Abstract

Macroscopic and microscopic dissipative structural patterns formed in the course of drying a series of poly (ethylene glycol) (PEG) having molecular weights ranging from 1,000 to 2×106 in aqueous solution have been studied on a cover glass. The broad ring patterns of the hill accumulated with the polymers are formed irrespective of the molecular weights of PEG molecules. The single round hills are formed also in the center in the macroscopic scale, when the molecular weight is large. The characteristic convection flow of the polymers and the interactions among the polymers and substrate are important for the macroscopic pattern formation. Cross-like fractal patterns are observed, especially for the diluted solutions in the microscopic scale. These patterns are determined mainly by the electrostatic and polar interactions between the polymers and/or between the polymer and the substrate in the course of solidification. Interestingly, these microscopic patterns are reflected based on the shape and size of the PEG polymers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Most structural patterns in nature and experiments in the laboratory form via self-organization accompanied by the dissipation of free energy and in the non-equilibrium state. Among several factors in the free energy dissipation, evaporation at the liquid surface and convection induced by the earth’s gravity are very important. Several papers on the drying pattern formation of monodispersed colloidal suspensions have been reported so far [1–16]. Electrostatic interparticle interactions have been pointed out as one of the important factors in the dissipative structures. Hydrophobic and hydrophilic interactions are also demonstrated to be important in the drying process. Gelbart et al. [4, 5, 7] examined the mechanism of solvent dewetting in annular ring structures formed by drying a diluted metal colloid on a substrate. Shimomura et al. [17] have studied intensively the dissipative patterns in the processes of film formation by drying polymer solutions.

In previous papers from our laboratory [18, 19], drying dissipative patterns on a cover glass have been studied for colloidal crystal suspensions of colloidal silica and polystyrene spheres. Quite similar macroscopic and microscopic structural patterns formed between the two kinds of spheres. The broad ring patterns of the hill accumulated with spheres in the outside edges and the spoke-like and ring-like cracks formed in the macroscopic scale. The existence of the small circle convection cells proposed by Terada [20–22] was supported. Structural patterns were observed in the course of drying the suspension of Chinese black ink on a cover glass and in a dish [23]. The clear broad ring and spoke-like patterns of the rims accumulated with particles formed especially in the central region of the film. Interestingly, the primitive vague patterns of valleys were formed already in the concentrated suspensions before dryness and they grow toward fine cracks in the course of solidification. Branch-like fractal patterns of the sphere association were observed in the microscopic scale. Capillary forces between the neighboring spheres at the air–liquid interface and the different rates of convection flows of water and spheres at the drying front were important for the pattern formation. Quite recently, drying dissipative structures have been studied also for a series of colloidal silica spheres ranging from 29 nm to 1 μm in diameter [24]. The drying patterns of aqueous suspensions of monodispersed bentonite particles were investigated in detail [25].

The drying structures have been studied further for the linear-type macrocations, i.e., poly (allylamine hydrochloride) [26]. Macroscopic broad ring patterns formed. Furthermore, beautiful string-like fractal patterns were observed in the microscopic scale. The drying experiments were made for n-dodecyltrimethylammonium chloride [27]. Recently, a series of anionic detergent molecules, sodium n-alkyl sulfates were used for studying the drying dissipative patterns [28]. Broad ring patterns formed in the macroscopic scale. Star-like, branch-like, arc-like and small block-like microstructures were also observed. The convection of water and detergents at different rates under gravity and the translational and rotational Brownian movement of the latter were important for the macroscopic pattern formation. Microscopic patterns were also determined by the translational Brownian diffusion of the detergent molecules and the electrostatic and the hydrophobic interactions between detergents and/or between the detergents and substrate in the course of the solidification. Quite recently, microscopic and macroscopic drying dissipative structural patterns have been studied for aqueous solutions of poly (oxyethylene alkylethers) [29].

From these studies on drying structures, very similar macroscopic broad ring patterns formed irrespective of the kind of solutes and their concentrations. Microscopic patterns such as branch-like, string-like, arc-like and small block-like ones were, however, reflected in the shape, size and flexibility of the solute molecules [30]. In this work, drying dissipative structures of a series of poly (ethylene glycol) are studied in detail. The main purpose of this work is to study the shape and size effect of the polymers in the drying dissipative patterns.

Experimental

Materials

Six kinds of poly (ethylene glycol), PEG1000, PEG2000, PEG7500, PEG20000, PEG500000 and PEG2000000 having the average molecular weights of 1,000, 2,000, 7,500, 20,000, 500,000 and 2,000,000, respectively, were purchased from Wako Pure Chemicals Co. (Tokyo, Japan). Degrees of polymerization are 22, 45, 170, 450, 11,400 and 45,500, respectively. The water used for the sample preparation was purified by a Milli-Q reagent grade system (Milli-RO5 plus and Milli-Q plus, Millipore, Bedford, MA, USA).

