Abstract

The present work is dedicated to a comparative analysis of calculation methods about clothing insulation with a thermal manikin operating under the thermal comfort regulation mode. The serial, global, and parallel calculation methods are considered and the thermal insulation results for garments (30) and ensembles (9) are discussed. The serial and parallel methods presents the higher and lower values, respectively, and the differences were sometimes significant. Considering the results for the effective thermal insulation, the mean values of the relative differences between the serial and global methods were 25.7% for the daily wear garments, 45.2% for the cold protective garments and 38.5% for the ensembles. The corresponding mean values for the global and parallel methods were 8.7, 15.8, and 10.5%, respectively. Since any uneven clothing insulation is to be expected as a source of error, particular care must be required when the calculation methods deal with cold protective clothing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The thermal protection provided by clothing is one of the characteristics that must be duly considered whenever human thermal environments are to be analyzed, either from a daily wear or occupational point of view. In the case of moderate environments, the knowledge provided by thermal questionnaires shows that the majority of people recognize that thermal comfort is influenced by clothing. Under severe thermal environments the performance of clothing becomes of much greater significance. In the case of extreme latitudes, the common sense states that this is particularly true when people are exposed to outdoor environments. For the remaining countries that are commonly exposed to other climates, the exposure to cold thermal environments is human made, takes place indoors, is linked to industrial activities and generally comes from the food industry.

The assessment of the thermal resistance provided by the clothes is measured with the help of human subjects or on thermal manikins since these methods are the most appropriate because they reproduce reliably the way the clothes are used. The thermal behavior of the clothing on a person is difficult to quantify because it is a dynamic phenomenon influenced by various factors (Parsons 2003). Thus, due to the simplicity and repeatability of the experimental procedures and precision of the results (Soltynski et al. 2000), the thermal manikin represents the most common tool used to measure the thermal insulation (ISO 9920 2007). Several standards address the measurement specifications of the thermal resistance by means of a thermal manikin (ISO 9920 2007; ISO 15831 2004; ASTM F 1291 2004; EN 342 2004) and three different methods are proposed to calculate the clothing insulation, namely the global, the serial and the parallel methods. Depending on the boundary conditions that are imposed to the thermal manikin, these methods give different values. Therefore a discussion concerning the method to be used was raised in the scientific community.

The operation of the thermal manikins can be set with the constant skin temperature, the constant heat flux or the thermal comfort regulation modes in the different body parts (Silva 2002; Melikov 2004). Nevertheless, the measurements are usually carried out by setting a uniform skin condition, which now corresponds to the standardized procedure. In this case, if we call for the common analogy between electrical and thermal networks, the general formula for defining the whole body resistance turns into a summation of the local resistances according to a typical parallel model. If the constant heat flux regulation mode is used instead, then the local resistances are summed according to a serial model (Havenith 2002). These control methods are the most frequent, and that is probably the reason why most of the research studies consider only the serial and parallel methods.

A lot of investigation has been developed so far in order to assess the features of these methods. Ten years ago, Nilsson (1997) stated that the uneven distribution of clothing has a significant effect on the results obtained with the different methods and showed that the discrepancy between the serial and parallel methodologies increases with non-uniform insulation, i.e., when the heat loss from the manikin body parts are different. In an inter-laboratory trial of thermal insulation measurements with cold protective clothing Anttonen (2000) pointed out that the serial method consistently presents higher values and that the difference to the parallel method can amount to 30% or more. Holmér (2001) concluded that the serial method overestimates the insulation values of an ensemble, particularly if the clothing is unevenly distributed over the body. The above three studies agree that the parallel method gives a more stable indication of the insulation of an ensemble. McCullough (2001) states that most of the research laboratories use the parallel method and refers that the uneven distribution of clothing insulation is rather the rule than the exception and so, for the case of usual clothing, higher values should be expected with the serial method. More recently, Kuklane et al. (2007) concluded that the insulation values calculated with the serial method should not be used in the IREQ standard (ISO/TR 11079 1993).

