Abstract

The yield of ethanol from oil palm empty fruit bunches (EFB) was increased on exploiting maleic acid pretreatment combined with fermentation of the pretreated whole slurry. The optimized conditions for pretreatment were to expose EFB to a high temperature (190 °C) with 1 % (w/v) maleic acid for a short time duration (3 min ramping to the set temperature with no holding) in a microwave digester. An enzymatic digestibility of 60.9 % (based on theoretical glucose yield) was exhibited using pretreated and washed EFB after 48 h of hydrolysis. Simultaneous saccharification and fermentation (SSF) of the whole slurry of pretreated EFB for 48 h resulted in 61.3 % theoretical yield of ethanol based on the initial amount of glucan in untreated EFB. These results indicate that maleic acid is a suitable catalyst not requiring detoxification steps for whole slurry fermentation of EFB for ethanol production, thus improving the process economics. Also, the whole slurry fermentation can significantly increase the biomass utilization by converting sugar from both solid and liquid phases of the pretreated slurry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Oil palm empty fruit bunches (EFB) are the major wastes of the oil palm industry. Approximately, 25.9 million and 19.8 million tons of EFB are annually produced from Indonesia and Malaysia, respectively [1, 2]. Owing to their abundant mass and high cellulose and xylan contents, EFB have attracted much attention as an ideal biomass for producing bioethanol [3, 4]. At present, EFB are left in waste ponds for self-decomposition or are burnt in the field for producing ash for fertilizer [4, 5].

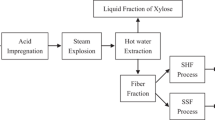

The major obstacle in producing ethanol from EFB is the high recalcitrance of EFB [6]. There have been several attempts to alleviate the recalcitrance of EFB by various pretreatment methods using ammonia, dilute sulfuric acid, sodium hydroxide, or steam [3, 7–10], in which, however, only washed biomass from pretreated slurry was used for ethanol production. The overall yield of ethanol from EFB could be increased by utilizing the soluble sugar in the liquid fraction of the pretreated slurry. Thus, in the present study, a maleic acid pretreatment step was introduced, which is known to produce less inhibitors [11, 12] as compared to using a strong acid such as sulfuric acid that generates substantial inhibitors from the degradation of sugar and lignin [13].

In general, although during the acid or alkali pretreatment [14, 15], a substantial amount of sugar is solubilized from hemicellulose and cellulose, most studies were focused on the hydrolysis and/or fermentation of the washed pretreated biomass [16–19]. To reduce the processing cost regarding the solid/liquid separation and to enhance the sugar recovery yield after pretreatment, both liquid and solid fractions should be utilized together as the whole slurry. So far, only a few studies have used the whole slurry of pretreated lignocellulose for ethanol fermentation [20, 21]. However, they all applied detoxification steps to the liquid phase of pretreated biomass for enhancing the ethanol yield. In this study, because of the toxicity of sulfuric acid in the process of whole slurry fermentation [21], maleic acid was applied in the pretreatment step as an alternative catalyst. Then, to decrease the cost of the solid and liquid separation process and to increase the sugar utilization, the whole slurry of maleic acid-pretreated EFB was used in simultaneous saccharification and ethanol fermentation without any additional treatments including detoxification or conditioning steps.

Materials and methods

Biomass and its composition analysis

Oil palm EFB were obtained from the Tropical Chase (Kuala Lumpur, Malaysia). The EFB were washed and milled to obtain particle sizes of 125–706 μm using a high-speed rotary cutting mill (MF 10; IKA, Staufen, Germany) and were further analyzed according to the Laboratory Analytical Procedure (LAP) of National Renewable Energy Laboratory (NREL; Golden, CO, USA) [22]. The carbohydrate and organic acid composition of pretreated or untreated EFB was analyzed by a high performance liquid chromatography (HPLC; Agilent 1100, Agilent Technologies, Waldbronn, Germany) equipped with a refractive index detector (G1362A, Agilent Technologies). HPLC was carried out on an SP0810 column (Pb2+ form; Shodex, Showa Denko, Kawasaki, Japan) to quantify sugars such as glucose, xylose, galactose, arabinose, and mannose, or on an Aminex HPX-87H column (H+ form; BioRad, Hercules, CA, USA) to determine the concentration of ethanol or inhibitors including furfural, hydroxymethylfurfural (HMF), acetic acid, formic acid, and levulinic acid, and glycerol. All analyses were conducted in triplicate.

