Abstract

Drying dissipative patterns were observed at room temperature on a cover glass, a watch glass, and a Petri glass dish during the course of dryness of aqueous solution of sodium salts of poly (d-glutamic acid), poly (l-glutamic acid), and their low molecular weight analogs, monosodium d-glutamate, monosodium l-glutamate, and monosodium dl-glutamate. The low molecular weight analogs were hygroscopic and their drying patterns were observed in a dry box coexisted with the bags of desiccant. The broad rings, which are the typical macroscopic drying patterns, were observed for all the samples. Optical isomeric effects on the drying patterns were not recognized. Spherulite (or hedrite) and rod-like crystals from the assemblies of helical main chains of the polymers are formed mainly at the inner area from the broad ring (except central area) and the broad ring area, respectively. Coexistence of sodium chloride enhanced the crystal structures by the cooperative interactions between the polymers and the salts. The typical dissipative crystallization such as accumulation, segregation, and orientation effects of crystals were observed in the drying patterns.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Most structural patterns in nature form via self-organization accompanied with the dissipation of free energy and in the non-equilibrium state. In order to understand the mechanisms of the dissipative self-organization of the simple model systems, instead of the much complex nature itself, the authors have studied the convectional, sedimentary, and drying dissipative patterns during dryness of colloidal suspensions and solutions, though these three kinds of structures are correlated strongly and overlapped each other [1–3]. Furthermore, studies on the drying patterns of colloidal suspensions and polymer solutions are highly important in the industrial aspects such as painting, printing, and micro-array device fields.

Typical convectional patterns are Benard cell [4, 5], the hexagonal circulating pattern, and Terada cell [6–8], the spoke-lines spreading whole the liquid surface accompanied with the huge number of cell convections in the normal direction of the spoke lines. These convectional patterns were observed often with the naked eyes in the intermediate and final stages in the convectional processes [9–17]. Recently, all the processes of the convectional patterns have been clarified experimentally [11, 13, 14]. Theoretical studies of the convectional patterns progressed mainly using Navier–Stokes equations [18–23]. However, these are not always successful yet when the theories are compared with the experimental results.

Sedimentary dissipative patterns during the course of drying suspensions have been studied in detail on a cover glass, a watch glass, a glass dish, and others, for the first time, in our laboratory [11, 24–31]. The broad ring-like patterns were formed in suspension state. It was clarified that the sedimentary particles were suspended above the substrate by the electrical double layers around the particles and always moved by the balancing of the force fields between the convectional flow and the gravitational sedimentation. Quite recently, dynamic bundle-like sedimentary patterns formed cooperatively from the spoke-like convectional structures of coffee [13] and black tea [14] coexisted with cream. It should be mentioned here that the sedimentary patterns are also formed in polymer solutions, though the patterns are not usually observed with the naked eye.

Drying dissipative patterns have been studied by many researchers for many kinds of colloidal particles [9, 10, 13–17, 24–49], linear-type synthetic and bio-polyelectrolytes [50–52], water-soluble neutral polymers [53, 54], ionic and non-ionic detergents [40, 55, 56], gels [57, 58], colloidal polymer complexes [59], and dyes [60]. The macroscopic broad ring patterns of the hill accumulated with the solutes formed. The broad rings moved inward when solute concentration decreased and/or solute size increased. For the non-spherical particles the round hill was formed in the central area in addition to the faint broad ring. Macroscopic spoke-like cracks or fine hills including flickering spoke-like ones were also observed for many solutes. Beautiful fractal patterns such as branch-, arc-, block-, star-, cross-, and string-like ones were observed in the microscopic scale.

One of the important findings in our experiments is that the primitive vague sedimentary patterns were formed already in the concentrated suspensions or solutions before dryness and they grew toward fine structures in the processes of the solidification [1–3]. It has been also clarified that information of the suspensions and solutions, shape and size of solute, and atmospheric humidity and temperature, for example, is transferred into the drying patterns [1–3]. Furthermore, dissipative crystallization of poly (allylamine hydrochloride) [49], poly (ethylene glycol) [61], sodium salt of poly (methacrylic acid) [62], poly-d-lysine and poly-l-lysine hydrobromides [63], hydroxypropyl cellulose [64], sodium salt of deoxyribonucleic acid [65], and sodium dextran sulfate [66] has been studied in detail. Accumulation, uneven distribution, symmetric distribution, ordering of the polymer single crystals, and further coupling of the single crystals with the dissipative broad ring patterns have been clarified.

