Abstract

The production of ε-poly-l-lysine (ε-PL) by Streptomyces sp. M-Z18 from glycerol was investigated in a 5-L jar-fermenter. Batch fermentations by Streptomyces sp. M-Z18 at various pH values ranging from 3.5 to 4.5 were studied. Based on the analysis of the time course of specific cell growth rate and specific ε-PL formation rate, a novel two-stage pH control strategy was developed to improve ε-PL production by shifting the culture pH from 3.5 to 3.8 after 36 h of cultivation. By applying the strategy, the maximal ε-PL concentration and productivity had a significant improvement and reached 9.13 g L−1 and 4.76 g L−1 day−1, respectively, compared with those in one-stage pH control process where the pH value is controlled at 3.5 (7.83 g L−1 and 3.13 g L−1 day−1). Fed-batch fermentation with two-stage pH control strategy was also applied to produce ε-PL; final ε-PL concentration of 30.11 g L−1 was obtained, being 3.3-fold greater than that of batch fermentation. To our knowledge, it is the first report on production of ε-PL from glycerol in fermenter scale and achievement of high ε-PL production with two-stage pH control strategy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

ε-Poly-l-lysine (ε-PL) is an unusual, naturally occurring homo-polyamide of l-lysine with amide linkages between ε-amino and α-carboxyl groups. ε-PL has antimicrobial activity against most Gram-positive and Gram-negative bacteria, fungi, yeast and some viruses, etc. [1, 2]. Moreover, it is biodegradable, edible and non-toxic, and therefore, of interest to the food and pharmaceutical industry [3]. Currently, ε-PL is mainly used as a natural food preservative in many countries, including Japan, Korea, and the United States [4], and its safety has been confirmed by in vivo studies [5]. In addition, it can also act as an emulsifying agent, disinfectant, drug delivery carrier, endotoxin remover and biosensor [6].

ε-PL production has been achieved from glucose in batch and fed-batch systems by Streptomyces albulus S410 [7], Streptomyces albulus IFO 14147 [8] and Kitasatospora sp. MY 5-36 [9] with aerobic fermentation. Two-stage pH strategy is widely used in microbial fermentation, including in ε-PL production [7, 8]: in the first 48 h (phase I), the pH is kept above 5.0 to increase the cell growth; for the rest period of fermentation (phase II) the pH is maintained at around 4.0 to increase the ε-PL production. This strategy was applied to overcome the shortcoming of insufficient Streptomyces albulus S410 biomass for ε-PL producing when glucose was used as carbon source. Despite that very good productivities were achieved by the conversion of glucose, the possibility to obtain ε-PL from an inexpensive and renewable source is topical. That sort of substrate is the waste glycerol. It is received in large amounts as a waste product during the manufacturing of biodiesel from plant oils and animal fats. The waste glycerol is co-produced in a weight ratio of about 10% of the biodiesel [10]; conversion of this waste glycerol into substantial chemicals, such as 3-hydroxypropionic acid [11], 2,3-butanediol [12], 1,3-propandiol [13], PHB [14], succinic acid [15], by microbial fermentation would solve the problem of waste disposal. Therefore, it has the economic feasibility of ε-PL fermentation using glycerol as the carbon source by ε-PL-producing strains.

It is reported that several ε-PL-producing strains including Streptomyces No. 346 [16], Streptomyces noursei NRRL 5126 [17] and Streptomyces sp. M-Z18 [18] were able to ferment glycerol. However, in all these processes, ε-PL production was in minor quantity.

In this study, the effect of pH on ε-PL production by Streptomyces sp. M-Z18 from glycerol was systematically studied. A novel two-stage pH control strategy was established based on kinetic analysis, and successfully used for the enhanced production of ε-PL. Subsequently, a fed-batch culture was carried out with two-stage pH control strategy, and a more efficient production was observed. To the best of our knowledge, this is the first report on production of ε-PL from industrial glycerol in fermenter scale.

Materials and methods

Microorganism

Streptomyces sp. M-Z18 was isolated from soil as described by Nishikawa and Ogawa [19] and has been subjected to ultraviolet and nitrosoguanidine mutagenesis as described by Hiraki et al. [20].