Despite of the disadvantages of the serial method it is still considered in the standards EN 342 (2004) and ISO 15831 (2004).

The present work extends these previous analysis and addresses the study of the thermal insulation of clothing by considering a thermal manikin operating under the thermal comfort regulation mode. In fact, the results obtained with the three calculation methods are also different with this control method. Hence, the main objectives are aimed to compare the results obtained with the global, the serial, and the parallel methods, to highlight their characteristics and to quantify the differences obtained when different types of clothes are used. Accordingly, the measurements were performed with garments and ensembles and the results are presented and discussed for the basic, effective, and total clothing insulations. The distribution of clothing insulation over the body is also discussed and its influence on the results of the calculation methods is shown.

Methods

Thermal insulation of clothing

The heat exchanges between the human body and the environment depend on various factors, namely the clothing thermal characteristics, the clothing fit, the surrounding thermal and aerodynamic fields and the body movement (Fan and Qian 2004; Havenith and Nilsson 2004; Holmér 2004; Kuklane et al. 2004; Caravello et al. 2007). The thermal insulation provided by clothing is thus affected by the activity and the environmental conditions. The measurement of clothing insulation should therefore be carried out under reference conditions. In the case of measurements with thermal manikins, the test specifications are referred in different standards, namely in ISO 9920 (2007). Such measurements are defined in terms of the heat loss and the mean skin temperature of the manikin and the environmental conditions within the test chamber (air velocity, operative temperature, difference between air and mean radiant temperatures and relative humidity).

To calculate the thermal resistance of a given ensemble or garment, several expressions and definitions are proposed in the literature and the clothing insulation can be presented in terms of the total clothing insulation (I T), the effective clothing insulation (I cle for ensembles and I clu for garments) and the intrinsic or basic clothing insulation (I cl for ensembles and I cli for garments).

The total clothing insulation, I T (m2 °C W−1), is used to define the insulation from the skin surface to the environment, including the effect of the increased surface area represented by the clothing area factor, f cl, and the thermal resistance at the surface of the clothed body. From the experimental data I T can be calculated by

where T o is the operative temperature (°C), \( \bar T_{{{\text{sk}}}} \) is the mean skin temperature (°C), and \( \overline {\dot Q} _{{\text{s}}} \) is the sensible heat flux obtained by area weighing (W m−2).

At the body surface, the mechanisms of sensible heat transfer between the human body and the environment are due to convection (C), radiation (R), and conduction (K). The conductive heat exchange is related to the area of the body parts in direct contact with external surfaces and is mostly very small. In the present experiment, the manikin is hung from the head, thus the conductive heat exchange is nil. The combined thermal resistance to this heat flow transferred between the skin/clothing surface and the environment is called thermal insulation of the boundary air layer, I a (m2 °C W−1) defined by

where h c and h r are the mean convective and radiative heat transfer coefficients (W m−2 °C−1), respectively. Detailed work about the thermal insulation of the air layer and the convective and radiative heat transfer coefficients around the human body was developed by Oliveira et al. (2004) and Quintela et al. (2004), respectively.

For practical applications, the surface thermal insulation between an ensemble and the environment is estimated by performing a measurement with the nude manikin (ISO 9920 2007) and the correct way to do this is to measure I a under the same environmental conditions as the clothing tests (McCullough 2001). Thus, in the present experiments the thermal insulation of the air layer was estimated using Eq. 1.