Observation of the dissipative structures

0.1 mL of the aqueous solution of PEG sample was dropped carefully and gently on a micro cover glass (30 mm×30 mm, thickness No.1, 0.12–0.17 mm, Matsunami Glass Co., Kishiwada, Osaka, Japan) in a dish (60 mm in diameter, 15 mm in depth, Petri Co., Tokyo, Japan). The cover glass was used without further rinsing in this work. The extrapolated value of the contact angle for pure water was 31±0.2 ° from the drop profile of a small amount of water (0.2, 0.4, 0.6 and 0.8 μL) on the cover glass. A pipet (1 mL, disposable serological pipet, Corning Lab. Sci. Co.) was used for the dropping. Observation of the macroscopic and microscopic drying patterns was made for the film formed after the suspension was dried up completely on a cover glass in a room air-conditioned at 25 °C and 65% in humidity of the air. Concentrations of PEG polymers ranged from 1×10−7 to 0.01 monoM.

Macroscopic dissipative structures were observed with a digital HD microscope (type VH-7000, Keyence Co., Osaka) and a Canon EOS 10 camera with macro-lens (EF 50 mm, f=2.5) and a life-size converter EF. Microscopic structures were observed with a laser 3D profile microscope (type VK-8500, Keyence) and a metallurgical microscope (Axiovert 25CA, Carl-Zeiss, Jena GmbH).

Results and discussion

Macroscopic and microscopic dissipative structures

Figure 1 shows the typical patterns formed in drying the PEG7500 solutions at the concentrations ranging from 1×10−7 to 0.01 monoM. The broad ring patterns were observed at the wide concentration range. A main cause for the broad ring formation is due to the convection flow of water and the polymer in the different rates, where the rate of the latter will be slower than that of the former under gravity. Especially, the flow of the polymers drops from the center area toward the outside edges in the lower layer of the liquid. This phenomenon, which was observed on a digital HD microscope directly from the movement of the very rarely occurred aggregates of the colloidal particles of Chinese black ink (not PEG), is important [23]. The convection flow is enhanced by the evaporation of water at the liquid surface, resulting in the lowering of the solution temperature in the upper region. When the polymer molecules reach the edges of the drying frontier at the outside region of the liquid, a part of the molecules will turn upward and return to the center region. However, the movement of the most molecules may stop at the frontier region by the disappearance of water (solidification). This process must be followed by the broad ring accumulation of the molecules near the circular edges. It should be noted that the broad ring formation has been observed for all the solutions and suspensions examined by our group [18, 19, 23–29], T. Okubo, D. Onoshima, K. Kimura, A. Tsuchida, in preparation, T. Okubo, M. Hibino, H. Ogawa, K. Kimura, A. Tsuchida, in preparation, T. Okubo, H. Togawa, K. Kimura, A. Tsuchida, in preparation, T. Okubo, T. Yamaguchi, A. Otake, in preparation and further by other researchers [4, 5, 7]. Recently, microgravity experiments were made for the observation of the drying dissipative patterns of deionized suspension of colloidal silica spheres (A. Tsuchida, N. Nakagawa, K. Yoshikura, J. Okamoto, M. Itoh, T. Okubo, in preparation). Surprisingly, the broad ring patterns did not disappear even in microgravity. This supports that both the gravitational and the Marangoni convections contribute to the broad ring formation on earth but the latter is still important in microgravity.

Patterns formed for PEG7500 at 25 °C. a [PEG7500]=1×10−7 monoM, b 1×10−6 monoM, c 1×10−5 monoM, d 1×10−4 monoM, e 1×10−3 monoM, f 0.01 monoM. In water, 0.1 mL, length of the bar is 4.0 mm. Extended pictures of the area given by squares are shown in Fig. 2

We should note here that there appeared a hill in the center region in addition to the broad ring especially for PEG having high molecular weight. These hills in the central area have so far not been observed for the suspensions of any kind of spherical particles, but observed often for anisotropic-shaped molecules and particles. The translational movement of the anisotropic-shaped molecules and/or particles accompanied by the convectional flow of water will be restricted compared with those of spherical ones. The rotational movement of the highly associated molecules must also be difficult considering their anisotropic shape, and the sliding movement will be major especially in the area close to the substrate plane. It is highly plausible that this restricted Brownian movement is correlated to the appearance of the hill in the center. PEG molecules are linear molecules and have many hydroxyl groups regularly distributed along the main chain, and hydrogen-bonding interactions between the groups must be important. Thus, the PEG molecules, especially the heavy ones, should be associated.

