Abstract

One of the most common geological hazards in mining and civil projects is the occurrence of instability in the rock slopes. Rock slope behavior is mainly influenced by the presence of discontinuities in the rock masses. Therefore, the determination of shear strength parameters for these weak surfaces is of particular importance. There are various shear strength criteria for estimating the shear strength of discontinuities, which among them the Barton–Bandis criterion (B‒B criterion) and Mohr–Coulomb criterion (M‒C criterion) are the most widely used. Accurate estimation of shear strength properties does not only depend on the correct procedure of tests, but it requires an accurate and detailed explanation of test results. The uncertainty in the measured shear strength leads to many problems in the analyzing and designing of rock slopes. Therefore, to reduce the uncertainty and increase the accuracy of rock slopes analyzing, it is better to use probability methods. The probability distribution function can be assigned for each input parameter of the failure criterion. In this research, the results of the direct shear tests related to Azad pumped storage power plant project have been considered to estimate the shear strength properties of rock discontinuities. The results are divided into three groups based on the magnitude of the joint roughness coefficient (JRC). Shear strength for each group is estimated depending on the two most well-known criteria i.e., the B‒B criterion and the M‒C criterion. Further, the probability distribution functions (PDF) for each shear strength parameter are determined by @RISK software. Besides, the results of the empirical B‒B criterion are compared with the results of the direct shear tests for the three groups of rock joints. The confidence intervals associated with both criteria are estimated and compared together. The results showed that the overlapping of the confidence interval of the M‒C criterion with the confidence interval of B‒B criterion increases with increasing JRC of rock joint. The results show the B‒B criterion covers data of the direct shear test almost at low normal stress levels for different JRC groups too.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rock mass contains discontinuities such as bedding planes, joints, shear zones, and faults. In the design of any structure in the rock mass, one must pay attention to discontinuities when the stability of the structure is assessed (Aydan and Kawamoto 1990). Accordingly, engineers encounter some problems related to the jointed rock mass in mining, civil, petroleum, and geothermal engineering. At shallow depth, where stresses are low, the behavior of the rock mass is controlled by sliding on these discontinuities, especially in rock slope engineering (Broojerdi et al. 2018). Then understanding the aspects that control the shear strength of the discontinuities is necessary. The shear test on rock joints has been developed to estimate the shear strength of discontinuities. In the direct shear test, each specimen is subjected under the constant normal stress, and the shear stress is increased until the peak strength is reached (Muralha et al. 2014). The relationship between the peak shear strength and the normal stress can be represented by the Mohr–Coulomb criterion (M‒C criterion) or Barton–Bandis criterion (B‒B criterion) (Hoek 2007).

While the M‒C criterion is widely used in engineering practices, Brady and Brown (1993) indicate some imperfections for this criterion. One of them is that the strength envelopes of experimental tests are generally non-linear, and they can be considered as linear over a limited range of \( \sigma_{n} \) or \( \sigma_{3} \). As a result of this reason, the B‒B criterion has preferred more for shear strength of discontinuities and slope stability analysis. Although some studies have criticized the use of the B‒B criterion (Hong et al. 2008; Kulatilake et al. 1995), it is currently recommended and used by many researchers because of its ability to model the nonlinear behavior of rock joints (Barton 2016; Prassetyo et al. 2017; Sow et al. 2016). But even by considering the fact that the B‒B criterion is currently the most realistic empirical criterion, it didn’t supersede the linear M‒C criterion yet. There are still many computer codes that using the M‒C criterion in the rock engineering problems (Prassetyo et al. 2017).

