Abstract

Bacillus bacteria have major utility in large-scale production of industrial enzymes, among which proteases have particular importance. B. subtilis B22, an aerobic and chemotrophic strain, was isolated from kimchi and identified by 16S rRNA gene sequencing. Extracellular protease production was determined in basic medium, with 1% (w/v) casein as substrate, by submerged fermentation at 37 °C under blue, green, red and white light-emitting diodes (LEDs), white fluorescent light and darkness. Fermentation under blue LEDs maximized protease production (110.79 ± 1.8 U/mL at 24 h). Various agricultural waste products enhanced production and groundnut oil cake yielded the most protease (334 ± 1.8 U/mL at 72 h). Activity and stability of the purified protease were optimum at pH 7–10 and 20–60 °C. Activity increased in the presence of Ca2+, Mg2+ and Mn2+, while Fe2+, Zn2+, Co2+ and Cu2+ moderated activity, and Ni2+ and Hg2+ inhibited activity. Activity was high (98%) in the presence of ethylenediaminetetraacetic acid (EDTA) but inhibited by phenylmethanesulfonyl fluoride (PMSF). The protease was unaffected by nonionic surfactants, tolerated an anionic surfactant and oxidizing agents, and was compatible with multiple organic solvents. These properties suggest utility of protease produced by B. subtilis B22 under blue LEDs for industrial applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The enzymes protease, amylase, and lipase, produced by Bacillus species, play a vital role in industrial applications and are of worldwide commercial importance [1]. Protease is of greatest biotechnological interest, with a multitude of industrial applications in detergent, food, pharmaceutical, leather, textile, paper industries and in peptide synthesis [2,3,4]. Proteases hydrolyze bonds in protein molecules to yield smaller chains (peptides) and units (amino acids). They include a complex group of hydrolase enzymes comprising about 60% of global enzyme sales [4, 5]. The Enzyme Commission classifies proteases into group 3, subgroup 4 of the hydrolases [6]. While proteases are produced by animals, plants and microorganisms, microbial proteases are favored for industrial applications because of their extracellular properties and high production rate [5]. Microbial proteases are stable under acidic and alkaline conditions and tolerate surfactants, heavy metals and oxidizing agents [7].

Strains of Bacillus spp., particularly B. subtilis, are widely used in protease production. These bacteria grow fast, require only a short fermentation period, and secrete extracellular proteins into the medium [6, 8, 9]. Proteolytic enzymes can be produced by submerged and solid-state fermentation. Diverse agricultural waste materials such as wheat bran, soybean meal, cottonseed meal, rice bran, maize oil cake, linseed oil cake, coconut oil cake, mustard oil cake, groundnut oil cake, millet, lentil bran, orange peel, banana peel, and apple peel have been used for protease and amylase production by fermentation [10,11,12,13,14,15]. Advantages of agricultural waste materials include low cost and wide availability, ease of use, and high yields [12].

Light can directly influence the growth of several groups of bacteria (Chlorobi, Chloroflexi, Cyanobacteria, Proteobacteria and Firmicutes) that are able to obtain and sustain energy from photons [16, 17]. The non-phototrophic bacteria Bacillus subtilis, Deinococcus radiodurans and Pseudomonas aeruginosa can sense light by the light oxygen voltage (LOV) photoreceptor, and blue light sensing via the flavin adenine dinucleotide (BLUF) light photoreceptor has been reported for B. subtilis [18, 19]. The BLUF and LOV photoreceptors are involved in electron transfer mechanisms [20]. Blue light-emitting diodes (blue LEDs) have been found to enhance B. subtilis growth, increase secondary metabolite (phenolic and flavonoid) production from red yeast rice in solid-state fermentation, and maximize amylase production from agricultural waste products in submerged fermentation [21, 22]. LEDs contain a semiconductor diode; the wavelength and color of the emitted light depend on the properties of the semiconductor material [23]. LEDs are ultra-bright, with nominal heat release and less energy consumption compared to other light sources [24]. LED lighting can be constructed to emit very high light fluxes and high light intensities. LEDs have a long lifetime and their small size empowers multipurpose design [23, 25].

In the present study, a B. subtilis strain was isolated and used for protease production by submerged fermentation under ordinary fluorescent and LED lights, with various agricultural waste products as substrate. The protease was purified, substrate specificity was determined, and the enzyme characterized for stability and tolerance to pH, temperature, metal ions, inhibitors, oxidizing agents, surfactants, and organic solvents.

Materials and methods

Materials

Luria Bertani (LB) medium was obtained from Difco Laboratories (Becton, Dickson and Co., USA). The other chemicals and solvents were obtained from DAEJUNG Reagents and Chemicals co. Ltd. (Korea). LEDs were purchased from HM Trade Co. (Korea).