Media and culture conditions

Agar slant medium contained (g L−1): glucose 10, yeast extract 5, beef extract 5, MgSO4·7H2O 0.5, K2HPO4 1, and agar 20, along with pH 7.0. The pre-culture medium, M3G, consisted of (g L−1): glucose 50, yeast extract 5, (NH4)2SO4 10, KH2PO4 1.36, K2HPO4 0.8, MgSO4·7H2O 0.5, ZnSO4·7H2O 0.04, FeSO4·7H2O 0.03. Initial pH of the medium was adjusted to 6.8 with 2 M NaOH and/or 1 M H2SO4. Fermentation medium, modified the improved medium [18], consisted of (g L−1): industrial glycerol [Kerry Oleochemical Industrial (Shanghai) Co. Ltd.] 60, (NH4)2SO4 5, beef extract 10, KH2PO4 4, MgSO4·7H2O 0.8, FeSO4·7H2O 0.05. The media were sterilized in an autoclave for 20 min at 121 °C. In agar slant and M3G medium, glucose was separately autoclaved.

The strain was maintained on agar slants. It was incubated at 30 °C for 5–7 days. After growth and sporulation, two loopful of spores of Streptomyces sp. M-Z18 was transferred to 80 ml of the M3G medium in a 500-ml shake-flask and incubated at 30 °C and 200 rpm for 24 h on a rotary shaker. This culture was used as seed in the subsequent experiments.

Batch and fed-batch fermentations were performed in a 5-L jar-fermenter (Baoxing Corp. Shanghai, China) with 3.5 L working volume. 300 mL of pre-cultured seed was inoculated into 3.2 L sterilized fermentation medium with an initial pH of 6.8. Agitation was provided by two Rushton turbines and varied from 200 to 700 rpm, so that it could control dissolved oxygen (DO) at about 30% which was monitored with a DO electrode (Mettler Toledo). Aeration was provided by a ring sparger with a range of 0.5–2.5 vvm. The pH change was detected by a pH electrode (Mettler Toledo) during cultivation. The fermentation temperature was maintained using a re-circulating water bath at 30 °C.

Effect of pH on ε-PL production in batch fermentation

To investigate the effect of pH on ε-PL production, Streptomyces sp. M-Z18 was cultivated in fermentation medium in a 5-L jar-fermenter with the initial pH at 6.8. During the cultivation, when pH dropped from initial pH 6.8 to 3.5, 3.8 and 4.5 naturally, it was then maintained respectively at such pH by automatically added 12.5% (v/v) NH4OH solution to the culture broth until the end of cultivation.

Two-stage pH control strategy for ε-PL production in batch fermentation

Based on the analysis of specific cell growth rate and specific ε-PL formation rate, a two-stage pH control strategy was proposed as following: after pH decreased from initial 6.8 to 3.5, the pH was controlled at 3.5 for 36 h of cultivation, and then pH was step-wise shifted to 3.8 to further promote ε-PL synthesis in later cultivation.

Two-stage pH control strategy for ε-PL production in fed-batch fermentation

When the glycerol in ε-PL batch fermentation with two-stage pH control strategy was below 10 g L−1, a sterilized pure glycerol was automatically and pulsed added to the culture broth by peristaltic pump, to maintain the residual glycerol at about 10 g L−1. Similarly, when NH3–N concentration was below 1 g L−1, a sterilized 600 g L−1 (NH4)2SO4 solution was also added to fermentation culture in the same manner as feeding glycerol, to maintain the residual NH3–N at about 1 g L−1.

Analytical methods

Samples were withdrawn from fermenter for analysis at regular intervals. The broth was centrifuged (4,500×g, 5 min) and the precipitate was collected, washed twice with distilled water and dried at 105 °C to constant weight to determine the biomass of the culture (dry cell weight, DCW), the supernatant was used to determine ε-PL according to the procedure described by Kahar et al. [7], glycerol by a colorimetric method using periodate and acetylacetone reagents [21] or HPLC (DIONEX, U-3000, USA) using an ion exchange column (Aminex HPX-87H, 300 × 7.8 mm, Hercules, CA, USA) and a refraction index detector (Shodex RI-101, Japan) at 60 °C. The mobile phase was 5 mM H2SO4, and the flow rate was 0.6 mL min−1. Ammonia nitrogen (NH3–N) was analyzed by a colorimetric method using Nessler reagent [22].