If I a is subtracted to I T, we obtain the effective clothing insulation, I cle (I clu for garments) (m2 °C W−1),

or the intrinsic or basic clothing insulation, I cl (I cli for garments) (m2 °C W−1), if the surface area increase is considered

The f cl factor can be estimated from empirical expressions, namely the next one proposed by McCullough et al. (1985) for ensembles,

The thermal manikins divided into body parts that are independently controlled are useful to characterize the thermal resistance of clothing over each body part. However, this detailed information (surface temperature and heat flux of each part) raises an interesting discussion within the scientific community about the way to use these local data in order to calculate an equivalent thermal resistance of the whole body. Boundary conditions represented by equal skin temperatures were originally used in all body parts, but a constant heat flux was also considered (ISO 9920 2007). A control mode based on the thermal comfort equation proposed by Fanger (1972) was introduced by Madsen (1976) and it is also used nowadays. Therefore, depending on the thermal manikin control and on the calculation methods the thermal insulation can differ significantly. Havenith (2002) states that three calculation methods which are described in ISO 9920 (2007) are actually in use.

The global method (Oliveira et al. 2005a), i.e., the conventional method, performs an overall calculation and defines a whole body resistance, i.e., the area-weighted of all heat losses and skin temperatures of each body part are summed up before the insulation is calculated, like if we were dealing with a whole manikin made of only one segment. This is the general formula for defining the whole body resistance and the one that best fits the definition of thermal insulation expressed in ISO 9920 (2007).

The serial method makes use of the skin temperature and the heat flux from each segment to calculate the local resistances which are then summed according to a serial model. From a physical point of view and calling again for the analogy between heat transfer and electrical networks, the relative position of the local resistances over the human body is far from corresponding to a serial arrangement. Although this also cannot be considered as a true parallel model, because of the contact between body parts and the fact that the heat flux is not unidirectional (Havenith 2002), this configuration is closer to the reality. Also, it is important to note that the parallel method as mentioned in the literature does not necessarily correspond to the calculations of an equivalent resistance as given by a parallel model. For this reason the authors have renamed it as global, assigning the designation parallel to the method that represents a real parallel system. This physical analysis leads to the three above-mentioned methods used to estimate the thermal insulation of clothing which can be calculated from the following equations:

-

Global method

$$ I_{{\text{T}}} = \frac{{\sum {\left( {f_{i} \times \bar T_{{{\text{sk,}}i}} } \right) - T_{{\text{o}}} } }}{{\sum {\left( {f_{i} \times \dot Q_{{{\text{s,}}i}} } \right)} }} $$(6) -

Parallel method

$$ \frac{1}{{I_{{\text{T}}} }} = \sum {f_{i} \times \left( {\frac{{\dot Q_{{{\text{s}},i}} }}{{\bar T_{{{\text{sk,}}i}} - T_{{\text{o}}} }}} \right)} = \sum {f_{{\text{i}}} \times \frac{1}{{I_{{{\text{T,}}i}} }}} $$(7) -

Serial method

$$ I_{{\text{T}}} = \sum\limits_{i} {\left( {f_{i} \frac{{\bar T_{{{\text{sk,}}i}} - T_{{\text{o}}} }}{{\dot Q_{{{\text{s,}}i}} }}} \right)} = \sum\limits_{i} {f_{i} \times I_{{{\text{T,}}i}} } $$(8)

where f i represents the relationship between the surface area of segment i of the manikin, A i , and the total surface area of the manikin A (f i = A i /A). It is important to point out that the thermal insulation of the air layer, I a, was also calculated for the global, the parallel, and the serial methods and then used to calculate the corresponding effective and intrinsic clothing insulation values by Eqs. 3 and 4.

Comparing the three formulations, we can conclude that the global method (Eq. 6) is a general formula while the other two methods are specific cases. In fact, for uniform skin temperature conditions Eq. 6 turns into a summation of resistances according to a parallel model (Eq. 7), while for uniform heat flux conditions Eq. 6 turns into a summation of resistances according to a serial model (Eq. 8). Thus, the global method is the only one that can be considered correct for all manikin regulation modes. This is particularly relevant if the manikin operates under the thermal comfort regulation mode, as in this case only the global method is valid. However, the serial and parallel calculation methods are still used in practice.