In this work, drying dissipative patterns are studied at room temperature on a cover glass, a watch glass, and a Petri glass dish during the course of dryness of aqueous solution of sodium salts of poly (d-glutamic acid) (NaPDGA), poly (l-glutamic acid) (NaPLGA), and their low molecular weight analogs. One of the main purposes of this work is to clarify the stereo-specific effects of the biopolymers on the drying patterns. It should be mentioned here that the drying patterns of NaPLGA have been observed on a cover glass by the author’s group [51]. The broad ring size decreased transitionally below the critical polymer concentration of α-helix structure at the air–water interface.

Experimental

Materials

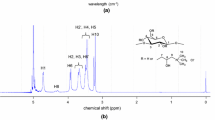

GR-grade of d-glutamic acid (specific rotation, \( \left[ \alpha \right]_{\text{D}}^{{20}} = - {29}.{5}\sim - {32}.{5}^\circ \)), l-glutamic acid (\( \left[ \alpha \right]_{\text{D}}^{{20}} = + {31}.{5}\sim + {32}.{5}^\circ \)), and dl-glutamic acid (\( \left[ \alpha \right]_{\text{D}}^{{20}} = 0\pm {1}^\circ \)) were purchased from Wako Pure Chemical Ind., Ltd. (Osaka). These solutions were neutralized with GR-grade of NaOH pellet to obtain the corresponding sodium salts of the glutamic acid, i.e., monosodium d-glutamate (NaDGA), monosodium l-glutamate (NaLGA), and monosodium dl-glutamate (NaDLGA). Poly-d-glutamic acid, sodium salt (NaPDGA, Lot no. 086K5100, molecular weight is unknown) was obtained from Sigma Co. Poly-l-glutamic acid (HPLGA1, molecular weight 2,000–15,000, Lot no. 2747F) and sodium salt of poly-l-glutamic acid (NaPLGA2, molecular weight 50,000–100,000, Lot no. 017 K5108) were purchased from MP Biochemicals Inc. (Solon Ohio) and Sigma Co. (St Louis, MO), respectively. Water used for the sample preparation was purified by a Milli-Q reagent grade system (Milli-RO5 plus and Milli-Q plus, Millipore, Bedford, MA).

Observation of the dissipative structures

Of the solution, 0.1 mL was dropped carefully and gently on a micro cover glass (30 × 30 mm, thickness no. 1, 0.12 to 0.17 mm, Matsunami Glass Co., Kishiwada, Osaka) set in a plastic dish (type NH-52, 52 mm in diameter, 8 mm in depth, As One Co., Tokyo). The cover glasses were used without further rinse. The contact angle of the pure water was 31 ± 0.5° from the drop profiles of water on an unrinsed cover glass. Extrapolation to the zero amount of water was made from the measurements at the several amount of water; 0.7 mL was set on a watch glass (50 mm in diameter, TOS TK-50, Toshinriko Co., Tokyo) and 0.7 mL of the sample was also set into a Petri glass dish (27 mm in inner diameter and 15 mm in height, TOP Co., Tokyo). The watch glass and glass dish were rinsed as thoroughly as possible. Dry box was a lunch box made of PMMA plastics (205 × 150 × 53 mm, Asvel Factory Co., Shanghai, China) with a transparent cap, from where the pictures of macroscopic patterns were taken. Four bags of chemisorptions-type desiccant (Nisso Dry-M50, Nisso Jushi Co., Ltd (Tokyo)) were set in the box. The disposable serological pipettes (1.0 ml, code 7077-1N, Corning Lab. Sci. Co.) were used for setting the sample suspensions.

The macroscopic patterns during dryness were observed on a desk covered with a black plastic sheet. A canon EOS-10D digital camera with a macro-lens (EF50 mm, aperture ratio, F = 2.5) and a life-size converter EF were used for taking pictures of macroscopic patterns. Microscopic drying patterns were observed with a metallurgical microscope (PME-3, Olympus Co., Tokyo).