Maleic acid pretreatment of EFB

EFB were suspended in various concentrations of maleic acid at a solid-to-liquid (S/L) ratio of 1:10 in SK-12 type vessels with an internal volume of 100 mL equipped with a thermocouple in an Ethos EZ Microwave Digestion Labstation (Milestone, Shelton, CT, USA). The EFB and maleic acid mixture slurry was digested for various holding times with 3 min ramping to a set temperature. To determine the enzymatic digestibility of pretreated EFB, the solid fraction separated from the pretreated slurry was washed with distilled water and filtered through a filtration cloth (pore size: 22–25 μm; Calbiochem, La Jolla, CA, USA) using distilled water until the pH of the wash water reached 6–7. The insoluble solids were transferred to aluminum dishes and vacuum-dried in a drying-oven (SH-450; BioFree, Seoul, Korea) at 45 °C for more than 3 days. For the whole slurry fermentation, the solid and liquid fractions were not separated.

Enzymatic digestibility of pretreated EFB

The effect of maleic acid pretreatment was validated by enzymatically hydrolyzing pretreated and washed EFB with cellulase (Celluclast 1.5 L, 58.7 FPU/mL; Novozymes, Bagsvaerd, Denmark) and β-glucosidase (Novozyme 188, 812.8 CBU/mL; Novozymes), according to the LAP of NREL [23]. Pretreated (test) or untreated (control) EFB were added to 10 mL of 0.05 M sodium citrate buffer (pH 4.8) at the final glucan concentration of 1 % (w/v). The extent of enzymatic saccharification was detected by HPLC or the dinitrosalicylic acid (DNS) assay [24]. One-way ANOVA with post hoc least significant difference (LSD) test was implemented using Statistica (Version 7.1, StatSoft, Tulsa, OK) to estimate the statistical significance of differences among experimental conditions.

Simultaneous saccharification and fermentation of EFB

Simultaneous saccharification and fermentation (SSF) was carried out to produce ethanol from untreated or pretreated EFB. Pretreated and washed EFB were added to the SSF media at the final glucan concentration of 3 % (w/v). SSF of untreated EFB and whole slurry of pretreated EFB was carried out by adding the biomass to the SSF media at the final biomass concentration of 6 % (w/v) based on untreated EFB. The pH of the whole slurry was adjusted to 4.8 (± 0.2) using 28 % (w/w) ammonia solution (Junsei Chemical, Tokyo, Japan) before SSF. The SSF media were autoclaved at 121 °C for 30 min, after which cellulase (Celluclast 1.5 L, 30 FPU/g glucan) and β-glucosidase (Novozyme 188, 30 CBU/g glucan) were added along with a 5 % (v/v) inoculum of Saccharomyces cerevisiae D5A (ATCC 200062) pre-cultured in YP media containing 1 % (w/v) yeast extract and 2 % (w/v) peptone. SSF was carried out for 72 h at 30 °C in flasks that had been equipped with needle-pierced silicone stoppers.

Growth of S. cerevisiae in the presence of maleic acid

The effect of maleic acid on the growth of S. cerevisiae was evaluated by adding various concentrations of maleic acid into the culture media composed of 1 % (w/v) yeast extract, 2 % (w/v) peptone, and 5 % (w/v) glucose in a 0.05 M citrate buffer. The final pH of the media was adjusted to 4.8 with 28 % (w/w) ammonia solution. The sterilized media were inoculated with pre-cultured S. cerevisiae D5A at 5 % (v/v) and incubated at 30 °C and shaken at 200 rpm for 48 h. The cell growth was monitored spectrophotometrically at 600 nm (Mark Microplate Spectrophotometer, Bio-Rad, Hercules, CA, USA).

Results and discussion

Effect of pretreatment variables

Acid pretreatment is known to aid the release of monomeric or oligomeric sugars by the almost complete solubilization of hemicellulose and the partial saccharification of cellulose [14, 25–27]. Therefore, in an acid pretreatment protocol, the total amount of sugar released may be related to the effectiveness of the pretreatment. In this study, the released reducing sugar was quantitatively determined by the DNS assay.

