Abstract

In this serial study, 486 thermal manikin tests were carried out to examine the effects of air velocity and walking speed on both total and local clothing thermal insulations. Seventeen clothing ensembles with different layers (i.e., one, two, or three layers) were selected for the study. Three different wind speeds (0.15, 1.55, 4.0 m/s) and three levels of walking speed (0, 0.75, 1.2 m/s) were chosen. Thus, there are totally nine different testing conditions. The clothing total insulation and local clothing insulation at different body parts under those nine conditions were determined. In part I, empirical equations for estimating total resultant clothing insulation as a function of the static thermal insulation, relative air velocity, and walking speed were developed. In part II, the local thermal insulation of various garments was analyzed and correction equations on local resultant insulation for each body part were developed. This study provides critical database for potential applications in thermal comfort study, modeling of human thermal strain, and functional clothing design and engineering.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Thermal insulation is one of the most important physical parameters to quantify clothing thermal comfort. It is also an important input parameter used in thermal comfort and thermal stress models (ISO 7730 2005; ISO 7933 2004; ISO 11079 2007). In workplaces with cold conditions, clothing with sufficient insulation is used to protect the human body against cold stress. If clothing thermal insulation is insufficient, the body core temperature may drop and the hypothermia could occur. Therefore, it is important to investigate how various factors affect clothing thermal insulation. Clothing thermal insulation can be measured using a heated manikin or human subjects in laboratory settings (ISO 15831 2004; Nielsen et al. 1985). Previous studies have demonstrated that the clothing thermal insulation can be largely affected by the wind, body movement, body posture, and clothing physical properties and design features such as the fabric air permeability and the clothing apertures (Belding et al. 1947; Bouskill et al. 2002; Breckenridge 1977; Gagge et al. 1941; Havenith et al. 1990; Havenith and Nilsson 2004; Kim and McCullough 2000; Morrissey and Rossi 2014; Nielsen et al. 1985; Nilsson et al. 2000; Nishi et al. 1975; Oguro et al. 2001; Olesen et al. 1982). The wind in the environment increases the convective heat transfer coefficient and may also compress the clothing or penetrate through the garment and openings, resulting in an accelerated decrease of the total thermal insulation. When a person moves, the pumping effect, depending on the air temperature, may either increase or decrease its total resultant thermal insulation (Vogt et al. 1983). In addition, the walking effect interacts with wind. The larger the wind speed, the smaller the walking effect on the resultant insulation. The effect of body walking on the resultant clothing insulation was larger for the ensembles with lower air permeability (Havenith and Nilsson 2004).

Many empirical equations have been developed to quantitatively characterize the effects of wind, body movement, and outer layer air permeability on resultant clothing insulation (Havenith and Nilsson 2004; Holmér et al. 1999; ISO 9920 2007; Nilsson et al. 2000). Such equations were developed based on the data obtained from different laboratories using different approaches. Havenith et al. (1990) analyzed the combined effect of wind and body movement by two steps and established an equation for correcting the resultant thermal insulation. The concept of relative air velocity to a person considering walking effect was used and adopted by ISO 9920 (2007). Nilsson and Holmér (1997) published an exponential equation based on the measurements with a movable heated manikin. By incorporating air permeability of the clothing outer layer, Nilsson et al. (2000) proposed a new equation for cold weather protective clothing. It showed that the equation of Nilsson et al. (2000) was accepted on high insulating clothing ensembles (total insulation of 2.24 ~ 4.61 clo). Later, Havenith and Nilsson (2004) reanalyzed the data from different sources and developed two individual equations for normal workwear and cold weather protective clothing. The equation for predicting the resultant clothing thermal insulation of workwear was based on the previous data published by Holmér et al. (1999) and their data measured on human subjects (Havenith et al. 1990). The equation was limited to total clothing insulation of 1.22–1.84 clo, walking speed 0–1.2 m/s, and wind 0.15–3.5 m/s. For the cold weather clothing, reanalysis of the data of Nilsson et al. was made and a new equation was developed with improvement of a range of 0.14–18-m/s wind speed. Later, the ISO 9920 (2007) adopted these two equations for estimating resultant clothing thermal insulation. Due to a lack of data on light clothing ensembles, ISO 9920 proposed an empirical equation for very light clothing (the intrinsic insulation below 0.6 clo) by interpolation of the equation of the nude body with the equation of the light workwear. The equation indicates that the correction factor of an individual ensemble depends on the clothing intrinsic insulation, which makes the prediction complicated. The validity of those equations is unclear.