Results and discussion

Time profiles of ε-PL fermentation by Streptomyces sp. M-Z18 from glycerol without pH control

The typical fermentation process of Streptomyces sp. M-Z18 without pH control is shown in Fig. 1. It was observed that the pH of the culture broth decreased from its initial value of 6.8 to 3.4 within the initial 30 h of fermentation, but the pH did not varied much afterward. Before the pH decreased to 3.4, the cell growth increased rapidly and reached the maximum of 8.14 g L−1 at 30 h of cultivation. However, after the cell growth reached the maximum, a decrease of mycelia growth was observed, probably due to the extremely low pH value. The ε-PL accumulation started when the pH was lower than 4.0, and reached the maximum of 3.47 g L−1 at 84 h. However, ε-PL accumulation stopped afterward indicating no ε-PL production occurred in prolonged cultivation. When the cell growth increased in the initial 30 h of fermentation and the ε-PL accumulated from 18 to 84 h during the fermentation, the glycerol was consumed. The concentration of glycerol was decreased from its initial concentration of 60.0 to 40.0 g L−1 within 54 h and was consumed slowly afterward; the residual glycerol concentration remained at 33.0 g L−1 even after 96 h of cultivation. Compared with production of ε-PL from glucose by S. albulus S410 [7], S. albulus IFO 14147 [8], Kitasatospora sp. PL6-3 [23] and even by this strain itself (Streptomyces sp. M-Z18)[18], the decrease of pH is slower and final pH is higher in the ε-PL fermentation from glycerol by Streptomyces sp. M-Z18. As a result, the time profile of carbon source (glucose/glycerol) consumption, cell growth and ε-PL accumulation observed for cultivation of Streptomyces sp. M-Z18 is non-consistent with what was observed for other ε-PL-producing strains species previously reported [7, 8, 23]. From the above observation, it is deduced that the pH in the culture broth is critical in the cell growth and ε-PL production. Therefore, by proper control of pH in the culture broth, the cell growth may be prolonged which might enhance the production of ε-PL.

Effect of pH on ε-PL production by Streptomyces sp. M-Z18 from glycerol in batch fermentation

As shown in Fig. 2, the effects of pH values on ε-PL fermentations by Streptomyces sp. M-Z18 from glycerol were investigated. At pH lower than 3.5 or higher than 4.5, ε-PL was very low. Thus, the time-course data of these fermentations and the related kinetic parameters are not presented.

During the cultivation, when it decreased from initial 6.8 to 3.5, 3.8 and 4.5, the pH was then maintained respectively at such value until the end of cultivation (shown in Fig. 2d). As shown in Fig. 2a, cell growth increased when pH was increased from 3.5 to 4.5. With the increase of pH, the time to reach stationary phase shortened and the cell concentration increased. When the pH was set at 4.5, DCW reached a maximum of 19.22 g L−1 at 46 h. Figure 2b shows that the relatively higher maximum ε-PL concentrations of 7.83 and 6.49 g L−1 were obtained at the pH of 3.5 and 3.8, respectively. This suggested that the production of ε-PL using Streptomyces sp. M-Z18 was affected by pH value and either low (3.0) or high (4.5) pH was not beneficial for ε-PL production. Consistent with increasing of cell growth, the consumption of glucose was increased from pH 3.5 to 4.5 (Fig. 2c), but the increase in cells did not lead to high ε-PL production at the higher pH value. The reason may be that almost all intracellular ATP were consumed when large cells grew at the higher pH, therefore there is no or less ATP left for ε-PL biosynthesis by ε-PL synthetase [24].

To analyze the kinetic characteristics of the effect of pH on cell growth and ε-PL production, specific cell growth rate (μx) and specific ε-PL formation rate (q p) were calculated based on the data in Fig. 2. As shown in Fig. 3, the profiles of the specific cell growth rate and specific ε-PL formation rate under various controlled pH bioprocesses exhibited similar tendencies, but the maximum q p achieved at different fermentation times. Figure 3b demonstrates that the higher value of q p was found in pH 3.5 before 36 h, while in pH 3.8 the value of q p were significantly higher than pH 3.5 after 36 h. Meanwhile, Fig. 3a shows that when the lower pH was kept, the specific growth rate was decreased rapidly after pH was controlled at the set values. These results indicate that it is important to keep the cell growth at certain μx by pH control for enhancing ε-PL production in the late phase of fermentation. Therefore, to improve the efficiency of ε-PL production, it is thus presumed that ε-PL accumulation in fermentative system by Streptomyces sp. M-Z18 was separately regulated: pH 3.5 was preferred in the early stage of cultivation (before 36 h) to ensure higher specific ε-PL formation rate, and pH 3.8 was then required after 36 h to maintain the cell growing at certain μx for enhancing ε-PL synthesis advance.

