Abstract

Dissolved oxygen and pH are critical factors influencing cell growth and metabolism. In our previous work, we constructed the recombinant strain Mortierella alpina CCFM698, which has the ability to produce EPA at room temperature. However, our experiments showed that the dissolved oxygen produced by the aeration and agitation of the fermenter was insufficient for cell growth and EPA synthesis by this recombinant strain. Moreover, the optimum pH for cell growth was incompatible with that of EPA accumulation. This study introduced a combined strategy of two-stage pH control with oxygen-enriched air in fed-batch fermentation to facilitate both cell growth and EPA production in M. alpina CCFM698. After 10 days of fermentation in a 7.5 L tank, the biomass production reached 41.2 g/L, with a lipid content of 31.5%, and EPA accounting for 26.7% of total lipids. The final EPA production reached 3.47 g/L, which is the highest yet achieved by M. alpina. This study reveals the critical role of dissolved oxygen and pH control for EPA production of M. alpina, and provides an easy and efficient strategy for industrial production of EPA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Eicosapentaenoic acid (EPA, C20: 5) is a long-chain polyunsaturated fatty acid (PUFA) of the ω-3 series, noted for its physiological functions [1,2,3,4], and widely used in medicine, health products, and the food and feed industries [5]. For decades, marine fish oils have served as the primary sources of EPA. However, the dwindling stocks of marine fish, complexity of extraction, and increasing oceanic pollution have become limiting factors [6]. Therefore, much research has prioritised the exploitation of new sources of ω-3 PUFAs through production by microbial lipids [7]. Mortierella alpina is a fungal species used in industrial production of arachidonic acid (ARA, C20: 4) [8]. However, the wildtype M. alpina produces only a small amount of EPA under low temperature conditions, insufficient for industrial production [9]. In our previous work, the recombinant strain M. alpina CCFM698, capable of producing EPA at room temperature, was obtained by overexpressing the ω-3 fatty acid desaturase derived from Phytophthora parasitica in the M. alpina ATCC32222 [10]. The new strain Mortierella alpina CCFM698 was able to convert ARA into EPA with a conversion rate of 68.1% at 28 °C under shake-flask conditions. Therefore, research into a suitable expansion culture under fermentative conditions may provide the possibility of industrially producing EPA using M. alpina CCFM698.

Dissolved oxygen (DO) is considered a key factor in the EPA biosynthesis process. Crucially, insufficient DO inhibits cell growth and product synthesis, as PUFAs, such as EPA, are formed via an enzymatic desaturation mechanism that requires oxygen [11]. Cui et al. increased the percentage of DO in the fermentation process from 5 to 330% [12]. Their results showed that the biomass yield increased as DO increased, indicating that insufficient DO was a limiting factor for cell growth. Besides raising the speed of the agitator and aeration, there are many other common ways to increase the DO include increasing the tank pressure and adding an oxygen-enriched medium or oxygen-enriched air. Peng et al. increased the DO of their system by adding 4% n-hexane combined with the regulation of the agitation speed, which significantly increased the yield of ARA produced by M. alpina ME-1 to a level 50.3% higher than that of the control group [13]. Similarly, Jin et al. used a two-step strategy of adjusting the agitation speed and adding 3% and 5% ethanol at 5 d and 7 d, respectively, to promote the accumulation of ARA; thereby, increasing the final ARA yield by 1.7 times [14]. However, M. alpina is physically sensitive to the shearing force induced by high agitation rates. The resulting damage to the cells and inhibition of cellular self-repair is not conducive to lipid synthesis, requiring the agitation speed to be controlled within a suitable range [15]. Despite the promise of earlier studies, our previous work showed that under growth-promoting aeration and agitation conditions in a 7.5 L fermenter, the DO was insufficient for cell growth and EPA synthesis by M. alpina CCFM698 [16]. However, until now, there has been little study of the strategy of using oxygen-enriched air to enhance the DO for EPA production in M. alpina. It is important to note that high DO is not always beneficial for lipid accumulation. Oxygen uptake is not a rate-limiting factor at high oxygen concentrations, while the accumulation of reactive-oxygen species (ROS) can be detrimental to microbial biomass and product yields [17]. In addition, DNA, proteins, lipids, and other biomolecules are also susceptible to damage by ROS [18]. Therefore, the application of oxygen-enriched air needs to be controlled within a suitable range.

