Abstract

In the UK, stabbing is the most common cause of homicide. The weapons used include knives, swords, screwdrivers and glass shards. Quantifying the exact force used in a stabbing incident is considered to be a difficult area due to the large number of variables present, such as sharpness of weapon, angle of attack and relative movements of the people involved. Having quantifiable data would allow a forensic pathologist to make a more informed decision when it comes to answering the commonly posed question in court “what was the degree of force involved in the stabbing incident?” The answer to this question is considered significant in determining an alleged assailant’s intent to cause harm. This paper presents results of the first detailed study relating geometry of screwdrivers to the forces required for penetration. Additionally, a range of other blunt weapons such as pens and chisels have also been studied. A silicone rubber–foam analogue has been used as the main skin simulant owing to it having similar mechanical properties to that of human skin and giving highly repeatable results. Different screwdrivers of varying shape and size have been tested (i.e. slotted, Phillips, posidriv and Torx), along with other implements including chisels and pens. The weapon geometry was characterised and related to the peak force required for penetration. Our results show that there is a direct correlation between the cross-sectional area of a screwdriver head and the amount of force required for penetration. Screwdrivers with larger cross-sectional areas require a significantly greater force to penetrate (forces in the region of 100–120 N) but “sharper” slotted screwdrivers penetrate with much lower forces (∼30 N). The forces required for penetrating the rubber–foam analogue with screwdrivers are higher than for “sharp” knives, but in some cases similar to the forces required for stabbing with “blunt” knives. For the other weapons such as chisels and biros, the force required for penetration was again high and there was found to be a good relationship between area of the implement making contact and penetration force.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Stabbing is the commonest method of committing murder in Britain [1–4]. The typical weapons used can include knives, swords, screwdrivers and glass shards. According to the most recent figures released by the Home Office, there were 207 homicides in England and Wales which involved knives or sharp instruments from October 2008 and to October 2009 [3].

Quantifying the exact force used in a stabbing incident is considered to be difficult area due to the large number of variables present. Having quantifiable data would allow a forensic pathologist to make a more informed decision when it comes to answering the commonly posed question in court “what was the degree of force involved the stabbing incident?” The answer to this question is considered significant in determining an alleged assailant’s level of intent to cause harm. The current practise among forensic pathologists is to use a three-point scale which categorises the force required to cause an injury as either mild, moderate or severe [1].

There have been several studies concentrating on the forces required to penetrate skin with knives. The force required depends on the tip radius of the weapon, the velocity of the attack and the type of thrust (e.g. overhand or underhand), the tension in the skin relative to area of the body and alignment with the Langer lines of cleavage, the underlying bone structure and any items of clothing [5–12].

However, there is considerably less information on the forces required for stabbing with other implements. A case review by Faller-Marquardt and Pollack for a screwdriver stabbing stated the “stabbing force necessary to penetrate the skin is considerably higher with screwdrivers than with pointed knives.” [13]. However, there was no attempt to relate the forces to weapon geometry.

Homicidal attacks involving screwdrivers are comparatively rare [14] but since the weapon used by assailants is often determined by opportunity [15], screwdrivers, chisels and other implements are used as weapons in stabbing attacks. For example, screwdrivers are readily available, they can be concealed without too much difficulty and they can be accounted for if stopped by the authorities.

The aim of the current paper is to present results from a systematic study of how much force is required to penetrate synthetic skin simulants using blunter objects such as screwdrivers, pens and chisels. The forces required for penetration are related to the geometry of the weapon, in particular, the force increases as the cross-sectional area. The results are discussed in terms of the stress required for skin penetration.

Materials and methods

A range of stabbing instruments have been used to determine the force for penetration as a function of weapon geometry. The stabbing instruments studied included a variety of screwdrivers with different geometry heads and other implements such as pens and chisels. All the implements tested were new on purchase and acquired from Wheelhouse (a local hardware store in Hounslow, London) and the website of the trade retailer Screwfix. The pens and pencils were purchased from the retailer Paperchase within Highcross Shopping Centre, Leicester.