The input parameters of rock joint models are vital in any stability analysis. Feng and Lajtai (1998) indicated the controlling role of the parameters such as JCS and JRC in slope stability analysis. The shear strength of rock joints at two dam sites and at Stripa research mine by using the distribution of residual friction angle, JCS0 and JRC0 were presented by Vik and Johansen (1990). An additional realistic and consistent solution for stability analyses of rock structures was provided when the uncertainties in the strength parameters were considered. In the deterministic analysis, failure modes are ignored, but in the probabilistic analysis, they are considered with their relative probability of happening acquired from simulation based on statistical data. Quek and Leung (1996) used the probabilistic analysis for stability analysis of underground rock excavations with considering the uncertainties in the geometric as well as the material parameters. Kveldsvik et al. (2008) derived the input parameters of B‒B criterion from the data set of Åknes rock slope, Norway. Through the back-calculation of 100,000 m3 rock slides, they introduce the JRC parameter as the parameter that has the most effect on safety factor. Duzgun and Bhasin (2009) used the first-order reliability method (FORM) for probabilistic modeling of the plane failure problem in the rock slope with the B‒B criterion. Zhao et al. (2016) performed a reliability analysis for a plane rock slope system by considering the B‒B criterion. The results demonstrated that the reliability index decreases dramatically by a small increase in the uncertainty of parameters such as JRC and \( \varphi_{r} \).

Du et al. (2011) selected some samples of natural rock joints with different lithological characteristics and different sizes to study the reliability of the empirical estimation of joint shear strength by the JRC–JCS model. The shear strengths of samples under dry and saturated conditions were compared to those estimated by the JRC–JCS model. For natural rock joints with joint surfaces closely matched, the results show that the reliability of the empirical estimation of joint shear strength by the JRC–JCS model is good under both dry and saturated conditions, but this reliability is questionable for natural rock joints with joint surfaces mismatched. Iakovlev (2015) compared the M‒C criterion and B‒B criterion by considering the accuracy and the data requirements of them. The data were collected from Siilinjärvi mine site rocks through laboratory and in situ tests. The results showed that the B‒B criterion in the amount of required data for relevant parameters and also in the validity of results are prime rather than the M‒C criterion. This research suggested that further studies must consider the variability of JRC parameter at appropriate locations i.e., samples. The JRC parameter which suggested as a useful index for describing discontinuities by the International Society for Rock Mechanics (Barton 1978) and has been widely used in engineering practices, could be the most appropriate parameter to be investigated. An interesting approach that took in the study of Sow et al. (2016) is that by considering the JRC value as some distinct but relevant groups, the B‒B criterion compared with the direct shear tests results. However, the number of data and experimental tests must be as much that leads to reliable conclusions with the least possible uncertainties.

As mentioned earlier, in most rock engineering practices, the B‒B criterion consider closely associated with M‒C criterion. The main reason for it is that the B‒B criterion known for well predicting the non-linear behavior and the M‒C criterion for the simplicity and the linearity which compliances more with continuum modeling approach. Based on the literature reviewed here, comparing the B‒B criterion and M‒C criterion by considering the most distinguishing parameter is more appropriate.

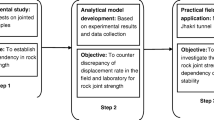

In this study, a set of laboratory tests is done on existing samples of the upper reservoir (direct shear tests on natural and saw-cut surfaces, uniaxial compressive strength (UCS), Schmidt hammer, joint profiling) to study the capability of the B‒B criterion (the well-known empirical criterion for rock joint behavior). This is done by using the samples gathered from the rock slopes of the upper reservoir of the Azad pump storage power plant project in the west of Iran. The data have been analyzed and divided into three groups (A, B and C) depending on the magnitude of JRC. Then the variability of parameters (cohesion, friction, JCS, basic friction angle) was analyzed and the B‒B criterion was compared to the experimental data to check its validity.

Methodology

Study area

Azad pump storage power plant project is under construction in the Kurdistan province of Iran. The project includes a set of the upstream reservoir, powerhouse and transformer caverns, main shaft, surge tank, and access and conveyance tunnels (Fig. 1).

Layout of existing structures in Azad pump storage power plant project (Geology report of Azad dam (in Persian) 2014)

The upper reservoir of the Azad pump storage power plant project is located inside the Sanandaj–Sirjan Zone. In the studied area, Upper Cretaceous rocks are outcropped. Kss unit consists of Meta sandstone with scattered layers of schist and phyllite encompasses the upper reservoir. This unit consists of sandstone with a thickness of several centimeters to a maximum of 1 m, which has been slightly altered (Fig. 2). Stereographic projection of joint sets and their characteristics are presented in Fig. 3.

