Abstract

We evaluated the feasibility of whole slurry (pretreated lignocellulose) saccharification and fermentation for producing ethanol from maleic acid-pretreated rice straw. The optimized conditions for pretreatment were to treat rice straw at a high temperature (190 °C) with 1 % (w/v) maleic acid for a short duration (3 min ramping to 190 °C and 3 min holding at 190 °C). Enzymatic digestibility (based on theoretical glucose yield) of cellulose in the pretreated rice straw was 91.5 %. Whole slurry saccharification and fermentation of pretreated rice straw resulted in 83.2 % final yield of ethanol based on the initial quantity of glucan in untreated rice straw. These findings indicate that maleic acid pretreatment results in a high yield of ethanol from fermentation of whole slurry even without conditioning or detoxification of the slurry. Additionally, the separation of solids and liquid is not required; therefore, the economics of cellulosic ethanol fuel production are significantly improved. We also demonstrated whole slurry saccharification and fermentation of pretreated lignocellulose, which has rarely been reported.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The production of biofuels or chemicals from lignocellulose remains economically unfeasible, mainly because of the high costs associated with producing sugars from lignocellulose [1, 2]. Lignocellulose is mainly composed of cellulose surrounded by hemicellulose and lignin. The interactions between cellulose, hemicellulose, and lignin are strong, protecting lignocellulose from chemical and microbial attack, making it difficult for saccharification to proceed [3]. Acidic pretreatment of lignocellulose is often used prior to its enzymatic hydrolysis [4]. At a high temperature, acidic pretreatment releases various compounds from lignocellulose, including xylose, mannose, galactose, glucose, and acetic acid [5]. In addition, through the dehydration of sugar monomers, pentose and hexose sugars are converted into 2-furaldehyde (furfural) and 5-hydroxymethyl-2-furaldehyde (HMF), respectively [6, 7]. These compounds are further converted into organic acids, such as formic acid from furfural and HMF and levulinic acid from HMF [4]. These byproducts of pretreatment are typical fermentation inhibitors and need to be detoxified or eliminated before the fuel production step [8, 9].

Most efforts at cellulosic ethanol production have been made using washed pretreated lignocellulose [10–12]. During the washing step, all the inhibitors generated during the pretreatment process are removed. Therefore, for more realistic industrial applications of cellulosic ethanol, the use of unwashed pretreated lignocellulose slurry needs to be evaluated. There are few published studies regarding whole slurry saccharification and fermentation of pretreated lignocellulose for ethanol production [13, 14]. In these studies, a detoxification process using dilute sulfuric acid was required [13]. Additionally, pretreatment with maleic acid was not sufficiently effective for lignocellulose with a high lignin content [14]. In this study, saccharification and fermentation, using pretreated lignocellulose as whole slurry, were applied to rice straw. After pretreatment with maleic acid at a high temperature, pretreated rice straw was tested as a substrate for ethanol production using cellulase and Saccharomyces cerevisiae. We sought to determine the feasibility of whole slurry processing without the need for solid/liquid (S/L) separation, detoxification steps, or removal of pretreatment inhibitors with the overall aim of improving the process economics of cellulosic fuel production.

Materials and methods

Lignocellulosic biomass and its compositional analysis

Rice straw harvested from Yeonggwang, Korea, in 2011 was used as the lignocellulosic biomass in this study. Rice straw was washed with tap water, air-dried, milled using a cutting mill (MF 10; IKA, Staufen, Germany), and sieved to give particles of 90–1000 μm. Carbohydrates, acid-insoluble lignin, ash in the solid fraction, along with sugars and their degradation byproducts in the liquid fraction after pretreatment were analyzed following the Laboratory Analytical Procedure (LAP) of the National Renewable Energy Laboratory (NREL; Golden, CO, USA) [15–18]. An Aminex HPX-87P column (Bio-Rad, Hercules, CA, USA) was used to quantify sugar monomers. High performance liquid chromatography (HPLC; Agilent 1100, Agilent Technologies, Waldronn, Germany) employing an HPX-87H column (Bio-Rad) was used to measure levels of furfural, HMF, acetic acid, formic acid, levulinic acid, glycerol, and ethanol as previously described [1].