Isolation and identification of bacteria

The bacterial strain B22 was isolated from homemade kimchi using LB medium containing 1% tryptone, 0.5% yeast and 0.5% NaCl. Microbiological pour plates were used to isolate colonies, which were streaked on LB agar plates to obtain a pure culture. The isolated B22 strain was screened by biochemical and carbon utilization tests. B22 produced protease on skimmed milk agar plates and formed a proteolytic zone around the colonies. The protease-producing B22 genomic DNA was extracted using the GenElute™ Bacterial Genomic DNA Kit (Sigma-Aldrich Co. LLC, St. Louis, MO, USA). The purity of the DNA was checked using a NanoDropTM 2000 Spectrophotometer. DNA was amplified by polymerase chain reaction (PCR) using primers 27F (forward primer) 5′-AGAGTTTGATCCTGGCTCAG-3′ and 1492R (reverse primer) 5′-ACGGCTACCTTGTTACGACTT-3′. The PCR mixture included 2 µL (10 ng) of DNA as the template, with each primer at a concentration of 0.5 µM, 1.5 mM MgCl2, and each dNTP at a concentration of 50 µM, as well as 1 µL of Taq DNA polymerase and buffer, as recommended by the manufacturer (MBI Fermentas, Germany). PCR was carried out with a Mastercycler Personal Thermal Cycler (Eppendorf) as follows: initial denaturation at 95 °C for 1 min; 40 cycles of denaturation (3 min at 95 °C); annealing (1 min at 55 °C) and extension (2 min at 72 °C); followed by a final extension (5 min at 72 °C) [26]. The PCR-amplified DNA was partially sequenced by 16S rRNA gene sequencing using the Big Dye terminator cycle sequencing kit (Applied BioSystems, USA). Sequencing was determined on an Applied Biosystems model 3730XL automated DNA sequencing system. The relatedness of the gene sequence of strain B22 to reference sequences in the Nucleotide Database of the National Center for Biotechnology Information (NCBI) was determined using BLASTn. Reference sequences of 16S rDNA from Bacillus spp. were downloaded and multiple nucleotide alignments of the selected sequences were made using ClustalX. A phylogenetic tree was constructed (neighbor-joining method) using MEGA version 3.1, with 1000 bootstrap replications to validate internal branches. The gene sequence of B22 was submitted to NCBI.

Bacterial growth and protease activity under various light sources

B22 cells (100 µL) from the stock culture were inoculated into 150 mL of autoclaved LB broth in 250-mL Erlenmeyer flasks. The flasks were incubated in a box on a rotatory shaker at 37 °C and 150 rpm under various light sources and colors (light intensity 150 µmol/m2/s): fluorescent white light (400 nm); darkness (360 nm); blue LEDs (460–490 nm); red LEDs (620–645 nm); green LEDs (520–550 nm); white LEDs (380–780 nm). The box contained LED chambers and a temperature controller with a 12 V power supply. B22 growth was monitored for 24 h at 4-h intervals by optical density at 600 nm and protease activity was measured concurrently.

Protease was measured according to Qureshi et al. [27] with minor modifications. Briefly, 1.0 mL of casein substrate (0.5% substrate dissolved in 50 mM sodium phosphate buffer at pH 7.6) was mixed with supernatant (culture centrifuged at 9000×g for 10 min at 4 °C) and 0.5 mL of glycine NaOH buffer (pH 9.0). The mixture was incubated at 40 °C for 0.5 h after which enzyme activity was halted by adding 0.5 mL of trichloroacetic acid (15% v/v). The solution mixture was centrifuged at 6000×g for 10 min to remove undigested protein. A 0.5 mL aliquot of supernatant, 2.5 mL of sodium carbonate buffer (50 mM, pH 7.5), and 0.5 mL of Folin reagent were added. The solution mixture was held at room temperature for 0.5 h and optical density read at 660 nm. A standard curve was constructed using a tyrosine standard; one unit of protease activity was defined as the quantity of enzyme required to release 1 µmol tyrosine from the substrate per minute.

Protease production

Protease was produced by B22 in a basic medium (pH 8.0) consisting of (g/L) casein (10.0); peptone (5.0); yeast extract (5.0); MgSO4·7H2O (0.2); KH2PO4 (1.0); Na2CO3 (5.0). B22 was added (1% v/v) to 300 mL of medium in a 500-mL Erlenmeyer flask and incubated at 37 °C in an orbital shaker at 120 rpm for 24 h under the various light sources. Protease production (activity) was measured at 4, 8, 12, 16, 20 and 24 h.

Among the light sources and colors, blue LEDs resulted in the most B22 growth and greatest protease production, so blue LEDs were used to further enhance protease production using locally obtained agricultural waste materials (5 g ground oil cake, coconut oil cake, mustard oil cake, linseed oil cake, cotton seed meal, soybean meal and wheat bran per L at pH 8.0) with B22 incubated at 37 °C and 150 rpm. Protease activity was measured at 24, 48, 72, 96 and 120 h of fermentation. Carbohydrate, protein, lipid, moisture, and ash contents of the agricultural materials were determined following the Association of Official Analytical Chemists (AOAC) methods [28].