Hence, a comprehensive study and understanding of the effects of air and body movement on resultant clothing insulation are required. In this study, we selected 17 sets of clothing ensembles with a total thermal insulation of 0.95–3.66 clo to investigate clothing resultant insulation using a movable heated manikin. High wind conditions (above 3.5 m/s) were also introduced to further extend and examine the impact of high wind speed and combined high wind with walking on the resultant clothing insulation. Further, due to a lack of understanding on clothing local thermal insulation, clothing total thermal insulation is applied to develop a model (Tanabe et al. 2002; Wan and Fan 2008). Actually, the local clothing thermal insulation at different body parts varies greatly as a result of different body shapes. This suggests the importance of understanding of how the clothing local insulation varies and contributes to overall clothing insulation. Thus, the second purpose of this study was to investigate the local clothing thermal insulation. In part I, the individual and interaction effects of walking and wind on clothing total insulation were investigated, and empirical equations used for predicting resultant clothing thermal insulation were developed and compared with previous equations.

Methodology

Clothing ensembles

In this study, 17 sets of clothing ensembles were selected and their thermal insulation was measured under nine different conditions. These ensembles may be divided into three groups, depending on their total thermal insulation. Group 1 (G1) is identified as light clothing with a clo value from 0.9 to 1.49. The group 2 (G2) ensembles are moderate thick garments, and the clo value is ranged from 1.5 to 2.3; all ensembles of group 3 (G3) are cold weather protective clothing with a clo value higher than 3.2. The same shoes were worn for all the tests. The configuration and other detailed information of all tested ensembles are listed on Table 1.

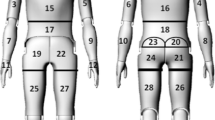

Thermal manikin

In this study, a 34-zone “Newton” thermal manikin (Measurement Technology Northwest, Seattle, WA, USA) equipped with walking and sweating functions was used (as shown in Fig. 1). This manikin could control its surface temperature or heating power of each body segment individually. To record the manikin surface temperature, thermocouple wires were embedded in each segment of the manikin. The heat flux generated during experiment at each body part was recorded by ThermDAC® software.

Wind

Three levels of wind speed were introduced, namely no wind (minimal ambient air circulation: 0.15 m/s), 1.55-m/s wind, and 4.0-m/s wind. In order to obtain these wind speeds, a wind tunnel consisted of three continuously variable transmission (CVT) fans was placed in the climatic chamber. These three fans with a diameter of 0.6 m were installed vertically. The rotating speed of the three fans was controlled by a Siemens Micromaster 440 frequency adjuster (Siemens AG, Munich, Germany). The distance between the three fans and the manikin was set to 1.45 m, and the front side of the manikin was always facing to the wind tunnel. The distribution of wind speed over an area was measured at a distance of 0.45 m from the manikin. The wind speed was measured by air speed probe SWA 31 (Swema AB, Farsta, Sweden) at 3-min intervals. A mean value was reported for each test scenario. The detailed information is shown in Table 2.

Calculations

The total thermal insulation of each ensemble was calculated by the parallel method using the following equation

where \( {I}_t \) is the total clothing thermal insulation (clo), \( \overline{T_{sk}}\kern0.5em \mathrm{and}\kern0.5em {T}_{\mathrm{a}} \) are the manikin surface temperature and the air temperature, respectively (°C), H i is the observed dry heat loss at the segment i (W/m2), A i is the surface area of the segment i (m2), and A is the total surface area (m2).