Results and discussion

Drying patterns of low molecular weight analogs, NaDGA, NaLGA, and NaDLGA

Three kinds of NaGA were hygroscopic and did not dry up on the substrate in a room. Figure 1a–d shows the macroscopic patterns during the course of dryness of NaDGA on a cover glass in a dry box. After 2 months the broad ring patterns appeared clearly, but dryness of the central area was still incomplete as is shown in Fig. 1c. Pictures d, e, and f are the drying patterns of NaDGA, NaLGA, and NaDLGA 1.5 years after setting the initial solutions. The broad rings originating from the convection appeared clearly at the outside edge irrespective of the samples examined. The spoke lines, which also originated from the convection patterns in the cooperated processes of dryness, i.e., convection, sedimentation, and solidification, were observed especially in the broad ring area [1–3]. The drying patterns NaDGA, NaLGA, and NaDLGA look to be quite similar to each other (see d to f) and insensitive to the optical isomerism (chirality) of the molecules.

Figure 2 shows the microscopic drying patterns of NaDGA, NaLGA, and NaDLGA on a cover glass in a dry box. Single crystals of NaGA are known to be needle-like [67, 68]. However, curved rod-like microstructures are accumulated densely at the outside area near the broad ring and less densely at the central region, respectively. A main cause for the bending of the needles will be due to the irregular super-saturation taking place by the convectional stages followed by the solidification process. It should be mentioned here that the bent rods were not oriented at the central area of the dried film and further any differences in the drying patterns were not recognized among the different optical isomers.

Sizes of the drying broad rings (d f) were very small compared with those of the initial liquid (d i). The ratios d f/d i values are shown in Fig. 3. The d f/d i values are between 0.1 and 0.3 and increased as solute concentration increased and were quite insensitive to the optical isomer. Increase in the broad ring size with the molecular weight has often observed for poly (ethylene glycol) [61], polylysine hydrobromide [63], and hydroxypropyl cellulose [64]. This result is due to the very large excluded volumes of the polymers compared with those of the low molecular weight analogs.

Drying patterns of NaPDGA, NaPLGA, and NaPDGA + NaPLGA

Figure 6 shows the macroscopic drying patterns of NaPDGA (a–d), NaPLGA (e–h), and their mixture NaPDGA + NaPLGA (1:1) (i–l) on a cover glass. Total polymer concentration decrease from the left edge (0.02 monoM) to the right (0.0006 monoM). NaPDGA was slightly hygroscopic in contrast with NaPLGA and the mixture NaPDGA + NaPLGA. The broad rings were observed clearly at the outside edges irrespective of polymer concentration. A secondary faint broad ring also appeared in the inner area of the main broad ring at the outside edge (see pictures h and j, for example). This will be due to the coexistence of the helical and coil-rich conformation of the polymer chain and/or the rather high distribution in the molecular weight of the polymers. It should be recalled here that the size of the broad ring shrank around the central area of the initial solution at the concentrations lower than the critical concentration m* for NaPLGA [51]. The similar shrinking of the broad rings appeared again in the present work as is shown in Fig. 4, where sizes of the primary broad rings (d f) of NaPDGA (shown by open circles), NaPLGA (triangles), and NaPDGA + NaPLGA (1:1, squares) are shown as a function of polymer concentration. The m* values are close to 0.003 monoM being close to the previous work [51, 69].

The d f/d i values are shown in Fig. 5. The symbols being located at unity are the values corresponding to the primary broad rings, and the symbols at the smaller values than unity are the secondary broad rings. All the ratios are insensitive to the optical isomerism of the polymer when the experimental errors are taken into account (Fig. 6).

Plots of d f/d i of NaPDGA (open circle, open triangle, open square), NaPLGA2 (close circle, close triangle, close square), and NaPDGA + NaPLGA2 (circled dot operator, inverted open triangle, dotted open square) solutions on a cover glass (open circle, close circle, circled dot operator), a watch glass (open triangle, close triangle, inverted open triangle), and glass dish (open square, close square, dotted open square) as a function of polymer concentration