In this paper, the evaluation of several garments and ensembles is used to compare the experimental results given by the three calculation methods when the manikin operates under the thermal comfort regulation mode. The results are presented and discussed in order to highlight the differences between the calculation methods and the corresponding errors that can be expected when the serial and parallel methods are used.

Individual garments and ensembles

To support the present analysis, 30 garments and 9 clothing ensembles were considered. The garments comprised 22 daily wear clothes (shoes, socks, underwear, trousers, shirts, and jackets…), and 8 cold protective coats and waistcoats. In the case of the ensembles, the results from previous studies focusing the occupational exposure to cold thermal environments in Portuguese industrial units (Oliveira et al. 2005b, 2007) were taken into account. An outcome of those studies shows that the typical cold protective ensemble used by the Portuguese workers can be represented by a combination of ordinary winter clothes (shoes, thick socks, briefs, trousers, long-sleeve flannel shirt, and a sweater) plus a cold protective garment for the most severe workplaces, particularly for those individuals operating in freezing and refrigerating cold stores.

According to the clothing data gathered during that survey, a common ensemble, referred hereafter as ensemble 0, was made up by selecting a representative piece of each garment. For the other ensembles a cold protective garment was added. A group of 8 cold protective jackets, kindly made available by 4 firms from the food industry were analyzed in the present study. This way we had available 9 typical ensembles used by Portuguese workers often exposed to cold environments. The experiments were carried out with the head of the manikin uncovered (i.e., no hair) and no gloves. The list of all the clothes tested is presented in Tables 1 and 2 together with a description of the textile components and the mass of the garments.

Climate chamber

The measurements were carried out in the climate chamber (CC) at the Laboratory of Industrial Aerodynamics (LAI). The CC with 4.5 m × 4.5 m of floor area and variable ceiling height (3 m in this work), has several capabilities to control air temperature, humidity, and air velocity in a wide range of conditions. The indoor environmental conditions were imposed through control of the inner wall temperatures and the tests took place under calm conditions, with air velocities within the CC lower than 0.15 m s−1.

Thermal manikin

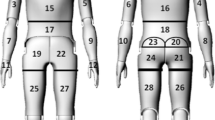

The thermal manikin used in this study (“Maria”, P. T. Teknik, Denmark), shown in Fig. 1, is made of a fiberglass armed polyester shell covered with a thin nickel wire wound around all the body to ensure heating and temperature measurement. It is articulated at the shoulders, hips, and knees by joints made of a circular cut in such a way that standing as well as sitting postures are quite natural. During the tests the manikin stood still placed at the center of the CC and kept in a supporting frame, hung from the head and with the feet 0.15 m away from the floor. The manikin has 16 independent parts controlled by a computer according to the relation between dry heat losses and skin temperature of the human body for conditions close to thermal comfort (Fanger 1972; Madsen 1976)

Physical parameters

The physical parameters of the environment were measured under ISO 7726 (1998) requirements and using equipment from Brüel and Kjær. The operative temperature and the air velocity were monitored with the thermal comfort meter (type 1213) and the air (T a) and globe (T g) temperatures were measured at three levels (feet, ankles, and head) with the heat stress monitor (type 1219), enabling the vertical temperature distribution to be checked within the CC.

Experimental procedure

The tests were carried out according to ISO 9920 (1995), which fits the specifications of the new ISO 9920 (2007) as well, namely the variation ranges of the mean skin temperature (\( \bar T_{{{\text{sk}}}} \)) and the heat flux (\( \overline {\dot Q} _{{\text{s}}} \)) of the manikin, respectively, 32–34°C and 40–80 W m−2. In order to guarantee the precision of the manikin, the experimental sessions for garments and ensembles were preceded by a temperature calibration of the thermal manikin. This procedure consists in maintaining the thermal manikin with the heating function off in two climate conditions of the chamber for a sufficient period to ensure that the mass of the manikin is at the same temperature of the surrounding air. From this data a linear calibration equation is set by the software which leads to a maximum temperature difference of 0.1°C.