Test protocol

In thermal manikin measurements, the ISO 15831 standard (2004) was followed. The constant temperature mode was used, and the manikin’s surface temperature was kept constant at 34 °C. Three different levels of walking speed of 0, 35, and 55 double steps per minute (corresponding to 0, 0.75, and 1.2 m/s, respectively) and three wind speeds (0, 1.55, and 4.0 m/s) were used. Thus, totally, nine testing conditions were created. The air temperature (measured by Betatherm/MTNW temperature sensors), relative humidity (measured by a Vaisala humidity sensor, Vaisala Oy, Vantaa, Finland), and air velocity (determined by a TSI air velocity transducer 8475, TSI Inc., Shoreview, MN, USA) were monitored throughout the whole experiment. The thermal insulation of each ensemble under all nine different test conditions was determined. The boundary air layer’s thermal insulation was also measured. Each clothing ensemble was tested at least three times to ensure that the test variability should be lower than 5 %. The testing ambient temperature was appropriately adjusted to ensure that any segmental heat flux of the manikin should be higher than 20 W/m2. The data acquisition frequency was set at 10 s.

Results

Table 3 shows the percentage of reduction of total thermal insulation in different test conditions. The percentage was based on the data while the manikin was standing at a 0.15-m/s wind (i.e., the reference condition). The decrease of thermal insulation of the nude body due to wind is larger than that of clothed body, whereas the insulation reduction of the nude scenario due to walking is mostly smaller than that of the clothed body. Both wind and body movement and their interactions largely affect the total clothing thermal insulation. The maximum change occurs in the condition of walking at 1.2 m/s with a 4.0-m/s wind, ranging from 31.6 to 68.6 %. In general, the reduction rate for the ensemble of G1 with a low insulation is the biggest (56.8 to 68.6 %), followed by G2 (42.6 to 60 %), and the G3 with the highest insulation showed the lowest decrease of thermal insulation (31.6 to 49.1 %). Comparing with the reference condition, the 4-m/s wind causes a total thermal insulation reduction of 55.9 ~ 64.2, 37.5 ~ 47.2, and 30.7 ~ 39 % for G1, G2, and G3, respectively. The walking speed of 1.2 m/s without wind results in 13.6 ~ 44.1 % decrease in the total thermal insulation compared with that of the reference condition. Furthermore, the walking effects for EN 12 and EN 10 are the lowest among the clothing groups G1 and G3, respectively, namely 20.8 and 15.1 %.

Effect of wind on total thermal insulation

The effects of wind speed on clothing resultant thermal insulation under three different levels of walking speed are shown in Fig. 2. It is obvious that the total thermal insulation decreases with the increasing air velocity under all three levels of walking speed (refers to Fig. 2a–c). The linear regression models under three walking conditions are shown in Eq. 2, and the coefficients are presented in Table 4. The resultant insulation shows a linear relationship with the static thermal insulation. Moreover, in any case of three walking speeds, the slope in the condition of 1.55-m/s wind is steeper than that in the condition of 4.0 m/s wind. Comparing the slopes in different walking speed, it shows that the slope increases with the walking speed, which indicates that the difference between resultant thermal insulation and static insulation decreases with the increasing of walking speed.

where I t,r is the resultant clothing insulation (clo) and I t,static is the static clothing insulation in a specific condition (clo).

Effect of walking on total thermal insulation

Figure 3 presents the effects of walking speed on the total clothing thermal insulation under three different wind speeds. Similarly, the dynamic thermal insulation shows a linear relationship with the reference thermal insulation in different walking speeds (refers to Fig. 3a–c). The format of the regression model is the same with Eq. 2. As the difference in the effect of walking between the two walking speeds was minimal, a universal model was developed. The coefficients under three wind conditions are presented in Table 5. The slope increases with the increasing wind speed, which indicates that the effect of walking speed on the dynamic thermal insulation is attenuated at high wind speed. Moreover, the walking speed of 0.75 m/s causes the decrease of the static thermal insulation, but a further increasing of walking speed shows a minimal effect.