Figure 7 shows the typical examples of the microscopic drying patterns of NaPLGA on a cover glass (a, b). Pictures c to f are the patterns of NaPDGA + NaPLGA on a watch glass. Spherulite and hedrite crystal structures are observed clearly a, b, and c to f, respectively. The Maltese crosses, though incomplete, appeared in the pictures e and f from polarizing microscopy. The spherulite and hedrite structures have been observed in the drying patterns of aqueous solutions of poly (ethylene glycol) [61, 70–73] and sodium salt of poly (methacrylic acid) [62]. It should be noted here that the spherulite and hedrite patterns were observed so often at the inner broad ring areas except the central region of the dried film. The rod-like crystal structures formed mainly in the broad ring area (see Fig. 10a below for NaPLGA on a watch glass, for example). Iizuka et al. reported the rod-like liquid crystals for the concentrated aqueous solution of NaPLGA [74]. It should be noted here that the rod-like crystals in this work are similar to the liquid-crystal patterns of hydroxypropyl cellulose [64, 75, 76], sodium salts of deoxyribonucleic acid [77], and polynucleotide complexes [78]. Formation of the microstructures of the spherulite (or hedrite) and the rod-like crystals at the different places of the dried film is one of the dissipative effects, which takes place during the course of dryness, especially in the convectional processes.

Optical (a–d) and polarizing (e, f) microscopic drying patterns of aqueous NaPLGA1 (a, b) and NaPDGA + NaPLGA1 (1:1) (c–f) solutions on a cover glass (a, b) and a watch glass (c–f) at 25 °C; 0.1 ml (b, c), 0.7 ml (a, d–f), [NaPLGA1] = 0.02 ml, [NaPDGA + NaPLGA1] = 0.02 monoM, full scale is 100 μm (a–d), length of the picture frame (e, f) is 2.6 × 3.4 mm

Drying patterns of NaPDGA, NaPLGA, and NaPDGA + NaPLGA with coexistence of sodium chloride

Figure 8 shows the macroscopic drying patterns of aqueous solutions of NaPDGA + NaCl (a to d) and NaPLGA + NaCl (e to h) on a cover glass. The main broad rings remained at the outside edges irrespective of the salt concentration. However, broadening of the ring took place by the addition of NaCl. Interestingly, secondary broad rings became clear with coexistence of sodium chloride. In the presence of the excess amount of sodium chloride at 0.2 M, cubic single crystals were isolated.

Figures 9 and 10 show the influences of the sodium chloride coexisted upon the microscopic patterns of NaPDGA + NaPLGA on a cover glass and a watch glass, respectively. An important finding is clear from the pictures, i.e., the microscopic patterns shifted slightly from the microstructures of the rod-like assemblies toward the hedrite structures. This pattern shift will be due to (a) the conformational change from the stretched helical rod to the coil-like main chains. (b) Cooperative interaction between NaPGA polymers and the salt (see, Fig. 9c and g, for example) and the segregation effect between the polymers and the salt (see, Figs. 9d and 10h, for example) are also important.

Concluding remarks

In the present work, (a) rod-like liquid-crystal assemblies of the helical-chains, (b) spherulite crystals, and (c) hedrite-type single crystals are observed. Interestingly, these patterns are localized and accumulated at the different places in a dried film. Rod-like crystals formed mainly in the broad ring area, whereas spherulite and hedrite crystals appeared at the inner broad ring areas except the central region of the drying film. Localized accumulation of each pattern is one of the typical dissipative effects. The main cause is due to the distortional forces upon the polymer molecules raised by the convectional flow of solvent and then the polymer themselves during the cooperative drying processes, where convection, sedimentation, and solidification processes coexist. The localized accumulation means that the polymer crystallization does not take place homogeneously on earth. In other words, homogeneous crystallization is almost impossible to take place in the gravity, since the gravitational convection always takes place on earth. Microgravity experiments of the drying dissipative patterns of deionized suspension of colloidal silica spheres were made [79]. It is surprising to note that the broad ring patterns still appeared even in microgravity. This supports strongly that both the gravitational and the Marangoni convections contribute to the broad ring formation on earth, and the latter is still important in microgravity, because the differences in the local solution temperature always takes place by the evaporation of solvent even in microgravity. We should note here that the broad ring patterns are formed already in the processes of convectional flow of water and polymer themselves in solution state. The broad ring-like sedimentation patterns have been observed in many colloidal systems as was described already in Introduction. We should further note that the sedimentation process also should exist during the course of drying solution systems, though the direct observation is difficult compared with the suspension systems.