Besides the DO, pH is another key factor in the EPA biosynthesis process. In general, pH can affect enzyme activity and nutrient availability through altering the electrostatic charge of the cell membrane [19]. A previous study confirmed that initial pH was a crucial factor for the PUFA yield [20]. Moreover, because EPA is an intracellular metabolite, both the cell biomass and the EPA conversion rate must be concurrently promoted to produce a high final EPA yield. Hwang et al., using 14% (v/v) NH4OH as a pH regulator and as part of the N source, achieved a final dry cell weight (DCW) of 72.5 g/L with a total lipid yield of 45.8 g/L and ARA production of 18.8 g/L [21]. Considering that the use of NH4OH to regulate pH is widespread in the industrial production of amino acids, these results suggest that using 14% (v/v) NH4OH as a pH regulator and partial N source may also benefit the biomass and EPA production by M. alpina CCFM698. However, previous studies have usually found that cell growth and metabolite production were optimised at quite different pH values [22]. Li et al. established a pH-shift strategy for efficient production of ARA by M. alpina through fed-batch culture, which increased ARA production by 40% [23].Therefore, a two-stage pH control strategy in the fermentation process may be an effective tactic to increase EPA production by M. alpina CCFM698.

In this study, we aimed to establish an efficient strategy for high fermentative production of EPA by M. alpina CCFM698. First, the effects of oxygen-enriched air on EPA production by this strain in batch fermentation were investigated in a 7.5 L fermenter. Subsequently, to obtain higher biomass and EPA production, the use of 14% (v/v) NH4OH as a pH regulator and partial N source with fed-batch fermentation was investigated. Furthermore, a strategy of two-stage pH control with fed-batch fermentation was investigated to further increase EPA production. Finally, a combined strategy of two-stage pH control with oxygen-enriched air was developed to enhance the EPA production in fermentative conditions. This study may provide guidance for industrial-scale production of EPA by M. alpina CCFM698.

Materials and methods

Strain and culture conditions

M. alpina CCFM698 was constructed in our laboratory and preserved in the General Microbiology Center of the China Microbial Culture Conservation Management Committee. This strain can convert ARA into EPA at room temperature [10]. The strain was maintained on GY agar slant medium (30 g/L glucose; 2 g/L potassium nitrate; 5 g/L yeast extract; 3 g/L magnesium sulphate heptahydrate; 1 g/L sodium dihydrogen phosphate; 20 g/L agar) at 4 °C and transferred every 3 months. A single GY slant (1 × 1 cm) covered with M. alpina CCFM698 mycelium was transferred into a 250 mL flask containing 100 mL of fresh seed medium (20 g/L glucose; 10 g/L potassium nitrate; 5 g/L yeast extract; 0.25 g/L magnesium sulphate heptahydrate; 1 g/L sodium dihydrogen phosphate) and cultured at 28 °C, 200 rpm for 48 h. When the cells grew into white spheroids, the mycelia pellets were homogenised using a sterilised disperser (IKA T10, Germany) and inoculation was carried out twice using 1% of the cells, which were cultured at 28 °C, 200 rpm for 36 h each time. After that, 10% (v/v) of the seed culture was used to inoculate the fermentation broth. The basic fermentation medium comprised 50 g/L glucose, 20 g/L soybean meal, 0.25 g/L magnesium sulphate heptahydrate, and 2 g/L sodium dihydrogen phosphate. For basic fermentation conditions, M. alpina CCFM698 was grown in a 7.5 L fermentation tank (New Brunswick Scientific, USA) containing 4.0 L fermentation medium, rotational speed of 400 rpm at 28 °C, the pH was controlled at 6.0 using 1 M sodium hydroxide and 1 M sulphuric acid. Fermentation was carried out for 10 days. Sterile sampling using heat sterilisation was performed once every 24 h during the fermentation for the determination of fermentation parameters, and the adverse effects of foaming during fermentation were controlled by adding polypropylene glycol 2000 as a defoamer.