Types of screwdriver

The blade profiles of a number of different screwdriver types are shown in Fig. 1a and b. Figure 1a shows a schematic diagram of the different screwdriver blade geometries and Fig. 1b shows a photograph of the common blade types and the type of screw that they are designed to work with. The two specific types of screwdriver that are most commonly used as stabbing weapons are the slotted (flat blade) and Phillips (cross head), probably because these are the most ubiquitous; the blade profiles are shown as number 1 and 2, respectively, in Fig. 1a and b. Slotted screwdrivers have a flat-bladed end and are used to tighten/loosen screws that have a linear notch in the top. The Phillips or cross-head screwdriver has an X-shaped slot; these slots are arranged at 0°, 90°, 180° and 270°. Two other types of screwdrivers have also been tested, the posidriv and the Torx. The posidriv screwdriver has a similar appearance to a Phillips screwdriver; but has four additional slots or marker lines. If the driver slots are at 0°, 90°, 180° and 270°, the marker lines are at the intermediate positions of 45°, 135°, 225° and 315°. This gives the screwdriver four additional points of contact. Torx screwdrivers have a six-point star-shaped pattern.

Experimental details and method

The blade width and blade breadth (for the slotted screwdrivers only) and cross-sectional area of the screwdriver heads (for all screwdrivers) have been measured to characterise the weapon geometry.

To measure the blade width and blade breadth of the slotted screwdrivers, an Olympus stereomicroscope (Olympus SZ-X12, Olympus, Tokyo, Japan) was used to record an image of the blade. Measurements were made in Image Pro Plus v4 (Media Cybernetics, Berkshire, UK), this allowed the width and breadth of the blade to be obtained.

An alternative methodology was used to determine the cross-sectional area of the other screwdrivers as the geometry was more complex. The point of the screwdriver was pushed into plasticine® modelling clay up to the depth at which the width of the impression was equal to the width of the screwdriver shaft. The depth to which the screwdrivers were indented to determine the cross-sectional area is shown in Figs. 2 and 3 for a Phillips and posidriv screwdriver, respectively (please see electronic supplementary material for figures). This methodology produced repeatable results and gave a realistic cross-sectional area as this would be the critical area of the screwdriver which controls the contact stresses when a force is applied. The images were evaluated in Image Pro Plus v4 in the same manner as the blade width/breadths for the slotted screwdrivers and it was then possible to calculate the cross-sectional areas of the screwdriver heads. The same methodology, i.e. imprinting in plasticine was also used for the Torx screwdrivers.

Synthetic skin simulants

Skin is a viscoelastic material (i.e. its deformation is time/loading rate dependent) that has non-homogeneous anisotropic properties (i.e. different properties depending on the orientation of the weapon relative to the skin). Skin also has variable mechanical properties which depend on a range of factors including age, body weight, health and moisture content. Skin also has a high fracture resistance [16].

Pig flesh and cadaveric tissues [5, 6] have previously been used for testing the sharpness of knives and other objects. Pig tissue has similar mechanical properties to human skin but is generally thicker and tougher owing to a higher density of collagen in the tissue [5, 17, 18]. Synthetic chamois was also considered but the tensile strength is approximately four times lower than that of skin and it was therefore not considered to be a good option. One of the disadvantages of both pig flesh and human tissue for studies of this type is that the properties can change as a function of age owing to dehydration or degradation of the tissues. Additionally, for human tissue experiments, ethical permission is essential. We have used pig flesh for a number of experiments in this paper owing to its ability to mimic the human system closely.

A range of synthetic skin simulants have been used in the literature [17, 18] for studying knife penetration. The requirements of a good skin simulant are that it must be easy to manufacture (or obtain) in a reliable and repeatable manner and it must remain stable in normal room conditions so as to provide repeatable data. Furthermore, it should also have the same mechanical properties as human skin in particular in terms of tensile strength and tear strength [19].