The macroscopic patterns of the PEG1000 and 2000 solutions were quite similar to those of PEG7500 as shown in Fig. 1, though showing the pictures of these samples was omitted in this paper. It is clear that there is no molecular weight dependency in the patterns in the range of molecular weight between 1,000 and 7,500.

Figure 2 shows the extended patterns of the areas depicted by the squares in Fig. 1. The length of the bar is 600 μm. Cruciform microscopic patterns are observed clearly in a wide range of polymer concentrations from 1×10−7 to 0.001 monoM. These patterns look like fractal ones, and the fractal dimensions were estimated to be 1.11, 0.95, 1.05, 1.07, 1.15 and 1.14 at the polymer concentrations of 1×10−7, 1×10−6, 1×10−5, 1×10−4, 0.001 and 0.01 monoM, respectively. Rather low values of fractal dimensions are obtained compared with those of the typical 2D fractal patterns, 1.26 for Koch curve, for example. It should be noted here that the surfaces of the broad (actually rather fine) rings formed in the outside regions look structured strings in Fig. 2, which may support the structured accumulation of the linear-type PEG molecules. The cruciform patterns were observed only at 1×10−6 monoM for PEG1000 and only at 1×10−6 monoM, at 1×10−5 monoM and at 1×10−4 monoM for PEG2000, respectively. At the other concentrations, typical cruciform patterns were not observed. The extended pictures of PEG1000 and PEG2000 were also not shown in this report.

The drying dissipative patterns of PEG2000000 are shown in Fig. 3. The patterns are also not so different from those of PEG7500 shown in Fig. 1. Broad rings are also observed. Figure 4 shows the extended patterns of the areas depicted by the squares in Fig. 3. The length of the bar is 600 μm. The spot-like patterns were observed clearly in the polymer concentration range from 1×10−7 to 1×10−4 monoM, and the cruciform patterns were also composed of the block-like spots. At the rather high polymer concentrations of 0.001–0.01 monoM, broad ring regions were composed of fine and regularly structured rings and/or strings. The macroscopic and microscopic patterns of PEG20000 and PEG500000 were also similar to those of PEG2000000 or in between PEG7500 and PEG2000000, though the pictures demonstrating these are omitted in this paper. It is suggestive that both the macroscopic and microscopic patterns of a series of PEG samples are quite similar irrespective of their molecular weights. These observations support the idea that one of the main factors influencing the drying patterns is the linear shape of the molecules.

Patterns formed for PEG2000000 at 25 °C. a [PEG2000000]=1×10−7 monoM, b 1×10−6 monoM, c 1×10−5 monoM, d 1×10−4 monoM, e 1×10−3 monoM, f 0.01 monoM. In water, 0.1 mL, length of the bar is 4.0 mm. Extended pictures of the area given by squares are shown in Fig. 4

Area and drying time

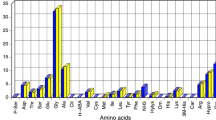

Figure 5a and b show the final areas covered with the polymers in the dried film (S f ) and the drying times (T) respectively for a series of PEG samples as a function of their molecular weights (M w ). Experimental errors of ±10%, rather large. S f increased as M w and/or polymer concentration increased. These results are explained clearly by decrease in the surface tensions at the interface between air and the solution, i.e., S f increases when the surface tension of the solutions decreases. Decrease in the surface tension with increasing molecular weight and/or concentration of the polymers has been reported in the previous paper [31, 32]. Two-dimensional ordered structures were speculated from the enhanced surface activity of aqueous solution of PEG molecules.

Interestingly, the T-values were quite insensitive to both the molecular weight and the polymer concentration. It should be mentioned here that the T-values of the detergents such as n-dodecyltrimethylammonium chloride [27] and n-alkyl sulfates [28] decreased sharply when S increases, which is quite understandable because the drying process is fast when the liquid film is thin even though the area is large. The results for PEG molecules will support that the surface active solutions at high concentrations and/or high molecular weight are deliquescent and low in water activity.

Figure 6 shows the thickness of the film as a function of the distance from the center (r). The experiments were made directly using a laser 3D profile microscope. The experimental errors are estimated to be rather large at ±10%, since the central spots are not always just at the center. Surprisingly, the d − r profiles shown in Fig. 6 support the existence of the broad ring patterns for all the samples. Furthermore, the figure supports the existence of the round hills in the center for the high molecular weight PEG samples such as PEG20000, PEG500000 and PEG2000000. It should be noted further that the flat and thick regions were observed clearly for the high molecular weight polymers. We should recall that the central region of the film of the spherical particles were always extremely thin [18, 19, 27].