The effects of oxygen supply strategy on cell growth and EPA productivity

In this section, using the basic fermentation as control group, oxygen-enriched air was provided through a strategy of intermittent oxygen feeding to explore the effects of oxygen supply level on cell growth and EPA productivity. For the oxygen-enriched air fermentation strategy, the DO% values were controlled in the range of 10–50% by adding oxygen when DO% fell below 10% and withholding the oxygen feed whenever the DO% rose above 50%. The total ventilation was controlled within 0–1.0 vvm.

The effects of pH regulation buffer and fed batch on cell growth and EPA productivity

In this section, three groups of fermentation experiments were designed. The first group using batch fermentation with the oxygen-enriched air strategy, pH was controlled at 6.0 using 1 M sodium hydroxide and 1 M sulphuric acid. The second group underwent fed-batch fermentation (the initial glucose concentration was 30 g/L and the residual glucose concentration was maintained above 10 g/L by feeding), the other fermentation conditions were the same as the first group. The third group underwent fed-batch fermentation with 14% (v/v) NH4OH as a nitrogen source and pH controller, the other fermentation conditions were the same as the second group.

The effects of two-stage pH control combined with oxygen-enriched air on cell growth and EPA productivity by M. alpina CCFM698 with fed-batch fermentation

To investigate the effects of two-stage pH control on the biomass and EPA production by M. alpina CCFM698, fermentation experiments comparing three groups, all using 14% (v/v) NH4OH to regulate pH, were conducted. The pH of the first group was controlled at 6.0 from 0 to 240 h; that of the second group was controlled at 6.5 from 0 to 240 h; A two-stage pH control was performed in third group as follows: at phase 1 (0–96 h), the pH was set to 6.0, at phase 2 (96–240 h), the pH was set to 6.5. The DO% was maintained within 10% to 50% using oxygen-rich air during the fermentation process, the residual glucose concentration was maintained above 10 g/L by feeding 400 g/L glucose, and the initial glucose concentration was 30 g/L.

Determination of dry cell weight and glucose concentration

The determination of dry cell weight and glucose concentration were performed as previously described [24]. Briefly, the mycelia and culture medium were harvested by filtration. The fresh mycelia were washed with PBS buffer and stored at − 80 °C for 24 h. After that, the wet mycelia were transferred into a vacuum freeze-drier (LABCONCO, US) for lyophilisation, and the freeze-dried cells were weighed. The residual glucose concentrations were measured by a glucose assay kit (Nanjing Jiancheng Bioengineering Institute).

Fatty acid analysis

Lipids were extracted and methyl-esterified from approximately 50 mg of freeze-dried cells, as described previously [25]. The fatty acid methyl ester (FAME) profiles were analysed using gas chromatography–mass spectrometry (QP2010, Shimadzu Co., Kyoto, Japan) with a 30 m × 0.25 mm Rtx-WAXetr column (film thickness: 0.25 μm, Agilent Technologies, Santa Clara, California) and helium as the carrier gas. The following temperature programme was set: 40 °C for 5 min, ramp to 120 °C at 20 °C per min, ramp to 190 °C at 5 °C per min, hold for 5 min, ramp to 220 °C at 5 °C per min, and hold for 17 min. Fatty acids were quantified by integrating the peak-height areas and pentadecanoic acid was used as the internal standard to quantify the FAMEs.

Statistical analyses

GraphPad Prism version 6 (Graph Pad Software, San Diego, CA, USA) was used for statistical analyses. All values were the average of three replicates and expressed as mean ± standard deviation.