Interaction effect of air and body movement on clothing total thermal insulation

The relationship among air velocity, walking speed, and the total thermal insulation has been analyzed by multiple nonlinear regression. In order to ensure that the correction factor equals the unity for measurements made at the standing posture with the 0.15-m/s reference wind, a subtraction of this reference wind speed was made. The relative air velocity as defined in ISO 9920 (2007) was introduced to account for the effects of body movements on convective heat exchange (Havenith and Nilsson 2004). The correction factors for the boundary air layer’s thermal resistance I a were also analyzed. The prediction quality is judged by the correlation factor R 2 and the sum of squares for error (SSE) value.

The correction equation for the boundary air layer’s insulation reads

where I a,r is the resultant boundary air layer’s insulation (clo), I a is the reference boundary air layer’s insulation (clo), υ ar is the relative air velocity to a person (m/s), and w is the walking speed (m/s); the validity intervals for Eq. 3 are 0.15–5.2-m/s relative air velocity and 0–1.2-m/s walking speed; the correlation factor R 2 = 0.98; SSE = 0.009.

The 3-D figure of the correction equation for the reference boundary air layer’s insulation is plotted in Fig. 4. It should be noted that the relative air velocity has already been considered the wind speed and walking speed. In this study, the wind is blowing toward the front side of the manikin, and thus, the relative air velocity equals the sum of the wind speed and the walking speed (ISO 9920 2007).

For each of the three clothing groups, the relationship among the relative air velocity, walking speed, and correction factors for the reference total clothing insulation was determined by multiple nonlinear regressions. The correction equation is the similar to that made for the boundary air layer. For G3 and all testing ensembles, the air permeability was taken into account when performing the analysis. The coefficients a, b, c, and d; the correlation factor R 2; and SSE values for each garment group are displayed in Table 6. The prediction equations presented in ISO 9920 (2007) were revisited and shown in Table 6. The regression results exhibit a good correction equation with a R 2 higher than 0.71. It is obvious that these three garment groups show distinct coefficients. It was also found that the incorporation of clothing air permeability factor improves the R 2.

The correction equations for the total clothing insulation read

where Corr′ and Corr are the correction factors with and without considering air permeability, respectively, I t,r is the resultant clothing insulation (clo), I t is the reference clothing insulation (clo), υ ar is the relative air velocity to a person (m/s), w is the walking speed (m/s), p is the clothing air permeability (l/m2 s), and the validity intervals for the correction equations are 0.15–5.2-m/s relative air velocity and 0–1.2-m/s walking speed.

Comparison of predicted resultant insulation by our equations and ISO 9920

Table 7 presents an example of predicted resultant clothing insulation prediction using our equations and equations of ISO 9920 (2007). The comparison of predicted correction factors by our equations and those by ISO 9920 with measured value is plotted in Fig. 5. The overall R 2 of our equations and the equations adopted by ISO 9920 is 0.821 and 0.439, respectively. It indicates that our equations provide a much better prediction of the resultant thermal insulation than that by the ISO 9920. For nude scenario, the equation developed in this study provides a closer value than Eq. 33 in ISO 9920, especially in walking conditions. For normal workwear, under condition of 0.75-m/s walking with 1.55-m/s wind, Eq. 32 in ISO 9920 gives a much lower correction factor (i.e., the predicted resultant insulation by ISO 9920 are always lower) than those predicted by Eqs. 3 and 4 for G2 developed in our study. For example, the correction factors estimated by the ISO 9920 for the nude and G2 are 14.5 and 11.9 % lower than our observed values. For very light clothing with intrinsic insulation of 0.5 clo, Eq. 4 for G1 developed in our study gives a close prediction to Eq. 33 in ISO 9920. It should be noted that the prediction by Eq. 33 in ISO 9920 ranges from 0.347 (nude) to 0.512 (workwear), depending on the clothing intrinsic insulation. For high insulation clothing, ISO 9920 generated a higher correction factor than our equation (Eq. 5) developed in this study. It is indicated that our equation shows closer prediction than the ISO 9920 based on data reported by Bouskill et al. (2002). Based on the observed data by Havenith et al. (1990), our Eq. 4 developed for G2 showed a closer predicted correction factors than those by the ISO9920. An exception is that our equation gives a higher correction factor than the ISO 9920 when examining the data reported by the study of Nielsen et al. (1985). This might be related to the data shown in their study that were measured by human subjects. Lastly, it is also evident that our equation shows closer prediction than the ISO 9920 based on data reported by Morrissey and Rossi (2014).