Sample collection and characterization

To investigate the geological conditions of the reservoir and obtain the appropriate samples for rock mechanics laboratory tests. Eleven exploratory boreholes have been drilled with different depths around the upper reservoir locations (Table 1). With the aim of choosing the representative samples, samples were chosen according to a systematic scheme which obtained the assurance that they’ve been collected from all the boreholes and depths. Therefore, the selected samples were collected through all of the boreholes and depths. Though at some depths of each borehole, there was no natural joint for sampling.

A total of 435 m of diamond drill core were logged with 1382 discontinuity measurements taken. Boreholes were oriented in the horizontal and vertical directions at relatively high angles to the dominant structures. Samples for laboratory shear testing were selected from these boreholes (Fig. 4). The locations of exploratory boreholes drilled in the walls of the upper reservoir are presented in Fig. 5. The characteristics of discontinuities mapped in the exploratory boreholes are presented in Table 2.

Location of exploratory boreholes drilled in the upper reservoir (Geology report of Azad dam (in Persian) 2014)

Data collection and shear test

In this research, 104 laboratory specimens containing a plane of weakness were prepared to determine the strength parameters of the discontinuities of the upper reservoir of the Azad power plant project (Fig. 4). These specimens were mounted in a shear box using cement to hold the two halves securely in the box (Fig. 6). The purpose of the direct shear test was to measure peak and residual shear strength of rock joints as a function of normal stress. In this test, the sample was positioned such that the shear surface was approximately 10 mm above the top of the shear box rim. Then under a Constant Normal Load (CNL) condition, the shear load increased until the total shear displacement reached a maximum of approximately 10% of the sample size. Each sample is usually tested three times, at progressively higher normal loads. Due to the difficulties in obtaining a sufficient number of identical samples, the same discontinuity sample is often used for multistage testing, which allows the maximum information to be gained from each sample (Wines and Lilly 2003).

These data have been divided into three groups (A, B and C) depending on the magnitude of JRC. Group A includes specimens with JRC between 5 and 7; group B includes specimens with JRC between 8 and 9, JRC for group C changes between 10 and 13.

The peak and residual shear strength for each sample can be estimated by using the plots of the shear displacement versus shear stress (Fig. 7). Shear stress versus normal stress was drawn to determine the shear strength characteristics of the discontinuity.

The peak shear strength increases with increasing normal stress for joints with the same morphology and, the peak shear strength increases with increasing of the roughness of surface for the same applied normal stress. Dilation that shows the normal displacement during the shear displacement also is recorded during testing. This parameter indicates the effect of roughness and its role during the shear test.

Barton–Bandis criterion

Barton (1973) proposed the following empirical criterion for estimating rock joint shear strength:

where \( \tau_{\text{p}} \), \( \sigma_{\text{n}} \), \( \varphi_{\text{b}} \), JCS and JRC are peak shear strength, normal stress, basic friction angle, joint compressive strength, and joint roughness coefficient, respectively (Barton 1973; Barton and Bandis 1980). The basic angle of friction was later replaced with the residual angle of friction φr to accommodate weathering effects (Barton and Choubey 1977).

Where joint walls are unweathered, JCS is equal to the compression strength \( (\sigma_{\text{c}} ) \) of the rock, but if the joint walls are weathered, it may reduce to \( \tfrac{1}{4}\sigma_{\text{c}} \). Barton and Choubey describe that the (JCS) value can be estimated in the field or in the laboratory using a Schmidt hammer (Barton 1976). The JRC could be estimated by comparing the appearance of a discontinuity surface with standard profiles produced by Barton and Choubey (1977). The other common method for Estimating the JRC is a back analysis of a tilt test, if \( \alpha \) is the tilt angle at which sliding occurs JRC is given by following equation (Barton and Bandis 1980):

where \( \sigma_{{{\text{n}}_{0} }} \) and \( \varphi_{\text{r}} \) are normal stress-induced by weight of the block itself and residual friction angle, respectively.

The basic friction angle can be estimated from direct shear tests performed on saw-cut joints. As well as Barton and Choubey presented the basic friction angles for various unweathered rocks obtained from flat and residual surfaces (Barton and Choubey 1977).

Statistical analysis

Statistical analysis is being used in geotechnical engineering problems worldwide. The statistical analysis procedure is consisting of a correlation between two variables in the form of linear and non-linear regression and also the evaluation of the correlations. The evaluation of correlations is done in terms of 95% prediction band and 95% confidence band (Aghababaei et al. 2019; Bozorgzadeh and Harrison 2019). An extensive description of these terms and concepts would be found in Ang and Tang (2007) textbook.