The mean skin temperature, the heat flux of the manikin, and the room physical parameters were continuously monitored on computers, enabling an easy check of the establishment of steady state conditions.

In order to satisfy the ISO 9920 (1995) specifications, different environmental conditions were used for individual garments and for ensembles (see electronic supplementary material). Preliminary tests carried out in the CC under environmental conditions similar to the ones of the tests have shown that the air and globe temperatures were uniform with a maximum difference between the head and ankle levels of 0.3°C for T a and 0.5°C for T g. In these experiments, the mean radiant temperature (\( \bar T_{{\text{r}}} \)) was estimated from the air and globe temperatures taking into account the equation proposed in ISO 7726 (1998) for natural convection and the results showed that the difference between T a and \( \bar T_{{\text{r}}} \) was always lower than 1°C. Accordingly, the values of T a and T o measured in all the tests (see electronic supplementary material), show a maximum difference of 0.5°C.

The garments required comparatively higher room temperatures than the ensembles, thus leading to the measurement of different thermal insulations of the air layer (I a). For each CC condition the value of I a was determined by operating the manikin nude. For the garments, the values of I a calculated with the serial, global, and parallel methods ranged between 0.84 and 0.79 clo, while for the ensembles the corresponding variation was between 0.81 and 0.79 clo.

Data acquisition was started after achieving stationary conditions and lasted for 20 min, from which just the final 10 min were considered for analysis. During the acquisition period, the heat flux and the skin temperature of each body part were recorded every minute. Each experimental session did not take more than 45 min.

Results and discussion

In the next paragraphs, the results obtained with the individual garments are presented first and then a corresponding analysis is presented and discussed for the ensembles. Following ISO 9920 (2007) procedure, the basic (I cli) and effective (I clu) thermal insulations are presented for individual garments, while for ensembles the analysis is focused on the corresponding basic (I cl) and effective (I cle) values and also on the total thermal insulation (I T). The statistic significance of the differences between calculations methods were assessed by multiple t test and considering a significance level of 95%. The detailed results and figures of this research can be found elsewhere (Oliveira 2006).

Figure 2 shows, for daily wear garments, the basic (I cli) and effective (I clu) thermal insulations obtained with the global, serial, and parallel calculation methods. By adopting a graphic representation with growing I cli and I clu values, the garments with similar thermal insulation values appear closely together, allowing an easy identification of identical groups of garments and a more clear analysis. The values obtained with the serial method are the highest, followed by the global and the parallel methods. The limits of the thermal insulation values calculated with the three methods are presented in Table 3. Considering the basic (I cli) and the effective (I clu) thermal insulations, Table 4 shows that the mean value of the relative differences between the serial and global methods (serial/global-1) are 33.6 and 35.2%, respectively. For the global and parallel methods, the mean values of the relative differences (parallel/global-1) are −8.6% for I cli and −8.7% for I clu. We must underline that these results do not include those garments with I cli values, calculated through the serial method, that are lower than 0.1 clo. In these cases, from practical reasons and because of the lower thermal insulation values, the relative differences were not estimated.

In the case of the cold protective garments (see Fig. 3; Table 3) the serial method also presents the higher values. However, it is important to notice that the differences shown by the calculation methods are enhanced. Table 4 shows that the mean values of the relative differences between the serial and global methods are 78.4% for I cli and 83.5% for I clu. For the global and parallel methods, the mean values of the relative differences are −15.2 and −15.8%, respectively, for I cli and I clu. Thus, the results obtained with the daily wear and cold protective garments clearly highlight the differences shown by the calculation methods.

If the different types of garments are compared (see Table 4), the results show that the cold protective clothes are responsible for higher differences between the calculation methods than the daily wear and this can be easily understood because with the cold protective garments the insulation is much more unevenly distributed. Considering the I cli results, the mean value of the relative difference between the serial and global methods is 33.6% for the daily wear garments and 78.4% for the cold protective garments. The corresponding mean values of the relative differences for the global and parallel methods are −8.6% and −15.2%, respectively.