Batch culture for ε-PL production with two-stage pH control strategy by Streptomyces sp. M-Z18 from glycerol

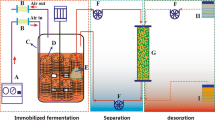

Based on the effect of pH on ε-PL accumulation, it was favorable to use a pH-shifted controlled process instead of a constant-pH controlled fermentation strategy. An optimal two-stage pH controlled strategy was developed to optimize ε-PL production as follows: after the pH was naturally decreased from initial pH 6.8 to 3.5, culture pH was controlled at pH 3.5 until 36 h of cultivation, and then pH was shifted to 3.8 to further promote ε-PL synthesis in later cultivation. Time course of two-stage pH controlled strategy for ε-PL fermentation was shown in Fig. 4. As expected, ε-PL concentration (9.13 g L−1) and productivity (4.13 g L−1 day−1) in the two-stage pH controlled fermentation process was further enhanced by 16.6 and 52.1%, respectively, compared with those of fermentation with pH controlled at 3.5 (shown in Table 1).

Fed-batch culture for ε-PL production with two-stage pH control strategy by Streptomyces sp. M-Z18 from glycerol

During the fermentation process, the cultivation pH would increase immediately when glycerol was depleted and resulted in depolymerization of existing ε-PL, as mentioned by Kahar et al. [7]. Therefore, we attempted to feed glycerol in order to avoid a pH increase during the cultivation. As was shown in Fig. 5, glycerol and NH3–N were added to fermentation culture when the substrates were below 10 and 1 g L−1, respectively. After 173 h fermentation, the ε-PL concentration and productivity reached 30.11 g L−1 and 4.18 g L−1 day−1, respectively, at the end of the fermentation (shown in Table 1).

Time course of fed-batch fermentation for ε-PL production from glycerol by Streptomyces sp. M-Z18 using the two-stage pH control strategy on DCW (filled square), ε-PL concentration (filled circle), Residual glycerol (filled triangle), Residual NH3–N (filled diamond) with pH (solid line) shifted from 3.5 to 3.8 at 36 h of cultivation; and kept residual glycerol and NH3–N at about 10 g L−1, 1 g L−1, respectively

Kinetic analysis of ε-PL production at different culture conditions by Streptomyces sp. M-Z18 from glycerol

Table 1 listed the results of constant-pH controlled strategy, two-stage pH control strategy, fed-batch fermentation with two-stage pH control strategy, and the parameters were analyzed. It was observed that two-stage pH control strategy could not only considerably improve the production of ε-PL but also increase the ε-PL productivity. The production of ε-PL was increased by 16.6% (from 7.83 to 9.13 g L−1), compared with that in the fermentation process of pH 3.5. Furthermore, the productivity of ε-PL was enhanced from 3.13 g L−1 day−1 (pH 3.5) to 4.76 g L−1 day−1 with this strategy. The results showed that the two-stage pH control strategy remarkably improved the productivity of ε-PL from glycerol by Streptomyces sp. M-Z18. Moreover, the two-stage pH control strategy was also beneficial for the cell growth, and 15.97 g L−1 of DCW was obtained at the end of the fermentation, compared with that in the fermentation process of pH 3.5 (13.00 g L−1). Finally, the fed-batch fermentation with two-stage pH control strategy enhanced the production of ε-PL further; and increased ε-PL production to 30.11 g L−1 from 7.83 g L−1 by Streptomyces sp. M-Z18.

Conclusion

This paper developed a novel two-stage pH control strategy based on the kinetic analysis for efficient ε-PL fermentation using Streptomyces sp. M-Z18 from glycerol. This method was proved a better strategy for the enhancement of ε-PL concentration, yield, and productivity. By applying this pH-shift control strategy, the ε-PL concentration, yield and productivity were increased by 16.6, 7.04 and 52.1%, respectively, compared with the best results of single pH-controlled process (pH3.5). Fed-batch fermentation with the novel two-stage pH control strategy was applied to ε-PL production and achieved the maximal ε-PL concentration and productivity of 30.11 g L−1 and 4.18 g L−1 day−1, respectively.