For some statistical analysis, the @RISK software was used. @RISK is a risk analysis software that allows performing a wide range of statistical operations on large data sets. The operations are consisting of Monte Carlo simulation, standard correlation, sensitivity and scenario analysis, distribution fitting, and so on. In this study, @RISK was used for finding the best distribution fit for each parameter. The confidence interval selected to 90% for all distributions. Thus, 5% of upper and lower values in each data sets were ignored.

Results and discussion

Shear strength of rock joints based on the Mohr–Coulomb criterion

The results of the direct shear test, depending on the M‒C envelope for groups (A, B and C) are shown in Table 3. It is mentioned that the friction and cohesion for each test were estimated at first, and then the statistical parameters of them are calculated for each group. In addition, histograms and probability distribution functions (PDF) for each parameter were determined based on @RISK software and presented in Figs. 8, 9, and 10. There are some abnormalities in the upper and lower ends of friction angle’s PDF (Figs. 8 and 9). In these figures, the best distribution was selected based on the results of the tests. Although it was expected that the number of tests in this study should prevent such abnormalities, this fact must be considered in future studies that the number of tests must exceed what is presented here to avoid such abnormalities in the PDF histograms.

The best fit, confidence and prediction intervals of shear strength of discontinuities for three JRC groups (A, B and C) are shown in Figs. 11, 12 and 13. The shear strength parameters of rock joint for each group based on the best fit and confidence interval are presented in Table 4.

Shear strength of rock joints based on the Barton–Bandis criterion (JRC, JCS and \( \varphi_{\text{b}} \))

To estimate the magnitudes of JRC in this research, the profile of Barton and Choubey (1977) has been used. As mentioned previously, rock specimens were divided into three groups (A, B and C) based on the magnitude of JRC. The joint roughness coefficient (JRC) was determined using a profilometer, also known as a Barton comb. The magnitudes of JCS, which were estimated depending on the uniaxial compressive strength of intact rock and Schmidt hammer for groups (A, B and C) are presented in Table 5. Moreover, histograms and distribution functions related to the magnitudes of JCS by using @RISK software for three groups are shown in Fig. 14.

The magnitudes of the basic friction angle \( (\varphi_{\text{b}} ) \) were estimated based on the saw-cut test. The basic friction angle for the three groups is shown in Table 5. Histograms and distribution functions for the basic friction angle were determined and shown in Fig. 14.

Comparison of experimental data and Barton–Bandis criterion

Comparison between the experimental strength and the calculated strength by B‒B criterion for the three groups of rock joints are shown in Figs. 15, 16 and 17. To compare better between the results of the M‒C criterion and B‒B criterion to estimate the shear strength of rock joints, the confidence intervals associated with both criteria are plotted. The calculated values by B‒B criterion are almost higher than the measured peak shear strength for group A. These figures indicate, the overlapping of the confidence interval of the M‒C criterion with the confidence interval of B‒B criterion increase with increasing JRC of rock joint. The results show the B‒B criterion covers data of the direct shear test almost at low normal stress levels for different JRC groups.

For group A (JRC 5–7), the lower and upper confidence interval of M‒C and B‒B envelopes intersect with each other at 0.25 MPa of normal stress. For group B (JRC 8–9), the intersections of envelopes for upper and lower intervals occur at 0.7 and 1.25 MPa of normal stress, respectively. For group C (JRC 10–13), the intersection between envelopes takes place two times at 0.8 and 2.8 MPa of normal stress for the upper confidence interval. For three JRC groups and for normal stress levels lower than previous stress levels (0.25, 0.7, 0.8 MPa), the M‒C criterion predicts shear strength higher than the direct shear test. For normal stress levels greater than stress levels (0.25, 0.70, 0.8 MPa), B‒B criterion predicts shear strength higher than the direct shear test. The figures indicate that the M‒C criterion, which obtained from the results of the direct shear test and B‒B criterion have the maximum and minimum compliance for JRC 10–13, 5–7, respectively. Therefore, it can be concluded that by the increase of JRC magnitude, the compliance between the previous two criteria increases. According to the results of direct shear tests that fall between B‒B criterion envelopes for three JRC groups, it can be concluded that the estimation of B‒B criterion with the data obtained from the direct test for JRC 10-13 has the minimum error and for JRC 5–7 has the maximum error. It also worthy to note that the variation of the data has been increased by the increase of JRC magnitudes. However, this observation agrees with the results and findings of Iakovlev (2015).