Figure 4 is assigned to the ensembles and shows the basic (I cl), effective (I cle) and total (I T) thermal insulations obtained with the three methods. As for the garments, the same general comments can be reproduced. Accordingly, as shown on Table 3, the parallel and serial methods always present the lower and higher values, respectively, and the values of the global method are in between those two. This characteristic is thus common to all the tests. Therefore, it can be pointed out as one of the main distinctive features of the calculation methods. The mean relative differences between the calculation methods for I T, I cl, and I cle are presented in Table 4. Considering the I T values, the mean value of the relative difference between the serial and global methods was 37.2%, while it reduces to −6.6% for the case of the global and parallel methods. For I cl the mean value of the relative difference was 58.3% for the serial and global methods and −10.1% between the global and parallel methods. The corresponding differences for I cle were 63.8 and −10.5%, respectively, for serial and global and for the global and parallel methods.

Taking into account the results for the garments and the ensembles, it is important to underline that the differences between the serial and global methods are always statistically significant (P < 0.05), while for the corresponding differences between the global and parallel methods are not significant (P > 0.05).

It must be emphasized that the smaller differences between the calculation methods are obtained with ensemble 0 (no cold protective jacket), which is the one with the most uniform clothing insulation. In contrast, ensembles 1–8 have higher insulations in the upper body parts as a result of their cold protective coats and waistcoats. Therefore the differences between the calculation methods are enhanced (see Fig. 4). In addition, it is important to notice that the tests were realized with the head and the hands of the manikin nude and that this condition plays a role in the results. Thus, these results clearly demonstrate the influence that the uneven distribution of the clothing insulation has in the calculation methods, particularly in the increase of results obtained with the serial method. Figure 5 illustrates the discrepancy of insulation over the whole body. It shows the total thermal insulation calculated with the serial method for each body part and for ensembles 0 and 8. As they have the lowest and highest total insulation values, the comparison can better illustrate the asymmetrical protection provided. It is evident in both cases that the higher insulation values are located in the upper body parts, i.e., in the trunk and the upper limbs. However, while ensemble 8 has an extreme distribution of clothing insulation, ensemble 0 is much more “homogeneous”. In this case, the relative differences between the serial and global methods are 13.9% for ensemble 0 and 44.5% for ensemble 8, when considering the I T values. The corresponding relative differences between the global and parallel methods are −4.2 and −7.4%, respectively.

Conclusions

In the present paper a wide sample of thermal insulation data, obtained with a manikin operating under the thermal comfort regulation mode, was gathered through measurements with garments (cold protective and daily wear) and ensembles (cold protective). The comparative analysis with the global, parallel, and serial thermal insulation calculation methods has shown that the serial always leads to the highest values. In contrast, the lowest values must be expected whenever preference is given to the parallel method. The differences between the calculation methods were, in some cases, significant, and greater discrepancies arise when the distribution of clothing becomes less uniform. These results are in good agreement with the general characteristics of the calculation methods stated in the literature (Nilsson 1997; Anttonen 2000; Holmér 2001). The main contribution of the present work is hoped to provide further understanding since use was made of a thermal manikin operating under the thermal comfort equation regulation mode, which leads to different results when the thermal insulation is calculated on the basis of the three methods. Therefore, it must be underlined that whenever the comfort regulation mode is used, then the general formula for defining the whole body resistance, i.e., the global method (Eq. 6), should be used. In fact, the global method is the only one suitable for all manikin regulation modes while, as stated, the other two methods are specific cases.

In the case of garments, the cold protective clothes present higher differences between the calculation methods than the daily wear. On the other hand, a non-uniform clothing distribution between the lower and upper parts of the body was observed in all the ensembles tested, but the results highlight that the higher differences between the calculation methods correspond to the highly insulating ensembles which are precisely those where the insulation is not evenly distributed. Thus, in studies identical to the present, in which a cold protective garment is added to a common ensemble, we can conclude that the discrepancy between the calculation methods increases with the thermal insulation of the protective garment added.