Results and discussion

The effects of oxygen-enriched air strategy on cell growth and EPA productivity in the batch fermentation

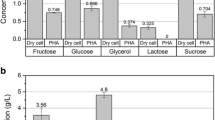

As mentioned, the aim of the oxygen-enriched air strategy was to overcome the inability of the standard aeration and agitation conditions of the fermenter to produce sufficient DO for cell growth and the accumulation of EPA by M. alpina CCFM698. The effects of the oxygen-enriched air strategy on DO%, DCW, total fatty acids (TFA), EPA production, and residual glucose concentration were investigated in batch fermentation (Fig. 1). In the control group, it can be seen that the DO% decreased rapidly after the inoculation of fermentation, falling to 0 at 48 h and then remaining at 0 until 192 h, which indicated the huge demand of DO for cell growth and the synthesis of EPA by M. alpina CCFM698 during the fermentation process. Furthermore, in the control group, the glucose was not fully consumed, and 20 g/L of glucose remained at the end of fermentation, the starting concentration having been 50 g/L. This showed that insufficient DO impeded the consumption of glucose, which hindered the growth of mycelia and the accumulation of lipids. This is consistent with Nie et al. [11], who designed a novel microporous ceramic membrane gas distributor to improve oxygen supply, which promote the increase of DCW, TFA, and ARA content in TFA.

With the oxygen-enriched air strategy, by the end of fermentation the DCW reached 24.5 g/L, the TFA production was 4.43 g/L. Oxygen-enriched air strategy significantly increased the EPA percentage (%TFA), and the EPA yield increased 1.82 times to reach 1.01 g/L, suggesting that the oxygen-enriched air greatly increased the DO of the system and in turn the EPA production. An adequate supply of oxygen has been demonstrated to be important for activating fatty acid elongase and desaturases, and enhancing the desaturation–elongation of long-chain polyunsaturated fatty acids [26]. Moreover, the glucose consumption rate of the cells was also accelerated through this strategy. As mentioned, the residual glucose concentration of the control group was about 20 g/L at the end of fermentation (from an initial value of 50 g/L). However, in the oxygen-enriched air group, the glucose was exhausted at 144 h, showing that the glucose level in this group was insufficient at the late stage of fermentation, which hindered the accumulation of lipids. Furthermore, the high initial glucose concentration of 50 g/L in the batch fermentation may have prolonged the lag phase of cell growth. To improve the biomass and EPA production, we designed a follow-up experiment with the fermentation methodology switched from batch to fed batch. Here, it is important to note that M. alpina is reportedly unable to maintain general metabolic activity in high oxygen conditions, and resorts to consuming fatty acids as an energy source to adapt to such circumstances [27]. This implies that the application of oxygen-enriched air needs to be controlled within a suitable range. Here, we controlled the DO% within the range 10–50%.

The effects of using NH4OH to regulate pH combined with oxygen-enriched air strategy on cell growth and EPA productivity with fed-batch fermentation

Excessive initial concentration of glucose in batch fermentation prolongs the lag phase of cell growth, while low concentrations of glucose are unable to meet the demand for cell growth and lipid accumulation. To escape this trade-off, fed-batch fermentation is necessary for increasing EPA production [28, 29]. In an attempt to increase the biomass and EPA productivity by M. alpina CCFM698, the effects of using 14% (v/v) NH4OH as a pH regulator and partial N source were investigated in a 7.5 L fermenter under a strategy of controlled addition of oxygen-enriched air (Fig. 2).

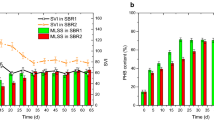

The results showed that the DO% of the three groups was maintained at 10–50% under this strategy, and the average consumption rate of glucose in the batch fermentation and fed-batch fermentation groups was about 8 g/(L·d), while it was slightly higher in the group using NH4OH to regulate pH. In other words, the use of NH4OH to regulate pH increased the rate of glucose utilisation. Furthermore, the experimental results showed that the DCW, TFA, and EPA percentage and production under fed-batch fermentation were significantly improved when compared with batch fermentation, with the DCW increased by 16.7%, the TFA increased by 84.1%, and the EPA increased by 79.1% (Fig. 2). These results suggested that insufficient glucose in batch fermentation was a limiting factor for the accumulation of lipids, while fed-batch fermentation was beneficial to cell growth and EPA production by M. alpina CCFM698. Moreover, when compared with the fed-batch fermentation group, the use of NH4OH to regulate pH significantly increased DCW (from 28.6 to 37.2 g/L), TFA (from 8.1 to 12.5 g/L), EPA production (from 1.8 to 2.9 g/L), and total glucose consumption (from 60 to 70 g/L) (Fig. 2). Together, these results show that using 14% (v/v) NH4OH as a pH regulator and partial N source with fed-batch fermentation coupled with an oxygen-enriched air strategy can effectively increase the biomass and EPA production by M. alpina CCFM698.