Protease extraction and purification

Protease extraction and purification procedures of Farhadian et al. [3] were used with minor modifications. The fermentation medium was centrifuged at 9000×g for 10 min at 4 °C; the supernatant contained crude enzyme. Protease was precipitated by adding ammonium sulfate to 85% saturation. The suspension was kept overnight at 4 °C, then the precipitate was obtained by centrifuging at 8000×g for 30 min. The precipitate was dissolved in a 20 mM phosphate buffer (pH 6.5), dialyzed against the same buffer at 4 °C, loaded onto the gel filtration column, and equilibrated with 20 mM phosphate buffer at pH 6.5. The sample was eluted at a flow rate of 0.4 mL/min. The eluted fractions were dialyzed against 20 mM Tris–HCl buffer at pH 8, freeze dried, and stored at − 20 °C for further characterization.

SDS-PAGE analysis

Sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) was used to identify the crude protease by molecular weight. This included 12% running gel buffered at pH 8.8 with 1.5 M Tris–HCl and 5% stacking gel buffered at pH 6.8 with 0.5 M Tris–HCl, and staining with Coomassie Brilliant Blue [7]. Protein bands of the enzyme produced by B. subtilis B22 were visualized and molecular weight (kDa) determined by comparison with a standard commercial protein ladder (BLUEstain™ Protein ladder, 8–240 kDa; Catalog No. P007-500) and commercial Bacillus licheniformis protease (Sigma-Aldrich; Product Code P5380) as a positive control.

Effect of pH and temperature on protease activity and stability

The effect of pH on the purified protease activity was determined at pH 3.0–12.0 using 0.1 M sodium acetate (pH 3–5), phosphate (pH 5.5–7.5), Tris–HCl (pH 8–10) and glycine–NaOH (pH 10.5–12) as buffers, with 0.5% casein as the substrate. The mixture was incubated for 15 min and protease activity was measured. The pH stability of the enzyme was also determined by incubating purified protease without substrate in the aforementioned buffers for 1 h at 37 °C. Activity was then measured using the standard assay and compared to that at the start of the experiment (100% control) [29].

The effect of temperature on activity of the purified protease was determined by incubating at 20–90 °C for 15 min in 20 mM Tris–HCl buffer at pH 8 with casein as the substrate. To determine stability, the protease was incubated without substrate at 20–90 °C (pH 8) for 1 h and activity was measured. Activity was compared to that at the start of the experiment (100% control) [29].

Substrate specificity

Substrate specificity of the purified protease was determined for 0.5% albumin, azocasein, bovine serum albumin (BSA), gluten, glycogen, gelatin, hemoglobin and pullulan, and compared to casein. The enzyme (100 µL) was mixed with 500 µL of substrate. The mixtures were incubated at 37 °C for 30 min and protease activity was measured relative to that of casein (100%) [29].

Effects of metal ions, inhibitors, surfactants, and oxidizing agents on protease activity

Activity of the purified protease was determined in the presence of various metal ions (5 mM Cu2+, Fe2+, Mn2+, Ca2+, Mg2+, Hg2+, Ni2+, Co2+ and Zn2+), inhibitors (5 mM) EDTA (ethylenediaminetetraacetic acid) and PMSF (phenylmethanesulfonyl fluoride), surfactants (5 mM) CTAB (cetyltrimethylammonium bromide), SDS (sodium dodecyl sulfate), Triton X-100 and Tween 80, and oxidizing agents (5%) H2O2 and sodium perborate. Enzyme and test solutions were mixed with 0.5% casein, incubated at 37 °C for 1 h, and protease activity was assayed; enzyme activity in the absence of the respective compounds (0.5% casein control) was considered as 100% [29].

Effects of organic solvents on enzyme activity

Protease activity was determined in the presence of 10 and 20% methanol, ethanol, 2-propanol, chloroform, acetone, hexane, isoamyl alcohol, toluene, isopropanol and DMSO. The solvents were mixed with enzyme and 0.5% casein, incubated at 37 °C for 1 h, and assayed for protease activity. Enzyme activity in the absence of organic solvents was the control (100%) [29].

Statistical analyses

All tests were conducted in triplicate and statistical analyses were performed using SPSS 17.0 (SPSS Inc., USA). Data are reported as means ± standard deviations. ANOVA with Duncan’s multiple range test was used to compare treatment response means, with significance at p ≤ 0.05.