The optimum temperature for the maleic acid pretreatment of EFB was determined by assaying for the total reducing sugars released at various temperatures (such as at 130, 150, 170, and 190 °C) by fixing other conditions such as 1 % (w/v) of maleic acid and 1:10 of S/L ratio for the 90 s holding with a 3 min ramping to the set temperature. Upon increasing the temperature from 130 to 190 °C, the yield of the reducing sugar measured after enzymatic hydrolysis (at 50 h) significantly increased. On raising the temperature from 150 to 170 °C, the sugar yield concomitantly rose from 6.9 to 9.0 g reducing sugar/g EFB, as shown in Fig. 1a, which could be attributed to a higher reaction rate constant at a higher temperature akin to observations made in other pretreatment studies [11, 28, 29]. The highest yield of the reducing sugar was obtained at 190 °C (p < 0.1), this was selected as the optimum pretreatment temperature for further maleic acid pretreatments of EFB.

Effect of (a) pretreatment temperature, (b) pretreatment time, and (c) maleic acid concentration on the yield of reducing sugar (by DNS) from 100 g of EFB. In the pretreatment, the EFB solids concentration was 10 % (w/v), and the temperature was increased to the set temperature with a 3 min ramping in a microwave digester

The EFB pretreatment was carried out to find an optimal holding time (Fig. 1b, from 0 to 600 s) after ramping for 3 min at 190 °C in the microwave digester, with a fixed acid concentration and an S/L ratio at 1 % (w/v) and 1:10, respectively. It was observed that the yield of the reducing sugar rather decreased with increasing the pretreatment holding time. Thus, for further experiments, the holding time after 3 min of ramping was considered unnecessary.

The influence of acid concentration on the amount of reducing sugar released from EFB was studied by varying the maleic acid concentration (0–2 %) while maintaining the other conditions (i.e., 190 °C, 3 min ramping time, and 1:10 of S/L ratio). Consequently, from the control pretreatment experiment without using maleic acid (i.e., water), 5.5 g of reducing sugar was obtained from 100 g EFB, whereas pretreatment with 0.5 % (w/v) maleic acid raised the yield to 8.5 g/100 g EFB. The highest yield for reducing sugar (i.e., 15.3 g/100 g EFB) was obtained at 1 % (w/v) maleic acid. In another study involving the use of maleic acid for cellobiose hydrolysis, the optimum concentration of maleic acid was determined to be 0.6 % (w/v) [30]. This difference in the optimum maleic acid concentration could be because of the higher recalcitrance of EFB compared with that of cellobiose [3, 28]. Consequently, 1 % (w/v) was selected as the optimum concentration of maleic acid for further pretreatment experiments.

Compositional analysis of pretreated EFB

The composition of untreated EFB was determined to be 39.2 % (w/w) glucan, 17.4 % xylan, 2.5 % galactan, 4.5 % arabinan, and 31.8 % lignin on a dry weight basis (Table 1). The pretreatment of EFB was carried out at the optimal conditions of 190 °C, 3 min ramping to 190 °C without holding, and 1 % (w/v) acid concentration at 1:10 of S/L ratio. The insoluble solids recovery yields based on the initial dry weight of EFB were found to be 63.3 % (w/w), which was similar to that of aqueous ammonia pretreatment [3]. For instance, the higher amount of glucan compared to hemicellulose was retained in the insoluble solids of maleic acid-pretreated EFB. However, 73.6 % of xylan was solubilized into the liquid fraction of pretreated EFB. Conversely, only 27.4 % of lignin was removed, which was significantly lower than that from ammonia-pretreated EFB (41.1 %) [3]. This difference could be because of the fact that while acid acts on hemicellulose, alkali mainly targets lignin [14, 15]. Acetic acid, which is known to be derived from the acetylation between hemicellulose and lignin [13], was found to be the only inhibitor among the detected by-products or degradation products such as furfural, HMF, levulinic acid, and formic acid from the liquor fraction of maleic acid-pretreated EFB. In this study, the low levels of degradation products could be attributed to the use of maleic acid and the short pretreatment time (3 min) using the microwave digester. Moreover, others have reported that maleic acid pretreatment of lignocellulose formed a lower concentration of furfural as compared to that produced on using sulfuric acid [11]. Thus, owing to the less formation of inhibitors, maleic acid is considered as a suitable acid catalyst [12, 26, 30–32].