Discussion

In this study, both individual and interaction effects of wind and body movement on the total thermal insulation of the boundary air layer and various types of clothing ensembles were systematically investigated using a movable thermal manikin. It is evident that the wind and body movement and their interactions show distinct impacts on the total thermal insulation provided by ensembles. The wind and body movements cause a remarkable reduction of clothing total thermal insulation. This is consistent with previous documented studies (Belding et al. 1947; Breckenridge 1977; Havenith et al. 1990; Havenith and Nilsson 2004; Kim and McCullough 2000; Nielsen et al. 1985; Nilsson et al. 2000; Nishi et al. 1975; Oguro et al. 2001; Olesen et al. 1982). We also found that the wind caused a sharp reduction in the boundary air layer’s insulation, which is more pronounced than those at the clothed body regions (Havenith et al. 1990). For thin and light ensembles, the wind and body movement caused greater reductions of total thermal insulation, which is mainly as result of the high air permeability of those ensembles and the larger unclothed areas. In contrast, a relative smaller reduction was observed in multilayer-thick ensembles. Clothing ensembles with a similar thermal insulation range, such as those of G2 and G3, were investigated in previous studies. A reduction of 37.5 ~ 47.2 % in total thermal insulation of G2 found in this study is consistent with the findings of Havenith et al. (34 ~ 40 %) with a condition of 4.1-m/s wind (Havenith et al. 1990). Under the reference wind condition, the total resultant insulation decreases linearly with the increasing walking speed as demonstrated in Fig. 3. A similar development trend was found in two previous studies (Havenith and Nilsson 2004; McCullough and Kim 1996). Under three different walking speeds, a larger reduction in the thermal insulation was observed in a stronger wind condition. The resultant thermal insulation showed a linear correlation with the thermal insulation determined at the reference wind condition (shown in Fig. 2). In contrast, the difference in reduction of thermal insulation caused by two walking speeds (0.75 and 1.2 m/s) was insignificant under all three air speeds. The effect of walking speed was minimal at higher wind speed conditions. This is in line with a previous study by Havenith and Nilsson (2004). In addition, the effect of walking on the resultant thermal insulation also depended on the garment fit. As shown in Table 3, the tight fit EN 12 and EN 10 presented the lowest among the clothing groups G1 and G3, respectively, whereas the loose fit EN 11 in G3 showed a higher reduction due to body motion. Those might be related to the garment structure. The tight fit garment develops smaller air gap layer along human body; then, the air ventilation caused by body motion is minimal, resulting in lower reduction in thermal insulation.

