisiting large size direct shear testing of rock mass foundations. In: Pina C, Portela E, Gomes J (eds) 6th international conference on dam engineering, Lisbon, Portugal. LNEC, Lisbon, p 10

Barton NR (1982) Shear strength investigations for surface mining. In: Brawner CO (ed) Stability in surface mining, Proceedings 3rd international conference. Vancouver, pp 171–196

Barton NR, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 12(1):1–54

Bowden FP, Tabor D (1956) The friction and lubrication of solids. Methuen’s monographs on physical subjects. Methuen & Co. Ltd, London

Brown ET (ed) (1981) Suggested methods for determining shear strength. In: Rock characterisation testing and monitoring, Pergamon Press, Oxford, pp 129–140

Byerlee JD (1978) Friction of rocks. Pure Appl Geophys 116:615–626

Coulson JH (1971) Shear strength of flat surfaces in rock. In: Proceedings of the 13th symposium on rock mechanics, Illinois. ASCE 1971, pp 77–105

Deere DU (1968) Geological considerations. In: Stagg KG, Zienkiewicz OC (eds) Rock mechanics in engineering practice. Wiley, New York, pp 1–20

Engelder JT, Scholtz CH (1976) The role of asperity indentation and ploughing in rock friction––II. Int J Rock Mech Min Sci Geomech Abstr 13:155–163

Fecker E, Rengers N (1971) Measurement of large scale roughness of rock planes by means of profilograph and geological compass. In: Proceedings symposium on rock fracture, Nancy, France, Paper 1–18

Fookes PG (1997) Geology for engineers: the geological model, prediction and performance. Q J Eng Geol 30:293–431

Goodman RE (1995) Block theory and its application. Géotechnique 45(3):383–423

Grasselli G, Egger P (2003) Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int J Rock Mech Min Sci 40:25–40

Halcrow China Ltd. (2002) Investigation of some selected landslides in 2000 (vol 2). GEO Report No. 130, Geotechnical Engineering Office, Hong Kong, p 173. http://www.cedd.gov.hk/eng/publications/geo_reports/geo_rpt130.htm

Hencher SR (1976) A simple sliding apparatus for the measurement of rock friction. Géotechnique 26(4):641–644

Hencher SR (1977) The effect of vibration on the friction between planar rock surfaces. Unpublished Ph.D. thesis, Imperial College of Science & Technology, the University of London

Hencher SR (1981) Report on slope failure at Yip Kan Street, Aberdeen, on 12th July, 1981. Geotechnical Control Office Report No. GCO 16/81, Hong Kong Government, p 26 plus 3 Appendices (unpublished)

Hencher SR (1984) Three direct shear tests on volcanic rock joints. Geotechnical Control Office Information Note, IN 5/84, Hong Kong Government, p 33 (unpublished)

Hencher SR (1987) The implications of joints and structures for slope stability. In: Anderson MG, Richards KS (eds) Slope stability––geotechnical engineering and geomorphology. Wiley, UK, pp 145–186

Hencher SR (2012a) Discussion of comparison of different techniques of tilt testing and basic friction angle variability assessment by Alejano, Gonzalez and Muralha. Rock Mech Rock Eng 45:1137–1139

Hencher SR (2012b) Practical engineering geology. Spon Press, London, New York, p 450

Hencher SR (2014) Characterizing discontinuities in naturally fractured outcrop analogues and rock core: the need to consider fracture development over geological time. In: Advances in the study of fractured reservoirs. Geological Society of London Special Publication, Advances in the Study of Fractured Reservoirs, vol 374, pp 113–123. doi:10.1144/SP374.15

Hencher SR, Richards LR (1982) The basic frictional resistance of sheeting joints in Hong Kong granite. Hong Kong Eng 11(2):21–25

Hencher SR, Richards LR (1989) Laboratory direct shear testing of rock discontinuities. Ground Eng 22(2):24–31

Hencher SR, Toy JP, Lumsden AC (1993) Scale dependent shear strength of rock joints. In: Proceedings of the 2nd international workshop on scale effects in rock masses, Lisbon, pp 233–41

Hencher SR, Lee SG, Carter TG, Richards LR (2011) Sheeting joints—characterisation, shear strength and engineering. Rock Mech Rock Eng 44:1–22

Hoek E (2014) Shear strength of discontinuities. https://www.rocscience.com/hoek/corner/4_Shear_strength_of_discontinuities.pdf

Hoek E, Bray J (1981) Rock slope engineering. Institution of Mining and Metallurgy, London, p 358

Hudson JA, Harrison JP (1997) Engineering rock mechanics. Pergamon, Oxford, p 444

International Society for Rock Mechanics (1978) Suggested methods for the quantitative description of discontinuities in rock masses. Int J Rock Mech Min Sci Geomech Abstr 15:319–368

Kulatilake PHSW, Um J, Panda BB, Nghiem N (1999) Development of new peak shear strength criterion for anisotropic rock joints. J Eng Mech 125:1010–1017

Kveldsvik V, Nilsen B, Einstein HH, Nadim F (2008) Alternative approaches for analyses of a 100,000 m3 rock slide based on Barton–Bandis shear strength criterion. Landslides 5:161–176