Enzymatic digestibility of maleic acid-pretreated EFB

Pretreated (190 °C, 3 min ramping, and 1 % (w/v) maleic acid) and water-washed EFB were hydrolyzed with 60 FPU cellulase per gram of glucan for 48 h, resulting in the highest enzymatic digestibility of maleic acid-pretreated EFB (60.9 %; Fig. 2), which was significantly higher than that (41.4 % enzymatic digestibility with 60 FPU/g glucan) obtained from EFB pretreated by soaking in aqueous ammonia [3]. In addition, despite the decreased lignin removal in the maleic acid pretreatment (27.4 %) compared to that in the ammonia pretreatment (41.1 %) [3], a relatively higher enzymatic digestibility was observed in the maleic acid pretreatment. Therefore, it could be concluded that the extent of lignin removal was not a key factor in determining the enzymatic digestibility of maleic acid-pretreated EFB.

SSF of maleic acid-pretreated EFB

SSF of untreated EFB, washed insoluble solids from pretreated EFB, or the whole slurry of pretreated EFB was carried out (Fig. 3). For more fundamental yield analysis, the ethanol yield was expressed as a percentage of the theoretical maximum yield of ethanol (i.e., 51 % (w/w) ethanol/glucose) based on the total glucan content of initial EFB, prior to pretreatment. The ethanol yields after 48 h of SSF were 9.7 and 39.0 % from the untreated EFB and the pretreated and washed EFB, respectively. In the case of the whole slurry fermentation of pretreated EFB, the ethanol yield after 48 h SSF increased to 61.3 %, which was 57.2 % higher than that of the pretreated and washed EFB. This difference could be attributed to the increased amount of soluble sugars in the liquid fraction of the whole slurry along with low levels of the inhibitors from sugar degradation (Table 2). According to the whole slurry fermentation using sulfuric acid-pretreated lignocellulose in a previous study [21], only around 50 % ethanol yield was obtained because of the higher inhibition by pretreatment byproducts in the sulfuric acid-pretreated slurry (i.e., higher furfural formation) and neutralization salt. Moreover, if a yeast that is metabolically engineered to ferment xylose is used in the SSF of the whole slurry, the ethanol yield could further increase.

Simultaneous saccharification and ethanol fermentation of untreated EFB, washed and pretreated EFB, and whole slurry of pretreated EFB. The SSF media for untreated EFB and the washed and pretreated EFB contained EFB loadings based on the final concentration of 3 % (w/v) glucan. In the SSF media for the whole slurry of pretreated EFB, the loading amount of the whole slurry of pretreated EFB referred to the final concentration of 6 % (w/v) of untreated EFB (before pretreatment). The SSF media containing EFB were incubated with Saccharomyces cerevisiae D5A and 30 FPU Celluclast 1.5 L and 30 CBU Novozyme 188 per gram of glucan at pH 4.8 and 30 °C for 48 h

Effect of ammonium maleate on growth of S. cerevisiae

The inhibitory effect of neutralization salt (i.e., ammonium maleate) on the growth of S. cerevisiae D5A was investigated by batch culture in YPD medium containing various concentrations of maleic acid at 30 °C for 48 h (Fig. 4). Until 48 h of cultivation, the addition of maleic acid up to a concentration of 2 % (w/v) did not show any significant negative effect on the cell growth. Therefore, it could be presumed that the neutralized maleic acid salt of 1 % (w/v) used in this study for the whole slurry of pretreated EFB did not affect the yeast cell growth. Further increasing maleic acid concentration to 3 % (w/v) inhibited cell growth. Overall, the neutralized maleic acid salt showed less inhibitory effect on the yeast cell growth in comparison with the neutralized sulfuric acid salt [21]. Therefore, although acid is neutralized, the amount of a neutralized acid catalyst needs to be taken into account when designing an ethanol production process using the whole slurry of lignocellulose.