Several empirical equations were introduced in the ISO 9920 (2007) to estimate the combined effects of wind and body movement on both the boundary air layer’s insulation and the clothing total insulation. These prediction equations for the traditional workwear and cold weather protective clothing were separated. It should be noted that the measurements were conducted in different laboratories using a mixed method, i.e., human subjects and movable heated manikins (Havenith et al. 1990; Holmér et al. 1999; Nilsson et al. 2000). Havenith et al. (1990) found that the resultant thermal insulation was affected by its static insulation. In this study, the garments were divided into three groups and their individual empirical equations showed good predictions. For workwear in G2, although Eq. 32 (ISO 9920 2007) showed similar predictions as our equation developed, the validation range of our equation has been extended to a relative air speed of 5.2 m/s, as shown in Fig. 6. It should be emphasized that only part of the data presented in the studies of Havenith et al. (1990) and Holmér et al. (1999) were applied in the regression analysis, namely the thermal insulation measured in condition of air velocity less than 3.5 m/s. The thermal insulation data determined in the condition of 4.1-m/s wind were excluded in the regression model. We explored the possibility of extending Eq. 32 to higher relative air speed conditions. However, we found that Eq. 32 (ISO 9920 2007) failed to give a reasonable prediction if the relative air velocity is higher than 3.5 m/s. Surprisingly, the predicted resultant thermal insulation tends to increase with the increasing of air velocity (see Fig. 7). One possible reason could be that the data source of Eq. 32 in ISO 9920 was not well explored. Also, the thermal insulation determined by human subjects requires sophisticated technology and management, and it varies on different subjects, showing a low repeatability. This may cause an inaccuracy in the reported data. It has been demonstrated that, for a same type clothing ensemble, the thermal insulation measured by a heated manikin is higher than that obtained by human subjects (Havenith et al. 1990; Nishi et al. 1975; Vogt et al. 1983). On the contrary, Nielsen et al. (1985) and Olesen et al. (1982) found that the value measured by the manikin approach was lower. Therefore, it is essential to systematically investigate the effect of wind and body movement on the clothing total resultant insulation using the same testing method (as described in this study).

Resultant thermal insulation predicted by Eq. 32 (ISO 9920 2007) tends to increase with the increasing of air velocity

For cold weather protective clothing in G3, the air permeability was considered as an influential factor in Eq. 35 in ISO 9920 (2007). In our study, the correction factor R 2 increases from 0.72 to 0.86 if the air permeability factor was introduced, which reconfirms the effect of air permeability on the resultant insulation of thick ensembles (Morrissey and Rossi 2014). The parameters showed in Eq. 35 in ISO 9920 (2007) for the air velocity and walking speed are rather small, especially that the constant b is close to zero. It is thus indicated that the impacts of air velocity and walking speed on the reduction of total insulation are low. It should also be noted that the clothing air permeability (CAP) was estimated according to the study of Nilsson et al. (2000). The recommended CAP of impermeable clothing, densely woven clothing, and highly permeable clothing is 1, 50, and 1000, respectively. As these recommended values are constants, thus, using such estimated values may reduce the prediction accuracy. Generally, the CAP was difficult to determine because it is largely determined by the fabric air permeability, garment fit, openings, and vents (Bouskill et al. 2002). The consideration of only air permeability of the clothing in the regression model might not be enough. Several studies showed that the clothing ventilation affects the clothing thermal insulation (Bouskill et al. 2002; Dai and Havenith 2009) and the clothing ventilation property can be measured by the tracer gas method (Havenith et al. 2010). These suggest that future studies should explore the possibility of application of clothing ventilation parameters in the regression equation for predicting resultant clothing insulation.