Effects of two-stage pH control combined with oxygen-enriched air strategies on EPA production with fed-batch fermentation

To further increase EPA production by M. alpina CCFM698, the effects of a combined strategy of two-stage pH control with oxygen-enriched air on EPA production with fed-batch fermentation were investigated (Fig. 3 and Table 1). As can be seen, pH 6.0 was more conducive to cell growth while pH 6.5 was more beneficial to lipid synthesis and EPA production. When compared with the control group kept at a constant pH of 6.0, the DCW of the two-stage pH control group remained basically unchanged; however, the TFA increased by 10.7%, and the EPA production increased by 26.6%. At the end of fermentation, two-stage pH control strategy significantly increased the DCW, TFA percentages and EPA yields of M. alpina CCFM698. These results indicated that the optimal pH of cell growth was different from that of metabolite production. Similarly, Li et al., using a two-stage pH control strategy for ARA production by M. alpina, successfully increased the maximum ARA production to 8.12 g/L [23]. These experimental results vindicate the combined strategy of two-stage pH control with oxygen-enriched air in fed-batch fermentation to efficiently promote the biomass and the yield of EPA produced by M. alpina CCFM698.

These results are consistent with a previous study, which found that the fermentation steps of cell growth and metabolite production were optimised at quite different pH values [30]. Furthermore, Deng et al., who studied the effect of pH on ARA production by M. alpina, found that the cell biomass was the highest at pH 6.0, the total lipid yield was the highest at pH 6.5, and the total lipid yield was the lowest at pH 7.5 [31]. Yin et al. established a two-phase pH control strategy using ammonia and citric acid as pH regulators for the synthesis of docosahexaenoic acid (DHA) in Schizochytrium. By controlling pH at 7.0 for biomass accumulation and at 5.0 for DHA synthesis, the final cell dry weight (CDW) and DHA content reached 98.07 and 25.85 g/L, respectively, representing a significant enhancement of DHA production [32]. That recent study dovetails with our effective use of a combined strategy of two-stage pH control with oxygen-enriched air in fed-batch fermentation to increase the EPA production by M. alpina CCFM698.

Conclusions

In this work, we developed a combined strategy of two-stage pH control with oxygen-enriched air for highly efficient production of EPA by M. alpina CCFM698 with fed-batch fermentation. First, the oxygen-enriched air strategy was optimized, which greatly increased the DO% of the system and in turn the EPA production by M. alpina CCFM698. Subsequently, the use of 14% (v/v) NH4OH as a pH regulator and partial N source with fed-batch fermentation was investigated to further improve biomass and EPA production. Next, a two-stage pH control strategy for fed-batch fermentation was designed to further increase EPA production. Finally, EPA production was maximized at 3.47 g/L, which may provide a route to industrial production of EPA using M. alpina CCFM698.

References

Hirahashi J, Kawahata K, Arita M, Iwamoto R, Hishikawa K, Honda M, Hamasaki Y, Tanaka M, Okubo K, Kurosawa M, Takase O, Nakakuki M, Saiga K, Suzuki K, Kawachi S, Tojo A, Seki G, Marumo T, Hayashi M, Fujita T (2014) Immunomodulation with eicosapentaenoic acid supports the treatment of autoimmune small-vessel vasculitis. Sci Rep 4:6406

Wachtel N, Rohwer N, Pietzner A, Loew A, Weylandt KH (2018) Omega-3 fatty acid supplementation—a possible dietary adjunct to enhance immune therapy in cancer? J Cell Biotechnol 4:83