Shergold and Fleck have carried out a number of studies investigating the deep penetration of the skin by small diameter sharp and blunt punches. They used a silicone rubber layer cast on top of a polyurethane sponge (foam) to simulate skin [17]. Their findings showed that there was a direct correlation between the penetration mechanism and the geometry of the punch tip [20]. Kieser et al. showed that a sharp tip punch penetrated via a mode I crack whereas a blunt tip exhibited a mode II crack [21, 22]. Mode I cracks open when a normal tensile stress is applied perpendicular to the crack. Mode II cracks occur when sliding or “in plane” shear occurs in a direction perpendicular to the crack front. The same silicone rubber model skin analogue used by Shergold and Fleck has also been used for a study of biomechanical modelling of non-ballistic skin wounding [23].

A silicone rubber/foam skin analogue has been used for the majority of experiments in this study as it is the most practical option. Silicone rubber is used as it has the closest mechanical properties to skin (see Table 1) and importantly does not strain crystallise (i.e. the mechanical properties do not change with degree of elongation) [18].

Penetration testing

Experiments to determine the force for penetration of the skin were performed using an MTS servo-hydraulic materials testing system. The force for penetration was recorded using the testing system control software and the displacement or penetration of the implement into the skin analogue was recorded on a linear variable differential transformer. This allows the value of the maximum force required for penetration to be obtained from a typical force versus displacement plot as seen in Fig. 4. Figure 4 shows indentations made into three different silicone rubber/foam blocks and it can be seen that the repeatability of results is good. The maximum penetration force was obtained from the maximum on the force displacement plot as arrowed on the figure.

Each weapon/implement was tested for five times over different silicone rubber–foam blocks so an average value of penetration force was obtained.

In addition to the penetration testing, for the wounds made into pork we imaged the wound morphology produced.

Results

Slotted screwdrivers

Figure 5 shows a plot of the maximum force required for penetration of the skin/foam analogue as a function of the cross-sectional area of the screwdriver head. There is a linear trend that shows that as the cross-sectional area of the head increases, the force required for penetration also increases.

Figure 6 shows a similar plot where the maximum force for penetration is considered as a function of the blade angle, i.e. the angle between the two faces of the screwdriver blade. This figure shows that there is no correlation between the blade angle and the maximum force.

A number of the screwdrivers that were tested are those categorised as precision screwdrivers (see Fig. 7 in the electronic supplementary material). The results for these screwdrivers are plotted separately on Fig. 8 which that there is a good relationship between the cross-sectional area of the head and the force required for penetration. It should be noted that for these screwdrivers, the force required for penetration is low, in the range of 10–30 N.

Previous research by Hainsworth, Delaney and Rutty [11] investigated the quantification of sharpness of kitchen knives. From this work, a number of knives were selected that were classified as extremely sharp, very sharp, sharp and blunt and the forces required for penetration were measured using the materials testing system and the silicone rubber/foam analogue. Thus, for comparison, a plot of maximum force for a number of knives which have previously been classified as blunt to extremely sharp is shown on Fig. 9. A blunt knife would typically require a penetration force of approximately 35 N whereas for an extremely sharp knife, a force of approximately 12 N was required to penetrate the skin/foam analogue.

For screwdrivers that are not considered as precision screwdrivers, the forces required for penetration (Fig. 5) are comparable to those of a blunt knife for the smaller cross-sectional areas but once the cross-sectional area of the screwdriver is greater than 2 mm2, the force for penetration rises rapidly and for screwdrivers with large cross-sectional areas, the force can be greater than 100 N.

Phillips screwdrivers

The cross-sectional areas of the Phillips screwdrivers were obtained by imprinting in plasticine as described earlier. Figure 10 shows the maximum force for penetration against cross-sectional area for these screwdrivers. For these screwdrivers, the relationship between cross-sectional area and penetration force is less clear. Additionally, as the cross-sectional areas increase, the degree of scatter increases, and the data points are further away from the line of best fit. For the Phillips screwdrivers, the force required for penetration was similar to blunt knives for the screwdrivers with small cross-sectional areas. The force for penetration for larger screwdrivers was considerable and again rose to over 100 N.

Posidriv screwdrivers

The results for the posidriv screwdrivers are shown in Fig. 11. This shows that the relationship between cross-sectional area and maximum force for penetration does not follow a linear relationship and that there is considerable scatter in the forces required to puncture the foam/skin analogue.