Results and discussion

Identification of the bacterial strain

A bacterial strain (B22) was isolated from homemade kimchi and cultivated at optimum temperature (37 °C) and pH (7.0). Characteristics, biochemical tests, and carbon source utilization are shown in Table 1. B22 was Gram positive, rod shaped and motile. Biochemical characteristics suggest that B22 belongs to the genus Bacillus. The strain was unable to utilize d-xylose, β-gentiobiose and α-methyl-d-glucosidase but capable of using the other evaluated carbon sources. Molecular identification of B22 by 16S rRNA gene sequencing showed 100% homology with Bacillus subtilis. The 16S rRNA gene sequence was submitted to a BLAST search. Phylogenetic relationships were confirmed by investigating all correlated species recognized by the NCBI taxonomy and classification. A neighbor-joining phylogenetic tree was constructed for related Bacillus species and isolates (Fig. 1). The B22 isolate exhibited 100% nucleotide sequence similarity with nine isolates based on the GenBank database. Accession no. MH665589 was obtained from NCBI for the B. subtilis B22 isolate.

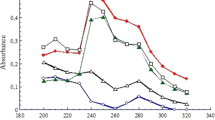

B22 growth and protease activity in LB medium under various light sources

B. subtilis growth in LB medium was measured (OD600) under various light sources. Blue LEDs maximized growth (OD600 = 1.9) while the average OD600 was 1.1 under other light sources (Fig. 2a). Protease produced by B22 appeared as bands on SDS-PAGE, consistent with the band of commercial B. licheniformis protease (Fig. S1). Protease production (activity) was also greater (77%) under blue LEDs compared to other light sources (average of 52%) (Fig. 2b). Light received by B22 in a liquid medium is transformed to a signal, enabling photochemical reactions which enhance growth and metabolic processes. The response to blue light can be attributed to LOV and BLUF photoreceptors in B. subtilis, which induce molecular changes [19, 20].

Protease production in submerged fermentation with agricultural waste materials

In submerged fermentation with casein as substrate, protease production was greatest (110.79 ± 1.8 U/mL at 24 h) under blue LEDs (Table 2). Therefore, blue LEDs were used to further enhance protease production using various agricultural waste materials as substrate.

B. subtilis grew fastest and protease production was greatest (334.17 ± 1.8 U/mL at 72 h) in medium containing groundnut oil cake (Table 3). Lesser amounts of protease were produced when the other substrates were used. Protease production was highest at 72 h, but decreased on further incubation, likely because one or more components of the medium became limiting to B22 growth. Substrate composition can have a major impact on protease production in submerged fermentation. The substrate must have a carbon and nitrogen content appropriate for the fermentation [12]. A substantial carbohydrate content stimulates the expression of hydrolytic enzymes [30]. Sathishkumar et al. [31] similarly reported high protease production by B. subtilis with groundnut oil cake as the substrate and Sankareswaran et al. [32] reported greater production with groundnut oil cake than with rice bran, wheat bran, coconut oil cake, and gingelly oil cake.

Groundnut oil cake, coconut oil cake, linseed oil cake and soybean meal have the highest protein and carbohydrate contents of the tested agricultural waste products (Table 4). Cottonseed meal and wheat bran have lower protein content than the others, but the differences were not significant. This affirms the value of using such agricultural waste materials as fermentation substrate for maximum production of protease.

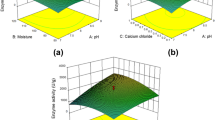

Effects of pH and temperature

Bacillus spp. are known to survive under extreme conditions, including acidic, alkaline, high-temperature and dry environments [33]. These properties are highly desirable for industrial applications. Protease produced by B. subtilis B22 exhibited high activity and stability at pH 7–10 (Fig. 3). Protease activity was maximal (98%) at pH 7.0 and 8.0 (Fig. 3a). However, good protease activity was observed at pH 6, 9, and 10 (73, 85, and 70%, respectively). The stability of protease at pH 8 was 93% and 83% at pH 9 (Fig. 3b). This is consistent with earlier reports suggesting that proteases produced by Bacillus strains are alkali tolerant, detergent compatible, and suitable for detergent preparations and processes such as tanning [4, 34,35,36]. The pH stability of protease produced by B22 at pH 7–10 exceeds that of currently available detergent proteases, including Subtilisin Novo and Savinase™, which have optimum stability at pH 8–10 [37].

Purified protease a activity (after 15 min with casein substrate) and b stability (activity after 1 h without substrate) under different pH conditions at 37 °C. The protease was produced by Bacillus subtilis B22 under blue LEDs in submerged fermentation. Error bars indicate standard deviations, where absent bars fall within symbols

Thermostability is important in determining the potential of enzymes for use in industrial processes requiring high temperatures. The activity and stability of the purified protease were good at 20–60 °C but greatest at 40 °C (98%) (Fig. 4a, b). This is similar to the activity and stability of other microbial proteases [4, 36, 38]. Thermostable enzymes have advantages for numerous commercial applications due to shorter reaction times and reduced contamination risks, as their active sites are protected against thermal denaturation [39, 40]. Thus, protease produced by B. subtilis B22 has good industrial potential for use under high heat and alkaline conditions.