Acidic pretreatment of rice straw

Ground dry rice straw (2 g) was suspended in 20 mL of maleic acid at various concentrations (0–2 %, w/v) in 100-mL vessels (SK-12 type; Milestone, Shelton, CT, USA) equipped with a thermocouple. The mixture of rice straw and maleic acid was allowed to digest for various holding times after 3 min ramping to a set temperature in an ETHOS EZ microwave oven (Milestone). Insoluble solids that separated from pretreated slurry were washed and filtered through a filter cloth (22–25 μm pore size; Calbiochem, La Jolla, CA, USA) with approximately 1 L of distilled water until the pH of the filtrate was 6–7. A portion of the representative insoluble solids was transferred to aluminum dishes and dried at 45 °C for 3 days for subsequent analysis of biomass composition. The remaining insoluble solids were stored at −20 °C until required. For whole slurry fermentation, the solid and liquid fractions of the pretreated slurry were not separated.

Enzymatic digestibility of pretreated rice straw

To evaluate the effectiveness of pretreatment, pretreated and washed rice straw was enzymatically hydrolyzed using 15 filter paper units (FPU) of Accellerase 1000 (Genencor, Rochester, NY, USA) per g glucan in pretreated and washed rice straw. By the definition of FPU, 0.1875 FPU of cellulase in a 0.5 mL assay aliquot is supposed to liberate 20 mg of glucose from 50 mg of filter paper in 60 min at 50 °C at pH 4.8 [19]. Pretreated or untreated rice straw at a final glucan concentration of 1 % (w/v) was added to 10 mL of 0.05 M sodium citrate buffer (pH 4.8) following the LAP of the NREL [20]. Enzymatic digestibility was expressed as the percentage of the theoretical maximum yield of glucose produced from the initial biomass. To determine the statistical significance of differences among experimental variables, one-way analysis of variance (ANOVA) in conjunction with the post hoc least significant difference test was performed using Statistica version 7.1 (StatSoft, Tulsa, OK, USA).

Simultaneous saccharification and fermentation (SSF) of rice straw

We used SSF to produce ethanol from untreated or pretreated rice straw. A final glucan concentration of 3 % (w/v) for untreated or pretreated washed rice straw was used following the NREL protocol for the SSF of lignocellulose [21]. A total biomass concentration of 6 % (w/v) based on untreated rice straw was used for whole slurry fermentation. For whole slurry SSF of pretreated rice straw, the pH of the SSF medium was adjusted to 4.8 (±0.2) using 28 % (w/w) ammonia solution (Junsei Chemical, Tokyo, Japan). After autoclaving the SSF media at 121 °C for 20 min, 15 FPU/g glucan of Accellerase 1000 was added to the SSF medium. The SSF medium was then inoculated with 5 % (v/v) S. cerevisiae D5A (ATCC 200062) that had been growing in YPD medium [1 % (w/v) yeast extract, 2 % (w/v) peptone, 2 % (w/v) glucose]. SSF was conducted for 60 h in a flask with a needle-pierced silicone stopper to vent CO2 produced during fermentation; flasks were incubated at 38 °C and 170 rpm. Ethanol yields were expressed as the percentage theoretical maximum based on the glucan content in the initial biomass before pretreatment.

Results and discussion

Effects of pretreatment temperature and time on the enzymatic digestibility of rice straw

The effects of pretreatment temperature on the enzymatic digestibility of rice straw were investigated at 160–190 °C. The concentration of maleic acid was 1 % (w/v), and solids loading was 10 % (w/v) with 3 min ramping to the desired temperature and a 90 s hold (Fig. 1). Upon increasing the temperature from 180 to 190 °C, a significant increase in enzymatic hydrolysis yield from 60.3 to 83.5 %, was observed with a 99 % confidence level. This can be attributed to the increased rate of chemical reactions at a higher temperature as previously demonstrated [13, 14]. Pretreatment at 190 °C resulted in the greatest levels of digestibility. Because of limitation in the equipment used, a further increase in temperature, beyond 190 °C, was not possible. Therefore, 190 °C was selected as the optimum temperature for pretreatment.