Torx screwdrivers

For Torx screwdrivers, Fig. 12 shows that there is good linear correlation between the cross-sectional area of the screwdriver head and the amount of force that was required for penetration.

Other implements

Two different chisels, two pens and a pencil were also tested. The details of these implements can be found in Table 2. The aim of these experiments was to see how these implements compared to the forces required for penetration with screwdrivers.

Figure 13 gives the force required for penetration with these implements. It can be seen that the 8-mm chisel requires less force for penetration at 29 N than the larger 14 mm chisel which requires 33 N. The force required for penetration by the pens varies from 31 to 44 N and the pencil requires 38 N of force to penetrate. For these instruments, Pen 02 had the sharpest tip (defined by the width across the tip), followed by Pencil 01 and Pen 01; this is reflected in the results as the amount of the force required for penetration increased with the less sharp-tipped implement.

Experiments using porcine flesh

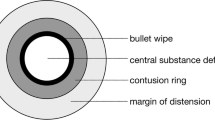

In addition to using the silicone rubber–foam blocks as the main skin simulant, tests were also carried out on porcine flesh, i.e. a pork leg. The results for the pork leg gave more scattered results owing to the greater variability of this testing material. Images of the resultant wounds are shown in Fig. 14 for slotted blades and Fig. 15 for Phillips head screwdrivers. It can be seen that the slotted screwdrivers give a characteristic “letterbox” wound morphology whilst the Phillips head leaves a wound that has fewer distinguishing features. The middle image of Fig. 15 shows some evidence of the four edges of the cross but generally the wounds have the characteristic shape of the shaft.

Discussion

A range of common types of screwdriver have been tested in order to determine the force required to penetrate the foam/skin analogue. A number of other implements such as pens, pencils and chisels, which could be used as a weapon in stabbing attacks, were also tested. A selection of knives that varied in the degree of sharpness were tested as a comparison to the blunter implements. Silicone rubber–foam blocks were the main skin simulant used.

For the slotted screwdrivers, a good correlation was found between the cross-sectional area of the screwdriver head and the force required for penetration. In all, 26 slotted screwdrivers of various sizes were tested and a good linear correlation was observed. The “smaller” slotted screwdrivers penetrate with forces between the range of 10 and 30 N, with the “larger” ones having a range of 70–130 N. Additionally, as the cross-sectional area of the screwdriver gets larger, the scatter in the force required for penetration increases.

The indentation of elastic materials such as silicone rubber has been investigated by a number of workers [24, 25]. For indentation by blunt cones (which can be applied to the geometry of weapons tested in this work), the indentation response of elastic materials is very close to the response that would be predicted by linear elasticity and early work by Sneddon on the theory of conical indentations of elastic solids is appropriate [26]. Essentially, the maximum force required for penetration can be understood by the force being related to a critical stress (defined as force/contact area) to puncture the silicone skin. Once the critical stress has been exceeded then the blade will penetrate through the skin to the foam analogue beneath. Skin behaves in a similar manner with the response being controlled by large elastic deflections initially up until the point at which the weapon penetrates the skin. An additional complexity in terms of interpreting the forces required is determined by the change in frictional effects and stress concentrating effects from the points on the different screwdriver geometries.

For the Phillips and posidriv screwdrivers, there was a less good correlation between cross-sectional area and force required for penetration. This could be that for these geometries, there is a more complex stress state beneath the screwdriver tip which means that the critical stress for penetration is less dependent on screwdriver cross-sectional area, or that the method used for determining cross-sectional area (with the indentation into plasticine) was subject to greater measurement error. However, the same general trend was observed in that the larger the screwdriver gets (whether it be a Phillips or posidriv), usually an increased amount of force is required to penetrate.

For Torx screwdrivers, as the Torx screwdriver increases in size, broadly speaking a larger force is required to penetrate. However, if the maximum cross-sectional area plot is examined closely, the values with respect to force for the Torx are lower than those seen for the slotted screwdrivers. For example, the largest Torx screwdriver had an area of 11.41 mm2 and it required approximately 45–55 N, whereas a slotted screwdriver of half that area would require the same amount of force. This can be explained as the points on the Torx screwdriver act to concentrate the stress locally, leading to a lower force to penetrate for a given cross-sectional area.