The data from each test were used in the B‒B empirical equation to calculate the estimated shear strength of the rock joint. The estimated values of shear strength were then plotted against the measured values of shear strength for each test (Figs. 18, 19, 20). The error in the estimated value is represented by the distance that each data point plots from the 1:1 diagonal line. Figure 18 indicates that for JRC 5–7, B‒B criterion predicts shear strength greater than the direct shear test. For JRC 8–9 and 10–13, shear strength predicted by B‒B criterion is sometimes greater and sometimes less than the results of the direct shear test. Of course, for group B, in most cases, B‒B criterion predicts shear strength greater than the direct shear test and for group C, in most cases, B‒B criterion predicts shear strength lower than the direct shear test. The estimated and measured values of shear strength are approximately distributed around 1:1 diagonal line with an equal distance for group C, especially at lower normal stresses. For shear strength values higher than 3 MPa, the points are under the 1:1 diagonal line, indicating that for shear strength values higher than 3 MPa, the estimated shear strength values are smaller than the measured values.

By comparing Figs. 18, 19 and 20, it can be noted the agreement between the B‒B criterion predicted shear strength and the direct shear test results is low for JRC groups A and C. The most agreement between these two is observed for JRC group B. Although this fact shouldn’t be ignored that for JRC group B and C the Barton–Bandis criterion estimates the shear strength close to the real strength or underestimate it respectively, which prevents the under-design issue in projects.

Conclusion

Since the behavior of rock slopes in rock masses with high strength is mainly influenced by existing joints and their characteristics, the exact determination of shear strength properties of joints is of particular importance. But the main problem with the estimated shear strength for rock joints is the uncertainty in shear strength parameters that can lead to many issues in the analyzing and designing of rock slopes. Also, the relation and compliance between the two most known criteria i.e. the B‒B criterion and the M‒C criterion, is so essential as argument earlier. To estimate the shear strength of rock joints in this research, the results of experiments and studies carried out on discontinuities in the upstream reservoir of the AZAD pumped storage power plant project were divided based on the magnitude of JRC into three groups. Shear strength for each group was estimated depending on the direct shear strength test and empirical B‒B criterion. Statistical characteristics and probability distribution functions for each shear strength parameter have been determined by using @RISK software. By determining the shape of the probability distribution function for shear strength parameters, probability methods can be used to reduce the uncertainty and increase the accuracy of analyzing and designing for rock slopes. A comparison between the results of the M‒C criterion (based on the direct shear test) and B‒B criterion for three JRC groups reveals that the B‒B criterion predicts the shear strength higher than the M‒C criterion for JRC group A, but it’s vice versa for JRC group C. The JRC group B is the range that these two criteria have the most agreement. In addition, the comparison between shear strength, which estimated by B‒B criterion and measured by direct shear tests, indicates that the B‒B criterion over-estimates the shear strength for low JRCs (e.g. JRC group A).

References

Aghababaei M, Behnia M, Moradian O (2019) Experimental investigation on strength and failure behavior of carbonate rocks under multistage triaxial compression. Int J Rock Mech Min Sci 123:104099

Ang AH-S, Tang WH (2007) Probability concepts in engineering planning and design: emphasis on application to civil and environmental engineering. Wiley, New York

Aydan Ö, Kawamoto T (1990) Discontinuities and their effect on rock mass. Paper presented at the international symposium on rock joints, Loen, Norway, 4–6 June 1990

Barton N (1973) Review of a new shear-strength criterion for rock joints. Eng Geol 7:287–332

Barton N (1976) The shear strength of rock and rock joints. Int J Rock Mech Min Sci Geomech Abstr 13:255–279

Barton N (1978) Suggested methods for the quantitative description of discontinuities in rock masses. ISRM Int J Rock Mech Min Sci Geomech Abstr 15:319–368