References

Okubo T (2006) In: Stoylov SP, Stoimenova MV (eds) Molecular and colloidal electro-optics. Taylor & Francis, New York, p 573

Okubo T (2008) In: Nagarajan R, Hatton TA (eds) Nanoparticles: syntheses, stabilization, passivation and functionalization. ACS Book, Washington DC, p 256

Okubo T (2010) Macromol Symp 288:67

Gribbin G (1999) Almost everyone’s guide to science. The universe, life and everything. Yale University Press, New Haven

Ball P (1999) The self-made tapestry. Pattern formation in nature. Oxford Univ Press, Oxford

Terada T, Yamamoto R, Watanabe T (1934) Sci Paper Inst Phys Chem Res Jpn 27:173, Proc Imper Acad Tokyo 10:10

Terada T, Yamamoto R, Watanabe T (1934) Sci Paper Inst Phys Chem Res Jpn 27:75

Nakaya U (1947) Memoirs of Torahiko Terada (Japanese). Kobunsya, Tokyo

Okubo T, Kimura H, Kimura T, Hayakawa F, Shibata T, Kimura K (2005) Colloid Polym Sci 283:1

Okubo T (2006) Colloid Polym Sci 285:225

Okubo T (2009) Colloid Polym Sci 287:167

Deegan RD, Bakajin O, Dupont TF, Huber G, Nagel SR, Witten TA (1997) Nature 389:827

Okubo T, Okamoto J, Tsuchida A (2009) Colloid Polym Sci 287:351

Okubo T (2009) Colloid Polym Sci 287:645

Okubo T, Okamoto J, Tsuchida A (2008) Colloid Polym Sci 286:1123

Okubo T (2008) Colloid Polym Sci 286:1307

Okubo T (2008) Colloid Polym Sci 286:1527

Palmer HJ (1976) J Fluid Mech 75:487

Anderson DM, Davis SH (1995) Phys Fluids 7:248

Pouth AF, Russel WB (1998) AIChEJ 44:2088

Burelbach JP, Bankoff SG (1998) J Fluid Mech 195:463

Deegan RD, Bakajin O, Dupont TF, Huber G, Nagel SR, Witten TA (2000) Phys Rev E 62:756

Fischer BJ (2002) Langmuir 18:60

Okubo T (2006) Colloid Polym Sci 284:1191

Okubo T (2006) Colloid Polym Sci 284:1395

Okubo T, Okamoto J, Tsuchida A (2007) Colloid Polym Sci 285:967

Okubo T (2007) Colloid Polym Sci 285:1495

Okubo T, Okamoto J, Tsuchida A (2008) Colloid Polym Sci 286:385

Okubo T, Okamoto J, Tsuchida A (2008) Colloid Polym Sci 286:941

Yamaguchi T, Kimura K, Tsuchida A, Okubo T, Matsumoto M (2005) Colloid Polym Sci 283:1123

Okubo T (2006) Colloid Polym Sci 285:331

Vanderhoff JW (1973) J Polym Sci Symp 41:155

Nicolas G, Prigogine I (1977) Self-organization in non-equilibrium systems. Wiley, New York

Ohara PC, Heath JR, Gilbert WM (1997) Angew Chem 109:1120

Maenosono S, Dushkin CD, Saita S, Yamaguchi Y (1999) Langmuir 15:957

Nikoobakht B, Wang ZL, El-Sayed MA (2000) J Phys Chem 104:8635

Ung T, Litz-Marzan LM, Mulvaney P (2001) J Phys Chem B 105:3441

Okubo T, Okuda S, Kimura H (2002) Colloid Polym Sci 280:454

Okubo T, Kimura K, Kimura H (2002) Colloid Polym Sci 280:1001

Okubo T, Kanayama S, Kimura K (2004) Colloid Polym Sci 282:486

Okubo T, Yamada T, Kimura K, Tsuchida A (2005) Colloid Polym Sci 283:1007

Okubo T, Nozawa M, Tsuchida A (2007) Colloid Polym Sci 285:827

Okubo T, Kimura K, Tsuchida A (2007) Colloids Surf B Biointerf 56:201

Okubo T, Nakagawa N, Tsuchida A (2007) Colloid Polym Sci 285:1247

Okubo T, Kimura K, Tsuchida A (2008) Colloid Polym Sci 286:621

Okubo T (2008) Colloid Polym Sci 286:1411

Okubo T, Otake A, Tsuchida A (2009) Colloid Polym Sci 287:1435

Okubo T, Kokufuta E, Nakamuro M, Yoshinaga K, Mizutani M, Tsuchida A (2010) Colloids Surfaces B Biopolym 80:193