Maehre HK, Jensen IJ, Elvevoll EO, Eilertsen KE (2015) Omega-3 fatty acids and cardiovascular diseases: effects, mechanisms and dietary relevance. Int J Mol Sci 16:22636–22661

Das UN (2003) Long-chain polyunsaturated fatty acids in the growth and development of the brain and memory. Nutrition 19:62–65

Lopez-Huertas E (2010) Health effects of oleic acid and long chain omega-3 fatty acids (EPA and DHA) enriched milks. A review of intervention studies. Pharmacol Res 61:200–207

Adarme-Vega TC, Thomas-Hall SR, Schenk PM (2014) Towards sustainable sources for omega-3 fatty acids production. Curr Opin Biotechnol 26:14–18

Fujita T, Kawashima H, Sakuradani E, Sakamoto T, Ando A, Ogawa J, Shimizu S (2016) Essential fatty acids for oleaginous fungus Mortierella alpina. Biocatal Agric Biotechnol 8:167–170

Dyal SD, Narine SS (2005) Implications for the use of Mortierella fungi in the industrial production of essential fatty acids. Food Res Int 38:445–467

Okuda T, Ando A, Negoro H, Muratsubaki T, Kikukawa H, Sakamoto T, Sakuradani E, Shimizu S, Ogawa J (2015) Eicosapentaenoic acid (EPA) production by an oleaginous fungus Mortierella alpine expressing heterologous the Δ17-desaturase gene under ordinary temperature. Eur J Lipid Sci Technol 117:1919–1927

Tang X, Chen H, Mei T, Ge C, Gu Z, Zhang H, Chen YQ, Chen W (2018) Characterization of an omega-3 desaturase from phytophthora parasitica and application for eicosapentaenoic acid production in Mortierella alpina. Front Microbiol 9:1878

Nie ZK, Ji XJ, Shang JS, Zhang AH, Ren LJ, Huang H (2014) Arachidonic acid-rich oil production by Mortierella alpina with different gas distributors. Bioprocess Biosyst Eng 37:1127–1132

Cui YQ, van der Lans RG, Luyben KC (1997) Effect of agitation intensities on fungal morphology of submerged fermentation. Biotechnol Bioeng 55:715–726

Peng C, Huang H, Ji X, Liu X, Ren L, Yu W, You J, Lu J (2010) Effects of n-hexadecane concentration and a two-stage oxygen supply control strategy on arachidonic acid production by Mortierella Alpina ME-1. Chem Eng Technol 33:692–697

Jin MJ, Huang H, Xiao AH, Zhang K, Liu X, Li S, Peng C (2008) A novel two-step fermentation process for improved arachidonic acid production by Mortierella alpina. Biotech Lett 30:1087–1091

Wu WJ, Zhang AH, Peng C, Ren LJ, Song P, Yu YD, Huang H, Ji XJ (2017) An efficient multi-stage fermentation strategy for the production of microbial oil rich in arachidonic acid in Mortierella alpina. Bioresour Bioprocess 4:8

Ge C, Chen H, Mei T, Tang X, Chang L, Gu Z, Zhang H, Chen W, Chen YQ (2017) Application of a omega-3 desaturase with an arachidonic acid preference to eicosapentaenoic acid production in Mortierella alpina. Front Bioeng Biotechnol 5:89

Shi K, Gao Z, Lin L, Wang WJ, Shi XQ, Yu X, Song P, Ren LJ, Huang H, Ji XJ (2018) Manipulating the generation of reactive oxygen species through intermittent hypoxic stress for enhanced accumulation of arachidonic acid-rich lipids. Chem Eng Sci 186:36

Sun XM, Geng LJ, Ren LJ, Ji XJ, Hao N, Chen KQ, Huang H (2018) Influence of oxygen on the biosynthesis of polyunsaturated fatty acids in microalgae. Biores Technol 250:868–876

Zhu BF, Xu Y (2010) Production of tetramethylpyrazine by batch culture of Bacillus subtilis with optimal pH control strategy. J Ind Microbiol Biotechnol 37:815–821