Substrate specificity

The specificity of the purified protease for various standard proteinaceous substrates is shown in Fig. 5. Maximum specificity was for albumin (88%), followed by azocasein (80%), BSA (45%), gluten (30%), gelatin (26%) and hemoglobin (26%), compared to casein (100% activity). The substrate specificity of protease reflects its capacity to hydrolyze peptide bonds between the amino acids of proteins. Bacillus proteases can cleave both natural and modified proteins [37]. Protease produced by B. subtilis B22 hydrolyzed peptide bonds of the evaluated proteinaceous substrates. Protease from Bacillus licheniformis K7A similarly showed good activity toward casein, azocasein, albumin and gelatin [37]. Moderate hydrolysis of BSA, gelatin and hemoglobin by the B22 protease was similar to that of protease produced by B. subtilis BUU1 isolated from marine sediment [4].

Effects of metal ions, inhibitors, surfactants and oxidizing agents

Activity of the purified protease in the presence of various metal ions, inhibitors, surfactants, and oxidizing agents is shown in Table 5. Activity was highest in the presence of 5 mM Ca2+ (122%) but exceeded 100% (0.5% casein-only control) in the presence of 5 mM Mg2+, Mn2+, Fe2+ and Zn2+. High activity in the presence of Co2+ (95%) and Cu2+ (88%) contrasted with complete inhibition by Ni2+ and Hg2+. Activity was also high with EDTA (98%) but there was no activity with PMSF. Activity of the protease was not affected by 5 mM Triton X-100 or Tween 20, but activity was less with SDS and greatly reduced by CTAB. The protease was stable in 5% (v/v) hydrogen peroxide and sodium perborate.

Metal ions affect the catalytic activity and stability of proteases. Protease produced by B22 under blue LEDs exhibited high activity and stability in the presence of Ca2+, Mg2+, and Mn2+. Stimulatory effects of Ca2+ and Mg2+ were similarly observed for protease produced by Bacillus firmus CAS 7 [36]. These cations facilitate interaction between the catalytic site of the protease enzyme and substrate [37]. This strategy necessitates metallic ions as cofactors. Ca2+, Mg2+ and Mn2+ defend against thermal denaturation by stabilizing enzyme structure while maintaining its active conformation at elevated temperatures [34, 35, 41]. In contrast, Fe2+, Zn2+, Co2+ and Cu2+ inhibited activity of the protease, as reported by Farhadian et al. [3]. These metal ions affect the catalytic site of the enzyme, causing loss of proteolytic activity. Hg2+ and Ni2+ usually inactivate enzymes, as observed in this study, and the inhibition is well documented in the literature [3, 36, 38]. Hg2+ is known to react with protein thiol groups (converting them to mercaptides) as well as histidine and tryptophan residues, which inactivates the enzyme [42].

Protease activity was not affected by EDTA but was completely inhibited by PMSF. EDTA does not affect the active site center of protease, consistent with the metalloprotease class of enzymes [41]. This property affords its use as a detergent additive [35]. In contrast, the PMSF inhibitor blocks the serine residue at the active site of protease, causing loss of proteolytic activity [4]. These findings are consistent with previous research on Bacillus licheniformis strains [7, 37]. Protease produced by B22 was not affected by the nonionic surfactants Triton X-100 and Tween-20. Activity was reduced 29% by the anionic surfactant SDS while the cationic surfactant CTAB reduced activity by 63%. Our findings and previous research on protease produced by Bacillus spp. further suggest the utility of this enzyme in detergent products [34, 43, 44]. Previous researchers reported an increase in the activity of protease from Bacillus sp. B001, B. cereus SIU1, and B. subtilis BUU1 in the presence of H2O2 [4, 34, 45]. The protease produced by B22 retained catalytic activity when exposed to the oxidizing agent H2O2 and activity was only reduced by 4% in the presence of sodium perborate.

Solvent tolerance

Tolerance of purified B22 protease to solvents at 10 and 20% (v/v) is shown in Fig. 6. The protease exhibited > 90% stability with the solvents hexane and isoamyl alcohol and > 80% stability with acetone, hexadecane and chloroform. Stability was less but exceeded 50% with DMSO, toluene, methanol, ethanol, isopropanol and 2-propanol. Solvents can be highly toxic and enzymes can lose activity due to reduction in structural and hydrophobic interactions [35]. Importantly, B22 protease was active in the presence of multiple solvents. Solvent-tolerant protease was similarly produced by Bacillus subtilis DR8806, B. cereus, and B. licheniformis K7A [3, 37, 46]. The stability of protease in the presence of organic solvents can be attributed to a larger number of negatively charged acidic amino acids compared to basic amino acids in the enzyme [35]. The negative charges maintain stability by forming a hydrated ion network with cations.