Okubo T, Suzuki H, Kitano H, Ohno K, Mizutani M, Tsuchida A (2010) Colloid Polym Sci 288:1233

Okubo T, Kanayama S, Ogawa H, Hibino M, Kimura K (2004) Colloid Polym Sci 282:230

Okubo T, Onoshima D, Tsuchida A (2007) Colloid Polym Sci 285:999

Okubo T, Ogawa H, Tsuchida A (2010) Colloid Polym Sci 288:245

Shimomura M, Sawadaichi T (2001) Curr Opin Coll Interf Sci 6:11

Okubo T, Yamada T, Kimura K, Tsuchida A (2006) Colloid Polym Sci 284:396

Kimura K, Kanayama S, Tsuchida A, Okubo T (2005) Colloid Polym Sci 283:898

Okubo T, Shinoda C, Kimura K, Tsuchida A (2005) Langmuir 21:9889

Okubo T, Emi I, Tsuchida A, Kokufuta E (2006) Colloid Polym Sci 285:339

Okubo T, Suzuki D, Yamagata T, Katsuno A, Mizutani M, Kimura H, Tsuchida A (2011) Colloid Polym Sci 289:807

Okubo T, Okamoto J, Tsuchida A (2010) Colloid Polym Sci 288:189

Okubo T, Yokota N, Tsuchida A (2007) Colloid Polym Sci 285:1257

Okubo T, Okamoto J, Takahashi S, Tsuchida A (2009) Colloid Polym Sci 287:933

Okubo T, Hagiwara A, Kitano H, Okamoto J, Takahashi S, Tsuchida A (2009) Colloid Polym Sci 287:1155

Okubo T, Okamoto J, Tsuchida A (2010) Colloid Polym Sci 288:981

Okubo T, Mizutani M, Takahashi S, Tsuchida A (2011) Colloid Polym Sci 288:1551

Okubo T, Mizutani M, Takahashi S, Tsuchida A (2010) Colloid Polym Sci 288:1435

Okubo T (2011) Colloid Polym Sci. 289:159

Groen H, Borissova A, Roberts KJ (2003) Ind Eng Chem Res 42:198

Daub CD, Leung K, Luzar A (2009) J Phys Chem B 113:7687

Okubo T, Kobayashi K (1998) J Colloid Interf Sci 205:433

Hay JN, Stabir M, Steven RLT (1969) Polymer 10:187

Godowsky YK, Slonimsky GL, Garber NM (1972) J Polym Sci 38:1

Kawashima K, Kawana R, Miyagi T, Umemoto S, Okui N (2003) J Macromol Sci B Phys 42:889

Machado JC, Silva GG, De Oliveira FC, Laval RL, Rieumont J, Licinio P, Windmoller D (2007) J Polym Sci B Polym Phys 45:2400

Iizuka E, Kondo Y, Ukai Y (1977) Polym J 9:135

Onogi Y, White JL, Fellers JF (1980) J Polym Sci Polym Phys 70:1465

Suto S, Hasegawa S (2002) J Mater Sci 37:4857

Iizuka E (1977) Polym J 9:173

Iizuka E (1978) Polym J 10:293

Tsuchida A, Okubo T (2003) Sen’I Gakkaishi 59:264

Acknowledgments

Financial supports from the Ministry of Education, Culture, Sports, Science, and Technology, Japan and Japan Society for the Promotion of Science are greatly acknowledged for Grants-in-Aid for Exploratory Research (17655046) and Scientific Research (B) (18350057) to T.O. and Scientific Research (B) (19350110) to A.T. The research fund from REX Co. (Tokyo) to T.O. is also appreciated deeply.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Okubo, T., Takahashi, S. & Tsuchida, A. Dissipative crystallization of sodium salts of poly (d-glutamic acid), poly (l-glutamic acid), and their low molecular weight analogs. Colloid Polym Sci 289, 1729–1737 (2011). https://doi.org/10.1007/s00396-011-2495-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-011-2495-8