Nisha A, Venkateswaran G (2011) Effect of culture variables on mycelial arachidonic acid production by Mortierella alpina. Food Bioprocess Technol 4:232–240

Hwang BH, Kim JW, Park CY, Park CS, Kim YS, Ryu YW (2005) High-level production of arachidonic acid by fed-batch culture of Mortierella alpina using NH4OH as a nitrogen source and pH control. Biotech Lett 27:731–735

Sattayasamitsathit S, Methacanon P, Prasertsan P (2011) Enhance 1,3-propanediol production from crude glycerol in batch and fed-batch fermentation with two-phase pH-controlled strategy. Electron J Biotechnol 14:4–4

Li X, Lin Y, Chang M, Jin Q, Wang X (2015) Efficient production of arachidonic acid by Mortierella alpina through integrating fed-batch culture with a two-stage pH control strategy. Biores Technol 181:275–282

Lu H, Chen H, Tang X, Yang Q, Zhang H, Chen YQ, Chen W (2019) Ultra performance liquid chromatography-Q exactive orbitrap/mass spectrometry-based lipidomics reveals the influence of nitrogen sources on lipid biosynthesis of Mortierella alpina. J Agric Food Chem 67:10984–10993

Hao G, Chen H, Du K, Huang X, Song Y, Gu Z, Wang L, Zhang H, Chen W, Chen YQ (2014) Increased fatty acid unsaturation and production of arachidonic acid by homologous over-expression of the mitochondrial malic enzyme in Mortierella alpina. Biotech Lett 36:1827–1834

Chi Z, Liu Y, Frear C, Chen S (2009) Study of a two-stage growth of DHA-producing marine algae Schizochytrium limacinum SR21 with shifting dissolved oxygen level. Appl Microbiol Biotechnol 81:1141–1148

Higashiyama K, Murakami K, Tsujimura H, Matsumoto N, Fujikawa S (1999) Effects of dissolved oxygen on the morphology of an arachidonic acid production by Mortierella alpina 1S–4. Biotechnol Bioeng 63:442–448

Ji XJ, Zhang AH, Nie ZK, Wu WJ, Ren LJ, Huang H (2014) Efficient arachidonic acid-rich oil production by Mortierella alpina through a repeated fed-batch fermentation strategy. Biores Technol 170:356–360

Qu L, Ren LJ, Sun GN, Ji XJ, Nie ZK, Huang H (2013) Batch, fed-batch and repeated fed-batch fermentation processes of the marine thraustochytrid Schizochytrium sp. for producing docosahexaenoic acid. Bioprocess Biosyst Eng 36:1905–1912

Xia Y, Chen Y, Liu X, Zhou X, Wang Z, Wang G, Xiong Z, Ai L (2019) Enhancement of antroquinonol production during batch fermentation using pH control coupled with an oxygen vector. J Sci Food Agric 99:449–456

Deng Z, Xiaojun JI, Nie Z, Yan J, Huang H (2013) High-level arachidonic acid-rich oil accumulation in Mortierella alpina though three-stage fermentation strategy. Chin J Bioprocess Eng 2013:4

Yin F-W, Zhang Y-T, Jiang J-Y, Guo D-S, Gao S, Gao Z (2019) Efficient docosahexaenoic acid production by Schizochytrium sp. via a two-phase pH control strategy using ammonia and citric acid as pH regulators. Process Biochem 77:1–7

Acknowledgements

This research was supported by the National Natural Science Foundation of China (31722041), the Fundamental Research Funds for the Central Universities (JUSRP51702A), the National First-class Discipline Program of Food Science and Technology (JUFSTR20180102), and the Jiangsu Province “Collaborative Innovation Center for Food Safety and Quality Control”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, M., Chen, H., Tang, X. et al. Two-stage pH control combined with oxygen-enriched air strategies for the highly efficient production of EPA by Mortierella alpina CCFM698 with fed-batch fermentation. Bioprocess Biosyst Eng 43, 1725–1733 (2020). https://doi.org/10.1007/s00449-020-02367-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02367-9