The pens and pencil required forces between the range of 25–50 N, and the chisels 27–34 N. These figures are comparable to that of a blunt knife, which required approximately 30–42 N to penetrate the silicone rubber and those of a slotted screwdriver which had a slightly larger cross-sectional area of the head.

A key issue from a forensic pathology aspect is in determining whether the blunter objects tested here generate incised wounds as in a stabbing, or a laceration. Lacerations that are caused by blunt objects have aspects of both crushing and tearing of the skin. Screwdrivers, however, do not appear to illustrate such traits despite being deemed as blunt objects. Images from all the different screwdriver types (slotted, Philips, posidriv and Torx) show wounds with clean cut and smooth edges. The break within the tissue does not suggest that it is caused by tearing. This point is accentuated by the fact that no injury is observed at the edges of the wounds themselves. In addition, there is no evidence of any bridging tissue. Thus, we conclude that a screwdriver injury is characteristic of an incised wound and not a laceration.

It should be noted that the numbers given for penetration force here relate to tests on a simple synthetic skin simulant which does not have the same complexities as in a real stabbing event. However, in order to relate the results in this work to the three-point scale of mild, moderate and severe used by pathologists, we can compare the force levels required with a range of knives that would be considered to range from very sharp to blunt as given earlier to give a context to the values quoted. Thus, for the screwdrivers with a large cross-sectional area which required 70–130 N of force to penetrate, it would be reasonable to consider these weapons as very blunt and therefore requiring severe force to inflict the injury. For the precision screwdrivers, where the force range for penetration was 10–15 N, these could be considered to be sharp weapons and thus the force would be in the mild category (analogous to a sharp knife). A blunt knife required 35 N to penetrate the skin analogue used here and this could be considered to be the point at which the force required for penetration changes from moderate to severe. Clearly, the results will be further influenced by the clothing worn by the victim, the position of the wound on the body and the age and health of the victim but the values above give a rough guide as to how the results might be interpreted on the three-point scale.

Conclusions

A number of different experiments have been carried using an array of implements that are traditionally considered to be blunt. The results have been analysed in terms of the correlation between force required and geometry of the weapon. The following conclusions can be drawn:

-

1.

There is a good correlation between the force required for penetration and cross-sectional area of the screwdriver head for slotted screwdrivers, the force required for penetration linearly increases as the cross-sectional area increases.

-

2.

The forces required for penetration are similar to those for a sharp knife for screwdrivers with small cross-sectional areas. For screwdrivers with cross-sectional areas greater than 2 mm2 the forces required for stabbing can be considerable (70–130 N) and much higher than those for blunt knives.

-

3.

For Phillips, posidriv and Torx screwdrivers, the force for penetration increases as the size of screwdriver increases. There is a reasonable correlation of force against cross-sectional area but not as strong as for slotted screwdrivers. There is greater scatter in the data.

-

4.

The biros, pens and chisels required a range of forces to penetrate the skin simulant, again, the biros and pens which had smaller cross-sectional areas of contact with the skin required smaller forces than the chisels.

-

5.

The wound morphology created by the screwdrivers was examined by microscopy and was found to be typical of an incised wound and showed no evidence of crushing or tearing at the wound extremities.

The results here show that depending on the size of the screwdriver, screwdrivers can generate injuries with forces comparable to that of a sharp knife, or be extremely blunt and require significant forces to penetrate. The size of the weapon is key to determining the level of force required.