With uneven distribution of clothing, the results obtained with the serial method often leads to an erroneous perception of the effective thermal insulation and the difference between the calculation methods is seen to increase. Thus, for cold protective clothes the local insulation values of the individual zones must always be considered, since this detailed data provides important information about the critical zones which can be used in the design stage of clothing. This is particularly relevant whenever we are interested on cold exposure. In fact, an inadequate distribution of insulation can have a negative impact on the wearer’s comfort and should be avoided whenever possible. Therefore, when designing new protective clothing, special attention must be given to this requirement in order to identify the critical body parts and to redesign the ensembles in order to obtain an adequate distribution of insulation over the whole body.

References

Anttonen H (2000) Interlaboratory trial of thermal manikin based on thermal insulation of cold protective clothing in accordance with ENV 342. In: Nilsson H, Holmér I (eds) Proceedings of the 3I3M—3rd International meeting on thermal manikin testing, National Institute for Working Life, 12–13 October 1999, Stockholm, Sweden, pp 25–28

ASTM F 1291 (2004) Standard method for measuring the thermal insulation of clothing using a heated thermal manikin. American Society for Testing and Materials, Annual Book of ASTM Standards, vol 11.03

Caravello V, McCullough E, Ashley CD, Bernard TE (2007) Apparent evaporative resistance at critical conditions for five clothing ensembles. Eur J Appl Physiol. doi:10.1007/s00421-007-0655-9

EN 342 (2004) Protective clothing—ensembles and garments for protection against cold. European Standard, European Committee for Standardization, Brussels

Fan J, Qian X (2004) New functions and applications of Walter, the sweating fabric manikin. Eur J Appl Physiol 92:641–644. doi:10.1007/s00421-004-1134-1

Fanger PO (1972) Thermal comfort—analysis and applications in environmental engineering. McGraw-Hill, New York

Havenith G (2002) Memorandum—Calculation of manikin clothing data. Loughborough, September. http://www.manikin.dk

Havenith G, Nilsson H (2004) Correction of clothing insulation for movement and wind effects: a meta-analysis. Eur J Appl Physiol 92:636–640. doi:10.1007/s00421-004-1113-6

Holmér I (2001) Validation of manikin insulation values in wear trials. Proceedings of the 4IMM—4th International meeting on thermal manikin testing, EMPA, St. Gallen, Switzerland, 27–28 September, pp 8–12

Holmér I (2004) Thermal manikin history and applications. Eur J Appl Physiol 92:614–618. doi:10.1007/s00421-004-1135-0

ISO 15831 (2004) Clothing—physiological effects—measurement of thermal insulation by means of a thermal manikin. International Standard, 1st edn. International Organization for Standardization (ISO), Geneva

ISO 7726 (1998) Ergonomics of the thermal environment—instruments for measuring physical quantities. International Standard, 2nd edn. International Organization for Standardization (ISO), Geneva

ISO 9920 (1995) Ergonomics of the thermal environment—estimation of the thermal insulation and evaporative resistance of a clothing ensemble. International Standard, 1st edn. International Organization for Standardization (ISO), Geneva

ISO 9920 (2007) Ergonomics of the thermal environment—estimation of the thermal insulation and water vapour resistance of a clothing ensemble. International Standard, 2nd edn. International Organization for Standardization (ISO), Geneva

ISO/TR 11079 (1993) Evaluation of cold environments—determination of required clothing insulation (IREQ). Technical Report, 1st edn. International Organization for Standardization (ISO), Geneva

Kuklane K, Holmér I, Gao C, Havenith G (2007) Calculation of clothing insulation by serial and parallel methods: effects on clothing choice by IREQ and thermal responses in the cold. Int J Occup Saf Ergon 13(2):103–116