Conclusions

This study showed that maleic acid would be a suitable catalyst for the production of ethanol from EFB, especially for the fermentation of pretreated whole slurry. Under the optimized conditions, 60.9 % enzymatic digestibility was obtained from pretreated EFB with 60 FPU of cellulase and 30 CBU of β-glucosidase per gram of glucan in 48 h of enzymatic hydrolysis. On using the pretreated whole slurry of EFB for SSF, 61.3 % of the theoretical maximum ethanol yield based on the initial glucan in untreated EFB was attained without any detoxification process. Thus, maleic acid pretreatment followed by fermentation using the whole slurry warrants a significantly high yield of ethanol from EFB with minimizing the solid/liquid separation cost and utilizing sugar in the liquid fraction of the whole slurry as well.

References

Bardant TB, Abimanyu H, Adriana N (2012) Effect of pretreatment technology on enzyme susceptibility in high substrate loading enzymatic hydrolysis of palm oil EFB and water hyacinth. Int J Environ Bioenerg 3:193–200

Daud WRW, Law K-N (2011) Review of oil palm fibers: oil palm fibers as papermaking material: potentials and challenges. Bioresources 6:901–917

Jung YH, Kim IJ, Han J-I, Choi I-G, Kim KH (2011) Aqueous ammonia pretreatment of oil palm empty fruit bunches for ethanol production. Bioresour Technol 102:9806–9809

Millati R, Wikandari R, Trihandayani ET, Cahyanto MN, Taherzadeh MJ, Niklasson C (2011) Ethanol from oil palm empty fruit bunch via dilute-acid hydrolysis and fermentation by Mucor indicus and Saccharomyces cerevisiae. Agric J 6:54–59

Alkhatib M, Abd RM, Alam MZ, Saleh HM (2011) Enzymatic hydrolysis of oil palm empty fruit bunch using immobilized cellulase enzyme. Afr J Biotechnol 10:18811–18815

Rozman HD, Ahmadhilmi KR, Abubakar A (2004) Polyurethane (PU)-oil palm empty fruit bunch (EFB) composites: the effect of EFBG reinforcement in mat form and isocyanate treatment on the mechanical properties. Polym Test 23:559–565

Kim JS, Choi WI, Kang M, Park JY, Lee J-S (2012) Kinetic study of empty fruit bunch using hot liquid water and dilute acid. Appl Biochem Biotechnol 167:1527–1539

Kim S, Park JM, Seo J-W, Kim CH (2012) Sequential acid-/alkali-pretreatment of empty palm fruit bunch fiber. Bioresour Technol 109:229–233

Shamsudin S, Shah UKM, Zainudin H, Abd-Aziz S, Kamal SMM, Shirai Y, Hassan MA (2012) Effect of steam pretreatment on oil palm empty fruit bunch for the production of sugars. Biomass Bioenerg 36:280–288

Sudiyani Y, Sembiring KC, Hendarsyah H, Alawiyah S (2010) Alkaline pretreatment and enzymatic saccharification of oil palm empty fruit bunch fiber for ethanol production. Menara Perkebunan 78:70–74

Kootstra AMJ, Beeftink HH, Scott EL, Sanders JPM (2009) Comparison of dilute mineral and organic acid pretreatment for enzymatic hydrolysis of wheat straw. Biochem Eng J 46:126–131

Kootstra AMJ, Mosier NS, Scott EL, Beeftink HH, Sanders JPM (2009) Differential effects of mineral and organic acids on the kinetics of arabinose degradation under lignocellulose pretreatment conditions. Biochem Eng J 43:92–97

Almeida JRM, Modig T, Petersson A, Hähn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349

Kim KH, Tucker M, Nguyen Q (2005) Conversion of bark-rich biomass mixture into fermentable sugar by two-stage dilute acid-catalyzed hydrolysis. Bioresour Technol 96:1249–1255

Ko JK, Bak JS, Jung MW, Lee HJ, Choi I-G, Kim TH, Kim KH (2009) Ethanol production from rice straw using optimized aqueous-ammonia soaking pretreatment and simultaneous saccharification and fermentation processes. Bioresour Technol 100:4374–4380

Pallapolu VR, Lee YY, Garlock RJ, Balan V, Dale BE, Kim Y, Mosier NS, Ladisch MR, Falls M, Holtzapple MT, Sierra-Ramirez R, Shi J, Ebrik MA, Redmond T, Yang B, Wyman CE, Donohoe BS, Vinzant TB, Elander RT, Hames B, Thomas S, Warner RE (2011) Effects of enzyme loading and β-glucosidase supplementation on enzymatic hydrolysis of switchgrass processed by leading pretreatment technologies. Bioresour Technol 102:11115–11120