Effects of pretreatment temperature on enzymatic digestibility. Pretreatment was conducted using 1 % (w/v) maleic acid, a solid loading of 10 % (w/v), and a 90 s hold with 3 min ramping to the set temperature. Enzymatic hydrolysis was conducted using 15 FPU of Accellerase 1000/g glucan at pH 4.8, 50 °C, and 200 rpm for 50 h

Pretreatment of rice straw over different holding times was performed after ramping for 3 min to 190 °C with a solids loading of 10 % (w/v) and 1 % (w/v) maleic acid (Fig. 2). A holding time of 180 s resulted in an increase of enzymatic digestibility from 71.7 to 91.5 %. However, a further increase in holding time to 360 s did not significantly increase enzymatic digestibility. Therefore, a 180-s holding time was selected as the optimal pretreatment time.

Effects of pretreatment time on enzymatic digestibility. Pretreatment was conducted using 1 % (w/v) maleic acid and solids loading of 10 % (w/v) for different holding times after 3 min ramping to 190 °C. Enzymatic hydrolysis was conducted using 15 FPU of Accellerase 1000/g glucan at pH 4.8, 50 °C, and 200 rpm for 50 h

Effects of maleic acid concentrations on the enzymatic digestibility of rice straw

The optimal maleic acid concentration for the pretreatment of rice straw was determined by varying the maleic acid concentration from 0.1 to 2.0 % (w/v). Solid loading was 10 % (w/v) for a 3 min holding time with 3 min ramping to 190 °C (Fig. 3). Enzymatic digestibility of 91.5 % was obtained when the concentration of maleic acid was 1.0 % (w/v). In previous studies, the optimal concentrations of maleic acid for the hydrolysis of cellobiose and wheat straw were 0.6 and 0.5 % (w/v) at 160 and 170 °C, respectively [22, 23]. In another study, the optimal maleic acid concentration for pretreatment of oil palm empty fruit bunches (EFB) was 1 % (w/v) [14].

Effects of maleic acid concentration on enzymatic digestibility. Pretreatment was conducted using various concentrations of maleic acid, solid loading of 10 % (w/v), and a 3 min hold with 3 min ramping to 190 °C. Enzymatic hydrolysis was conducted using 15 FPU of Accellerase 1000/g glucan at pH 4.8, 50 °C, and 200 rpm for 50 h

Compositional analysis of rice straw

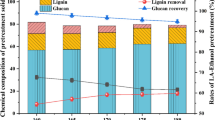

Untreated rice straw was composed of 35.8 % glucan, 11.3 % xylan, 3.3 % galactan, 3.4 % arabinan, 18.1 % acid insoluble lignin, and 11.9 % ash on a dry weight basis (Table 1). This composition was comparable to that of rice straw used in other studies [11, 24]. After rice straw was pretreated at the optimal conditions we determined, insoluble solids recovery yields were 53.2 % (w/w). Approximately, 100 % of mass balance closure was obtained for glucan, including glucose in the dissolved solids after maleic acid pretreatment. Most of the glucan was retained in the insoluble solids of pretreated rice straw (Table 1). Unlike glucan, most hemicellulose (85.7 %) was solubilized in the liquid fraction of pretreated rice straw. Therefore, the dissolved sugars in the liquid phase should be utilized. According to a previous study, maleic acid pretreatment of wheat straw resulted in nearly 100 and 90 % recovery of glucan and xylan, respectively, from solids and liquid [22]. These previous results, taken together with our results, indicate higher recovery and lower degradation of sugars for maleic acid pretreatment compared with sulfuric acid pretreatment [13]. Moreover, 40.6 % of lignin was removed from rice straw after maleic acid pretreatment. This degree of delignification of rice straw was much higher than that from EFB pretreated using maleic acid (27.4 %). This is possibly because rice straw is less complex, with weaker interactions between lignocellulose components than EFB. Maleic acid pretreatment resulted in lower levels of byproducts, such as acetic acid and furfural, compared with those generated when sulfuric acid was used during pretreatment [25]. This can mainly be attributed to the catalytic nature of maleic acid, which is more favorable for the hydrolysis of cellulose or hemicellulose, as opposed to monomer degradation [23, 26–28].

Whole slurry SSF of maleic acid-pretreated rice straw

To compare the fermentability of the pretreated whole slurry of rice straw with pretreated washed solid rice straw, SSF was conducted (Fig. 4). Ethanol yields were expressed as the percentage of the theoretical maximum yield of ethanol based on total glucan content in the untreated biomass. Given that ethanol production was determined on the basis of untreated biomass, yields were low when only pretreated washed biomass was used in SSF. Ethanol yields after 60 h were 58.1 and 37.3 % for pretreated washed and untreated rice straw, respectively. Use of whole slurry in SSF resulted in an ethanol yield of 83.2 %, 1.4-fold higher than that for pretreated washed rice straw (Fig. 4). This increase in ethanol yield was due to the increased use of glucan and glucose in the solid and liquid fractions of the pretreated whole slurry.