Kuklane K, Sandsund M, Reinertsen RE, Tochihara Y, Fukazawa T, Holmér I (2004) Comparison of thermal manikins of different body shapes and sizes. Eur J Appl Physiol 92:683–688. doi:10.1007/s00421-004-1116-3

Madsen TL (1976) Description of thermal manikin for measuring thermal insulation values of clothing. Thermal Insulation Report No. 48, Technical University of Denmark

McCullough EA (2001) The use of clothing in thermal comfort standards. Moving thermal comfort standards into the 21st Century, Cumberland Lodge, Windsor, 5–8 April, pp 292–300

McCullough EA, Jones BW, Huck J (1985) A comprehensive database for estimating clothing insulation. ASHRAE Trans 91:29–47

Melikov A (2004) Breathing thermal manikins for indoor environment assessment: Important characteristics and requirements. Eur J Appl Physiol 92:710–713. doi:10.1007/s00421-004-1142-1

Nilsson H (1997) Analysis of two methods of calculating the total insulation. In: Nilsson H, Holmér I (eds) Proceedings of a European seminar on thermal manikin testing, National Institute for Working Life, Stockholm, Sweden, 12 February, pp 17–22

Oliveira AVM (2006) Study of cold thermal environments: experimental developments and assessment of working conditions. Ph.D. Thesis, Faculty of Science and Technology, University of Coimbra, Coimbra, Portugal, ISBN-13: 978-972-8954-10-9. (in Portuguese)

Oliveira AVM, Gaspar AR, Quintela DA (2004) Assessment of the thermal insulation of the air layer with a movable thermal manikin. In: Silva MCG (ed) Proceedings of the ROOMVENT 2004—9th International conference on air distribution in rooms, University of Coimbra, Coimbra, Portugal, 5–8 September, ISBN 972-97973-1-5

Oliveira AVM, Gaspar AR, Quintela DA (2005a) Thermal insulation of cold protective clothing: static and dynamic measurements with a movable thermal manikin. In: Holmér I, Kuklane K, Gao G (eds) Proceedings of the ICEE 2005—11th International conference on environmental ergonomics, Lund University, Sweden, 22–26 May, pp 99–102, ISBN 91-631-7062-0

Oliveira AVM, Gaspar AR, Quintela DA (2005b) Cold stress in Portugal: evaluation of working thermal environments using the required clothing insulation index (IREQ). In: Holmér I, Kuklane K, Gao G (eds) Proceedings of the ICEE 2005—11th International conference on environmental ergonomics, Lund University, Sweden, 22–26 May, pp 581–584, ISBN 91-631-7062-0

Oliveira AVM, Gaspar AR, Quintela DA (2007) Occupational exposure to cold thermal environments: a field study in Portugal. Eur J Appl Physiol. doi:10.1007/s00421-007-0630-5

Parsons K (2003) Human thermal environments—the effects of hot, moderate and cold environments on human health, comfort and performance, 2nd edn. Taylor and Francis, London

Quintela DA, Gaspar AR, Borges C (2004) Analysis of sensible heat exchanges from a thermal manikin. Eur J Appl Physiol 92:663–668. doi:10.1007/s00421-004-1132-3

Silva MCG (2002) Measurement of comfort in vehicles. Meas Sci Technol 13:R41–R60. doi:10.1088/0957-0233/13/6/201

Soltynski K, Konarska M, Pyryt J, Sobolewski A (2000) Research on typical medical work clothing on humans and on a thermal manikin. In: Kuklane K, Holmér I (eds), Proceedings of Nokobetef 6 and 1st European Conference on Protective Clothing, National Institute for Working Life, Stockholm, Sweden, 7–10 May, pp 183–187

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Oliveira, A.V.M., Gaspar, A.R. & Quintela, D.A. Measurements of clothing insulation with a thermal manikin operating under the thermal comfort regulation mode: comparative analysis of the calculation methods. Eur J Appl Physiol 104, 679–688 (2008). https://doi.org/10.1007/s00421-008-0824-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00421-008-0824-5