Sanda T, Hasunuma T, Matsuda F, Kondo A (2011) Repeated-batch fermentation of lignocellulosic hydrolysate to ethanol using a hybrid Saccharomyces cerevisiae strain metabolically engineered for tolerance to acetic and formic acids. Bioresour Technol 102:7917–7924

Zaldivar J, Martinez A, Ingram LO (2000) Effect of alcohol compounds found in hemicellulose hydrolysate on the growth and fermentation of ethanologenic Escherichia coli. Biotechnol Bioeng 68:524–530

Kim Y, Mosier NS, Ladisch MR, Pallapolu VR, Lee YY, Garlock R, Balan V, Dale BE, Donohoe BS, Vinzant TB, Elander RT, Falls M, Sierra R, Holtzapple MT, Shi J, Ebrik MA, Redmond T, Yang B, Wyman CE, Warner RE (2011) Comparative study on enzymatic digestibility of switchgrass varieties and harvests processed by leading pretreatment technologies. Bioresour Technol 102:11089–11096

Dutta A, Dowe N, Ibsen KN, Schell DJ, Aden A (2010) An economic comparison of different fermentation configurations to convert corn stover to ethanol using Z. mobilis and Saccharomyces. Biotechnol Prog 26:64–72

Jung YH, Kim IJ, Kim HK, Kim KH (2012) Dilute acid pretreatment of lignocellulose for whole slurry ethanol fermentation. Bioresour Technol 132:109–114

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Laboratory analytical procedure: determination of structural carbohydrates and lignin in biomass. National Renewable Energy Laboratory, Golden, CO, USA

Selig M, Weiss N, Ji Y (2008) Laboratory analytical procedure: enzymatic saccharification of lignocellulosic biomass. National Renewable Energy Laboratory, Golden, CO, USA

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Elander RT, Dale BE, Holtzapple M, Ladisch MR, Lee YY, Mitchinson C, Saddler JN, Wyman CE (2009) Summary of findings from the biomass refining consortium for applied fundamentals and innovation (CAFI): corn stover pretreatment. Cellulose 16:649–659

Lu Y, Mosier NS (2007) Biomimetic catalysis for hemicellulose hydrolysis in corn stover. Biotechnol Prog 23:116–123

Lu XB, Zhang YM, Yang J, Liang Y (2007) Enzymatic hydrolysis of corn stover after pretreatment with dilute sulfuric acid. Chem Eng Technol 30:938–944

Jung YH, Kim IJ, Kim JJ, Oh KK, Han J-I, Choi I-G, Kim KH (2011) Ethanol production from oil palm trunks treated with aqueous ammonia and cellulase. Bioresour Technol 102:7307–7312

Kingston HM, Jassie LB (1986) Microwave energy for acid decomposition at elevated temperatures and pressures using biological and botanical samples. Anal Chem 58:2534–2541

Mosier NS, Sarikaya A, Ladisch CM, Ladisch MR (2001) Characterization of dicarboxylic acids for cellulose hydrolysis. Biotechnol Prog 17:474–480

Lu Y, Mosier NS (2008) Kinetic modeling analysis of maleic acid-catalyzed hemicellulose hydrolysis in corn stover. Biotechnol Bioeng 101:1170–1181

Mosier NS, Ladisch CM, Ladisch MR (2002) Characterization of acid catalytic domains for cellulose hydrolysis and glucose degradation. Biotechnol Bioeng 79:610–618

Acknowledgments

This work was supported by grants from the Advanced Biomass R & D Center of Korea (2011-0031353) funded by Korean Government (MEST) and from the Ministry for Food, Agriculture, Forestry and Fisheries (12128295500). A Korea University grant through the Institute of Biomedical Science and Food Safety at the Korea University Food Safety Hall is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jung, Y.H., Kim, I.J., Kim, H.K. et al. Whole slurry fermentation of maleic acid-pretreated oil palm empty fruit bunches for ethanol production not necessitating a detoxification process. Bioprocess Biosyst Eng 37, 659–665 (2014). https://doi.org/10.1007/s00449-013-1035-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-1035-y