Simultaneous saccharification and ethanol fermentation (SSF) of pretreated rice straw. In the SSF media, 3 % (w/v) glucan for untreated or pretreated washed rice straw was used. A total biomass concentration of 6 % (w/v) based on untreated rice straw was delivered for SSFs of the whole slurry of the maleic acid-pretreated rice straw. For SSF, rice straw was incubated with S. cerevisiae D5A and 15 FPU of Accellerase 1000/g of glucan at pH 4.8, 38 °C, and 170 rpm for 60 h

Based on the results obtained from this study, untreated rice straw (100 g) produces 7.6 g of ethanol by SSF, based on total glucan content in the initial biomass (Fig. 5). When solid rice straw is pretreated with maleic acid, 11.8 g of ethanol can be obtained from 100 g of biomass. However, when SSF is carried out using a whole slurry of pretreated rice straw without S/L separation, 16.9 g of ethanol is produced from 100 g of rice straw.

Mass balance for the conversion of rice straw into ethanol using whole slurry or washed solids of pretreated rice straw. Rice straw was pretreated with 1 % (w/v) maleic acid at 190 °C for 3 min with 10 % solids loading. Pretreated rice straw was hydrolyzed with 15 FPU Accellerase 1000/g glucan and fermented with S. cerevisiae D5A at 38 °C and 170 rpm for 60 h

In conclusion, maleic acid pretreatment of rice straw to generate a whole slurry can be effectively used in SSF without S/L separation. SSF of the whole slurry of maleic acid-pretreated rice straw resulted in an 83.2 % theoretical ethanol yield, which was higher than that when untreated rice straw was used. Therefore, whole slurry SSF using maleic acid-pretreated rice straw is a viable alternative for the ethanol production industry. It is more economical to use this whole slurry because S/L separation is not required, detoxification is not necessary, and the utilization of available sugars in the pretreated lignocellulosic biomass is maximal.

References

Jung YH, Park HM, Kim IJ, Park Y-C, Seo J-H, Kim KH (2014) One-pot pretreatment, saccharification and ethanol fermentation of lignocellulose based on acid-base mixture pretreatment. RSC Adv 4:55318–55327

Modenbach AA, Nokes SE (2012) The use of high-solids loadings in biomass pretreatment—a review. Biotechnol Bioeng 109:1430–1442

Rollin JA, Zhu Z, Sathitsuksanoh N, Zhang Y-HP (2011) Increasing cellulose accessibility is more important than removing lignin: a comparison of cellulose solvent-based lignocellulose fractionation and soaking in aqueous ammonia. Biotechnol Bioeng 108:22–30

Jung YH, Kim KH (2014) In: Pandey A, Negi S, Binod P, Larroche C (eds) Pretreatment of biomass: processes and technologies, 1st edn. Academic Press, Massachusetts

Liu ZL (2011) Molecular mechanisms of yeast tolerance and in situ detoxification of lignocellulose hydrolysates. Appl Microbiol Biotechnol 90:809–825

Almeida JRM, Modig T, Petersson A, Hähn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349

Klinke HB, Thomsen AB, Ahring BK (2004) Inhibition of ethanol-producing yeast and bacteria by degradation products produced during pre-treatment of biomass. Appl Microbiol Biotechnol 66:10–26

Jönsson LJ, Alriksson B, Nilvebrant N-O (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:16

Huang H, Guo X, Li D, Liu M, Wu J, Ren H (2011) Identification of crucial yeast inhibitors in bio-ethanol and improvement of fermentation at high pH and high total solids. Bioresour Technol 102:7486–7493

Kim Y, Mosier NS, Ladisch MR, Pallapolu VR, Lee YY, Garlock R, Balan V, Dale BE, Donohoe BS, Vinzant TB, Elander RT, Falls M, Sierra R, Holtzapple MT, Shi J, Ebrik MA, Redmond T, Yang B, Wyman CE, Warner RE (2011) Comparative study on enzymatic digestibility of switchgrass varieties and harvests processed by leading pretreatment technologies. Bioresour Technol 102:11089–11096