Lastly, for very light clothing ensembles with an intrinsic insulation less than 0.6 clo (i.e., the estimated total insulation is 1.2 clo), an indirect method (interpolation between Eqs. 32 and 33 for the nude body) in the ISO 9920 is used to predict clothing resultant insulation. In order to enhance prediction accuracy, it is suggested to consider our equation for G1 to replace Eq. 34 in ISO 9920 (2007). For Eq. 4 of G1 developed in this study, the relative air speed has been extended to a higher air velocity up to 5.2 m/s. The correlation factor R 2 and SSE of this equation are 0.93 and 0.153, respectively, which again indicates that the prediction accuracy is high. The 3-D figure for the correction factor of clothing ensemble G1 is plotted in Fig. 8. The condition with the largest wind speed and walking speed causes the smallest resultant thermal insulation, which supports that the equation developed for group G1 shows reasonable predictions. In addition, our Eq. 3 developed for the boundary air layer (see Fig. 4) shows good estimations to that predicted by Eq. 33 of ISO 9920 (refers to Table 7). It should be noted that the validity interval of our equation has been widely extended to a relative air speed of 5.2 m/s. We also explored the possibility of extending Eq. 33 to higher relative air speed conditions. However, we found that the resultant thermal insulation predicted by Eq. 33 (ISO 9920 2007) tends to increase with the increasing of air velocity under conditions of high wind speed and walking speed (see Fig. 9).

Resultant thermal insulation predicted by Eq. 33 (ISO 9920 2007) tends to increase with the increasing of air velocity under conditions of high wind speed and walking speed

Conclusions

The effects of wind and body movement on the resultant thermal insulation differ distinctively across different types of clothing. The effect is associated strongly with garment design features and CAP. The developed prediction equations for three different clothing ensemble groups have been presented. Compared with the prediction equations presented in ISO 9920 (2007), the presented equations showed a good agreement in the prediction of clothing resultant insulation and can be applied with a high air velocity. The databases are generated from very light to thick clothing ensembles, and the validation range of the empirical equations has been extended to higher relative air velocity conditions (over 5.0 m/s). The equations developed in this study exhibit potential applications in modeling human thermal comfort and thermo-physiological responses.

References

ASTM F2370 (2010) Standard test method for measuring the evaporative resistance of clothing using a sweating manikin. American Society for Testing and Materials, West Conshohocken

Belding HS, Russell HD, Darling RC, Folk GE (1947) Analysis of factors concerned in maintaining energy balance for dressed men in extreme cold: effects of activity on the protective value and comfort of an arctic uniform. Am J Physiol 49:223–239

Bouskill LM, Havenith G, Kuklane K, Parsons KC, Withey WR (2002) Relationship between clothing ventilation and thermal insulation. Am Ind Hyg Assoc J 63:262–268

Breckenridge JR (1977) Effects of body motion on convective and evaporative heat exchanges through various designs of clothing vol Clothing Comfort. Ann Arbor Science, Ann Arbor

Dai XQ, Havenith G (2009) Effect of clothing ventilation on thermal insulation and vapor resistance. Proceedings of the 13th International Conference on Environmental Ergonomics. Boston, Massachusetts, USA, pp 83–87

Gagge AP, Burton AC, Bazett HC (1941) A practical system of units for the description of the heat exchange in man with his thermal environment. Science 94:428–430

Havenith G, Nilsson HO (2004) Correction of clothing insulation for movement and wind effects, a meta-analysis. Eur J Appl Physiol 92:636–640

Havenith G, Heus R, Lotens WA (1990) Resultant clothing insulation: a function of body movement, posture, wind, clothing fit, and ensemble thickness. Ergonomics 33:67–84

Havenith G, Zhang P, Hatcher K, Daanen H (2010) Comparison of two tracer gas dilution methods for the determination of clothing ventilation and of vapour resistance. Ergonomics 53:548–558

Holmér I, Nilsson H, Havenith G, Parsons K (1999) Clothing convective heat exchange—proposal for improved prediction in standards and models. Ann Occup Hyg 43:329–337

ISO 11079 (2007) Evaluation of cold environments—determination of required clothing insulation (IREQ). International Organization for Standardization, Geneva

ISO 15831 (2004) Clothing—physiological effects—measurement of thermal insulation by means of a thermal manikin. International Organization for Standardization, Geneva

ISO 7730 (2005) Moderate thermal environments—determination of the PMV and PPD indices and specification of the conditions for thermal comfort. International Organization for Standardization, Geneva