Lambe TW, Whitman RV (1979) Soil mechanics. Wiley, New York, p 553

Lee SG, Hencher SR (2013) Assessing the stability of a geologically complex slope where strong dykes locally act as reinforcement. Rock Mech Rock Eng 46:1339–1351

Miller LD, Goldfarb RJ, Gehrais GE, Snee LW (1994) Genetic links among fluid cycling, vein formation, regional deformation and plutonism in the Juneau gold belt, southeastern Alaska. Geology 22:203–206

Muralha J, Grasselli G, Tatone B, Blumel M, Chryssanthakis P, Jiang Y-J (2013) ISRM suggested method for laboratory determination of the shear strength of rock joints: revised version. Rock Mech Rock Eng 47:291–302. doi:10.1007/s00603-013-0519-z

Nicholson GA (1994) A test is worth a thousand guesses––a paradox. In: Nelson, Laubach (eds) Proceedings of 1st NARMS symposium, pp 523–529

Ohnishi Y, Herda H, Yoshinaka R (1993) Shear strength scale effect and the geometry of single and repeated rock joints. In: Proceedings of the 2nd international workshop on scale effects in rock masses, Lisbon, pp 167–173

Palmström A, Broch E (2006) Use and misuse of rock mass classification systems with particular reference to the Q-system. Tunn Undergr Space Technol 21:575–593

Papaliangas TT (1996) Shear behaviour of rock discontinuities and soil–rock interfaces. Unpublished Ph.D. thesis, the University of Leeds

Papaliangas TT, Hencher SR, Lumsden AC (1994) Scale independent shear strength of rock joints. In: Proceedings ISRM international symposium on integral approach to applied rock mechanics, Santiago, pp 123–134

Patton FD, Deere DU (1970) Significant geological factors in rock slope stability. In: Proceedings symposium on planning open pit mines. A.A. Balkema, Johannesburg, pp 143–151

Power CM (1998) Mechanics of modelled rock joints under true stress conditions determined by electrical resistance measurements of contact area. Unpublished Ph.D. thesis, the University of Leeds

Power CM, Hencher SR (1996) A new experimental method for the study of real area of contact between joint walls during shear. In: Rock mechanics. Proceedings 2nd North American rock mechanics symposium, Montreal, pp 1217–1222

Ramsay JG, Huber MI (1987) The techniques of modern structural geology. In: Folds and fractures, vol 2. Academic Press, London, p 700

Read J, Stacey P (2009) Guidelines for open pit slope design. CSIRO Publishing, Australia, p 512

Richards LR, Cowland JW (1982) The effect of surface roughness on the field shear strength of sheeting joints in Hong Kong granite. Hong Kong Eng 10(10):39–43

Richards LR, Cowland JW (1986) Stability evaluation of some urban rock slopes in a transient groundwater regime. In: Proceedings conference on rock engineering and excavation in an urban environment, IMM, Hong Kong, pp 357–63 (discussion 501–506)

Simons N, Menzies B, Mathews M (2001) A short course in soil and rock slope engineering. Thomas Telford, London, p 432

Simpson B (1981) A suggested technique for determining the basic friction angle of rock surfaces using core. Int J Rock Mech Min Sci Geomech Abstr 18:63–65

Skempton AW (1985) Residual strength of clays in landslides, folded strata and the laboratory. Géotechnique 35(1):3–18

Swales MJ (1995) Strength characteristics of potential shear planes in coal measures strata of South Wales. Unpublished Ph.D. thesis, the University of Leeds

Toy JP (1993) An appraisal of the effects of sample size on the shear strength behaviour of rock discontinuities. Unpublished M.Sc. Dissertation, the University of Leeds

USBR (2009) Procedure for determining the angle of basic friction (static) using a tilting table test. United States Bureau of Reclamation USBR 6258-09

Wentzinger B, Starr D, Fidler S, Nguyen Q, Hencher SR (2013) Stability analyses for a large landslide with complex geology and failure mechanism using numerical modelling. In: Proceedings international symposium on slope stability in open pit mining and civil engineering, Brisbane, Australia, pp 733–746

Wyllie DC, Norrish NI (1996) Rock strength properties and their measurement. In: Turner AK, Schuster R (eds) Landslides investigation and mitigation, Special Report 247, pp 372–390

Zhang L, Einstein HH (2010) The planar shape of rock joints. Rock Mech Rock Eng 43:55–68

Acknowledgments

The permission by HCC Contractors (India) to use data from the Kishinganga HEP Project is gratefully acknowledged as is the assistance provided by the Contractor in the field and from engineers and engineering geologists from CH2MHILL (India) during field work. The design strategy for the slope in the case example was developed with Nick Swannell and Mike Palmer of CH2MHILL (UK). Shear tests reported here (raw data) were conducted at the University of Leeds by Kirk Handley, whose careful work is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hencher, S.R., Richards, L.R. Assessing the Shear Strength of Rock Discontinuities at Laboratory and Field Scales. Rock Mech Rock Eng 48, 883–905 (2015). https://doi.org/10.1007/s00603-014-0633-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-014-0633-6