Ko JK, Bak JS, Jung MW, Lee HJ, Choi I-G, Kim TH, Kim KH (2009) Ethanol production from rice straw using optimized aqueous-ammonia soaking pretreatment and simultaneous saccharification and fermentation processes. Bioresour Technol 100:4374–4380

Jung YH, Kim IJ, Han J-I, Choi I-G, Kim KH (2011) Aqueous ammonia pretreatment of oil palm empty fruit bunches for ethanol production. Bioresour Technol 102:9806–9809

Jung YH, Kim IJ, Kim HK, Kim KH (2013) Dilute acid pretreatment of lignocellulose for whole slurry ethanol fermentation. Bioresour Technol 132:109–114

Jung YH, Kim IJ, Kim HK, Kim KH (2014) Whole slurry fermentation of maleic acid-pretreated oil palm empty fruit bunches for ethanol production not necessitating a detoxification process. Bioproc Biosyst Eng 37:659–665

Sluiter A, Hames B, Hyman D, Payne C, Ruiz R, Scarlata C, Sluiter J, Templeton D, Wolfe J (2008) Laboratory Analytical Procedure: Determination of total solids in biomass and total dissolved solids in liquid process samples. National Renewable Energy Laboratory, NREL/TP-510-42621, Golden, CO

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2005) Laboratory Analytical Procedure: Determination of ash in biomass. National Renewable Energy Laboratory, NREL/TP-510-42622, Golden, CO

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2006) Laboratory Analytical Procedure: Determination of sugars, byproducts, and degradation products in liquid fraction process samples. National Renewable Energy Laboratory, NREL/TP-510-42623, Golden, CO

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Laboratory Analytical Procedure: Determination of structural carbohydrates and lignin in biomass. National Renewable Energy Laboratory, NREL/TP-510-42618, Golden, CO

Adney B, Baker J (2008) Laboratory Analytical Procedure: Measurement of cellulase activities. National Renewable Energy Laboratory, NREL/TP-510-42628, Golden, CO

Selig M, Weiss N, Ji Y (2008) Laboratory Analytical Procedure: Enzymatic saccharification of lignocellulosic biomass. National Renewable Energy Laboratory, NREL/TP-510-42629, Golden, CO

Dowe N, McMillan (2008) Laboratory Analytical Procedure: SSF experimental protocols-lignocellulosic biomass hydrolysis and fermentation. National Renewable Energy Laboratory, NREL/TP-510-42630, Golden, CO

Kootstra AMJ, Beeftink HH, Scott EL, Sanders JPM (2009) Optimization of the dilute maleic acid pretreatment of wheat straw. Biotechnol Biofuels 2:31

Mosier NS, Sarikaya A, Ladisch CM, Ladisch MR (2001) Characterization of dicarboxylic acids for cellulose hydrolysis. Biotechnol Prog 17:474–480

Hsu T-C, Guo G-L, Chen W-H, Hwang W-S (2010) Effect of dilute acid pretreatment of rice straw on structural properties and enzymatic hydrolysis. Bioresour Technol 101:4907–4913

Kootstra AMJ, Beeftink HH, Scott EL, Sanders JPM (2009) Comparison of dilute mineral and organic acid pretreatment for enzymatic hydrolysis of wheat straw. Biochem Eng J 46:126–131

Lu Y, Mosier NS (2007) Biomimetic catalysis for hemicellulose hydrolysis in corn stover. Biotechnol Prog 23:116–123

Lu Y, Mosier NS (2008) Kinetic modeling analysis of maleic acid-catalyzed hemicellulose hydrolysis in corn stover. Biotechnol Bioeng 101:1170–1181

Mosier NS, Ladisch CM, Ladisch MR (2002) Characterization of acid catalytic domains for cellulose hydrolysis and glucose degradation. Biotechnol Bioeng 79:610–618

Acknowledgments

This work was supported by grants from the Ministry of Trade, Industry & Energy (10047873 and 10049674). A Korea University grant through the Korea University Food Safety Hall for the Institute of Biomedical Science and Food Safety is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jung, Y.H., Park, H.M. & Kim, K.H. Whole slurry saccharification and fermentation of maleic acid-pretreated rice straw for ethanol production. Bioprocess Biosyst Eng 38, 1639–1644 (2015). https://doi.org/10.1007/s00449-015-1405-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1405-8