Barton N (2016) Non-linear shear strength descriptions are still needed in petroleum geomechanics, despite 50 years of linearity. Paper presented at the 50th U.S. rock mechanics/geomechanics symposium, Houston, Texas, 26–29 June 2016

Barton N, Bandis S (1980) Technical note: some effects of scale on the shear strength of joints. Int J Rock Mech Min Sci 17:69–73

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10:1–54

Bozorgzadeh N, Harrison JP (2019) Reliability-based design in rock engineering: application of Bayesian regression methods to rock strength data. J Rock Mech Geotech Eng 11:612–627

Brady BH, Brown ET (1993) Rock mechanics for underground mining. Springer, Dordrecht

Broojerdi MS, Behnia M, Aghchai MH (2018) Dynamic analysis of rock slopes using the distinct element method: a case study at the right abutment of the Upper Gotvand Dam, Iran. J Afr Earth Sci 145:53–67

Du S, Hu Y, Hu X, Guo X (2011) Comparison between empirical estimation by JRC–JCS model and direct shear test for joint shear strength. J Earth Sci 22:411–420

Duzgun H, Bhasin R (2009) Probabilistic stability evaluation of Oppstadhornet rock slope, Norway. Rock Mech Rock Eng 42:729

Feng P, Lajtai EZ (1998) Probabilistic treatment of the sliding wedge with EzSlide. Eng Geol 50:153–163

Geology report of Azad dam (in Persian) (2014) Mahab Ghodss consulting Engineering Co., Tehran, Iran

Hoek E (2007) Practical rock engineering. Online ed Rocscience

Hong ES, Lee JS, Lee IM (2008) Underestimation of roughness in rough rock joints. Int J Numer Anal Methods Geomech 32:1385–1403

Iakovlev D (2015) Comparison of Barton–Bandis and Mohr–Coulomb models for use in discontinuity shear stability analysis. M.Sc. Thesis, Aalto University

Kulatilake P, Shou G, Huang T, Morgan R (1995) New peak shear strength criteria for anisotropic rock joints. Int J Rock Mech Min Sci Geomech Abstr 32:673–697

Kveldsvik V, Nilsen B, Einstein HH, Nadim F (2008) Alternative approaches for analyses of a 100,000 m3 rock slide based on Barton–Bandis shear strength criterion. Landslides 5:161–176

Muralha J, Grasselli G, Tatone B, Blümel M, Chryssanthakis P, Yujing J (2014) ISRM suggested method for laboratory determination of the shear strength of rock joints: revised version. Rock Mech Rock Eng 47:291–302

Prassetyo SH, Gutierrez M, Barton N (2017) Nonlinear shear behavior of rock joints using a linearized implementation of the Barton–Bandis model. J Rock Mech Geotech Eng 9:671–682

Quek S, Leung C (1996) Reliability-based stability analysis of rock excavations. Int J Rock Mech Min Sci Geomech Abstr 1:29A

Sow D, Rivard P, Peyras L, Breul P, Moradian Z, Bacconnet C, Ballivy G (2016) Comparison of joint shearing resistance obtained with the Barton and Choubey criterion and with direct shear tests. Rock Mech Rock Eng 49:3357–3361

Vik G, Johansen P (1990) Determination of shear strength of rock joints at two dam sites and at Stripa Research Mine. Paper presented at the international symposium on rock joints, Loen, Norway, 4–6 June 1990

Wines D, Lilly P (2003) Estimates of rock joint shear strength in part of the Fimiston open pit operation in Western Australia. Int J Rock Mech Min Sci 40:929–937

Zhao L-h, Zuo S, Li L, Lin Y-l, Zhang Y-b (2016) System reliability analysis of plane slide rock slope using Barton–Bandis failure criterion. Int J Rock Mech Min Sci 88:1–11

Acknowledgements

The authors acknowledge the Iran water and power resources development company, Mahab Ghodss consulting Engineering Company for permission to use geological and rock mechanics data of the Azad pump storage power plant project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Behnia, M., Nateghpour, B., Tavakoli, J. et al. Comparison of experimental and empirical methods for estimating the shear strength of rock joints based on the statistical approach. Environ Earth Sci 79, 361 (2020). https://doi.org/10.1007/s12665-020-09080-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-020-09080-6