Conclusions

Significantly more protease was produced by Bacillus subtilis B22 in submerged fermentation under blue LEDs compared to white fluorescent and white, red or green LEDs, where production at 24 h was similar to that under darkness. Protease production was enhanced in medium containing 0.5% (w/v) agricultural waste materials (at 72 h groundnut oil cake ≫ coconut oil cake = linseed oil cake = soybean meal > cottonseed meal = wheat bran). The purified protease displayed high tolerance of and stability to broad ranges in pH (7–10) and temperature (20–60 °C). Catalytic activity increased in the presence of Ca2+, Mg2+ and Mn2+, and activity and stability were high in the presence of EDTA, nonionic surfactants Triton X-100 and Tween 20, and the oxidizing agents H2O2 and sodium perborate. The protease was stable with multiple organic solvents and activity was ≥ 80% with hexane, isoamyl alcohol, acetone, hexadecane and chloroform. Based on these properties and performance, protease produced by B. subtilis B22 in submerged fermentation under blue LEDs has a variety of potential applications, such as in detergent, leather, food fermentation and pharmaceutical industries.

References

Blanco AS, Durive OP, Pérez BS, Montesa DZ, Guerra PN (2016) Simultaneous production of amylases and proteases by Bacillus subtilis in brewery wastes. Braz J Microbiol 47:665–674. https://doi.org/10.1016/j.bjm.2016.04.019

Asoodeh A, Emtenani S, Emtenani S, Jalal R (2014) Enzymatic Molecular cloning and biochemical characterization of a thermoacidophilic, organic-solvent tolerant a-amylase from a Bacillus strain in Escherichia coli. J Mol Catal B Enzym 99:114–120. https://doi.org/10.1016/j.molcatb.2013.10.025

Farhadian S, Asoodeh A, Lagzian M (2015) Purification, biochemical characterization and structural modeling of a potential htrA-like serine protease from Bacillus subtilis DR8806. J Mol Catal B Enzym 115:51–58. https://doi.org/10.1016/j.molcatb.2015.02.001

Uttatree S, Charoenpanich J (2016) Isolation and characterization of a broad pH- and temperature-active, solvent and surfactant stable protease from a new strain of Bacillus subtilis. Biocatal Agric Biotechnol 8:32–38. https://doi.org/10.1016/j.bcab.2016.08.003

Lakshmi BKM, Muni Kumar D, Hemalatha KPJ (2018) Purification and characterization of alkaline protease with novel properties from Bacillus cereus strain S8. J Genet Eng Biotechnol 16:295–304. https://doi.org/10.1016/j.jgeb.2018.05.009

dos Santos Aguilar JG, Sato HH (2018) Microbial proteases: production and application in obtaining protein hydrolysates. Food Res Int 103:253–262. https://doi.org/10.1016/j.foodres.2017.10.044

Hmidet N, Ali NEH, Haddar A, Kanoun S, Alya KS, Nasri M (2009) Alkaline proteases and thermostable α-amylase co-produced by Bacillus licheniformis NH1: characterization and potential application as detergent additive. Biochem Eng J 47:71–79. https://doi.org/10.1016/j.bej.2009.07.005

Ward OP, Rao MB, Kulkarni A (2009) Proteases, production. Encycl Microbiol. https://doi.org/10.1016/B978-012373944-5.00172-3

Parrado J, Rodriguez-Morgado B, Tejada M, Hernandez T, Garcia C (2014) Proteomic analysis of enzyme production by Bacillus licheniformis using different feather wastes as the sole fermentation media. Enzyme Microb Technol 57:1–7. https://doi.org/10.1016/j.enzmictec.2014.01.001

Ramachandran S, Singh SK, Larroche C, Soccol CR, Pandey A (2007) Oil cakes and their biotechnological applications—a review. Bioresour Technol 98:2000–2009. https://doi.org/10.1016/j.biortech.2006.08.002

Hashemi M, Razavi SH, Shojaosadati SA, Mousavi SM, Khajeh K, Safari M (2010) Development of a solid-state fermentation process for production of an alpha amylase with potentially interesting properties. J Biosci Bioeng 110:333–337. https://doi.org/10.1016/j.jbiosc.2010.03.005

De Castro RJS, Sato HH (2013) Synergistic effects of agro industrial wastes on simultaneous production of protease and α-amylase under solid state fermentation using a simplex centroid mixture design. Ind Crops Prod 49:813–821. https://doi.org/10.1016/j.indcrop.2013.07.002

Karataş H, Uyar F, Tolan V, Baysal Z (2013) Optimization and enhanced production of α-amylase and protease by a newly isolated Bacillus licheniformis ZB-05 under solid-state fermentation. Ann Microbiol 63:45–52. https://doi.org/10.1007/s13213-012-0443-6

Sukumprasertsri M, Unrean P, Pimsamarn J, Kitsubun P, Tongta A (2013) Fuzzy logic control of rotating drum bioreactor for improved production of amylase and protease enzymes by Aspergillus oryzae in solid-state fermentation. J Microbiol Biotechnol 23:335–342. https://doi.org/10.4014/jmb.1204.04038