ISO 7933 (2004) Ergonomics of the thermal environment—analytical determination and interpretation of heat stress using calculation of the predicted heat strain. International Organization for Standardization, Geneva

ISO 9920 (2007) Ergonomics of the thermal environment—estimation of the thermal insulation and evaporative resistance of a clothing ensemble. International Organization for Standardization, Geneva

Kim CS, McCullough EA (2000) Static and dynamic insulation values for cold-weather protective clothing. In: Nelson CN, Henry NW (eds) ) Performance of protective clothing: issues and priorities for the 21st century, vol 7. ASTM STP 1386. American Society for Testing and Materials, Conshohocken, pp 233–247

McCullough EA, Kim CS (1996) Insulation values for cold weather clothing under static and dynamic conditions. Environmental ergonomics-recent progress and new frontiers. Freund Publishing House, London

Morrissey MP, Rossi RM (2014) The effect of wind, body movement and garment adjustments on the effective thermal resistance of clothing with low and high air permeability insulation. Text Res J 84:583–592

Nielsen R, Olesen BW, Fanger PO (1985) Effect of physical activity and air velocity on the thermal insulation of clothing. Ergonomics 28:1617–1631

Nilsson HO, Holmér I (1997) Development and clothing measurements methods with the thermal manikin TORE. In: Proceedings of the 5th Scandinavian Symposium on Protective Clothing, Danish Work Environment Fund, Elsinore, pp 30–35

Nilsson HO, Anttonen H, Holmér I (2000) New algorithms for prediction of wind on cold protective clothing. In: NOKOBETEF 6, the 1st European Conference on Protective Clothing, Norra Latin, Stockholm, Sweden, pp 17–20

Nishi Y, Gonzales RR, Gagge AP (1975) Direct measurement of clothing heat transfer properties during sensible and insensible heat exchange with thermal environment. ASHRAE Trans 81:183–199

Oguro M, Arens E, de Dear R, Zhang H, Katayama T (2001) Evaluation of the effect of air flow on clothing insulation and total heat transfer coefficient for each part of the clothed human body. J Archit Plan Environ Eng AIJ 549:13–21

Olesen BW, Sliwinska E, Madsen TL, Fanger PO (1982) Effect of body posture and activity on the thermal insulation of clothing. Measurement by a movable thermal manikin. ASHRAE Trans 88:791–805

Tanabe S, Kobayashi K, Nakano J, Ozeki Y, Konishi M (2002) Evaluation of thermal comfort using combined multi-node thermoregulation (65MN) and radiation models and computational fluid dynamics (CFD). Energy Build 34:637–646

Vogt JJ, Meyer JP, Candas V, Libert LP, Sagot JC (1983) Pumping effect on thermal insulation of clothing worn by human subjects. Ergonomics 26:963–974

Wan X, Fan J (2008) A transient thermal model of the human body–clothing–environment system. J Therm Biol 33:87–97

Wang F, Kuklane K, Gao C, Holmér I (2010) Development and validity of a universal empirical equation to predict skin surface temperature on thermal manikins. J Therm Biol 35:197–203

Wang F, Gao C, Kuklane K, Holmér I (2011) Determination of clothing evaporative resistance on a sweating thermal manikin in an isothermal condition: heat loss method or mass loss method? Ann Occup Hyg 55:775–783

Acknowledgments

This study was financially supported by projects from the Natural Science Foundation of Jiangsu Province (project no. BK20130312), the China Postdoctoral Science Foundation (project no. 2014 M551657), the Natural Science Research Project for Colleges and Universities in Jiangsu Province (project no. 14KJB540001), and the National Natural Science Foundation of China (project no. 51106021).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Y., Wang, F., Wan, X. et al. Clothing resultant thermal insulation determined on a movable thermal manikin. Part I: effects of wind and body movement on total insulation. Int J Biometeorol 59, 1475–1486 (2015). https://doi.org/10.1007/s00484-015-0958-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00484-015-0958-1