Micro-structures of the broad rings

Figures 7 and 8 show the microscopic drying surface structures of the broad-ring regions for the solutions of PEG2000, PEG7500, PEG20000 and PEG2000000 observed with a laser 3D profile microscope. Surprisingly, the patterns are similar to steep mountains having many peaks and valleys. Many events such as (a) many sizes of circulating convection flow of water and the polymers with different modes of movement, (b) polymer accumulation on a cover glass, (c) polymer orientation along the substrate wall, (d) water evaporation in the drying frontier regions followed by the capillary forces between polymer molecules, (e) shrinking of the patterns accompanied with solidification step, etc. should occur while the PEG solution dries on a glass cover, sometimes separately and sometimes cooperatively. The drying patterns of the solutions resemble mountains. We can therefore imagine us that the drying processes in this study are like the dissipative formation processes of a volcano in nature. The authors believe that the gravitational convection flow of the lava in viscous liquid state will also play an important role in the pre-solidification processes.

References

Vanderhoff JW (1973) J Polymer Sci Symp 41:155

Nicolis G, Prigogine I (1977) Self-organization in nonequilibrium systems. Wiley, New York

Cross MC, Hohenberg A (1993) Rev Modern Phys 65:851

Ohara PC, Heath JR, Gelbart WM (1997) Angew Chem 109:1129

Ohara PC, Heath JR, Gelbart WM (1998) Langmuir 14:3418

Uno K, Hayashi K, Hayashi T, Ito K, Kitano H (1998) Colloid Polymer Sci 276:810

Gelbart WM, Sear RP, Heath JR, Chang S (1999) Faraday Discuss 112:299

van Duffel B, Schoonheydt RA, Grim CPM, De Schryver FC (1999) Langmuir 15:7520

Maenosono S, Dushkin CD, Saita S, Yamaguchi Y (1999) Langmuir 15:957

Brock SL, Sanabria M, Suib SL, Urban V, Thiyagarajan P, Potter DI (1999) J Phys Chem 103:7416

Nikoobakht B, Wang ZL, El-Sayed MA (2000) J Phys Chem 104:8635

Ge G, Brus L (2000) J Phys Chem 104:9573

Chen KM, Jiang X, Kimerling LC, Hammond PT (2000) Langmuir 16:7825

Lin XM, Jaenger HM, Sorensen CM, Klabunde M (2001) 105:3353

Kokkoli E, Zukoski CF (2001) Langmuir 17:369

Ung T, Liz-Marzan LM, Mulvaney P (2001) J Phys Chem B 105:3441

Shimomura M, Sawadaishi T (2001) Curr Opin Colloid Interface Sci 6:11

Okubo T, Okuda S, Kimura H (2002a) Colloid Polymer Sci 280:454

Okubo T, Kimura K, Kimura H (2002b) Colloid Polymer Sci 280:1001

Terada T, Yamamoto R, Watanabe T (1934a) Sci Paper Inst Phys Chem Res Jpn 27:173; Proc Imper Acad Tokyo 10:10

Terada T, Yamamoto R, Watanabe T (1934b) Sci Paper Inst Phys Chem Res Jpn 27:75

Terada T, Yamamoto R (1935) Proc Imper Acad Tokyo 11:214

Okubo T, Kimura H, Kimura T, Hayakawa F, Shibata T, Kimura K (2005a) Colloid Polymer Sci 283:1

Okubo T, Yamada T, Kimura K, Tsuchida A (2005) Colloid Polymer Sci 283:1007

Yamaguchi T, Kimura K, Tsuchida A, Okubo T, Matsumoto M (2005) Colloid Polymer Sci 283:1123

Okubo T, Kanayama S, Ogawa H, Hibino M, Kimura K (2004a) Colloid Polymer Sci 282:230

Okubo T, Kanayama S, Kimura K (2004b) Colloid Polymer Sci 282:486

Kimura K, Kanayama S, Tsuchida A, Okubo T (2005) Colloid Polymer Sci 283:898

Okubo T, Shinoda C, Kimura K, Tsuchida A (2005b) Langmuir (in press)

Okubo T (2005) Molecular and colloidal electro-optics In: Stoylov SP, Stoimenova M (eds) Dekker, New York (in press)

Okubo T (1988) J Colloid Interface Sci 125:386

Okubo T, Kobayashi K (1998) J Colloid Interface Sci 205:433

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Okubo, T., Yamada, T., Kimura, K. et al. Drying dissipative structures of aqueous solution of poly (ethylene glycol) on a cover glass. Colloid Polym Sci 284, 396–404 (2006). https://doi.org/10.1007/s00396-005-1397-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-005-1397-z