Dar GH, Kamili AN, Nazir R, Bandh SA, Jan TR, Chishti MZ (2015) Enhanced production of α-amylase by Penicillium chrysogenum in liquid culture by modifying the process parameters. Microb Pathog 88:10–15. https://doi.org/10.1016/j.micpath.2015.07.016

Robertson JB, Davis CR, Jhonson JH (2013) Visible light alters yeast metabolic rhythms by inhibiting respiration. PNAS 110:21130–21135. https://doi.org/10.1073/pnas.1313369110

Richert I (2014) The influence of light and water mass on bacterial population dynamics in the Amundsen Sea Polynya. Elem Sci Anth 3:000044. https://doi.org/10.12952/journal.elementa.000044

Davis SJ, Vener AV, Vierstra RD (1999) Bacteriophytochromes: Phytochrome-like photoreceptors from nonphotosynthetic eubacteria. Science 286:2517–2520. https://doi.org/10.1126/science.286.5449.2517

Losi A, Polverini E, Quest B, Gärtner W (2002) First evidence for phototropin-related blue-light receptors in prokaryotes. Biophys J 82:2627–2634. https://doi.org/10.1016/S0006-3495(02)75604-X

Gomelsky M, Hoff WD (2011) Light helps bacteria make important lifestyle decisions. Trends Microbiol 19:441–448. https://doi.org/10.1016/j.tim.2011.05.002

Elumalai P, Park YJ, Min C, Shea PJ, Oh BT (2019) Red yeast rice fermentation with Bacillus subtilis B2 under blue light emitting diodes increases antioxidant secondary products. Bioprocess Biosyst Eng 42:529–539. https://doi.org/10.1007/s00449-018-2056-3

Elumalai P, Lim JM, Park YJ, Min C, Shea PJ, Oh BT (2018) Enhanced amylase production by a Bacillus subtilis strain under blue light-emitting diodes. Prep Biochem Biotechnol 49:143–150. https://doi.org/10.1080/10826068.2018.1550656

Margit Olle AV (2013) The effect of light-emitting diode lighting on greenhouse plant growth and quality. Agric Food Sci 22:223–234. https://doi.org/10.1016/j.envexpbot.2009.06.011

Yi ZL, Huang WF, Ren Y, Onac E, Zhou GF, Pengb S, Wanga XJ, Li HH (2014) LED lights increase bioactive substances at low energy costs in culturing fruiting bodies of Cordyceps militaris. Sci Hortic 175:139–143. https://doi.org/10.1016/j.scienta.2014.06.006

Morrow RC (2008) LED lighting in horticulture. Hort Sci 43:1947–1950. https://doi.org/10.1007/978-981-10-5807-3_7

Elumalai P, Parthipan P, Narenkumar J, Anandakumar B, Madhavan J, Oh BT, Rajasekar A (2019) Role of thermophilic bacteria (Bacillus and Geobacillus) on crude oil degradation and biocorrosion in oil reservoir environment. 3 Biotech 9:79. https://doi.org/10.1007/s13205-019-1604-0

Qureshi AS, Khushk I, Ali CH, Chisti Y, Ahmad A, Majeed H (2016) Coproduction of protease and amylase by thermophilic Bacillus sp. BBXS-2 using open solid-state fermentation of lignocellulosic biomass. Biocatal Agric Biotechnol 8:146–151. https://doi.org/10.1016/j.bcab.2016.09.006

Association of Official Analytical Chemists (AOAC) (2010) In: Horwitz W (Ed) Official methods of analysis of the Association of Official Agriculture Chemistry, Washington

Salihi A, Asoodeh A, Aliabadian M (2017) Production and biochemical characterization of an alkaline protease from Aspergillus oryzae CH93. Int J Biol Macromol 94:827–835. https://doi.org/10.1016/j.ijbiomac.2016.06.023

Acebal C, Castillon MP, Estrada P, Mata I, Costa E, Aguado J, Romero D, Jimenez F (1986) Enhanced cellulase production from Trichoderma reesei QM 9414 on physically treated wheat straw. Appl Microbiol Biotechnol 24:218–233. https://doi.org/10.1007/BF00261540

Sathishkumar R, Ananthan G, Arun J (2015) Production, purification and characterization of alkaline protease by ascidian associated Bacillus subtilis GA CAS8 using agricultural wastes. Biocatal Agric Biotechnol 4:214–220. https://doi.org/10.1016/j.bcab.2014.12.003

Sankareswaran M, Anbalagan S, Prabhavathi P (2014) Optimization of production of an extracellular alkaline protease by soil isolated Bacillus species using submerged and solid-state fermentation with agricultural wastes. Afr J Microbiol Res 8:872–877. https://doi.org/10.5897/AJMR11.1273