References

Hiraki J (2000) ε-Polylysine, its development and utilization. Fine Chem 29:18–25

Shima S, Matsuoka H, Iwamoto T, Sakai H (1984) Antimicrobial action of ε-poly-l-lysine. J Antibiot 37:1449–1455

Shih IL, Van YT, Shen MH (2004) Biomedical applications of chemically and microbiologically synthesized poly(glutamic acid) and poly(lysine). Med Chem 4:179–188

Yoshida T, Nagasawa T (2003) ε-Poly-l-lysine: microbial production, biodegradation and application potential. Appl Microbiol Biotechnol 62:766–772

Neda K, Sakurai T, Takahashi M, Ashiuchi M, Ohgushi M (1999) Two-generation reproduction study with teratology test of ε-poly-l-lysine by dietary administration in rats. Jpn Pharmacol Ther 27:1139–1159

Shih IL, Shen MH, Van YT (2006) Microbial synthesis of poly (l-lysine) and its various applications. Bioresour Technol 97:1148–1159

Kahar P, Iwata T, Hiraki J, Park EY, Okabe M (2001) Enhancement of ε-polylysine production by Streptomyces albulus strain 410 using pH control. J Biosci Bioeng 91:190–194

Shih IL, Shen MH (2006) Optimization of cell growth and poly(ε-lysine) production in batch and fed-batch cultures by Streptomyces albulus IFO 14147. Process Biochem 41:1644–1649

Zhang Y, Feng XH, Xu H, Yao Z, Ouyang PK (2010) ε-Poly-l-lysine production by immobilized cells of Kitasatospora sp. MY 5–36 in repeated fed-batch cultures. Bioresour Technol 101:5523–5527

da Silva GP, Mack M, Contiero J (2009) Glycerol: a promising and abundant carbon source for industrial microbiology. Biotechnol Adv 27:30–39

Raj SM, Rathnasingh C, Jo JE, Park S (2008) Production of 3-hydroxyl-propionic acid from glycerol by a novel recombinant Escherichia coli BL21 strain. Process Biochem 43:1440–1446

Petrov K, Petrova P (2009) High production of 2, 3-butanediol from glycerol by Klebsiella pneumoniae G31. Appl Microbiol Biotechnol 84:659–665

Menzel K, Zeng AP, Deckwer WD (1997) High concentration and productivity of 1, 3-propanediol from continuous fermentation of glycerol by Klebsiella pneumoniae. Enzym Microb Technol 20:82–86

Mothes G, Schnorpfeil C, Ackermann JU (2007) Production of PHB from crude glycerol. Eng Life Sci 7:475–479

Lee PC, Lee SY, Chang HN (2010) Kinetic study on succinic acid and acetic acid formation during continuous cultures of Anaerobiospirillum succiniciproducens grown on glycerol. Bioprocess Biosyst Eng 33:465–471

Shima S, Sakai H (1977) Polylysine produced by Streptomyces. Agric Biol Chem 41:1807–1809

Bankar SB, Singhal RS (2010) Optimization of poly-ε-lysine production by Streptomyces noursei NRRL 5126. Bioresour Technol 101:8370–8375

Chen XS, Tang L, Li S, Liao LJ, Zhang JH, Mao ZG (2011) Optimization of medium for enhancement of ε-Poly-l-Lysine production by Streptomyces sp. M-Z18 with glycerol as carbon source. Bioresour Technol 102:1727–1732

Nishikawa M, Ogawa K (2002) Distribution of microbes producing antimicrobial ε-poly-l-lysine polymers in soil microflora determined by a novel method. Appl Environ Microbiol 68:3575–3581

Hiraki J, Masakazu H, Hiroshi M, Yoshikazu I (1998) Improved ε-poly-l-lysine production of an S-(2-aminoethyl)-l-cysteine resistant mutant of Streptomyces albulus. Seibutsukogaku 76:487–493

Naviglio D, Romano R, Pizzolongo F, Santini A, De Vito A, Schiavo L, Nota G, Musso SS (2007) Rapid determination of esterified glycerol and glycerides in triglyceride fats and oils by means of periodate method after transesterification. Food Chem 102:399–406

AOAC International (formerly the Association of Official Analytical Chemists) (1995). Official Methods of Analysis Arlington, AOAC International, VA

Ouyang J, Xu H, Li S, Zhu HY, Chen WW, Zhou J, Wu Q, Xu L, Ouyang PK (2006) Production of ε-poly-l-lysine by newly isolated Kitasatospora sp. PL6-3. Biotechnol J 1:1459–1463

Yamanaka K, Kito N, Imokawa Y, Maruyama C, Utagawa T, Hamano Y (2010) Mechanism of ε-Poly-l-Lysine production and accumulation revealed by identification and analysis of an ε-Poly-l-Lysine-Degrading. Appl Environ Microbiol 76:5669–5675

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, XS., Li, S., Liao, LJ. et al. Production of ε-poly-l-lysine using a novel two-stage pH control strategy by Streptomyces sp. M-Z18 from glycerol. Bioprocess Biosyst Eng 34, 561–567 (2011). https://doi.org/10.1007/s00449-010-0505-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-010-0505-8