Abstract

In this paper, latest developments on Walter, a sweating fabric manikin, are reported. These include the improved simulation of “walking motion”, the design and construction of an automated water supply, and real-time measurement of evaporative water loss and regulation of “skin” temperature through the regulation of the pumps inside the manikin body. Testing of commercial garment ensembles showed that the measurement of thermal insulation and moisture-vapour resistance of clothing is very reproducible with the coefficient of variation being generally less than 5%. It was also shown that, in addition to the thermal insulation and moisture-vapour resistance, the percentage of moisture accumulation within clothing is a very useful parameter of clothing comfort. The improved manikin has been used to investigate the effects of walking motion on thermal insulation and evaporative resistance of clothing. The trend of the effects of walking speed up to 1.13 m s−1 for the nude manikin and when it was wearing garments of different sizes are reported.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Clothing thermal comfort can be evaluated by direct measurements on human subjects or objective simulation tests. Direct measurements on the human body are costly and may expose the subjects to danger, and the results tend also to be less accurate and reproducible. Therefore, various forms of objective simulation tests have been developed over the years. The best simulation test is the use of thermal manikins. Many thermal manikins (reviews of manikin developments: Holmer 1999; Fan and Chen 2002) have been developed around the world since the first one-segment and dry copper manikin from the US Army in the 1940s. Despite this, simulation of human perspiration remains a challenge. Existing sweating manikins can only “perspire” at a low rate (<200 g h−1; Goldman 2002) and the measurements are not accurate due to the indirect measurement of evaporative heat loss and the difficulty in measuring skin humidity accurately (Holmer 1999). They are also very expensive. The sweating fabric manikin Walter (US patent no. 6,543,657), developed by Fan and his co-workers, has shown great potential in terms of its ability in simulating perspiration, dressing and walking as well as measurement accuracy. In this paper, latest developments and results of commercial and experimental testing are reported.

General features of Walter

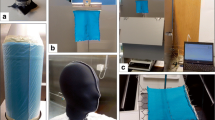

Walter has a man’s body. His main dimensions are listed in Table 1. Figure 1 is a front view of Walter.

Walter simulates perspiration using a waterproof, but moisture-permeable, fabric “skin”, which holds the water inside the body, but allows moisture to pass through the skin. Walter achieves a body temperature distribution similar to a real person by pumping warm water at the body temperature (37°C) from its centre to its extremities. Walter’s skin can be unzipped and interchanged with different versions to simulate different rates of perspiration. Unlike most existing manikins, with Walter it takes only one step to measure the two most important parameters—thermal insulation and moisture-vapour resistance (Fan and Chan 2002).

New functions of Walter

Skin temperature regulation

The mean skin temperature of Walter can now be adjusted by regulating the pumping rate of the pumps inside the manikin, which circulate warm water to the extremities. The regulation is performed by altering the frequency of the power supply to the pumps. Figure 2 shows the changes of the mean skin temperature with the frequency of the AC power supply.

Simulation of walking motion

Walter’s arms and legs can be motorised to simulate walking. A pair of joints has now been developed to better facilitate the walking motion. Walking pace can be adjusted mechanically. The speed can be changed using an AC frequency regulator to regulate the power supply to the motor that drives the motion. The speed may be varied from 0 to 4 km h−1. Figure 3 shows the manikin in walking motion.

Auto water supply and real-time measurement of evaporation rate

Automatic water supply to the manikin to compensate for the water loss is useful as it would greatly simplify the operation by reducing the frequency required to tender the manikin. The real-time measurement of water loss from the sweating manikin is necessary for the measurement of the dynamic responses of the manikin, ease of operation and improvements in measurement accuracy.

The basic idea of the system is to pump water from a water tank to the manikin. However, the challenge is to measure the amount of water added to or lost from the manikin. The obvious way to measure the water loss is to measure the weight of the manikin in real time using a balance. However, since the total weight of the manikin exceeds 75 kg and the water loss (or “perspiration”) is less than 1 kg h−1 or about 1~16 g min−1, an electronic balance, which can weigh up to 75 kg, will not be able to measure the small change of 1~16 g accurately, particularly when the water level in the manikin is moving up and down during the simulation of walking motion. In order to overcome this problem, the weight of a small water container, which connects to the manikin through tubes to create a siphon action, was weighed in real time.

The designed system is illustrated schematically in Fig. 4. The water in the small container is about 2.5 kg, sufficient for more than 3~5 h of perspiration. The container is not mechanically connected to the manikin, but linked through soft tubes, which ensure, by siphon action, that the water level in the manikin is the same as that in the container. The water-supply system has three switches. By opening one switch and closing the other, water can be pumped into the manikin when required to fill up the manikin with water, or pumped into the small water container periodically to fill up the small container when required. Figure 5 shows the real-time reading of the electronic balance when the clothed manikin is standing in still air.

Testing of commercial garments

Walter has been used for testing commercial garment ensembles. Using Walter, clothing thermal insulation, moisture-vapour resistance and percentage of moisture accumulation within clothing after wearing for 24 h can be accurately measured. Figure 6a–c shows some of the results. The coefficient of variation is generally less than 5%. The percentage of moisture accumulation on the clothing is a very useful parameter of clothing comfort in addition to the thermal insulation and moisture-vapour resistance. For example, comparing T-shirt A and T-shirt B, although they have very similar thermal insulation and moisture-vapour resistance, T-shirt B, made of a quick-drying finish, has much less moisture accumulation, indicating a “drier skin”.

Effect of walking motion on clothing insulation and moisture-vapour resistance

The improved manikin Walter was also used to investigate the effect of walking motion on clothing thermal insulation and moisture-vapour resistance. In this study, the thermal insulation and moisture-vapour resistance of the nude manikin, the manikin wearing just a pair of pants, and the manikin wearing four jackets of the same style and fabric, but in different sizes, were measured in still air under different walking speeds of 0, 0.35, 0.61, 0.87 and 1.13 m s−1. The results are shown in Fig. 7a, b where it can be seen that both thermal insulation and moisture-vapour resistance are reduced with increasing walking speed. The decreasing trends of the nude manikin and the nude manikin wearing just a pair of pants are similar, but very different from those when the manikin is wearing jackets. The reduction with walking speed for manikins wearing jackets was much faster due to air ventilation. It also appears that the thermal insulation and moisture-vapour resistance increases with garment size from small, medium and up to the large size. However, further enlargement of garment size to the extra large size does not increase and may reduce thermal insulation and moisture-vapour resistance. Optimum fitting is therefore important to clothing comfort.

Conclusions

We have demonstrated that the improved sweating manikin Walter is a reliable instrument for testing clothing thermal insulation, moisture-vapour resistance and the percentage of moisture accumulation within clothing, which are important parameters of thermal comfort. The manikin was also shown to be extremely useful for the investigation of the effects of walking motion and garment fits on clothing thermal insulation and evaporative resistance.

References

Fan J, Chen YS (2002) Measurement of clothing thermal insulation and moisture vapour permeability using a novel perspiring fabric thermal manikin. Meas Sci Technol 13:1115–1123

Goldman R (2002) E MAX and the heated, sweating and walking manikin. Proceedings of the 10th international conference on environmental ergonomics, Fukuoka, Japan, 23–27 September 2002, pp 447–450

Holmer I (1999) Thermal manikins in research and standards. Proceedings of international meetings on thermal manikin testing (3IMM), Stockholm, October 1999, pp 1–7

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, J., Qian, X. New functions and applications of Walter, the sweating fabric manikin. Eur J Appl Physiol 92, 641–644 (2004). https://doi.org/10.1007/s00421-004-1134-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00421-004-1134-1