References

Gilchrist MD, Keenan S, Curtis M, Cassidy M, Byrne G (2008) Measuring knife stab penetration into skin simulant using a novel biaxial tension device. Forensic Sci Int 177:52–65

Henderson JP, Morgan SE, Patel F, Tiplady ME (2005) Patterns of non-firearm homicide. J Clin Forensic Med 12:128–132

Home Office Statistical Bulletin (2009) Crime in England and Wales: Quarterly Update to December

Simpson K, Shepherd R (2003) Simpson’s forensic medicine, 12th edn. Arnold, London

Knight B (1975) The dynamics of stab wounds. Forensic Sci 6:249–255

Green MA (1978) Stab wound dynamics—a recording technique for use in medico legal investigations. J Forensic Sci Soc 18:161–163

Kaatsch HK, Mehrens C, Nietert M (1993) Der reproduzierbare Nesserstich. Rechtsmedizin 3:67–76

Jones S, Nokes L, Leadbetter S (1994) The mechanics of stab wounding. Forensic Sci Int 67:59–63

O’Callaghan PT, Jones MD, James DS, Leadbetter S et al (1999) Dynamics of stab wounds: force required for penetration of various cadaveric human tissues. Forensic Sci Int 104:173–178

Ankerson J, Birbeck A, Thomson R, Vanezis P (1998) The effect of knife blade profile on penetration force in flesh simulants. Technol Law Insur 3:125–128

Hainsworth SV, Delaney RJ, Rutty GN (2008) How sharp is sharp? Towards quantification of the sharpness and penetration ability of kitchen knives used in stabbings. Int J Leg Med 122:281–291

Chadwick EK, Nicol AC, Lane JV, Gray TG (1999) Biomechanics of knife stab attacks. Forensic Sci Int 105:35–44

Faller-Marquardt M, Pollak S (1996) Homicide with a screwdriver and simulation of a similar offence by self-infliction of injuries. J Clin Forensic Med 3:141–147

Schulz F, Colmant HJ, Trubner K (1995) Penetrating spinal injury inflicted by screwdriver: unusual morphological findings. J Clin Forensic Med 2(3):153–155

Croft AM, Ferllini R (2007) Macroscopic characteristics of screwdriver trauma. J Forensic Sci 52:1243–1251

Doran CF, McCormack BAO, Macey A (2004) A simplified model to determine the contribution of strain energy in the failure process of thin biological membranes during cutting. Strain 40:173–179

Ankersen J, Birkbeck AE, Thomson RD, Vanezis P (1999) Puncture resistance and tensile strength of skin simulants. Proc Inst Mech Eng H J Eng Med 213:493–501

Shergold OA, Fleck NA, Radford D (2006) The uniaxial stress versus strain response of pig skin and silicone rubber at low and high strain rates. Int J Impact Eng 32:1384–1402

Jussila J, Leppaniemi A, Paronen M, Kulomaki E (2005) Ballistic skin simulant. Forensic Sci Int 150:63–71

Shergold O, Fleck NA, King TS (2006) The penetration of a soft solid by a liquid jet, with application to the administration of a needle-free injection. J Biomech 39:2593–2602

Shergold O, Fleck NA (2005) Experimental investigation into the deep penetration of soft solids by sharp and blunt punches, with application to the piercing of skin. J Biomech Eng 127:838–848

Kieser J, Bernal V, Gonzalez P, Birch W, Turmaine M (2008) Analysis of experimental cranial skin wounding from screwdriver trauma. Int J Leg Med 122:179–187

Whittle K, Kieser J, Ichim I, Swain M, Waddell N (2008) The biomechanical modelling of non-ballistic skin wounding: blunt-force injury. Forensic Sci Med Path 4:33–39

Giannakopoulos AE, Panagiotopoulos DI (2009) Conical indentation of incompressible rubber-like materials. Intl J Solids Struct 46:1436–1447

Lim YY, Chaudhri MM (2004) Indentation of elastic solids with rigid cones’. Philos Mag 84:2877–2903

Sneddon I (1965) The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int J Eng Sci 3:47–57

Acknowledgements

Mr B. Kirkland, Mr G. Clarke and Dr S. Lawes are thanked for their assistance with the experimentation

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary materials

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 1348 kb)

Rights and permissions

About this article

Cite this article

Parmar, K., Hainsworth, S.V. & Rutty, G.N. Quantification of forces required for stabbing with screwdrivers and other blunter instruments. Int J Legal Med 126, 43–53 (2012). https://doi.org/10.1007/s00414-011-0562-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00414-011-0562-9