Lee S, Lee J, Jin YI, Jeong JC, Chang YH, Lee Y, Jeong Y, Kima M (2017) Probiotic characteristics of Bacillus strains isolated from Korean traditional soy sauce. LWT Food Sci Technol 79:518–524. https://doi.org/10.1016/j.lwt.2016.08.040

Deng A, Wu J, Zhang Y, Zhang G, Wen T (2010) Purification and characterization of a surfactant-stable high-alkaline protease from Bacillus sp. B001. Bioresour Technol 101:7100–7106. https://doi.org/10.1016/j.biortech.2010.03.130

Jain D, Pancha I, Mishra SK, Shrivastav A, Mishra S (2012) Purification and characterization of haloalkaline thermoactive, solvent stable and SDS-induced protease from Bacillus sp.: a potential additive for laundry detergents. Bioresour Technol 115:228–236. https://doi.org/10.1016/j.biortech.2011.10.081

Annamalai N, Rajeswari MV, Sahu SK, Balasubramanian T (2014) Purification and characterization of solvent stable, alkaline protease from Bacillus firmus CAS 7 by microbial conversion of marine wastes and molecular mechanism underlying solvent stability. Process Biochem 49:1012–1019. https://doi.org/10.1016/j.procbio.2014.03.007

Hadjidj R, Badis A, Mechri S, Eddouaouda K, Khelouia L, Annane R, El Hattab M, Jaouadi B (2018) Purification, biochemical, and molecular characterization of novel protease from Bacillus licheniformis strain K7A. Int J Biol Macromol 114:1033–1048. https://doi.org/10.1016/j.ijbiomac.2018.03.167

Jaouadi B, Ellouz-Chaabouni S, Rhimi M, Bejar S (2008) Biochemical and molecular characterization of a detergent-stable serine alkaline protease from Bacillus pumilus CBS with high catalytic efficiency. Biochimie 90:1291–1305. https://doi.org/10.1016/j.biochi.2008.03.004

Demirkan E, Dincbas S, Sevinc N, Ertan F (2011) Immobilization of B. amyloliquefaciens α-amylase and comparison of some of its enzymatic properties with the free form. Rom Biotechnol Lett 16:6690–6701

Saggu SK, Mishra PC (2017) Characterization of thermostable alkaline proteases from Bacillus infantis SKS1 isolated from garden soil. PLoS ONE 12:e0188724. https://doi.org/10.1371/journal.pone.0188724

Mokashe N, Chaudhari A, Patila U (2015) Optimal production and characterization of alkaline protease from newly isolated halotolerant Jeotgalicoccus sp. Biocatal Agric Biotechnol 4:235–243. https://doi.org/10.1016/j.bcab.2015.01.003

Kecha M, Benallaoua S, Touzel JP, Bonaly R, Duchiron F (2007) Biochemical and phylogenetic characterization of a novel terrestrial hyperthermophilic archaeon pertaining to the genus Pyrococcus from an Algerian hydrothermal hot spring. Extremophiles 11:65–73. https://doi.org/10.1007/s00792-006-0010-9

Joo HS, Kumar CG, Park GC, Paik SR, Chang CS (2003) Oxidant and SDS-stable alkaline protease from Bacillus clausii I-52: production and some properties. J Appl Microbiol 95:267–272. https://doi.org/10.1046/j.1365-2672.2003.01982.x

Jellouli K, Ghorbel-Bellaaj O, Ayed HB, Manni L, Agrebi R, Nasri M (2011) Alkaline-protease from Bacillus licheniformis MP1: purification, characterization and potential application as a detergent additive and for shrimp waste deproteinization. Process Biochem 46:1248–1256. https://doi.org/10.1016/j.procbio.2011.02.012

Singh SK, Singh SK, Tripathi VR, Garg SK (2012) Purification, characterization and secondary structure elucidation of a detergent stable, halotolerant, thermoalkaline protease of Bacillus cereus SIU1. Process Biochem 47:1479–1487. https://doi.org/10.1016/j.procbio.2012.05.021

Shah K, Mody K, Keshri J, Jha B (2010) Purification and characterization of a solvent, detergent and oxidizing agent tolerant protease from Bacillus cereus isolated from the Gulf of Khambhat. J Mol Catal B Enzym 67:85–91. https://doi.org/10.1016/j.molcatb.2010.07.010

Acknowledgements

This work was supported by Korea Environment Industry & Technology Institute (KEITI) through Public Technology Program based on Environmental Policy, funded by Korea Ministry of Environment (MOE) (2018000200001).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Elumalai, P., Lim, JM., Park, YJ. et al. Agricultural waste materials enhance protease production by Bacillus subtilis B22 in submerged fermentation under blue light-emitting diodes. Bioprocess Biosyst Eng 43, 821–830 (2020). https://doi.org/10.1007/s00449-019-02277-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-019-02277-5